Manufacture method for plugging resin into soft and hard combined circuit board

A soft-rigid combination, resin plug hole technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of labor and time, difficult groove 29, difficult to remove resin 28, etc., to reduce rework , Guarantee the effect of drilling position thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

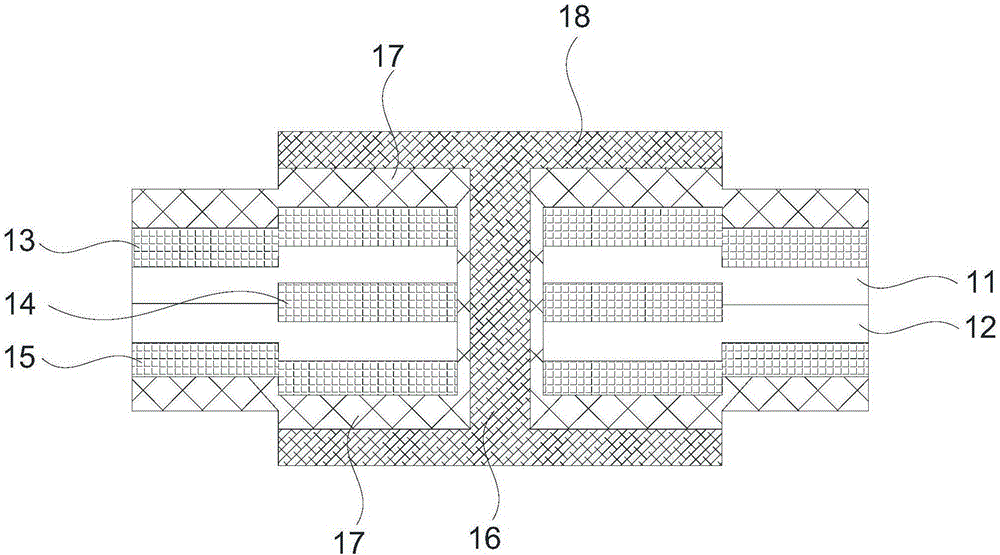

[0031] Such as figure 1 The shown three-layer flex-rigid circuit board includes a first base material 11, a second base material 12, an inner layer of wiring copper between the first base material 11 and the second base material 12, and the surface of the first base material 11 is covered with There is a first base copper 13 , and the surface of the second base material 12 is covered with a first base copper 15 . Resin plug holes 16 that can be used to make pads on the surface need to be made on the flexible and rigid circuit board. The manufacturing method includes the following steps:

[0032] Make the inner circuit pattern, and the drill hole corresponding to the circuit pattern leaves an isolated pad 14 larger than the diameter of the resin plug hole 16; the diameter of the isolated pad is 0.35mm larger than the diameter of the resin plug hole 16.

[0033] Use NO-FLOWPP to press to form a rigid-flex circuit board. After lamination, the surface of the rigid-flex circuit b...

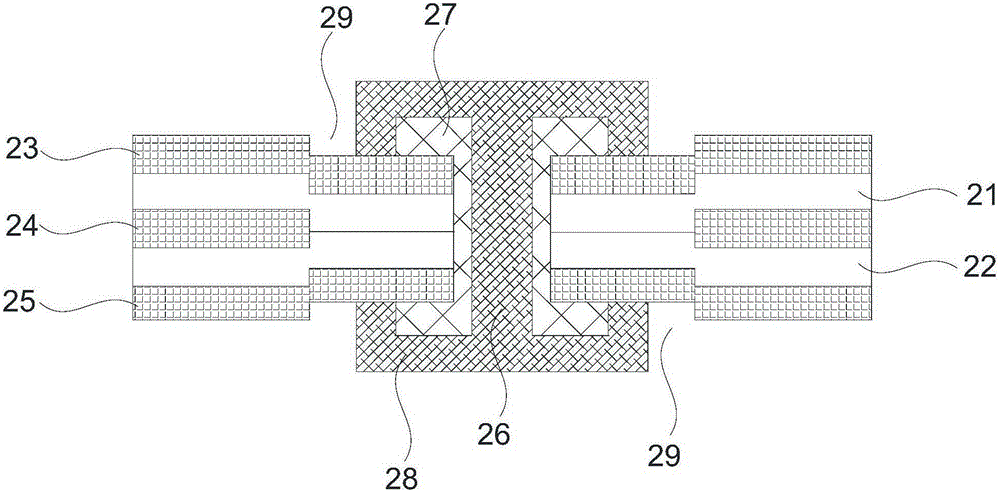

Embodiment 2

[0041] The PCB with the following parameter requirements is manufactured by using the manufacturing method of the resin plug hole of the present invention.

[0042] Inner core board:

[0043] 0.075mm0.5 / 0.5OZ (without copper) (2 pieces);

[0044] Number of layers: 8 layers;

[0045] Inner line width / line spacing: 0.1mm / 0.1mm, 0.091mm / 0.1mm

[0046] Outer layer line width / line spacing: 0.1 / 0.1mm (finished copper thickness 1.0OZ);

[0047] Sheet Tg: ≥170°;

[0048] Outer core board 0.36mm0.5 / 0.5oz (without copper) (2 pieces): 1 / 2OZ;

[0049] Hole copper thickness: 18um(min) / 20um(ave);

[0050] Surface treatment: immersion gold;

[0051] Finished board thickness: 1.6mm±10%;

[0052] Minimum drill bit: 0.2mm;

[0053] Drilling thickness to diameter ratio: 8:1;

[0054] Production PNL size: 304mm×457mm.

[0055] The specific production process is as follows:

[0056] 1. Cutting - According to the number of core boards with different thicknesses required and the PNL size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com