Compound type machining equipment for copper alloy flat wires

A processing equipment and composite technology, applied in the field of copper alloy flat wire processing equipment, can solve the problems of high production cost, high labor intensity, long process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

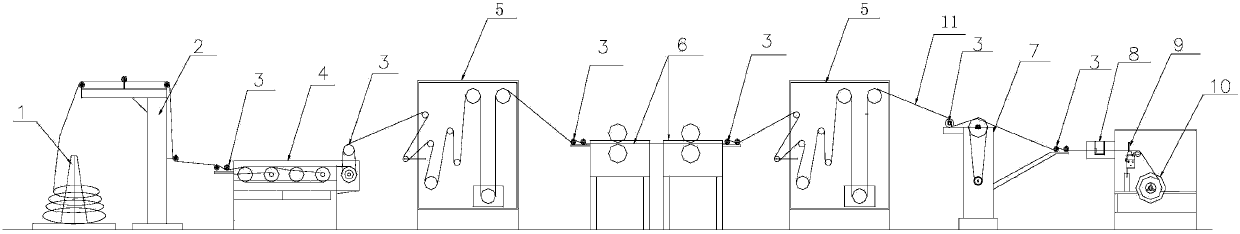

[0016] The invention provides a copper alloy flat wire composite processing equipment, such as figure 1 With the structure shown, the processing equipment has fewer processing procedures, high production efficiency and high processing precision.

[0017] like figure 1 The copper alloy flat wire composite processing equipment shown in the figure includes pay-off frame 2, multi-pass rolling equipment 4, online annealing equipment 5, twice continuous pressing equipment 6, online annealing equipment 5, and tension frame 7, which are successively arranged successively. And the finished wire drawing machine, the finished wire drawing machine includes a polycrystalline mold 8, a wire arrangement mechanism 9 and a wire take-up mechanism 10.

[0018] There are guide wheels 3 before a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com