Moulded interconnect device with heat conduction property and manufacturing method thereof

A technology for molding interconnect components and manufacturing methods, applied in semiconductor devices, printed circuit manufacturing, cooling/ventilation/heating renovation, etc., and can solve problems such as electrical damage, fire, and electrical temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The molded interconnection assembly with thermal conductivity and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to the relevant drawings. For ease of understanding, the same components in the following embodiments are described with the same reference numerals.

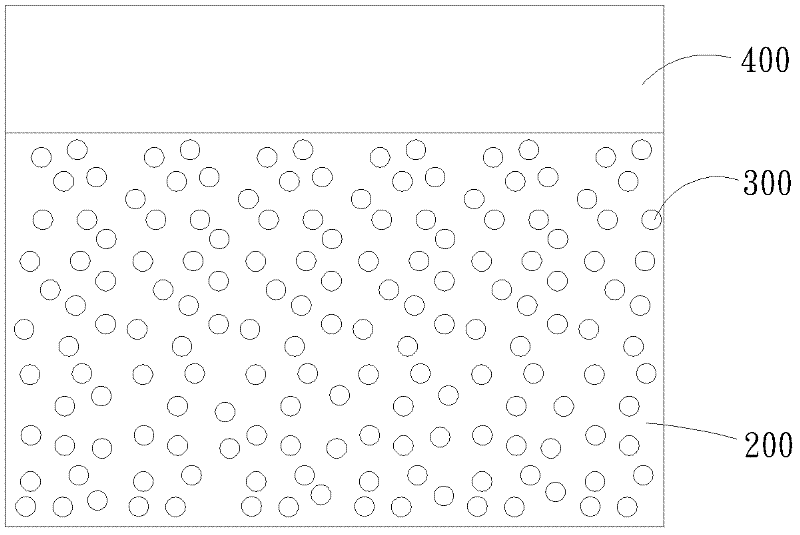

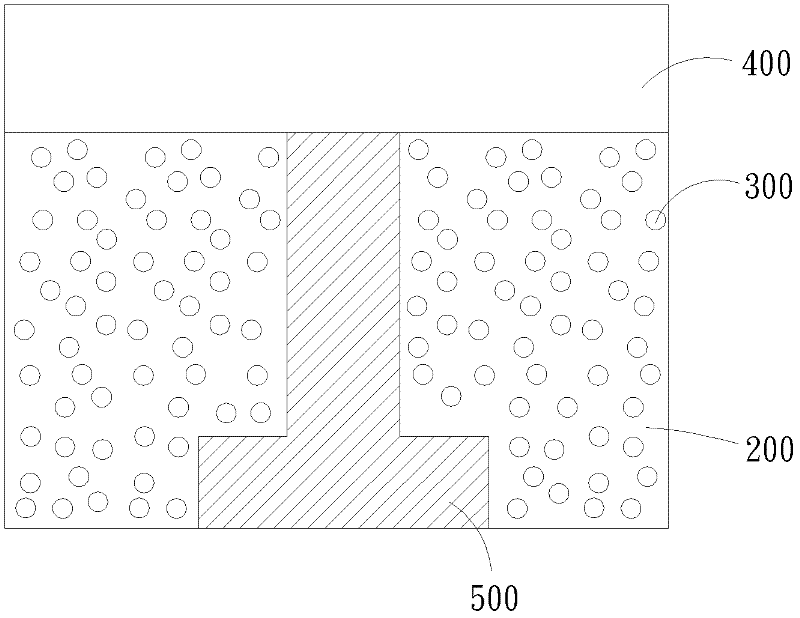

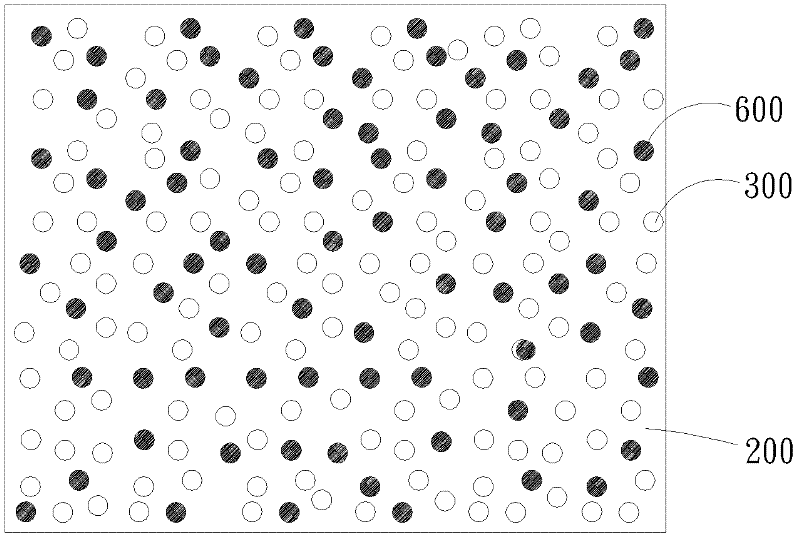

[0092] Please refer to figure 1 , figure 1 is a schematic diagram of a first embodiment of a molded interconnection assembly with thermally conductive properties of the present invention. figure 1 Among them, the molded interconnection component with heat conduction properties of the present invention includes a carrier component, a heat conduction component 300 and a metal layer 400 . Wherein, the carrier component is, for example, a non-conductive support material (Non-conductive support material) 200 or a metallizable support material. In the first embodiment, the carrier component is a non-conductive carrier 200 . Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com