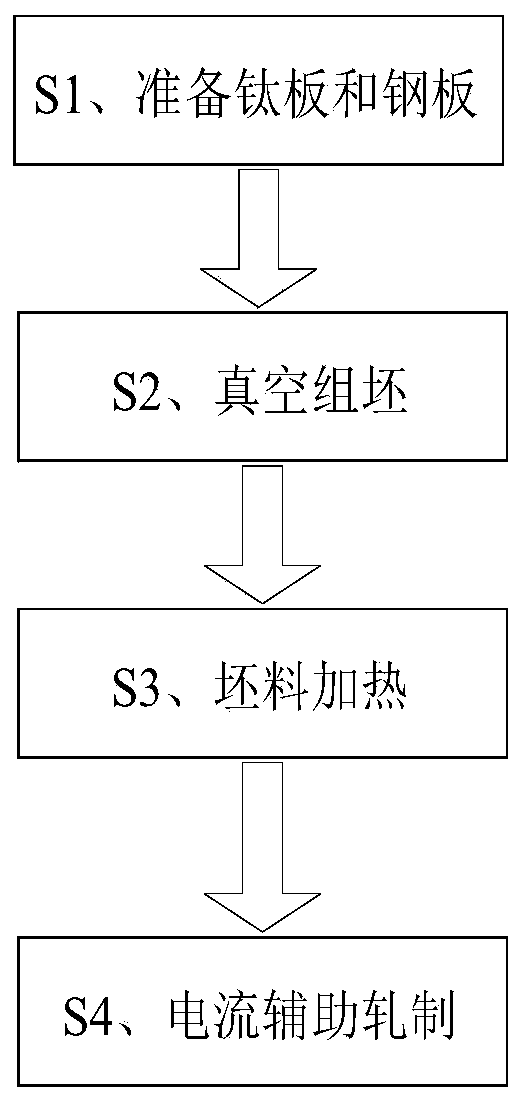

Method for preparing titanium steel composite plate through auxiliary hot rolling of pulse current

A pulsed current, clad plate technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of difficult to meet user requirements, high single-pass reduction rate, low bonding strength, etc., to suppress brittleness. Formation of compounds, realizing coordinated deformation, and improving the effect of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

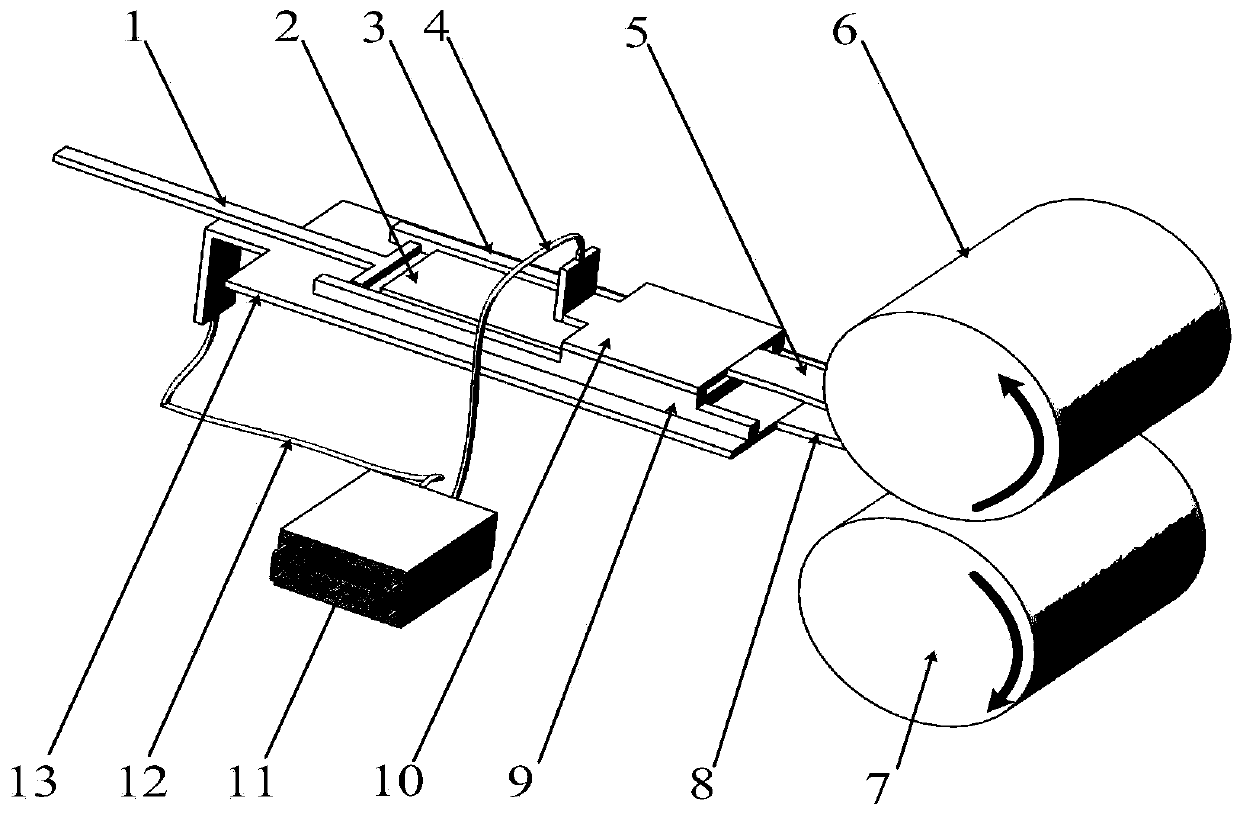

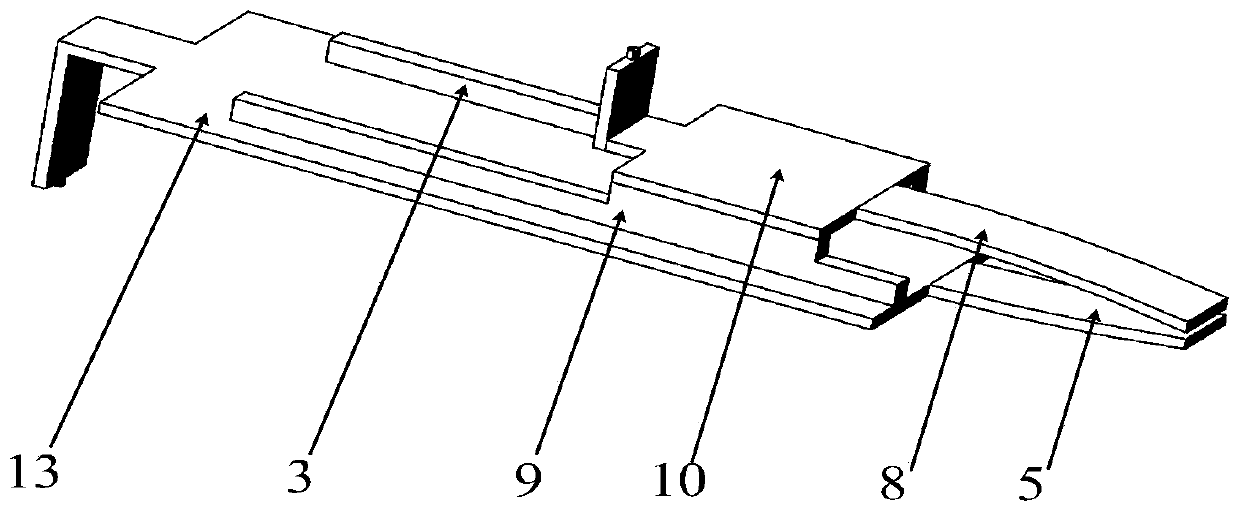

[0033] Example 1: A method of square wave pulse current assisted hot rolling of titanium-steel clad plate

[0034] The schematic diagram after forming the billet in step S2 in this embodiment is as follows Figure 4 As shown, 304 stainless steel plates 14 and 18 are used as substrates with a size of 100×50×3.5mm; TA1 titanium plates 16 and 20 are used as cladding plates with a size of 100×50×2mm, and isolation is added between TA1 titanium plates 16 and 20 Agent 21, use a wire brush to polish the contact surface of the titanium plate and stainless steel plate to remove the surface oxide layer and clean it with alcohol or acetone, use argon protection to seal the surroundings of the blank 2 and the joint between the welded pipe 17 and the blank 2 to prevent oxidation of the workpiece After the blank 2 is vacuumized, the welded pipe 17 is welded and sealed.

[0035] The schematic diagram of the rolling process of the square wave pulse current assisted hot-rolled titanium stainl...

Embodiment 2

[0038] Example 2: A method for sine wave pulse current assisted hot rolling of titanium-steel composite plate containing sheet-like pure iron intermediate layer

[0039] The schematic diagram after forming the billet in step S2 in this embodiment is as follows Figure 4 As shown, 304 stainless steel plates 14 and 18 are used as substrates with a size of 100×50×3.5mm; TA1 titanium plates 16 and 20 are used as cladding plates with a size of 100×50×2mm. The middle layer is made of pure iron sheet with a thickness of 50 μm. Add spacer 21 between TA1 titanium plates 16 and 20, use steel wire brush or sandpaper to polish the contact surface of titanium plate, stainless steel plate and pure iron plate to remove the surface oxide layer and clean it with alcohol or acetone. The joint between the welded pipe 17 and the blank 2 is tightly sealed to prevent oxidation of the workpiece, and the welded pipe 17 is welded and sealed after the blank 2 is vacuumed.

[0040] The schematic diagr...

Embodiment 3

[0043] Example 3: A method for hot-rolling a titanium-steel composite plate with a pure iron mesh middle layer assisted by a rectangular wave pulse current

[0044] The schematic diagram after forming the billet in step S2 in this embodiment is as follows Figure 4 As shown, 304 stainless steel plates 14 and 18 are used as substrates with a size of 100×50×3.5mm; TA1 titanium plates 16 and 20 are used as cladding plates with a size of 100×50×2mm. The middle layer is made of pure iron mesh with a thickness of 50 μm. Add spacer 21 between TA1 titanium plates 16 and 20, use steel wire brush or sandpaper to polish the contact surface of titanium plate, stainless steel plate and pure iron mesh to remove the surface oxide layer and clean it with alcohol or acetone, use argon protection to protect the surrounding and The joint between welded pipe 17 and blank 2 is tightly sealed to prevent the workpiece from being oxidized. After blank 2 is vacuumed, welded pipe 17 is welded and seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com