Rubber frame, backlight module and display device

A backlight module and plastic frame technology, applied in projection devices, printing devices, optics, etc., can solve problems affecting screen-to-screen ratio, save occupied space, increase screen-to-body ratio, and reduce non-effective viewing areas area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

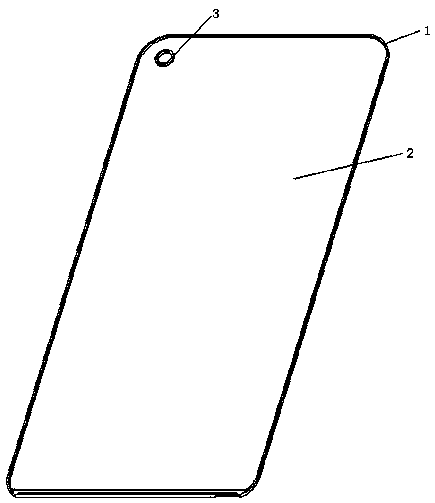

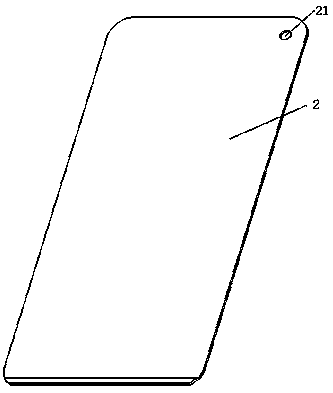

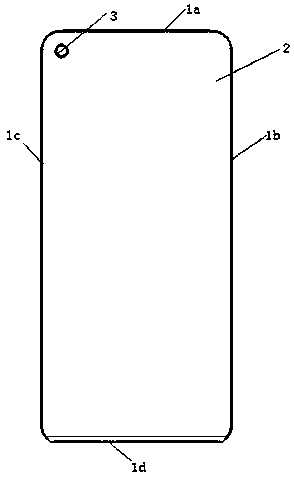

[0027] This embodiment provides a plastic frame, such as figure 1 and 2 As shown, the plastic frame includes a frame body 1 and a bottom plate 2 , the frame body 1 is arranged around the bottom plate 2 and forms an integral structure with the bottom plate 2 . The frame body 1 extends in a direction perpendicular to the bottom plate 2, and the bottom plate 2 is the bottom surface of the frame body 1, and the front of the frame body 1 is an opening for contact with the liquid crystal covering the frame body 1. The panel matches. The bottom plate 2 is provided with a positioning ring 3 along the extending direction of the frame body 1 , and the inner hole of the positioning ring 3 and the bottom plate 2 form a receiving space for accommodating the front camera. In this embodiment, the front camera is placed in the accommodation space formed by the inner hole of the positioning ring 3 and the bottom plate 2, which avoids reserving a groove on the top edge of the frame body 1, re...

Embodiment 2

[0036] This embodiment provides a backlight module, such as Figure 6-8 As shown, the backlight module includes a plastic frame 15, a light guide plate 8, and a backlight source 13; the light guide plate 8 is provided with a second through hole, and the aperture of the second through hole is the same as the outer diameter of the positioning ring 3. Matched with the diameter, the light guide plate is loaded in the plastic frame 15 and sleeved on the positioning ring 3 through the second through hole. The plastic frame 15 wraps the periphery of the light guide plate, and there is a gap between the bottom edge of the plastic frame 15 and the light guide plate, and the backlight source 13 is installed in the gap and connected to the light guide plate. 8 and the bottom edge are not in contact. In this embodiment, the plastic frame 15 adopts the plastic frame described in the above-mentioned embodiments, and details will not be described here.

[0037] Please continue to refer to ...

Embodiment 3

[0042] This embodiment provides a display device, which includes the backlight module described in the above embodiment, a front camera, and a liquid crystal panel mounted on the backlight module, and the front camera is assembled on the The positioning ring is used to accommodate the front camera through the positioning ring. Wherein, a display hole may be provided on the liquid crystal panel, and the front camera partially extends out of the positioning ring and is placed in the display hole, so that the front camera can take pictures through the display hole. image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com