Method for producing macromolecule orthodontic tooth crown

A manufacturing method and polymer technology, applied in orthodontics, dentistry, dental prosthetics, etc., to achieve precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

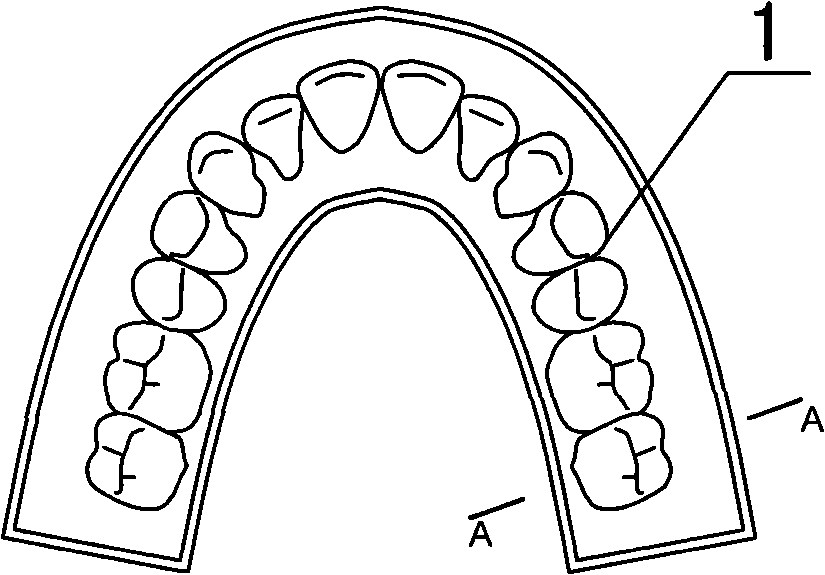

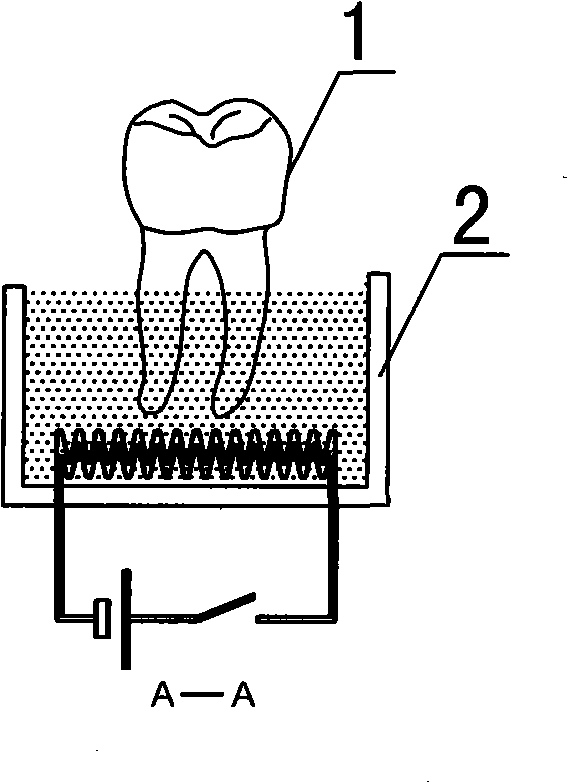

[0028] 1Precisely copy the tooth model and perform segmentation and restoration of the jaw.

[0029] Precise reproduction of teeth using precision molding materials. There are many options for molding materials, such as: gypsum, super-anhydrite, plastic, resin, metal, etc. The selected materials must have physical properties such as high precision, high strength, high temperature resistance, and wear resistance. Take super anhydrite or precision resin as an example: inject a mixture of super anhydrite and water with a water-powder ratio of 22:100, or a resin mixture with a curing agent and resin ratio of 1:7, into the tooth impression, oscillate fully, and discharge air bubbles. After curing, take it out and cut it into individual tooth models. According to the plaster model or other aids, the divided model teeth are rearranged and restored to their original shape.

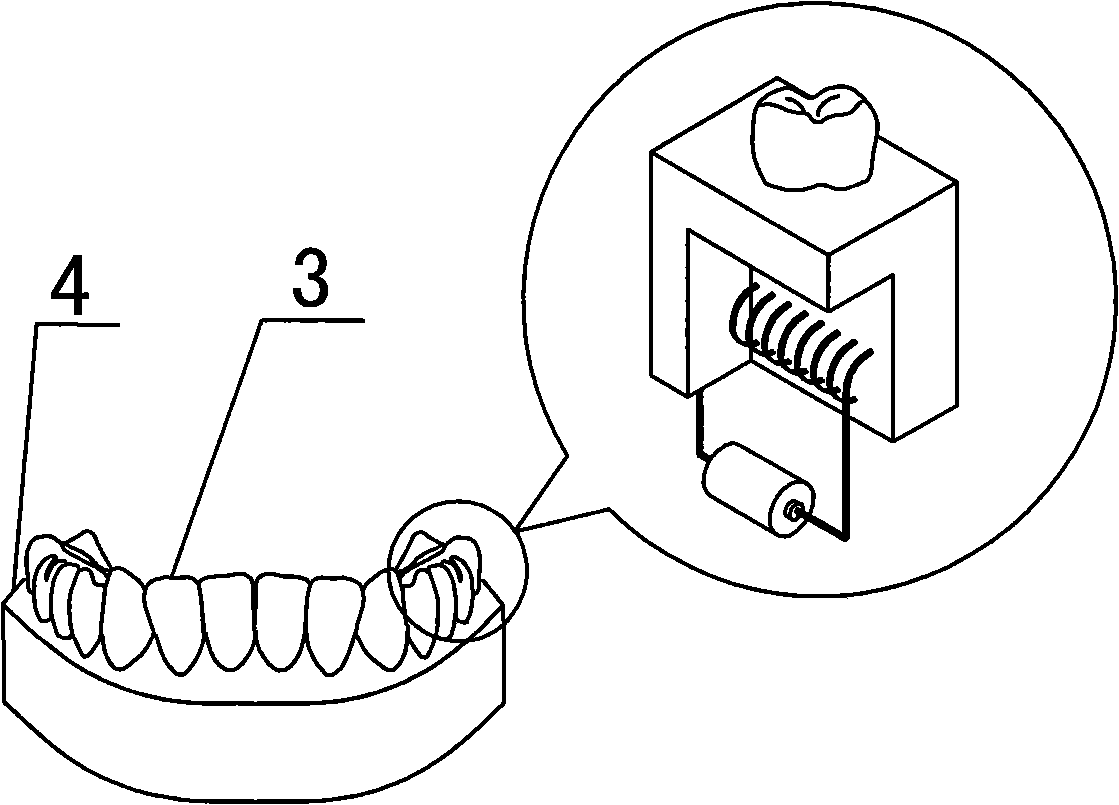

[0030] In order to adjust the position of model teeth more accurately and use computer-aided design of treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com