Exhaust pipe bending machine

A technology for bending machines and exhaust pipes, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as low operation accuracy, waste of exhaust pipes, and dents in pipe fittings, so as to ensure the quality of bend pipes and increase Usability, the effect of avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

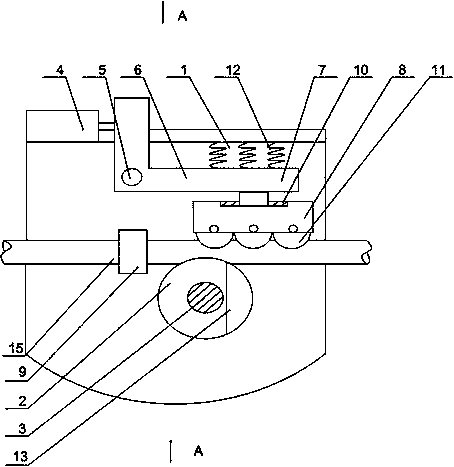

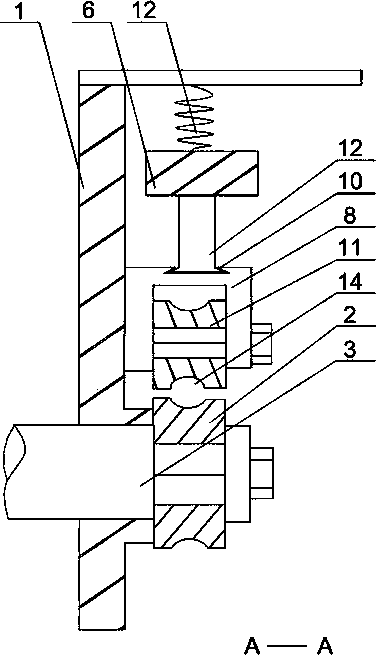

[0023] Such as Figure 1 to Figure 3 As shown, the exhaust pipe bending machine of the present invention includes a rotating disk 1, on which a pipe bend groove is installed, and on the rotating disk 1, a rotating handle 6 is hinged, and one end of the rotating handle 6 A connecting rod 7 is installed, and the other end of the rotary handle 6 is connected to the cylinder 4, and also includes a roller seat 8 and an exhaust pipe clamp 9 arranged on the rotating disk 1, and the roller seat 8 is provided with a trapezoidal groove 10, and the connecting rod The end of 7 is slidingly arranged in the trapezoidal groove 10, and a plurality of rollers 11 are installed in the roller seat 8, and guide grooves 14 matched with the groove of the elbow are opened on the roller 11, and the groove of the elbow is formed by the movable part. Composed of a fixed part, the fixed part is rotated on the rotating disk 1 through the rotating shaft 3, a protrusion is arranged on the movable part, and ...

Embodiment 2

[0025] Such as Figure 1 to Figure 2 As shown, on the basis of Embodiment 1, this embodiment further includes a plurality of torsion springs 12 , and the two ends of the torsion springs 12 are respectively connected to the rotating disk 1 and the rotating handle 6 . The two ends of the installed torsion spring 12 are respectively connected to the rotary disk 1 and the rotary handle 6. After the exhaust pipe 15 is bent, the torsion spring 12 returns to its elasticity, driving the roller seat 8 to return to its original position, so that the device can continue to perform new exhaust. Pipe 15 pipe bending process.

Embodiment 3

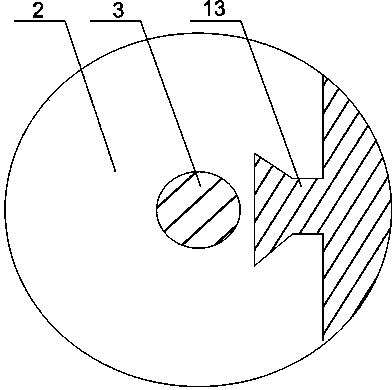

[0027] Such as image 3 As shown, this embodiment is based on Embodiment 1, the fixed part is the superior arc groove 2 , and the movable part is the inferior arc groove 13 . Because the bending angle of the exhaust pipe 15 changes little, the roller seat 8 is facing the elbow part of the exhaust pipe 15 during work, and the movable part is a inferior arc groove 13, so that the exhaust pipe 15 realizes a relatively high pressure under the impetus of the cylinder 4. Bending within a small range to ensure the strength of the bend, to avoid obvious depressions at the bend due to stress concentration, and to ensure the quality of the bend of the exhaust pipe 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com