Blanking and scraping device for road paving

A blanking and road technology, applied in the field of blanking and scraping devices for road paving, can solve the problems of reducing the quality of road paving, lack of scraping components, unfavorable road rolling, etc., to avoid agglomeration, avoid waste, and ensure flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

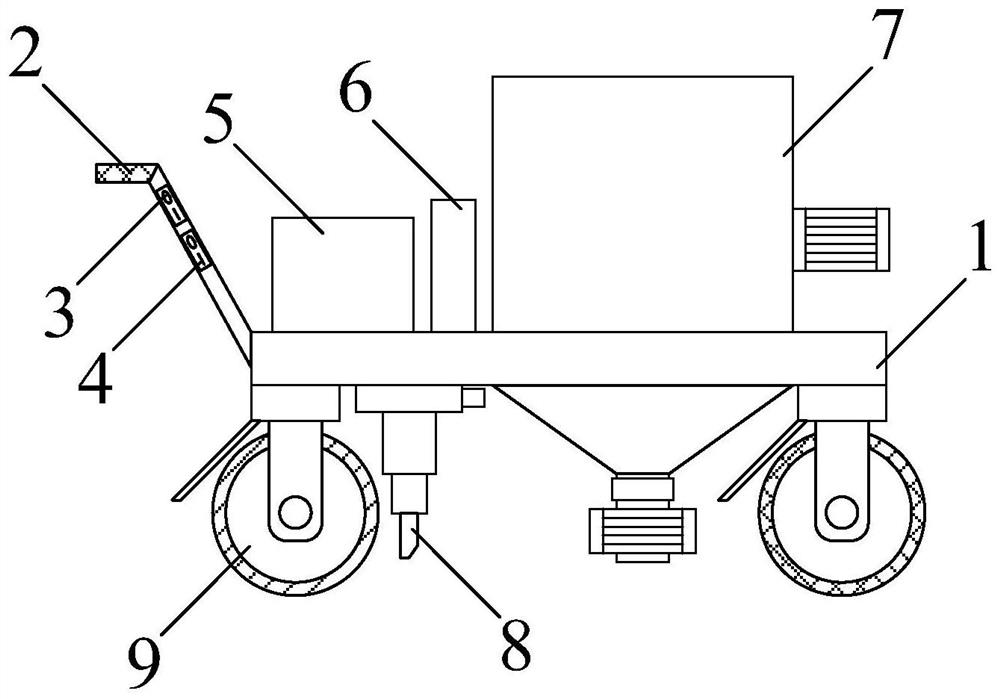

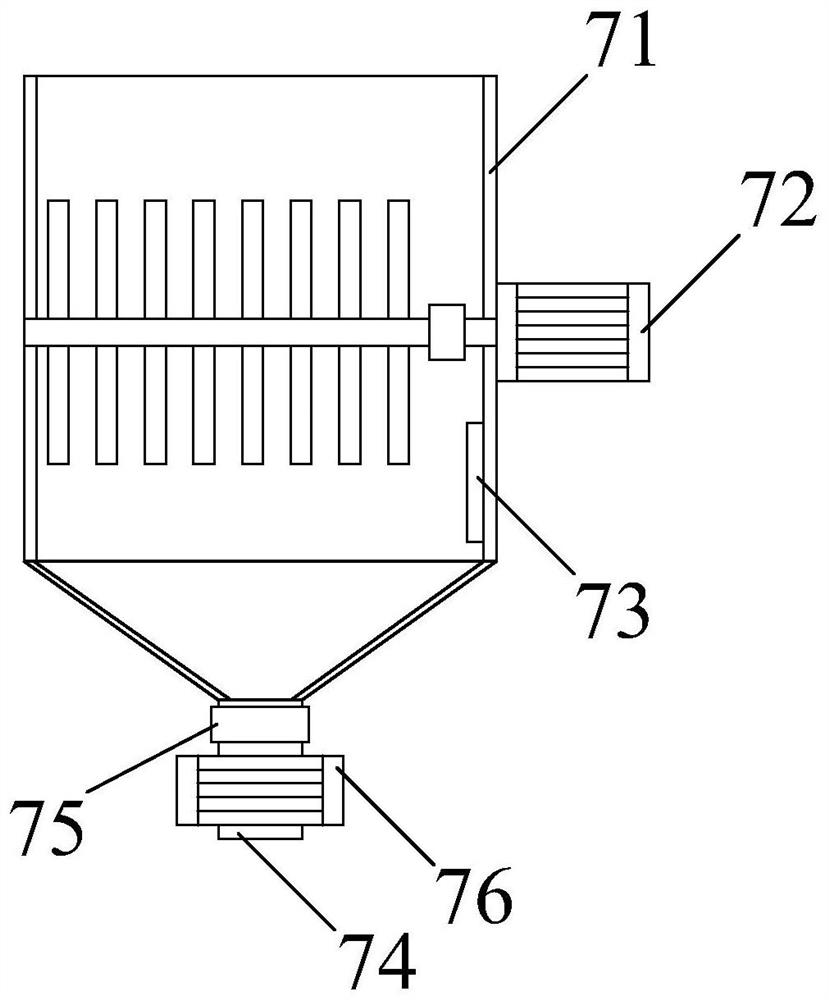

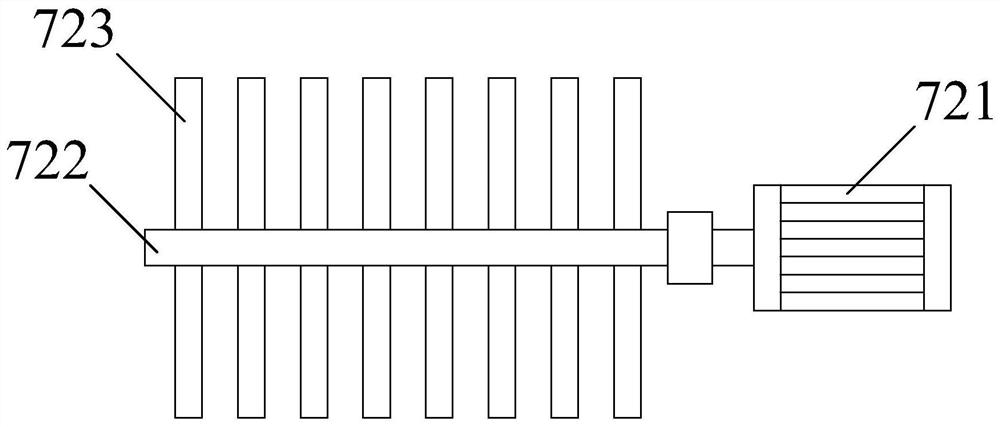

[0024] as attached figure 1 to attach Figure 4 shown

[0025] The present invention provides a blanking and scraping device for road paving, including a bottom plate 1, a handle 2, a first button switch 3, a second button switch 4, a battery 5, a PLC controller 6, a blanking assembly 7, and a scraping assembly 8 and universal wheels 9, the universal wheels 9 adopt four, and the universal wheels 9 are installed on the bottom four corners of the base plate 1; the handle 2 is installed above the middle position on one side of the base plate 1; the battery 5 is installed on The top of the bottom plate 1 is close to one end of the handle 2; the first button switch 3 is installed above the front side of the handle 2; the second button switch 4 is installed in the middle of the front side of the handle 2; the blanking assembly 7 is installed on The top of the base plate 1 is away from the end of the handle 2, and the lower end of the blanking assembly 7 penetrates to the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com