Patents

Literature

140results about How to "Reduce processing procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turbine shell end surface grinding device

ActiveCN108608268AAvoid clearingEasy to removeGrinding work supportsPlane surface grinding machinesPulp and paper industryTurbine

The invention relates to the technical field of grinding equipment, and particularly discloses a turbine shell end surface grinding device. The device comprises a grinding unit, a dust suction unit and an abutting unit; the grinding unit comprises a horizontal shaft, the end part of the horizontal shaft is connected with a grinding disc, and the grinding disc is provided with a groove; the dust suction unit comprises an air cylinder and a cam, the cam is fixed on the horizontal shaft, a piston rod of the air cylinder abuts against the periphery of the cam, a spring is fixedly arranged below anair cylinder piston, an air outlet one-way valve and a first air inlet one-way valve are arranged on the side wall of the air cylinder, a through hole is formed in the horizontal shaft, a dust suction hole is formed in a grinding wheel, the horizontal shaft is connected with a dust suction pipe, the dust suction pipe communicates with the first air inlet one-way valve, a branch pipe communicatingwith the dust suction pipe is further arranged, and the branch pipe is inserted into a mounting hole of a turbine shell; and the abutting unit comprises an inflator, a positioning block is slidably connected in the inflator, the air outlet one-way valve is connected with an exhaust pipe, and the exhaust pipe communicates with the inflator. By adopting the technical scheme, scrap iron can be cleared at the same time in the grinding process, so that manual cleaning is not needed.

Owner:重庆市乐珐机电有限责任公司

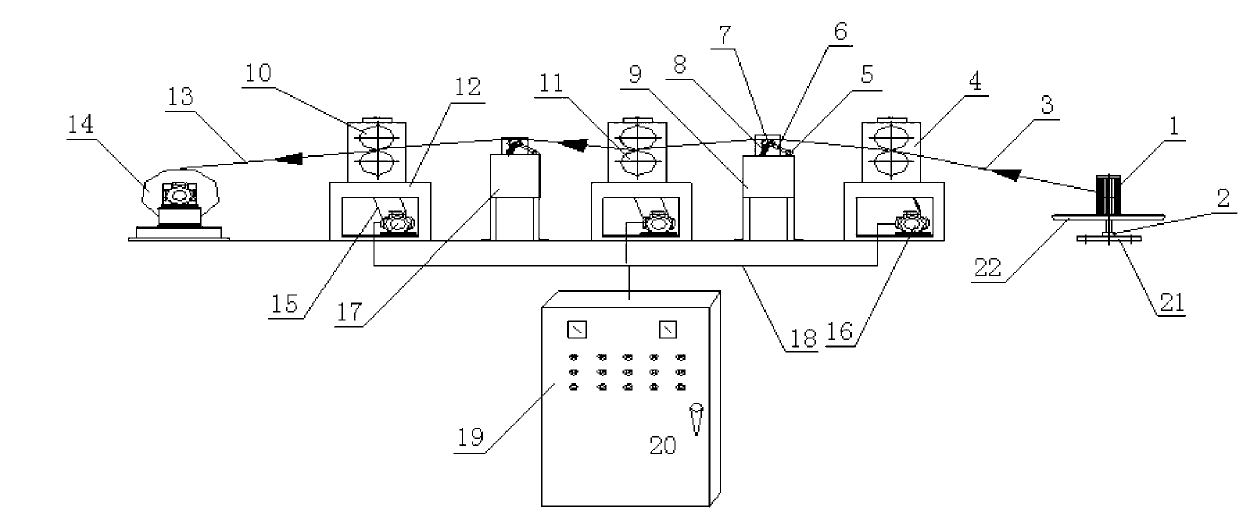

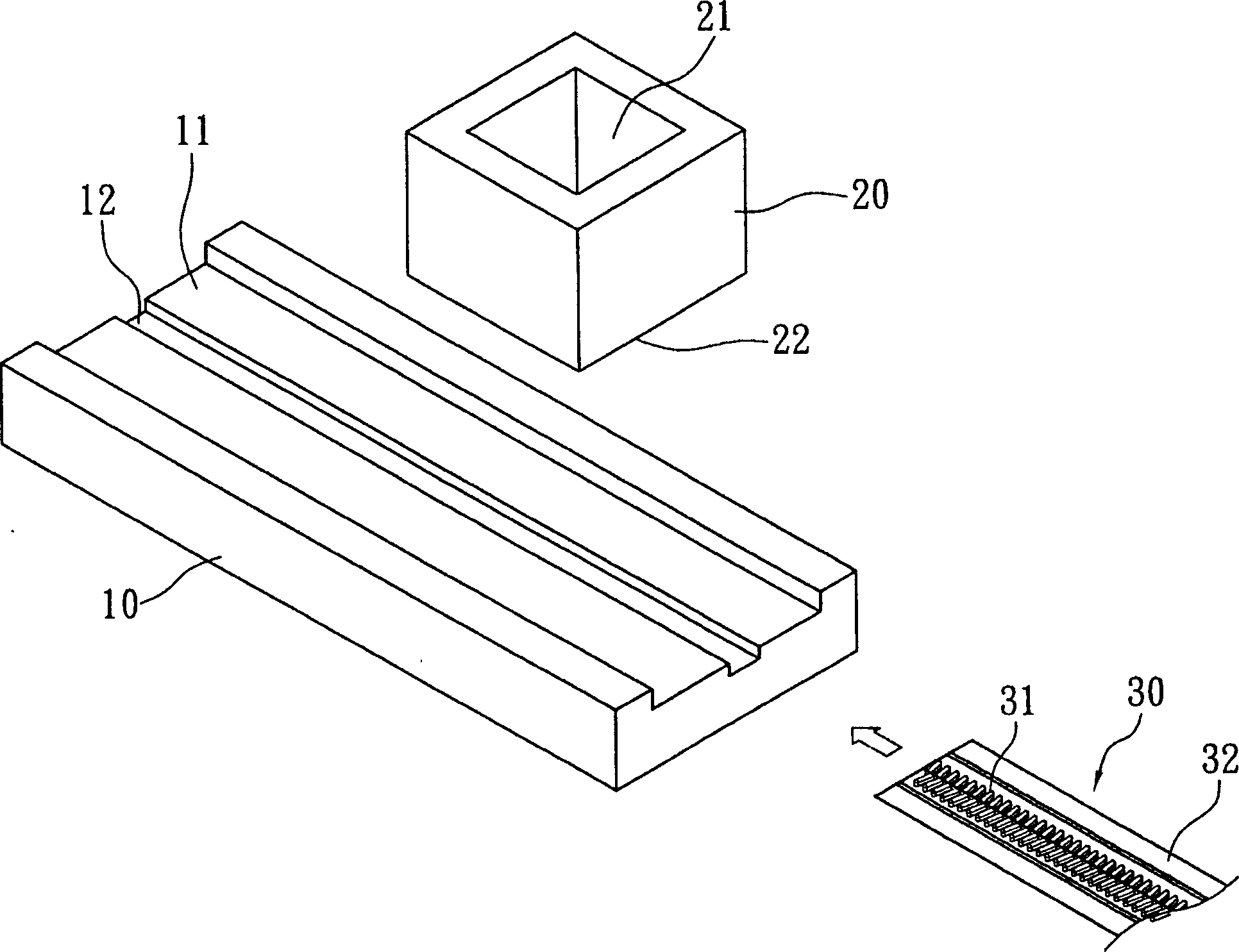

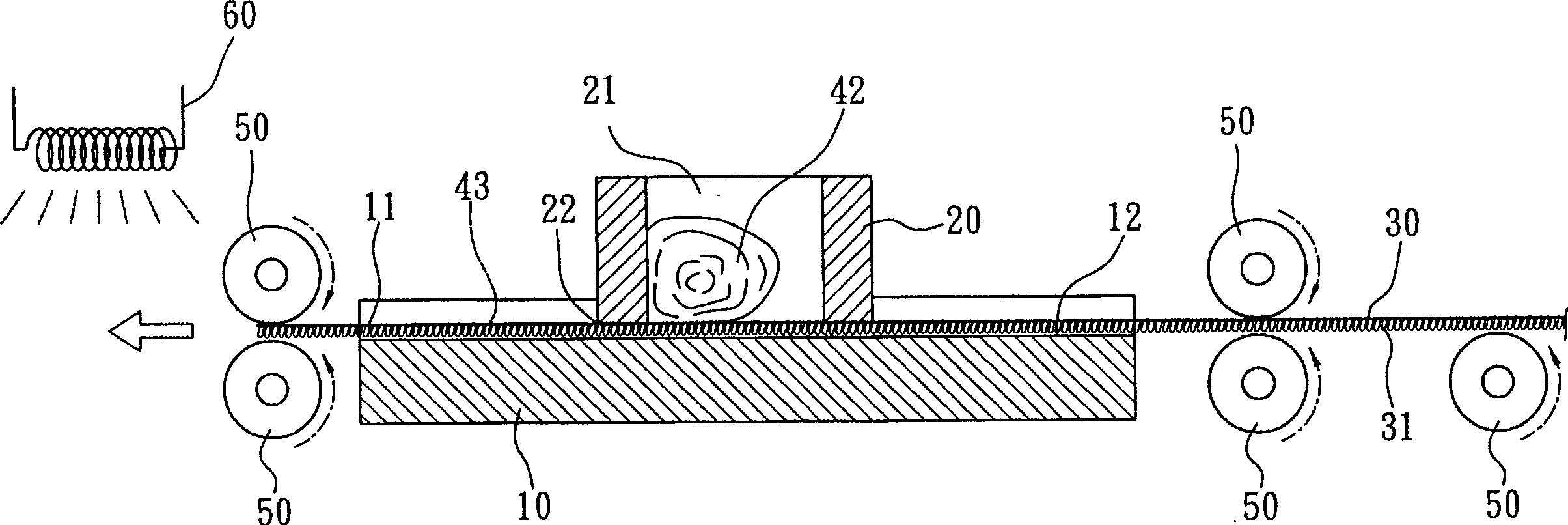

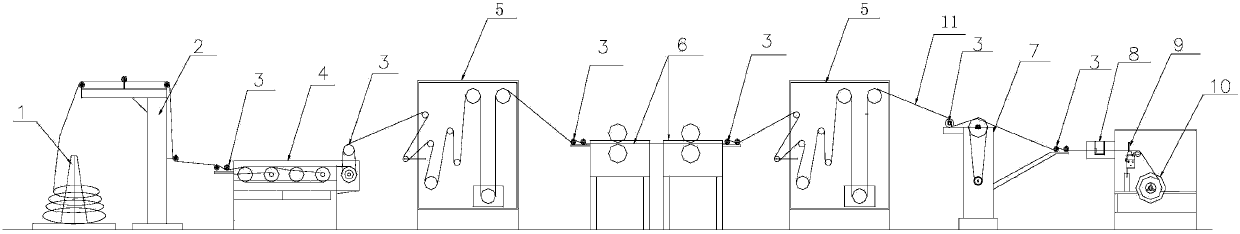

Rolling device for forming of copper alloy flat wires

InactiveCN103272840AImprove rolling precisionDimensionally stableMetal rolling arrangementsControl systemElectrical control

The invention discloses a rolling device for forming of copper alloy flat wires. The rolling device comprises a wire-unwinding mechanism, a plurality of sets of rolling mills, a synchronous tension mechanism, an electrical control system and a wire-rewinding machine. The wire-unwinding mechanism comprises a wire-unwinding plate and a halt air brake device. The rolling mills are composed of more than two stand-alone mills, and each rolling mill is composed of a rolling roller, a support, an electromotor and a belt. The synchronous tension mechanism is composed of a potentiometer, a connection rod, a guide wheel and a spring support. The electrical control system is composed of an electric cabinet, an electrical element, electric wires and cables and provides power for each rolling mill. According to the rolling device, a multi-channel continuous rolling method is utilized, the rolling device is high in accuracy, processing procedures of the copper alloy flat wires are shortened, operation speed is 1.5-2.0 times that of a conventional stand-alone mill, and production efficiency is improved. Meanwhile, as gradual rolling during a rolling process is utilized, the rolling size is very stable, the surfaces of the flat wires are smooth and bright, the fact that grooves and roughness of the surfaces of the flat wires occur in a drawing process of a traditional mould is avoided, and product quality is improved.

Owner:WUHU CHUJIANG ALLOY COPPER

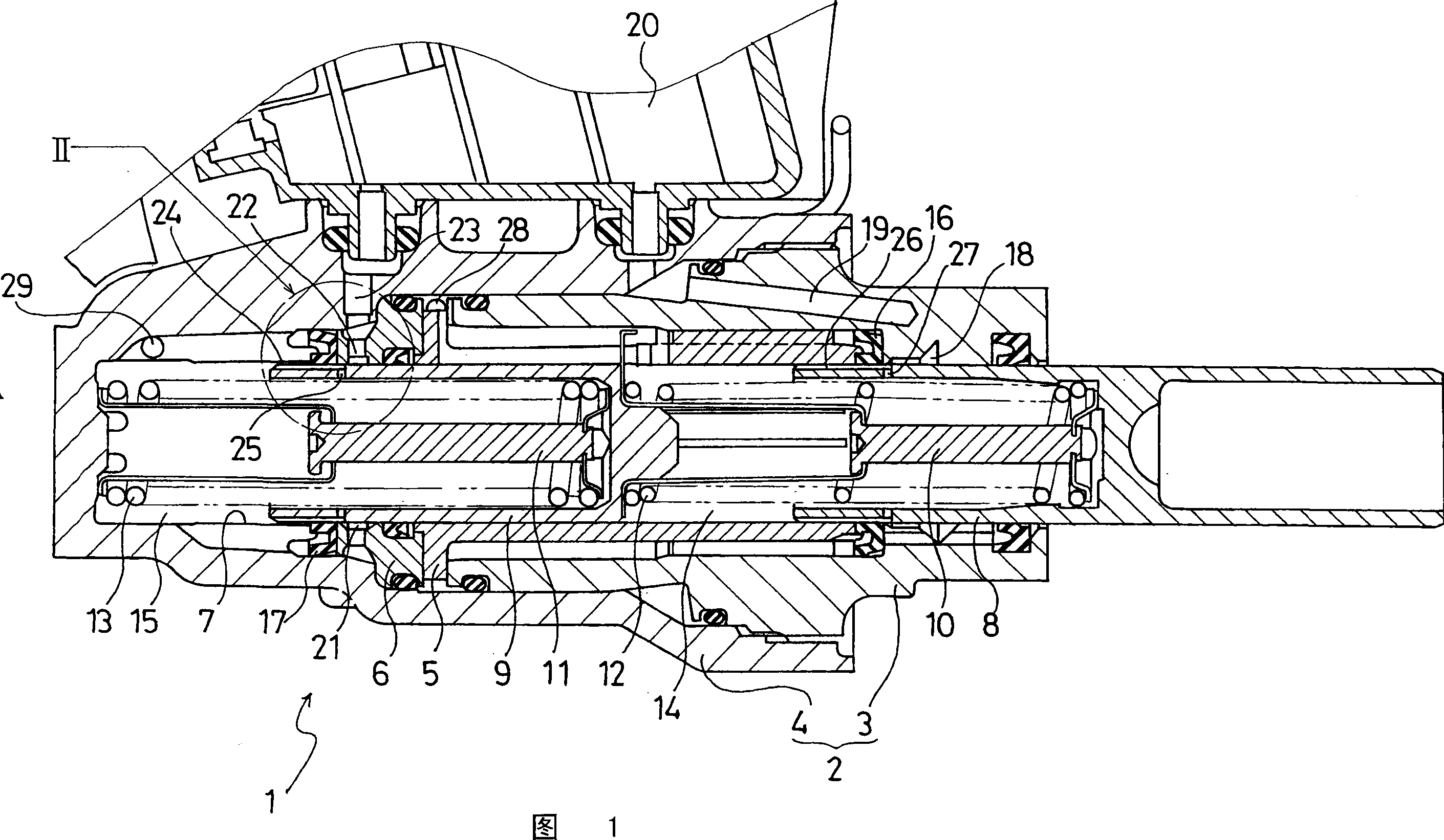

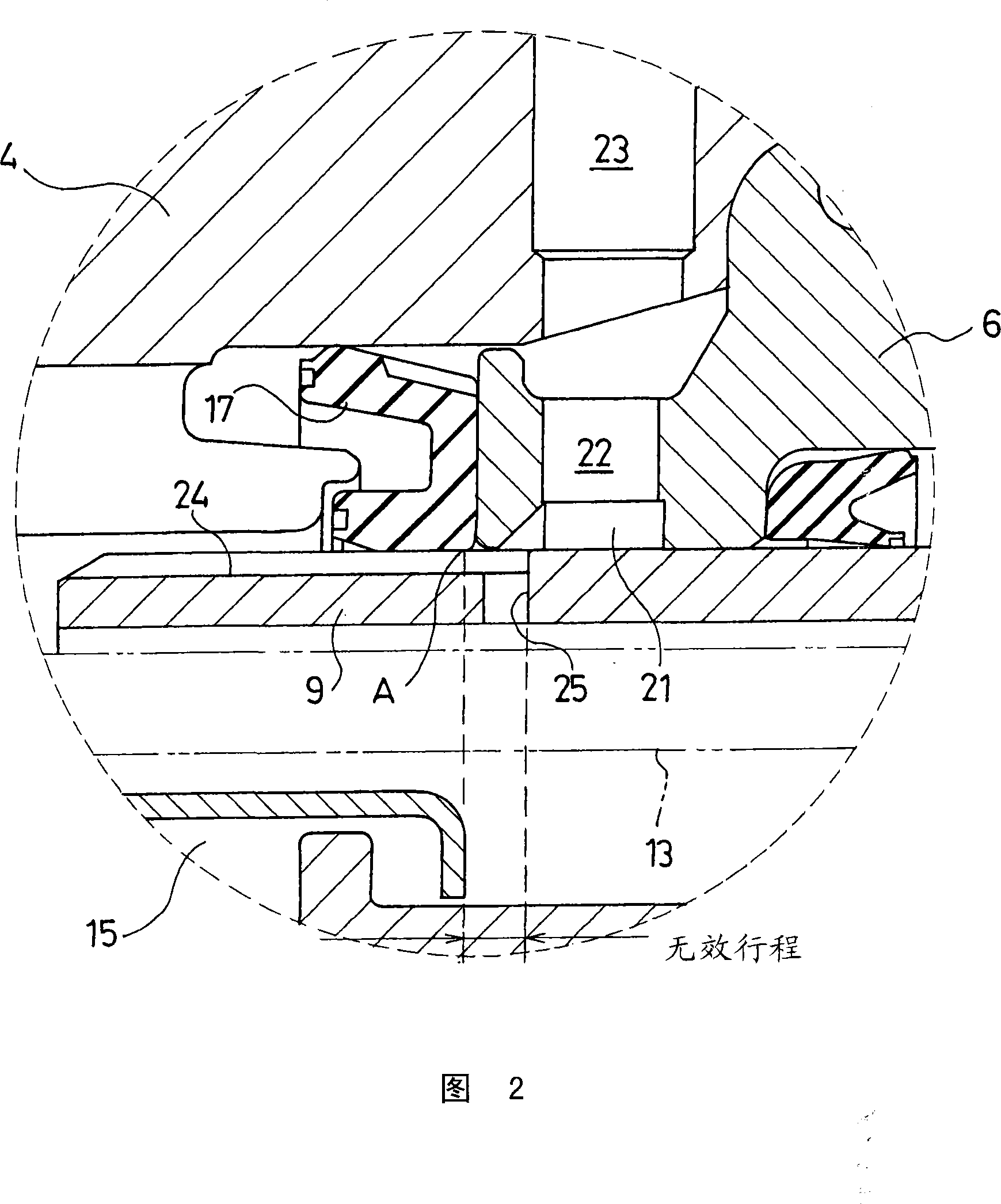

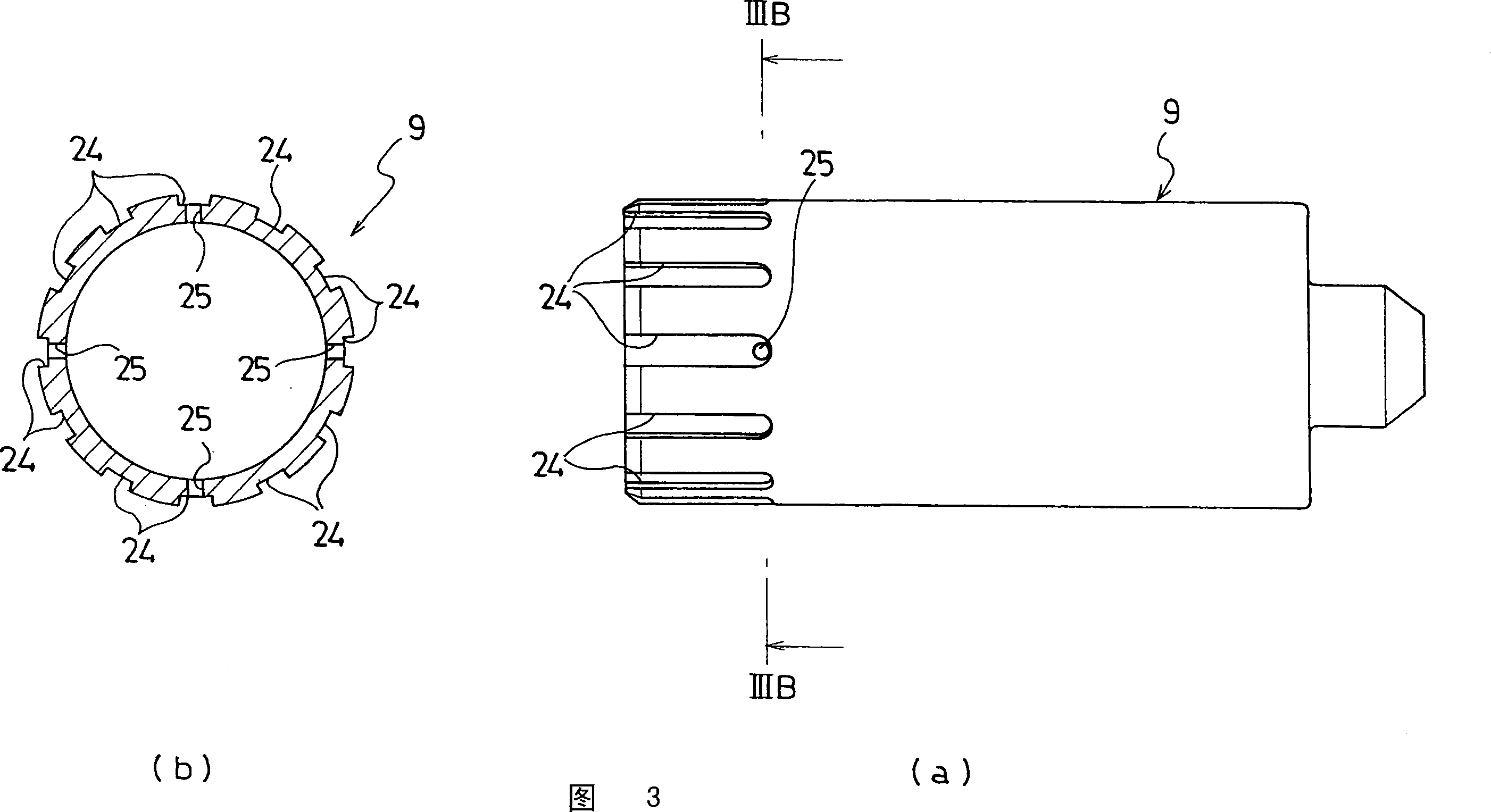

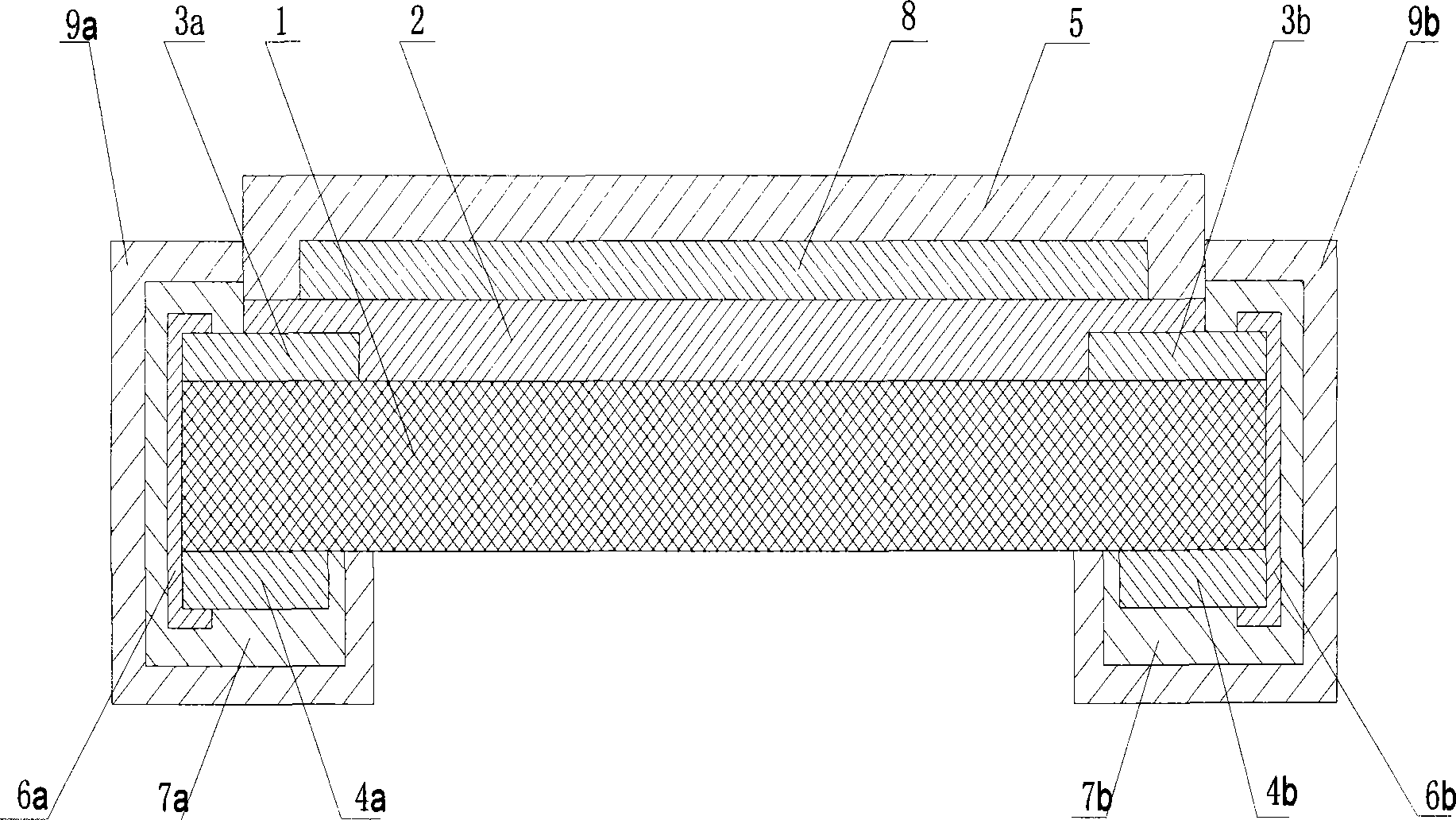

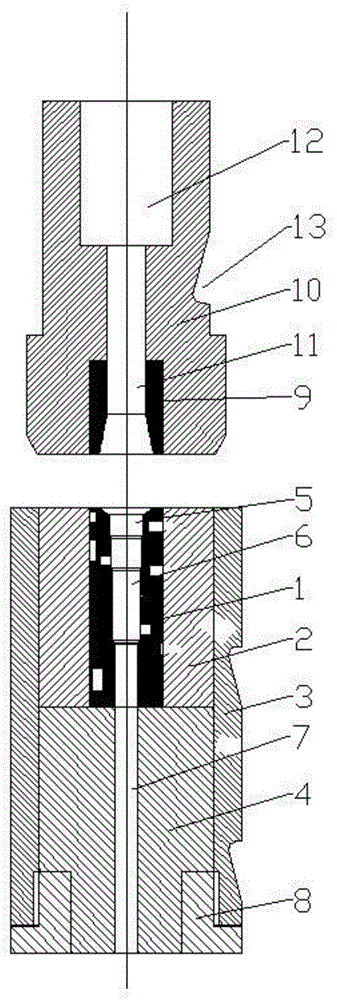

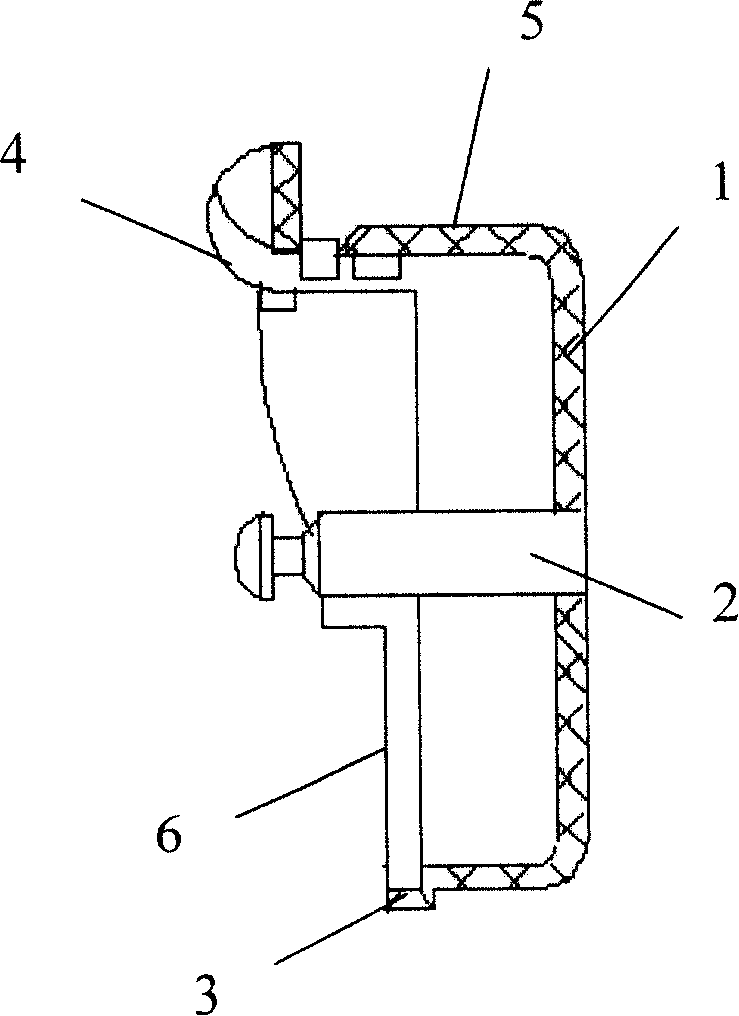

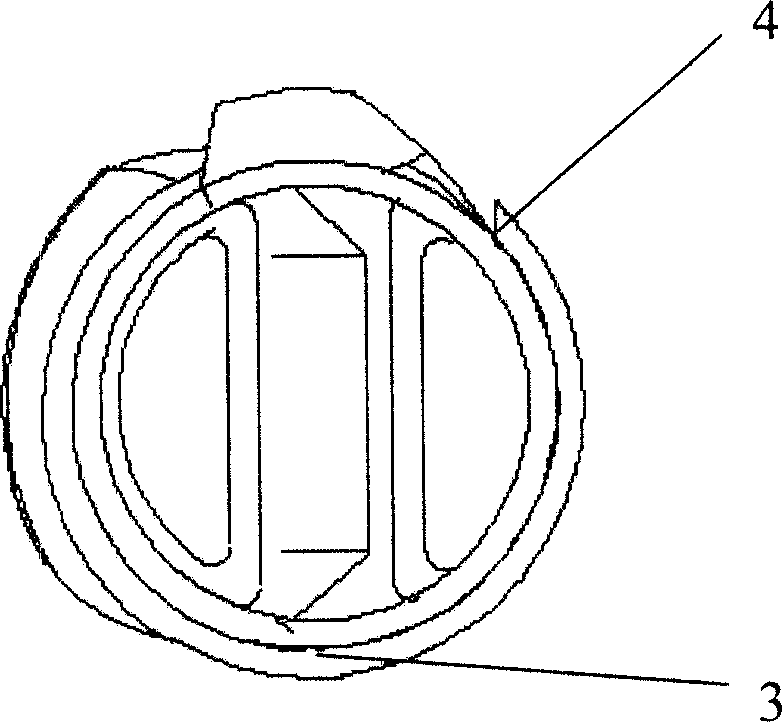

Master cylinder

InactiveCN101184659AGuaranteed StrengthReduced access areaFluid braking transmissionMaster cylinderEngineering

A master cylinder is provided with a secondary piston (9) having a predetermined number of second axial grooves (24) formed, at predetermined intervals in the circumferential direction, in the outer circumferential surface of a head section of the piston (9). Second radial holes (25) are formed in rear end sections of some of the second axial grooves (24), penetrating between the inner and outer circumferential surfaces of the piston (9). When the cylinder is not operated, a rear end section of the second axial grooves (24) and the second radial holes (25) are together closer to the rear side than a seal point A of a second cup seal (17), and as a result, a second liquid chamber (21) and a second liquid pressure chamber (15) are communicated via the second axial grooves (24) and the second radial holes (25). Further, when the rear end sections of the second axial holes (24) and the second radial holes (25) are closer to the front side than the seal point A, the second liquid chamber (21) and the second liquid pressure chamber (15) are cut out. By this, the piston is more easily worked and the strength of the piston is ensured, with ease of brake fluid supply assured.

Owner:BOSCH CORP

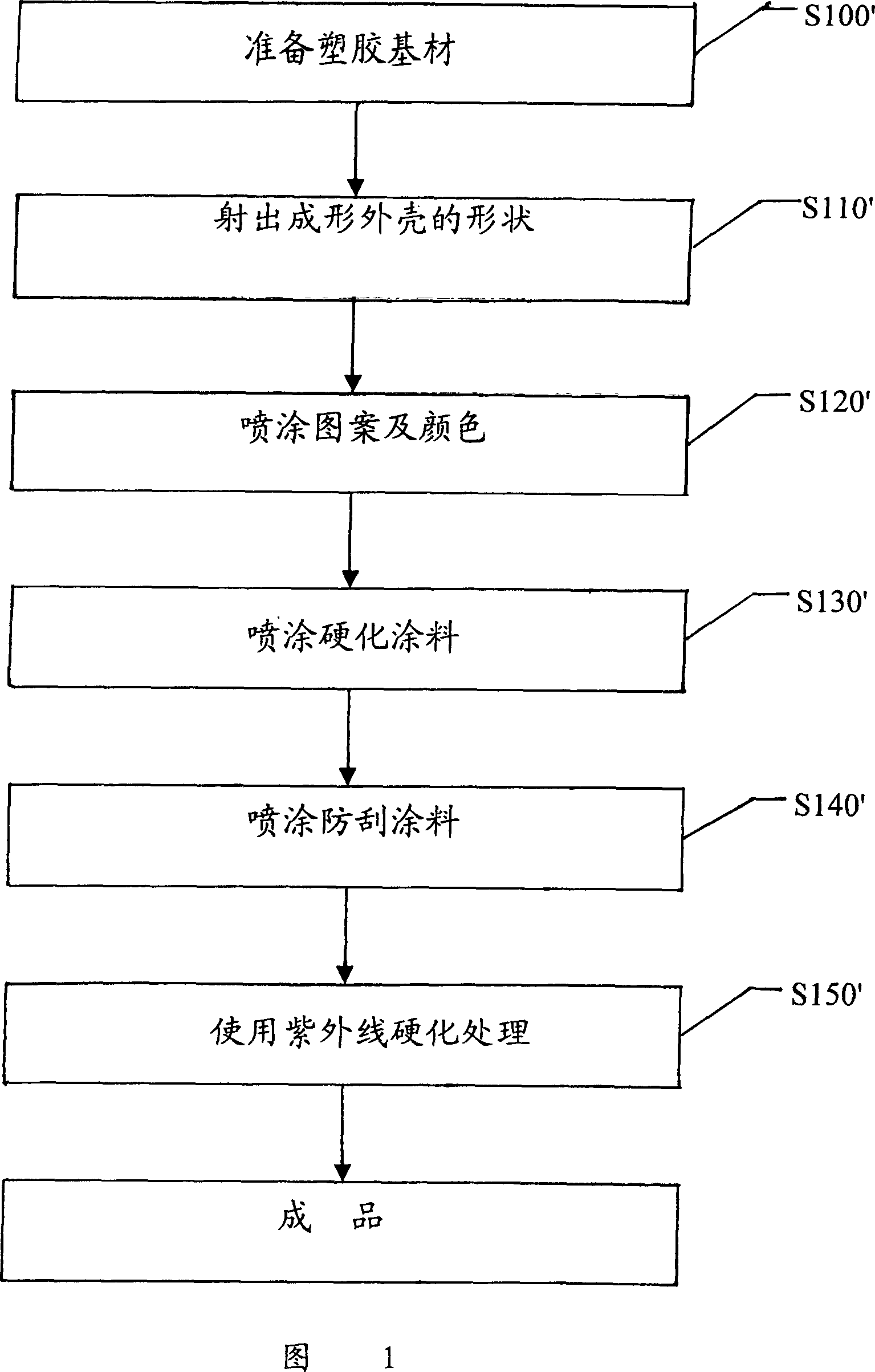

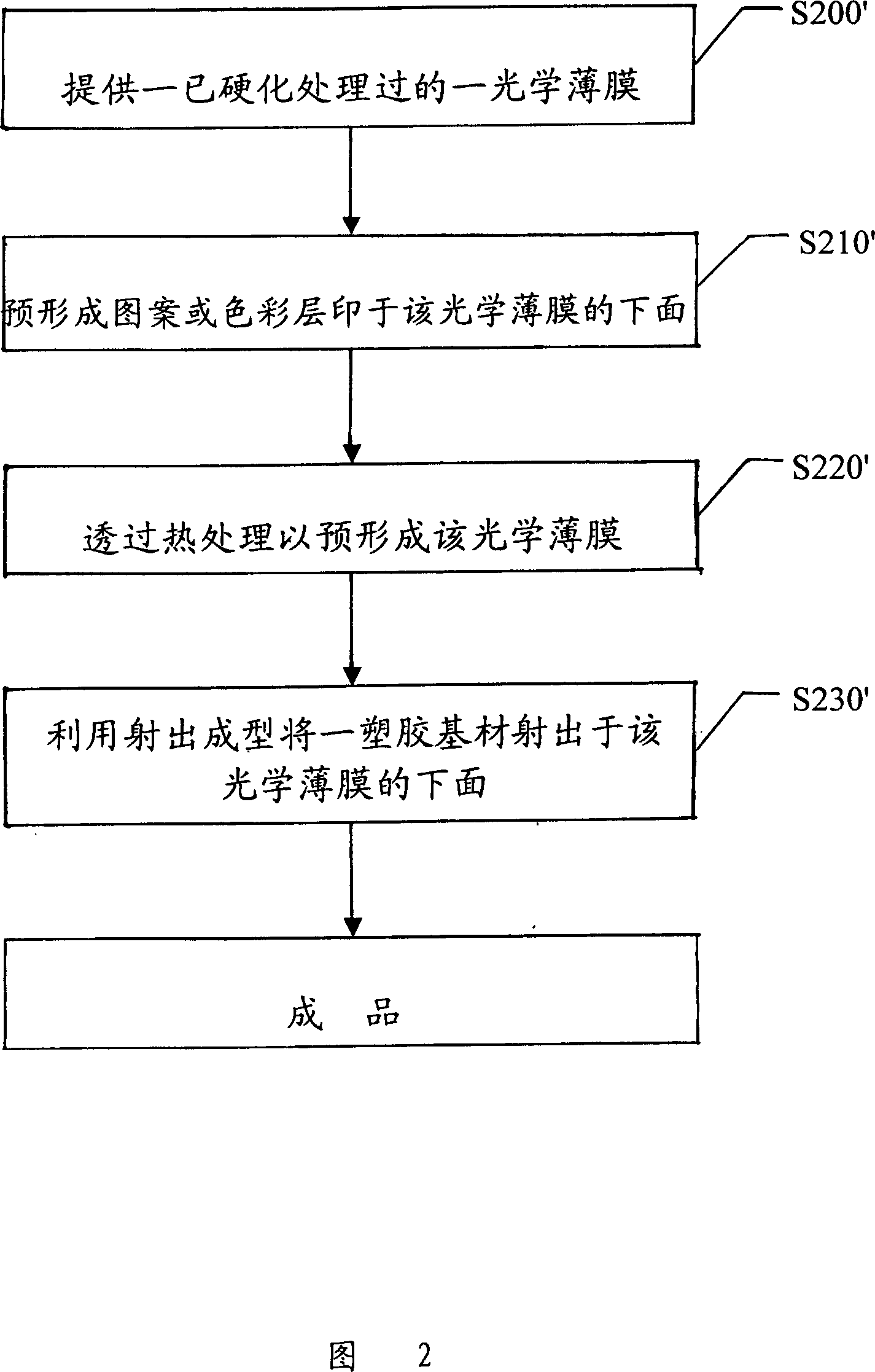

High hardness optical thin film formed inside mold, and fabricating procedure

ActiveCN101003195AImprove production yieldSave energyDecorative surface effectsSynthetic resin layered productsOptical thin filmHardness

A high-hardness optical film structure is disclosed, which can be used on the surface of a plastic shell for increasing its hardness and improving its scratch-resistant effect. It preparing process includes in mold lamination (IML), insert mould, hardening and transferring.

Owner:ENTIRE TECH CO LTD

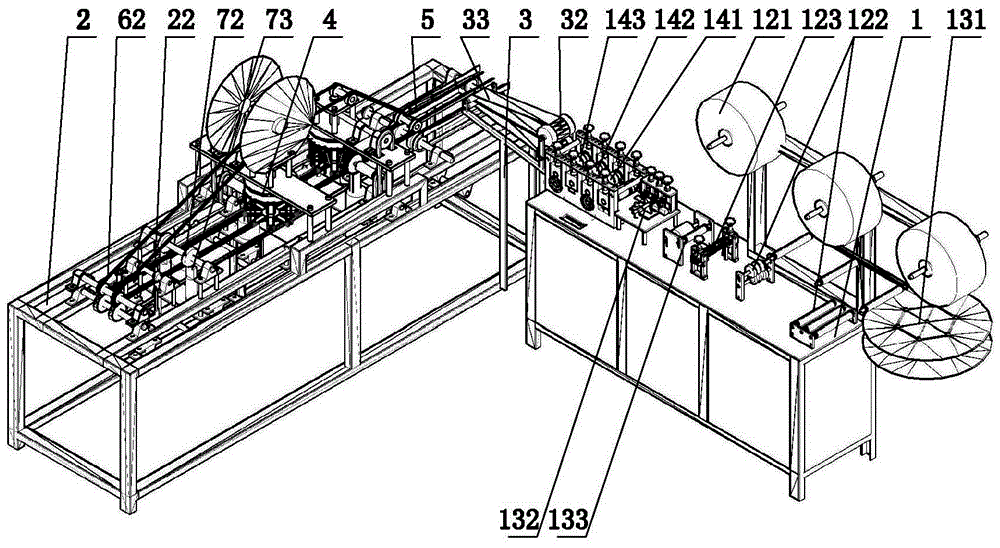

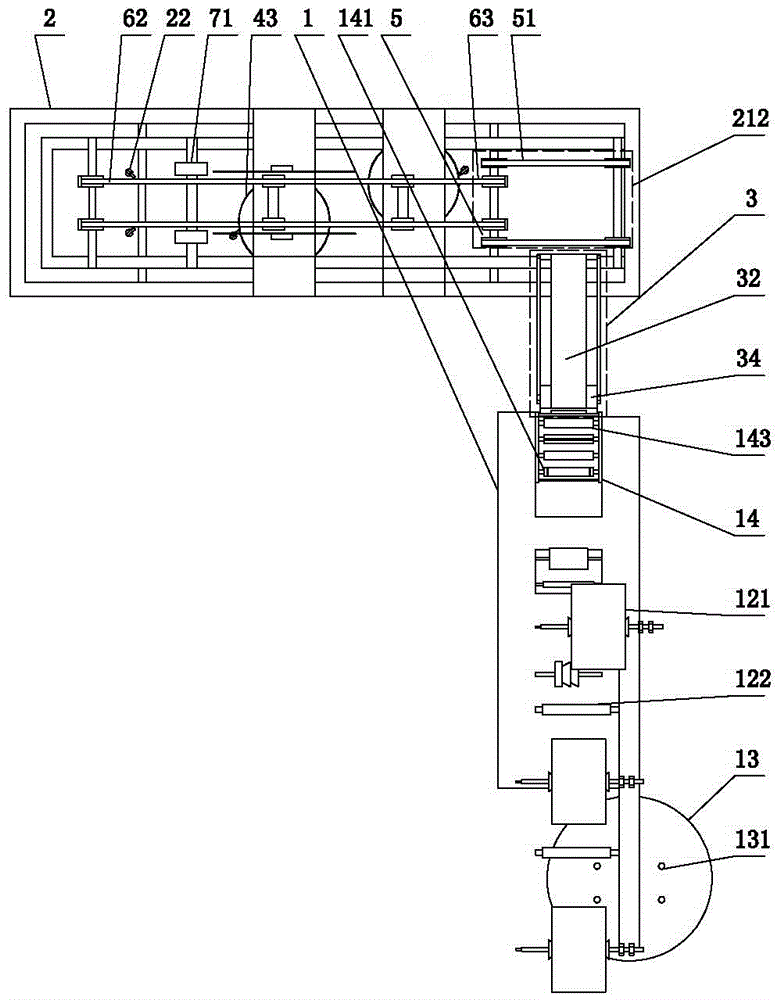

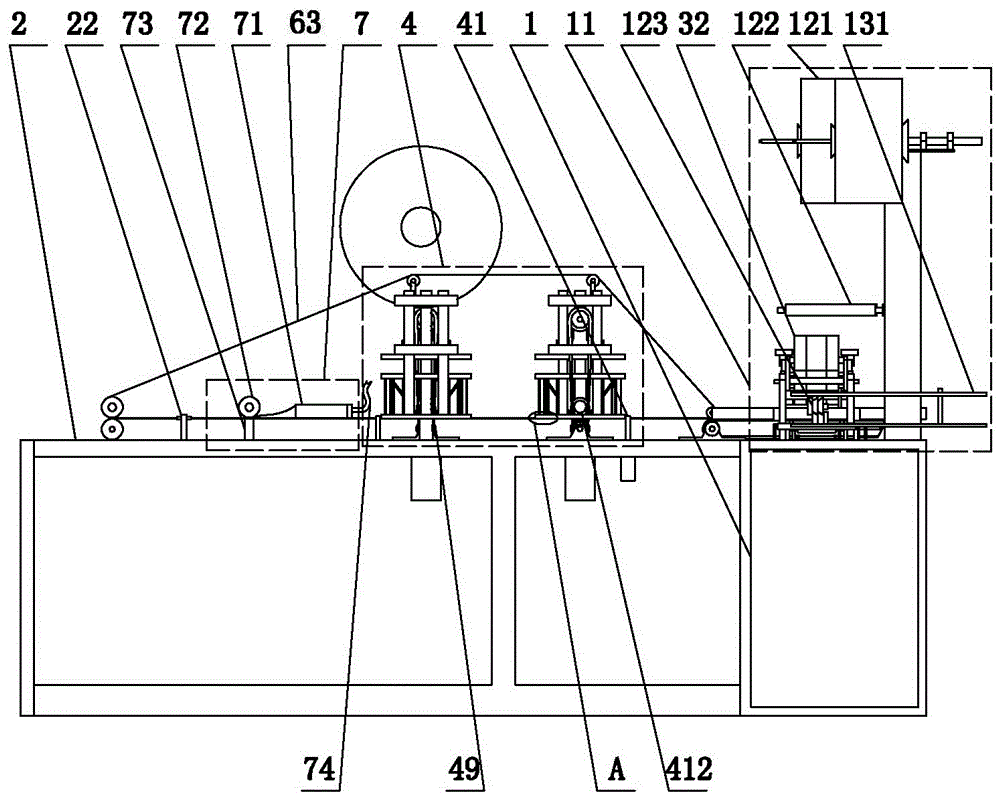

Automatic paper mask production machine

ActiveCN102940329BImprove productivity levelsReduce labor intensityProtective garmentRespiratorEconomic benefits

The invention relates to a full-automatic paper mask production machine. The mask production machine comprises a mask piece striking machine for forming a mask piece and an ear belt adhesion machine for adhering belts on a paper mask. A horizontal plane of a rack of the mask piece striking machine is vertical to a horizontal plane of a rack of the ear belt adhesion machine; and the mask piece striking machine is connected with the ear belt adhesion machine by a paper mask clamping and conveying device. The full-automatic paper mask production machine has the advantages of compact structure, high automation degree, convenience in operation, reliability in operation, accuracy in action, high working efficiency and the like. In the production process of equipment, the whole process of feeding the mask piece, conveying the ear belts, cutting off, welding, covering the edge, cutting off and outputting a finished product is automatically completed. The machining process is reduced; the mask productivity level is greatly improved; the labor intensity of workers is reduced; the labor cost is reduced; and the full-automatic paper mask production machine has obvious social and economic benefits.

Owner:湖北羽林防护用品有限公司

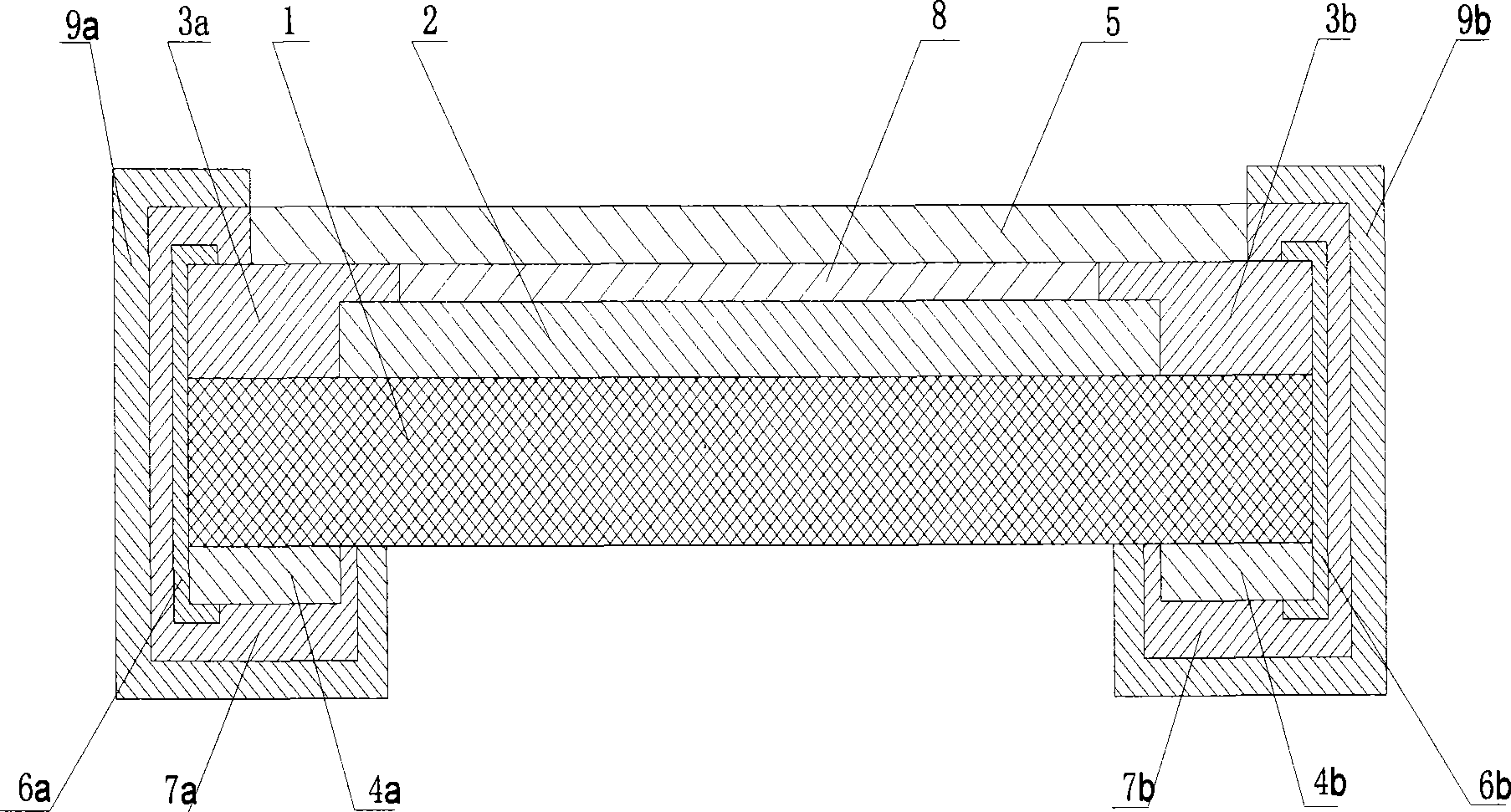

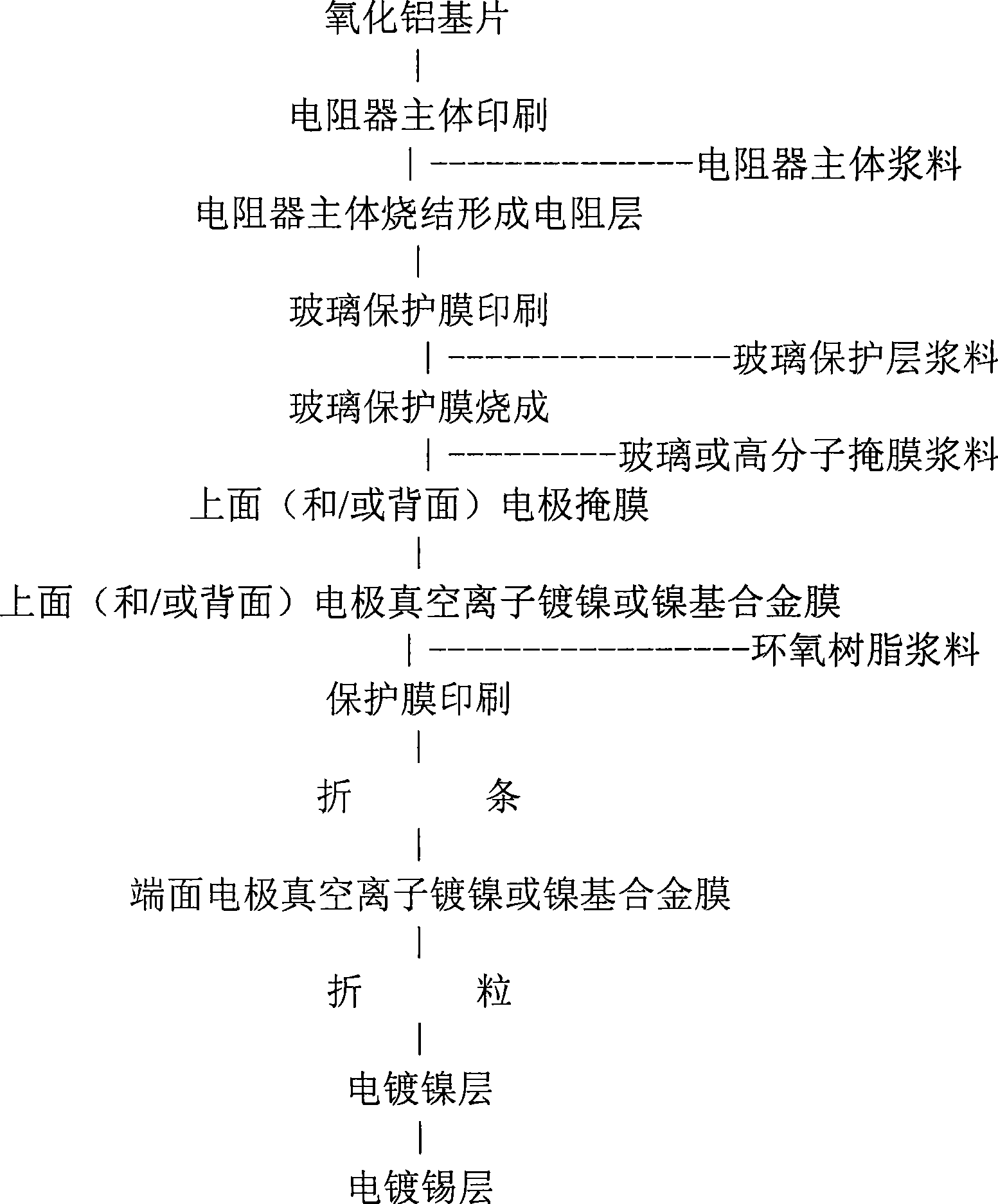

Nickel or nickel base alloy electrode sheet type resistor and method of producing the same

InactiveCN101369478AImprove reliabilityMeet electrical performance requirementsResistor chip manufactureResistor terminals/electrodesElectrical resistance and conductanceState of art

The invention discloses an electrode chip resistor of nickel or nickel base alloy and manufacture method thereof, which is invented for solving the problem that a chip resistor fault is easy to produce in the prior art. The resistor comprises an insulating substrate, on at least one side of which is formed with a resistor layer, and a pair of upper electrode layers formed at least on the upper of the resistor layer terminal and the upper of the insulating substrate, the resistor layer and the electrode layers are jointed together by physical joint between metal and metal, the electrode layers are nickel or nickel base alloy layers. The resistor formed adopting this method does not generate phenomenons of metallic layer separation and chemical reaction in actual use, because of using nickel or nickel base alloy to replace silver as electrode, not only can completely satisfy requirement of electric performance of the resistor, but also can reduce the processing procedure, greatly improves reliability of resistor use, the chip resistor of good electric performance can be manufactured with high efficiency and low cost.

Owner:杨金波 +1

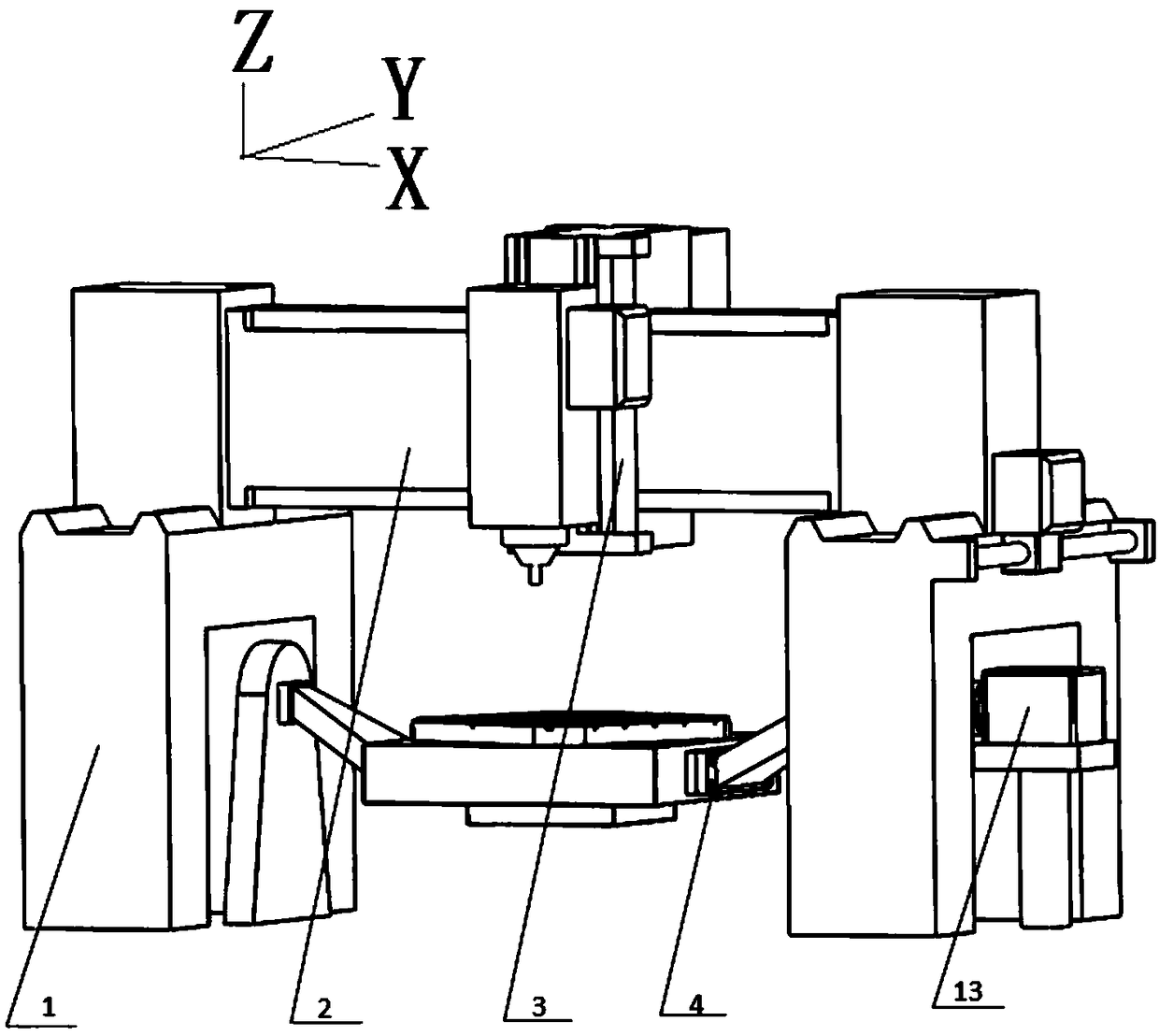

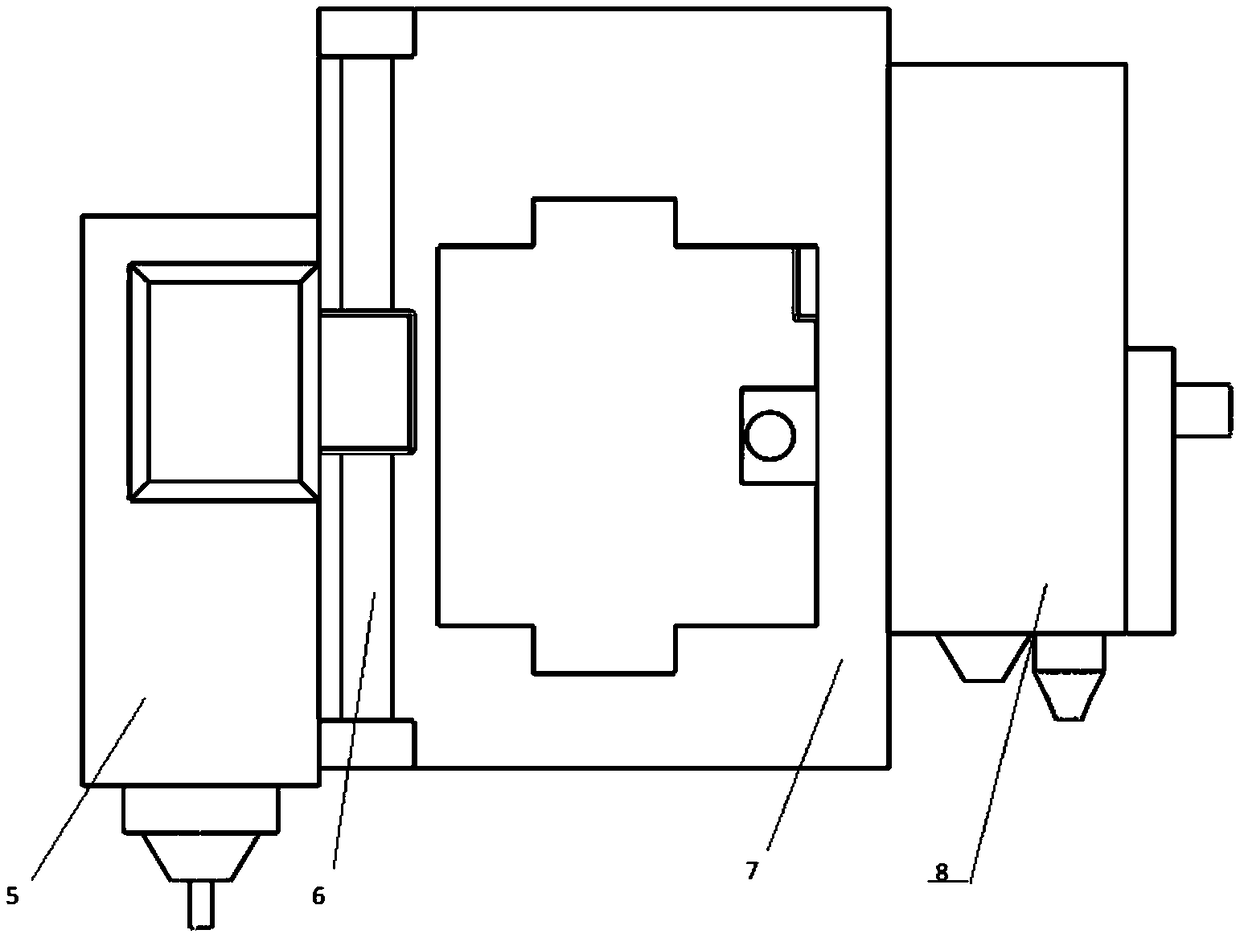

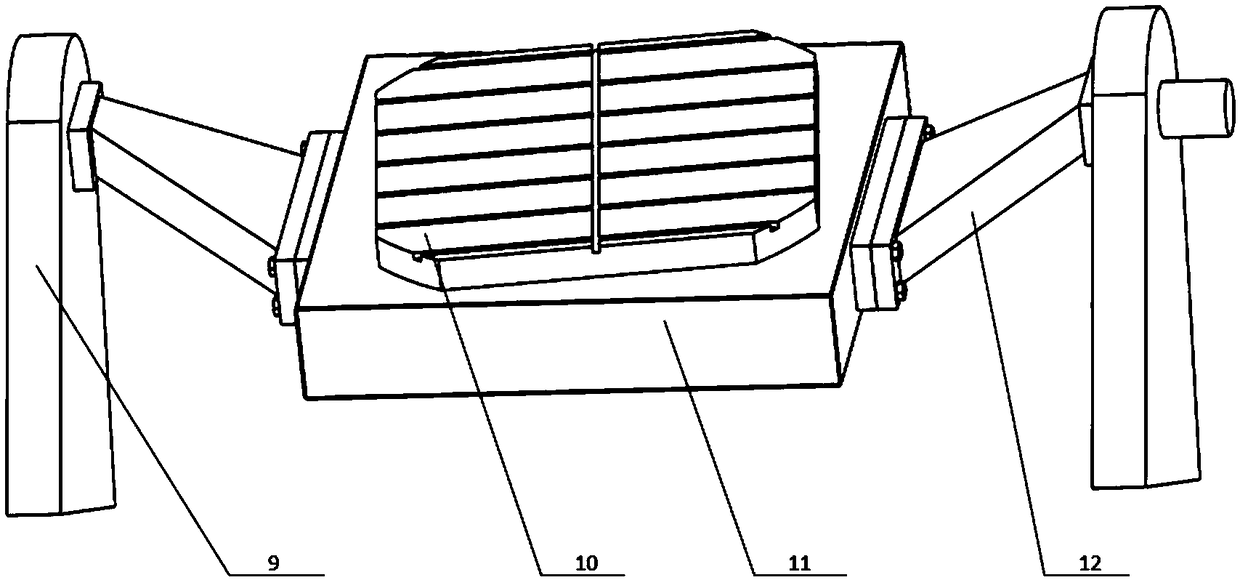

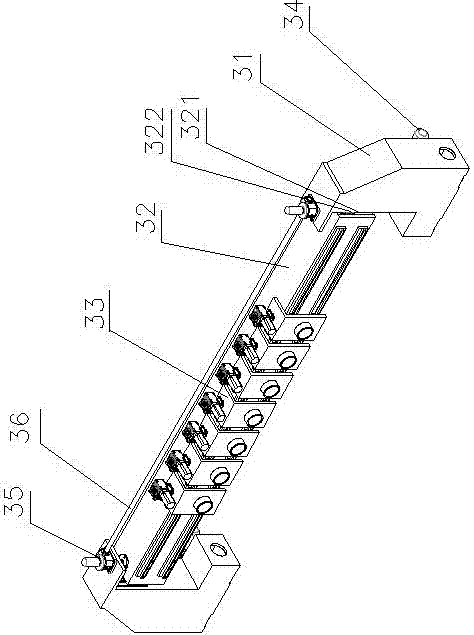

Five-axis additive manufacturing and subtractive manufacturing compound machining device

InactiveCN109228336AShorten the manufacturing cycleEasy to processManufacturing platforms/substratesOther manufacturing equipments/toolsMoving frameMachining

The invention discloses a five-axis additive manufacturing and subtractive manufacturing compound machining device, comprising a double-Z-axis additive manufacturing and subtractive manufacturing mould, support beams, a cross beam and a cradle type workpiece tray; the cross beam is arranged to be linearly fed along a guide rail on the top surface of the support beams along the horizontal Y-axis direction; the double-Z-axis increase and decrease material module is arranged to be linearly fed along the X-axis of the cross beam; the double Z-axis additive manufacturing and subtractive manufacturing mould comprises a moving frame, a print head and a milling head; the print head and the milling head are respectively installed at the two sides of the moving frame, and the print head and the milling head are arranged to slide along guide rails respectively arranged in the Z-axis direction so as to be linearly fed; in a space between the support beams at the two sides of the lower part of thecross beam, the cradle type workpiece tray rotates about the X-axis direction by means of two arms; the cradle-type workpiece tray is arranged to circumferentially rotate along the circumferential direction perpendicular to the plane where a fixed plate is positioned. The five-axis additive manufacturing and subtractive manufacturing compound machining device integrates additive manufacturing andsubtractive manufacturing, thus greatly reducing the component manufacturing cycle, and facilitating the manufacturing of parts with higher precision; furthermore, the device is wide in applicability.

Owner:WUHAN UNIV OF SCI & TECH

Method for manufacturing paper-plastic composite bag with window

InactiveCN102069602AVolume has little effectProduction costs are not affectedBox making operationsPaper-makingMolded pulpEngineering

The invention discloses a method for manufacturing a paper-plastic composite bag with a window, which comprises the steps of: (1) longitudinally cutting a window with preset width at the needed position of paper; (2) spreading glue on the surface on one side of a plastic film except the area corresponding to the window; (3) oppositely laminating the paper with one surface of the plastic film spreading with the glue to form a composite material; and (4) molding the composite material into the bag with the window which has the needed specification and shape. The manufacturing method is high in continuity of manufacturing procedures and high in production efficiency; and the product has unlimited window size and is low in manufacturing cost.

Owner:崔俊

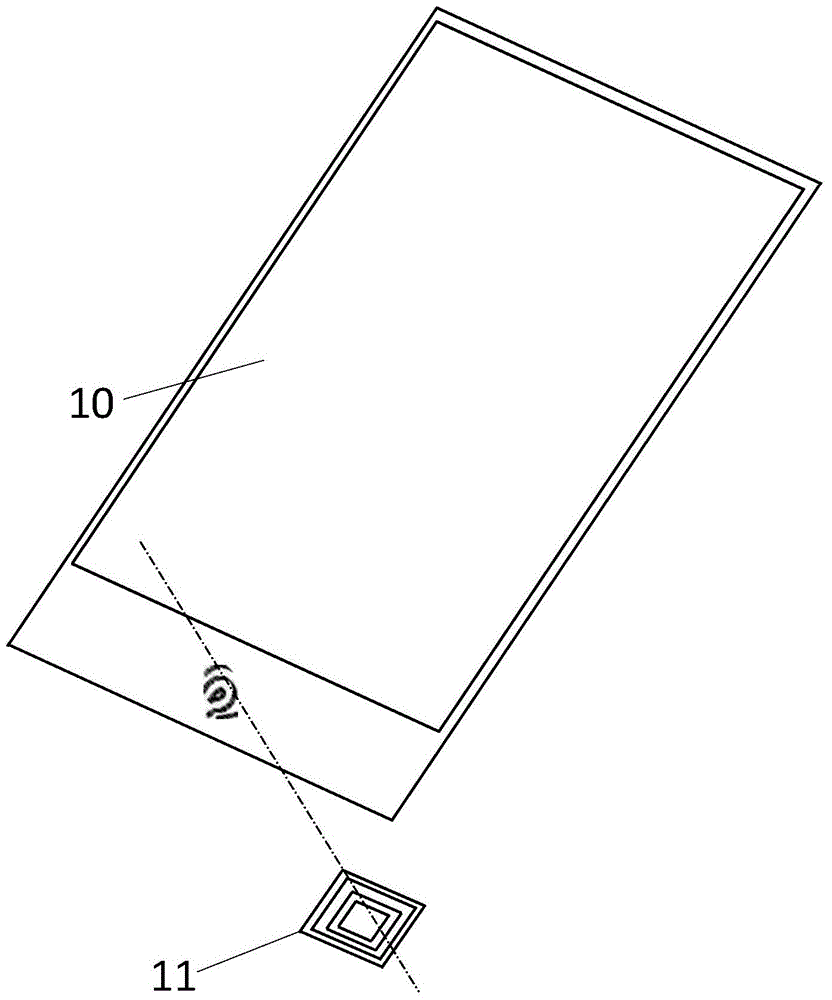

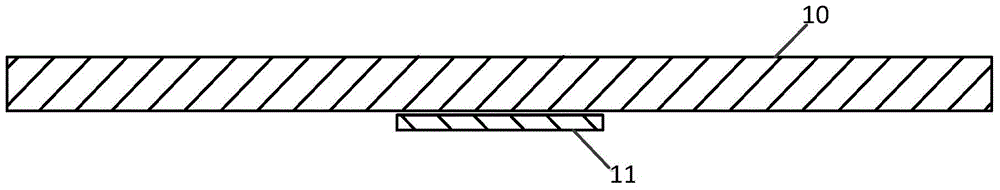

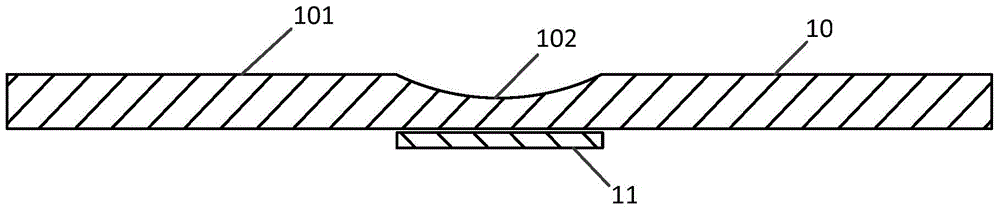

Mobile terminal

InactiveCN104407751ASolve the problem of differenceImprove satisfactionDigital data processing detailsCharacter and pattern recognitionComputer terminalTouchscreen

The invention discloses a mobile terminal, which comprises a capacitive touch screen. The mobile terminal is characterized in that the capacitive touch screen comprises a touch cover plate and a sensing identification module, wherein the sensing identification module is covered by the touch cover plate; the touch cover plate is 0.40 to 2.0mm thick. According to the embodiment of the invention, the touch cover plate and the sensing identification module are integrated on the touch screen, and a full-touch panel is adopted, so that the problem of difference caused by the independent assembly of the sensing identification module is visually and tactually solved, machining procedures are reduced, the production and utilization efficiency is improved, and the degree of satisfaction of a user is improved.

Owner:SHENZHEN GOODIX TECH CO LTD

Cold extrusion mold for output shafts and preparation method thereof

InactiveCN104525599AReduce processing proceduresAvoid it happening againExtrusion diesEngineeringExtrusion

The invention discloses a cold extrusion mold for output shafts. The mold is composed of an upper die and a lower die which are mutually matched, wherein the lower die comprises a lower die core and a lower die fixed sleeve, the center of the top of a main body of the lower die core is provided with a shaft head cavity with an upward opening, and the shaft head cavity is connected with a multistage ladder-like lower die cavity penetrating to the bottom of the main body; an inner ring of the lower die fixed sleeve is sleeved on the outer peripheral surface of the lower die core, and an outer ring of the lower die fixed sleeve is sleeved on the upper part of a lower die jacket; and a lower die base is sleeved on the lower part of the lower die jacket, the center of the lower die base is provided with a lower die knockout-pin cavity communicated with the lower die cavity, the bottom of the lower die base is contracted so as to form a cascade ring, and the cascade ring is nested into a lower die fixed seat. According to the scheme, the machining efficiency is high, the manufacturing cost of products is low, no cutting is generated, and no material loss is caused; and a forging die is abraded slowly, and the size precision of products is easily guaranteed.

Owner:浙江名将汽配有限公司

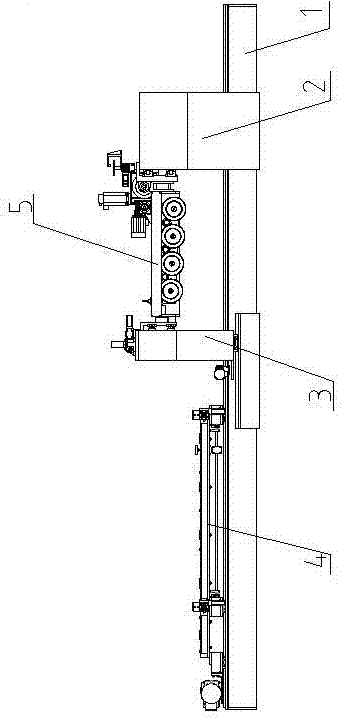

Numerical control steel plate longitudinal cutting forming machine

ActiveCN107159973AEasy to replaceStable deliveryFeeding apparatusLarge fixed membersMolding machineThermal deformation

The invention discloses a numerical control steel plate longitudinal cutting forming machine. The machine comprises a machine body (1), a main gantry assembly (2), a secondary gantry assembly (3), a conveying assembly (4), a cutting main machine assembly (5) and a numerical control system, relates to the field of steel plate longitudinal cutting equipment, and is special gold cutting equipment for achieving no thermal deformation, no extrusion deformation, no oxidation layer, high linear precision, multiline longitudinal separation and once forming on steel plates by a multipoint cutting mode. The machine longitudinally separates the steel plates with different thicknesses by using the multipoint metal cutting mode, improves the equipped level of basic machining, reduces environmental pollution, reduces comprehensive production cost, improves the machining precision, and lays solid foundation for realizing intelligent and individual demands.

Owner:泰安九和智能设备有限公司

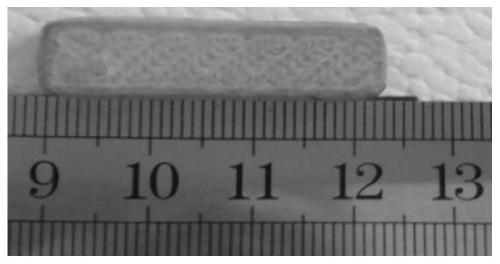

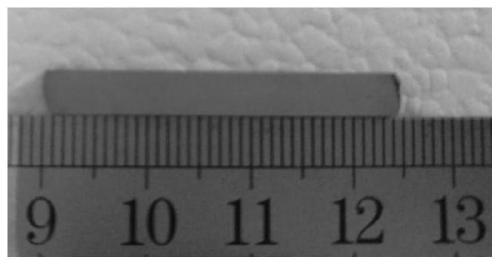

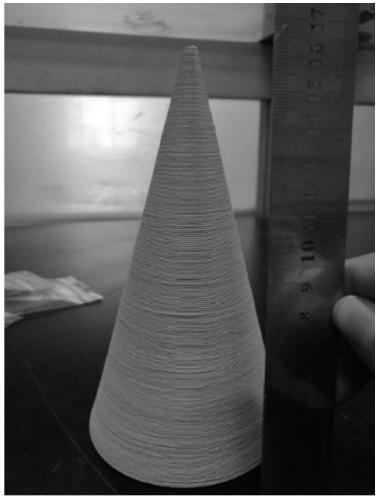

Method for preparing large-size complex silicon nitride ceramic

ActiveCN109761621AReduce manufacturing costFast molding speedAdditive manufacturing apparatusCeramic shaping apparatusDirect writingLarge size

The invention provides a method for preparing a large-size complex silicon nitride ceramic and relates to the method for preparing silicon nitride ceramics. The invention aims to solve the problem that the present direct writing molding technique cannot prepare large-size silicon nitride ceramic materials. The preparation method comprises the following steps: 1) weighting; 2) mixing; 3) 3D printing; 4) sintering, thereby finishing the preparation of the large-size complex silicon nitride ceramic. The method provided by the invention can be used for preparing the large-size complex silicon nitride ceramic.

Owner:HARBIN INST OF TECH

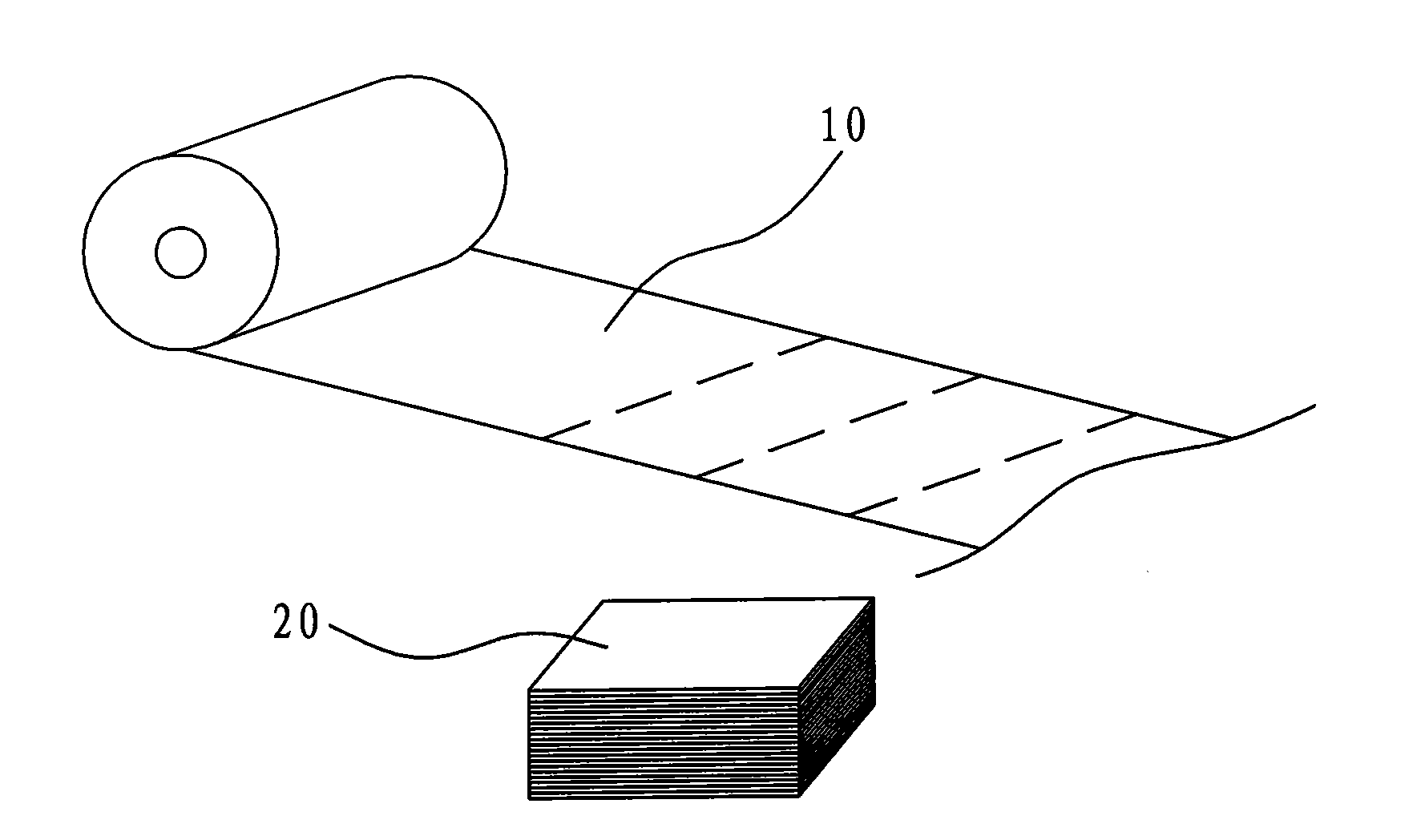

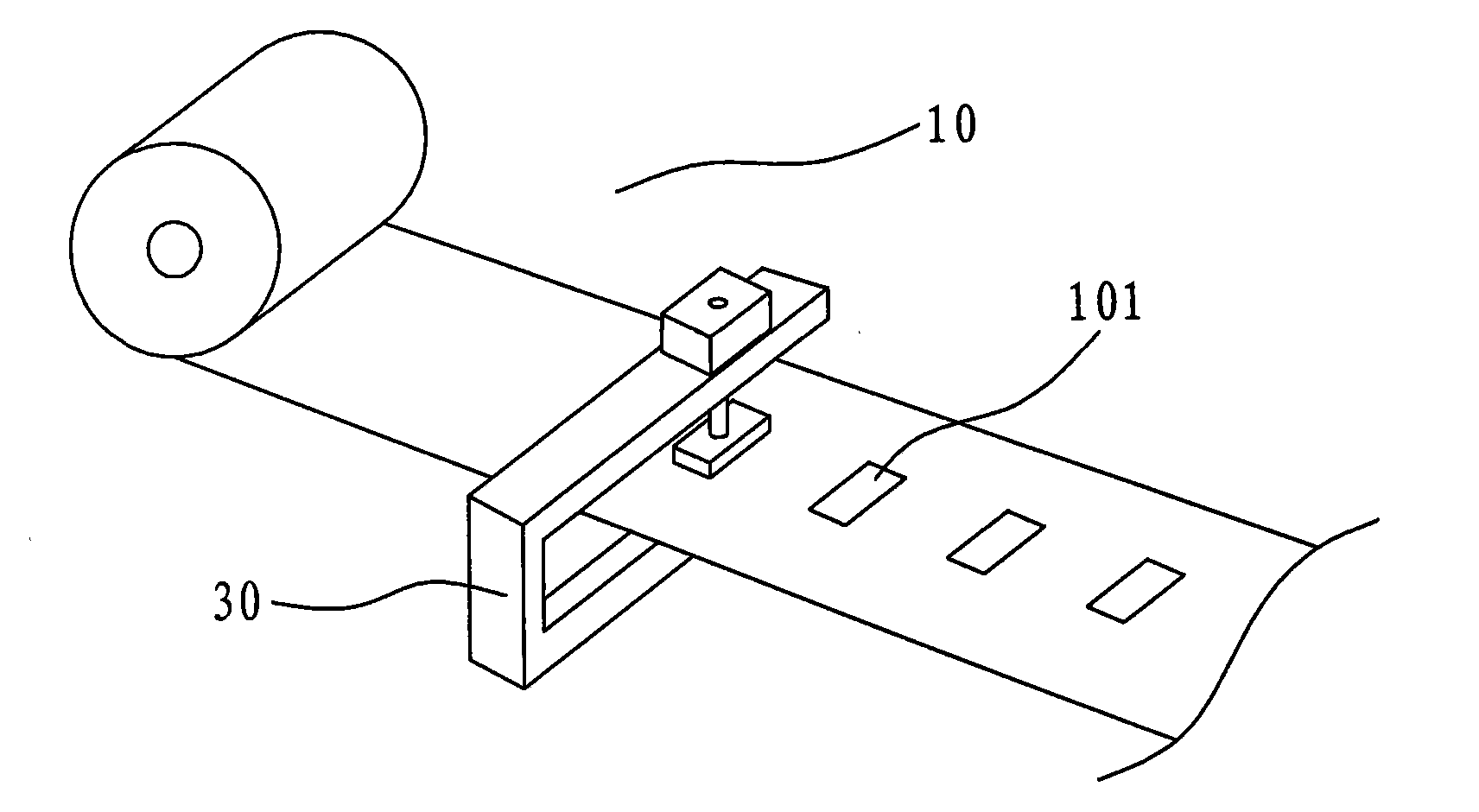

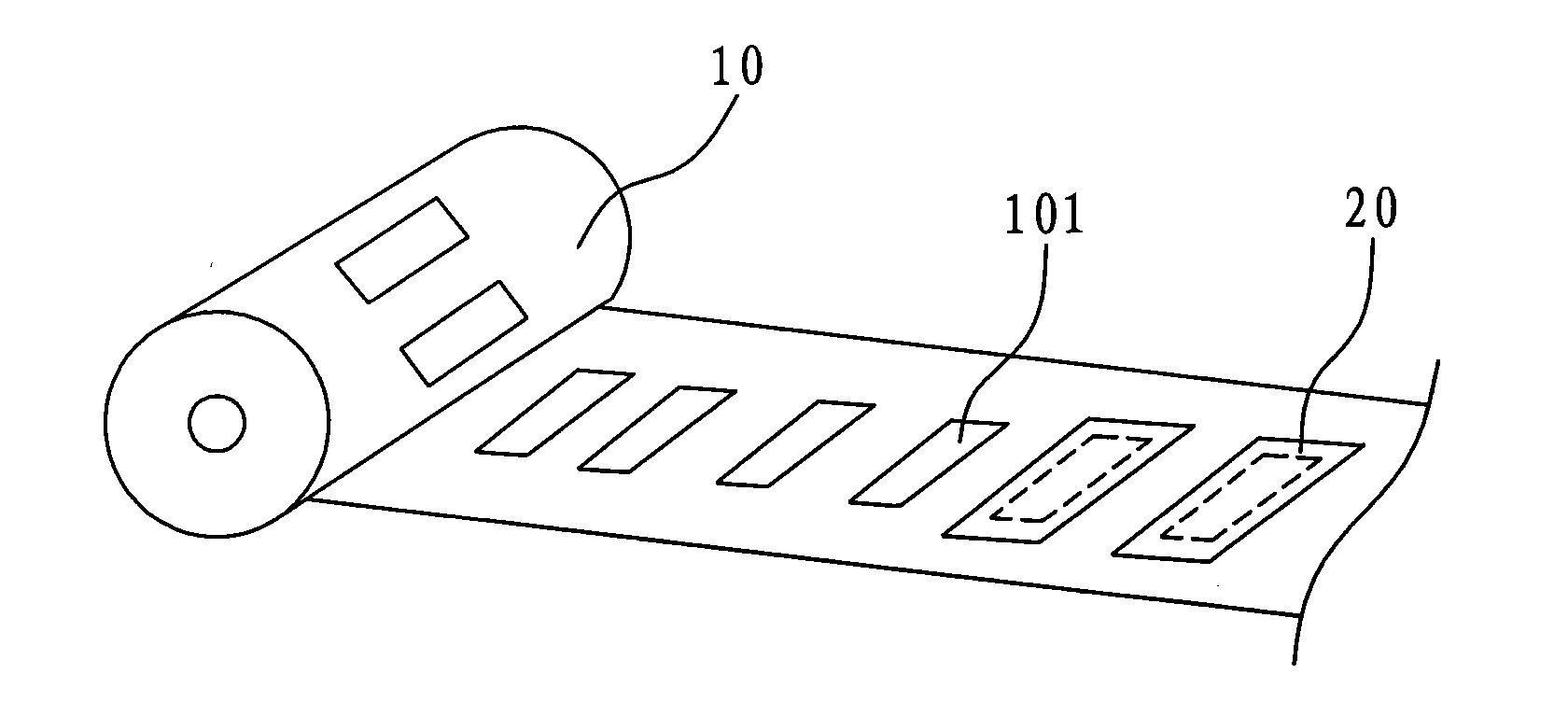

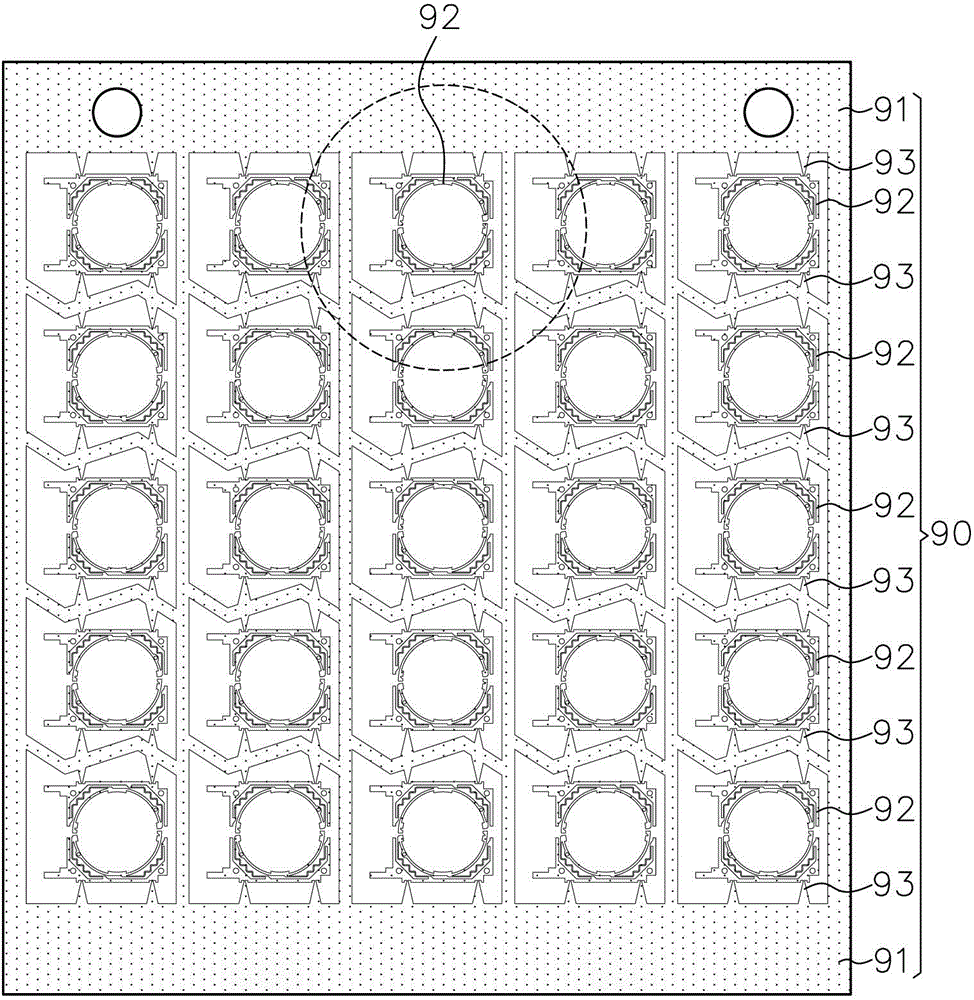

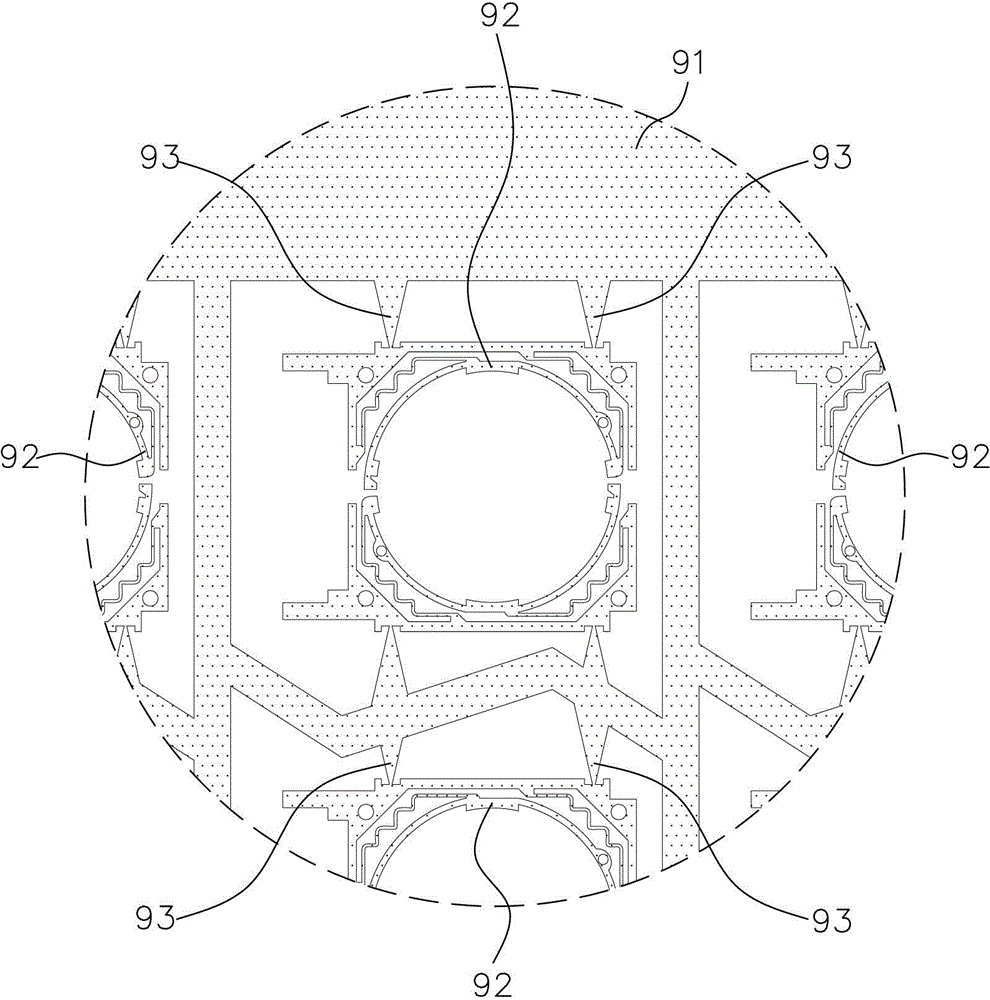

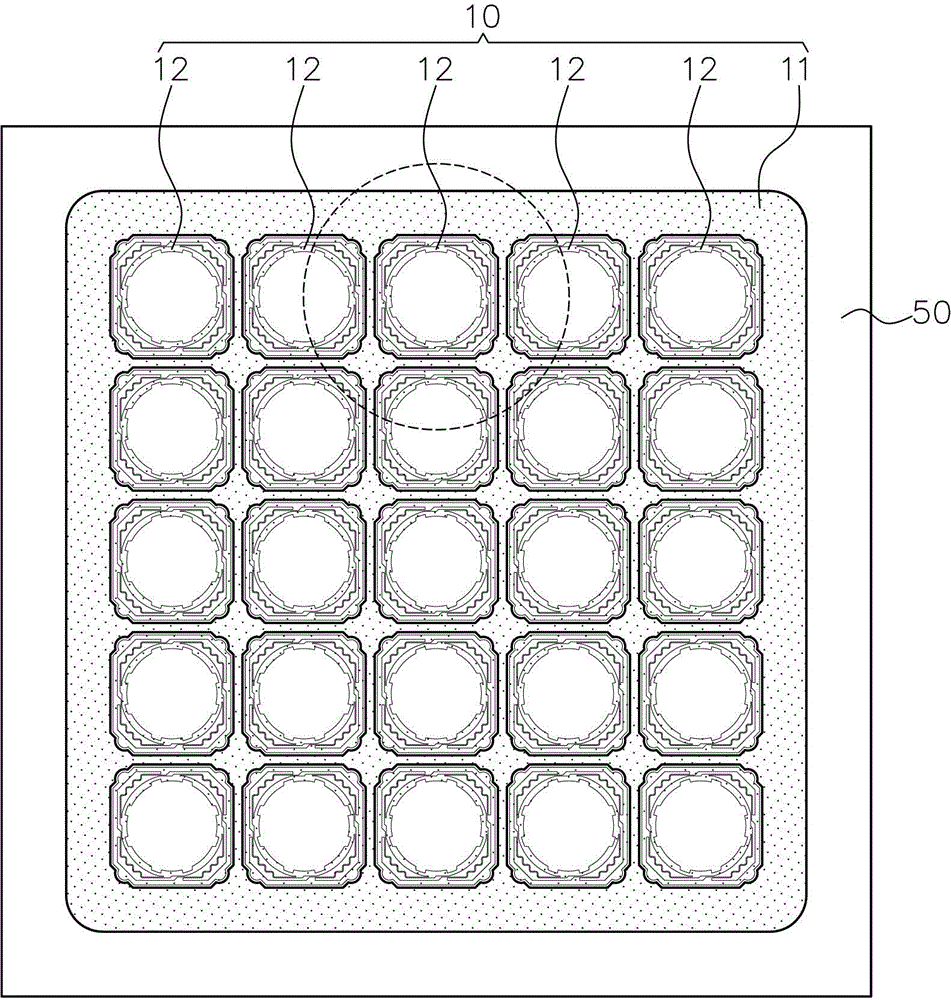

Connecting-point-free metal sheet etching method and metal element group manufactured with same

The invention discloses a connecting-point-free metal sheet etching method and a metal element group manufactured with the same. According to the method, single-face etching is adopted, arrangement of connecting points of a metal sheet to be etched is not needed, multiple formed metal elements are transferred onto a protection film through an anti-corrosion cure adhesive after film pressing, exposure, developing and etching are conducted on the metal sheet, and then the metal element group easy to peel is formed to be used in the later stage.

Owner:黄浩祥

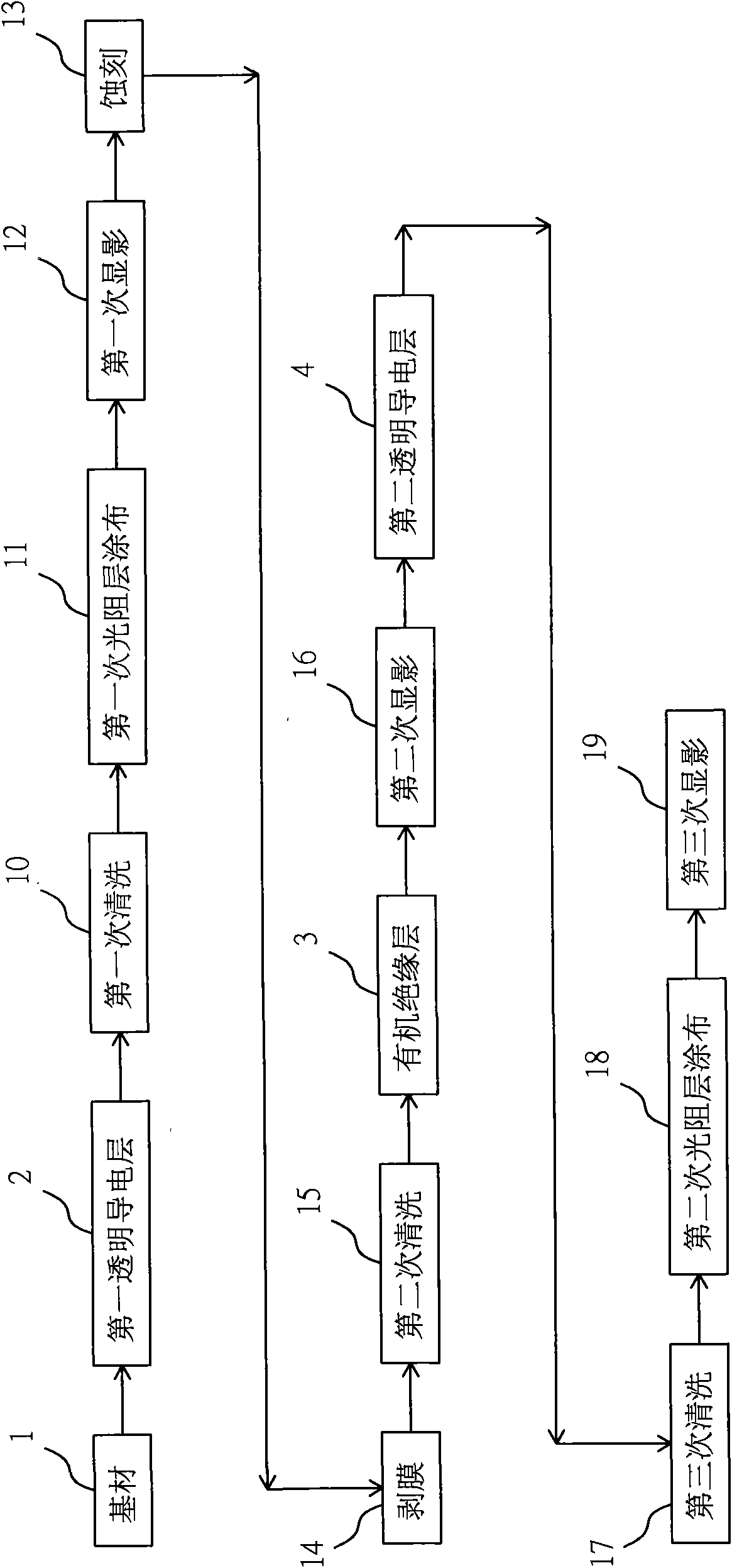

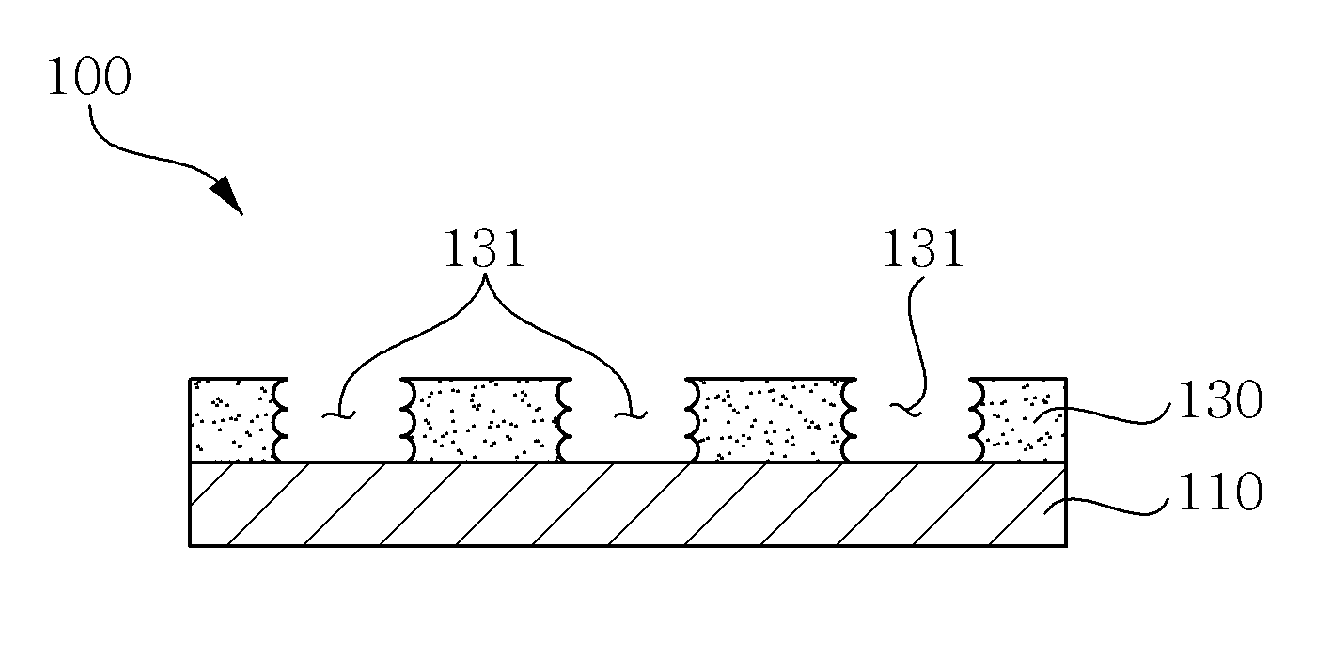

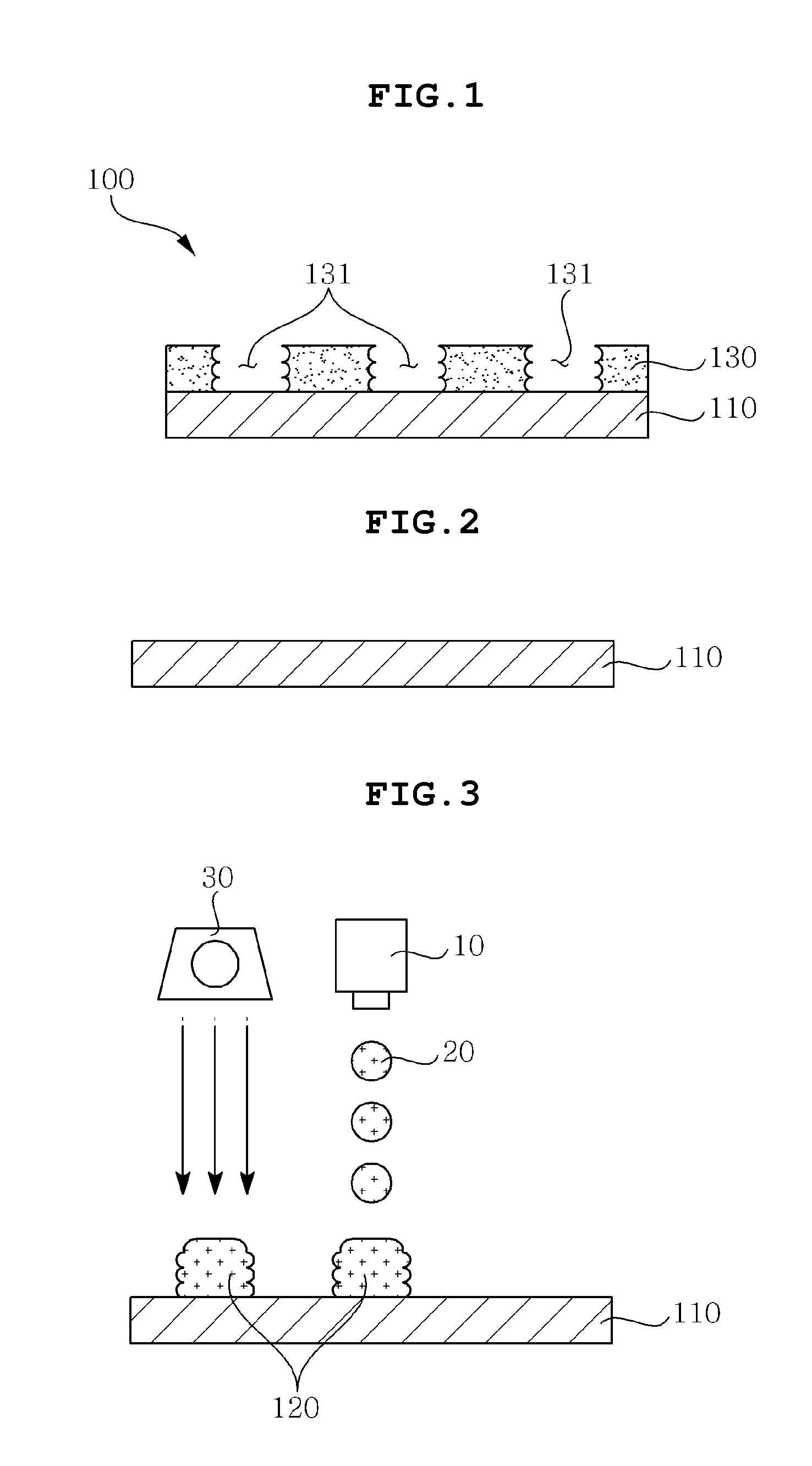

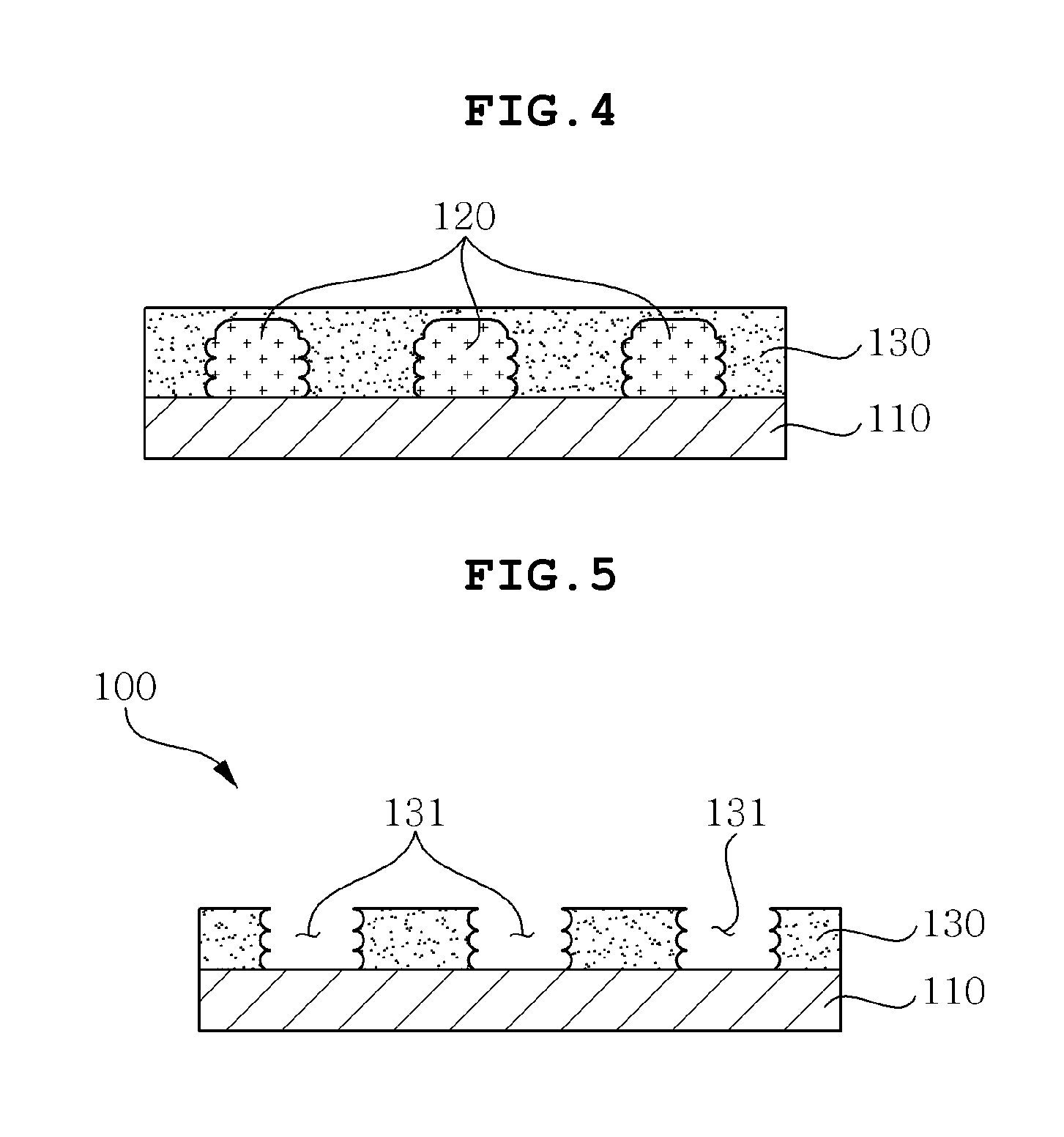

Method for manufacturing insulation layer of touch panel

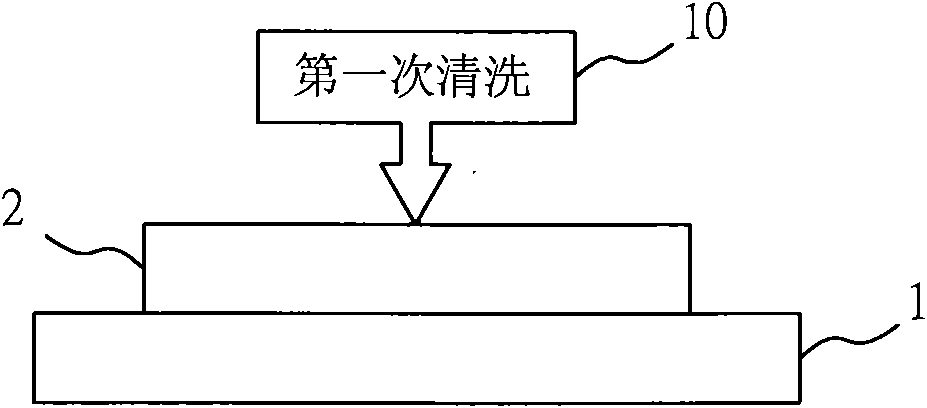

InactiveCN101807539AMeet needsReduce processing proceduresSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentInsulation layerEngineering

The invention relates to a method for manufacturing an insulation layer of a touch panel, which comprises the following steps of: plating a first transparent conducting layer on a substrate, cleaning for the first time, then coating a first photoresist layer to generate a conductive circuit graphic, developing for the first time, then etching and decoating the photoresist layer, cleaning for the second time to expose the conductive circuit, coating an organic insulation layer on the first transparent conducting layer, developing for the second time, then plating a second transparent conducting layer on the organic insulation layer, cleaning for the third time, coating a second photoresist layer on the second transparent conducting layer to generate another required conductive circuit graphic, and finally carrying out the third development on the conductive circuit graphic on the photoresist layer with a developer, therefore, the invention achieves the effects of reducing processing procedures and lowering cost when being used for manufacturing the insulation layer of the touch panel.

Owner:百倍光电股份有限公司

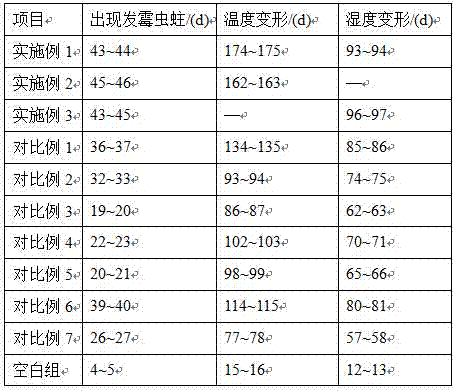

Method for preventing deformation and cracking of pines

InactiveCN107379178APrevent deformation and crackingDeformation and cracking are easyImpregnation spraying apparatusWood treatment detailsFiberBatch processing

The invention mainly relates to the technical field of wood product processing, and discloses a method for preventing deformation and cracking of pines. The method comprises arrangement, refrigeration, fermentation, primary drying, humidification and secondary drying; the method is simple and convenient in batch processing; no poisonous reagent is added in the treatment process to achieve safety and health; the water content of the treated pines is stable, and the water absorbing capacity is reduced, so that deformation and cracking are radically prevented, the service life is prolonged by 14.5%, and the use value of pine products is obviously improved; the cut pines are cut according to needed lengths; pine barks are retained; the protecting effect of the pine barks is improved, so that the color change in the pine treatment process is inhibited, and later unified bleaching treatment is convenient; and pine sections are put in a treatment chamber to gradually cool for refrigeration, so that the water in the pines is reduced under low-temperature environment, gaps among pine fibers are increased, the resistance of the pines to temperature and humidity is improved, the influence of environmental change to the pines is relieved, and deformation and cracking of the pines are prevented.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

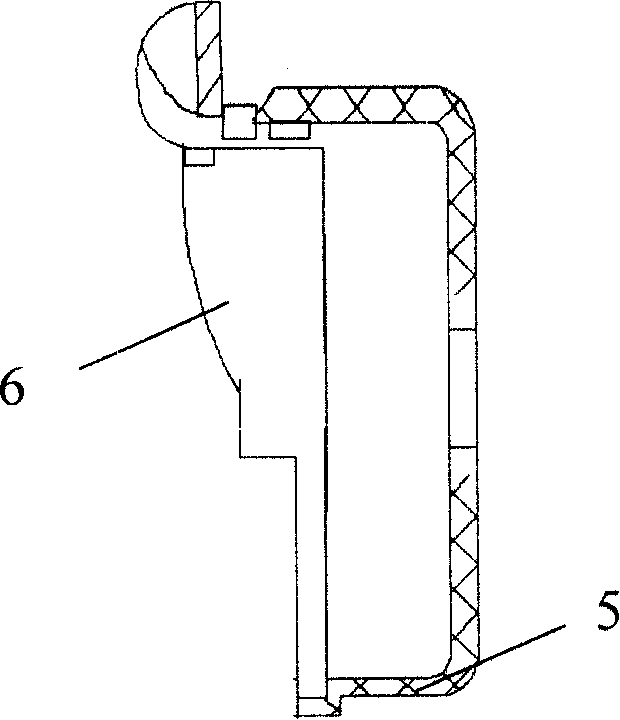

Sewing machine rotating shuttle frame and manufacturing method thereof

A shuttle frame in rotating shuttle of sewing machine is formed by connecting a first cylindrical shell and a second cylindrical shell, wherein, one end of the first cylindrical shell is provided with a thread hook; one end of the second cylindrical shell is sealed up; the other ends of the first cylindrical shell and the second cylindrical shell are mutually fixed; a circle of convex rail is arranged on the outer circumference of the first cylindrical shell; the first cylindrical shell is formed by plastic materials, while the second cylindrical shell is formed by metal materials; a solid metal shuttle core handle is arranged on an axis line inside the second cylindrical shell. The present invention also relates to a method for manufacturing the shuttle frame in the rotating shuttle of sewing machine, wherein, the shuttle frame in the rotating shuttle of sewing machine is divided into two parts to be processed independently and then assembled to form a complete shuttle frame. The present invention saves materials, reduces processing programs, decreases manufacture cost, simultaneously lightens the weight of the shuttle frame, reduces wear, prolongs life-span, is low in sound during the operation of the rail part, needs no lubricating oil to be added, and cannot pollute processed fabrics.

Owner:梁少俊

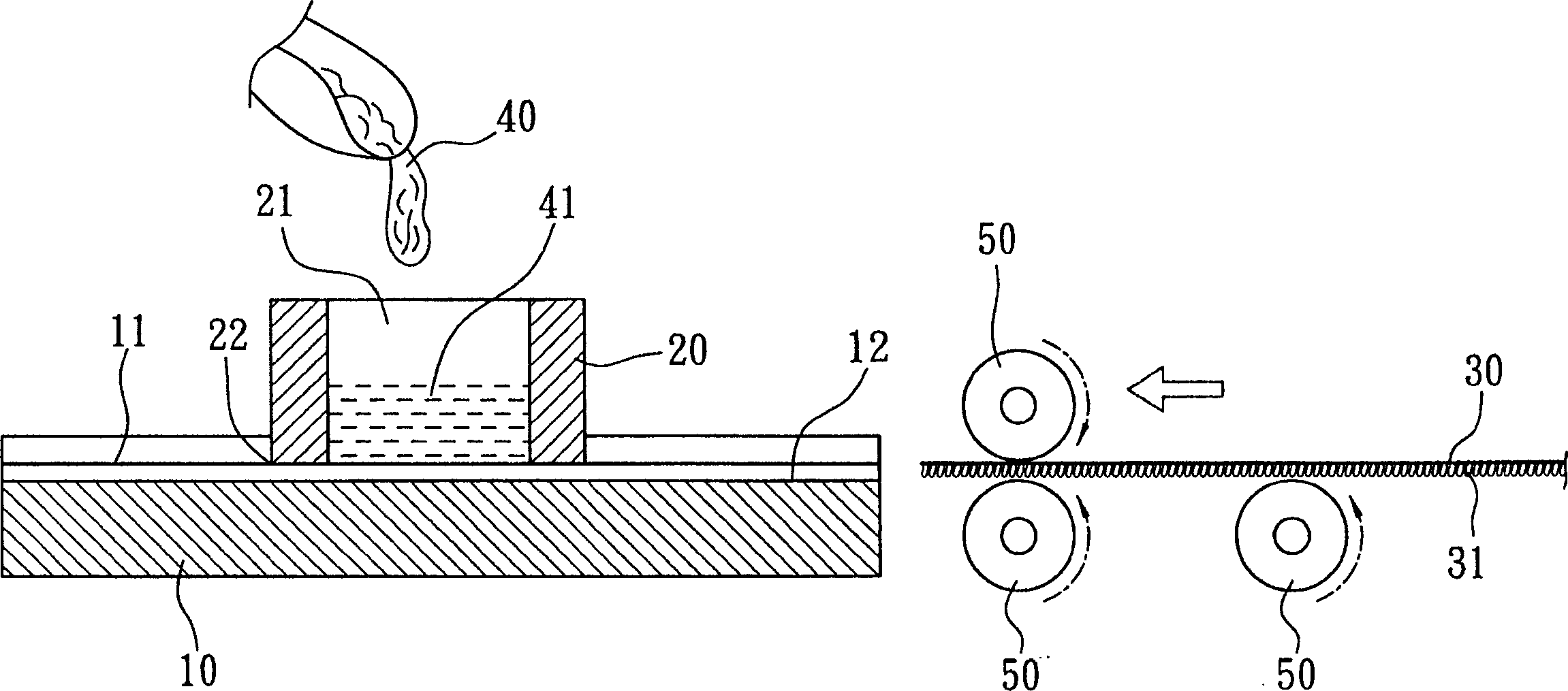

Method for soaking water-proof zipper in waterproof material

The present invention relates to a method for manufacturing penetrated water-proofing material for water-proof zipper. Said method includes the following steps: combining upper die and lower die, injecting PU adhesive into die cavity of upper die, making the zipper be passed through lower portion of die cavity so as to make the PU adhesive be penetrated into the tape cloth of zipper, and utilizing lower edge of upper die to form a doctor blade portion, when the zipper tape is conveyed, using said doctor blade to scrape off excessive liquid PU adhesive and make it be formed into a layer of film on said zipper tape so as to obtain the zipper with water-proofing function.

Owner:UNIVERSAL TRIM SUPPLY CO LTD

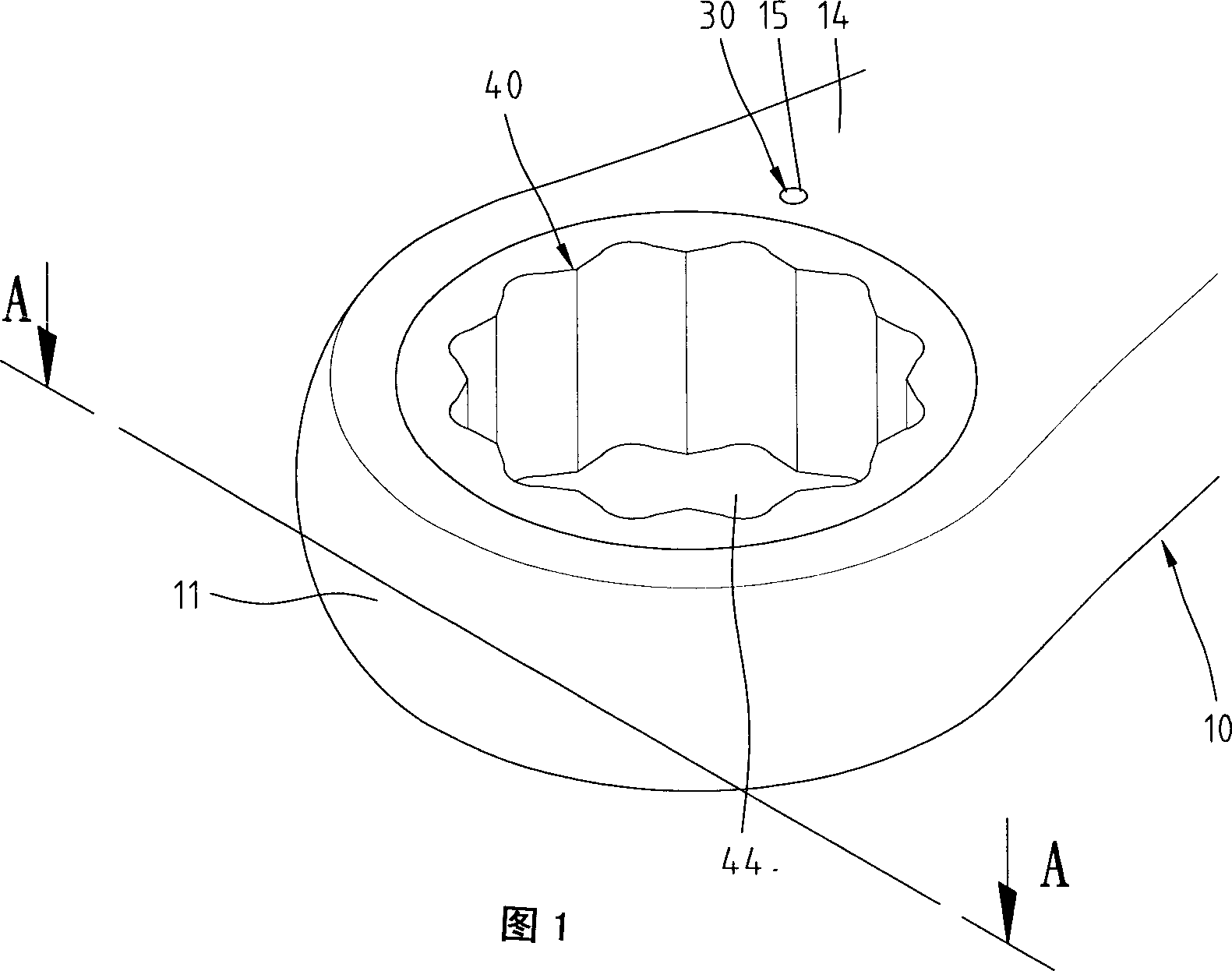

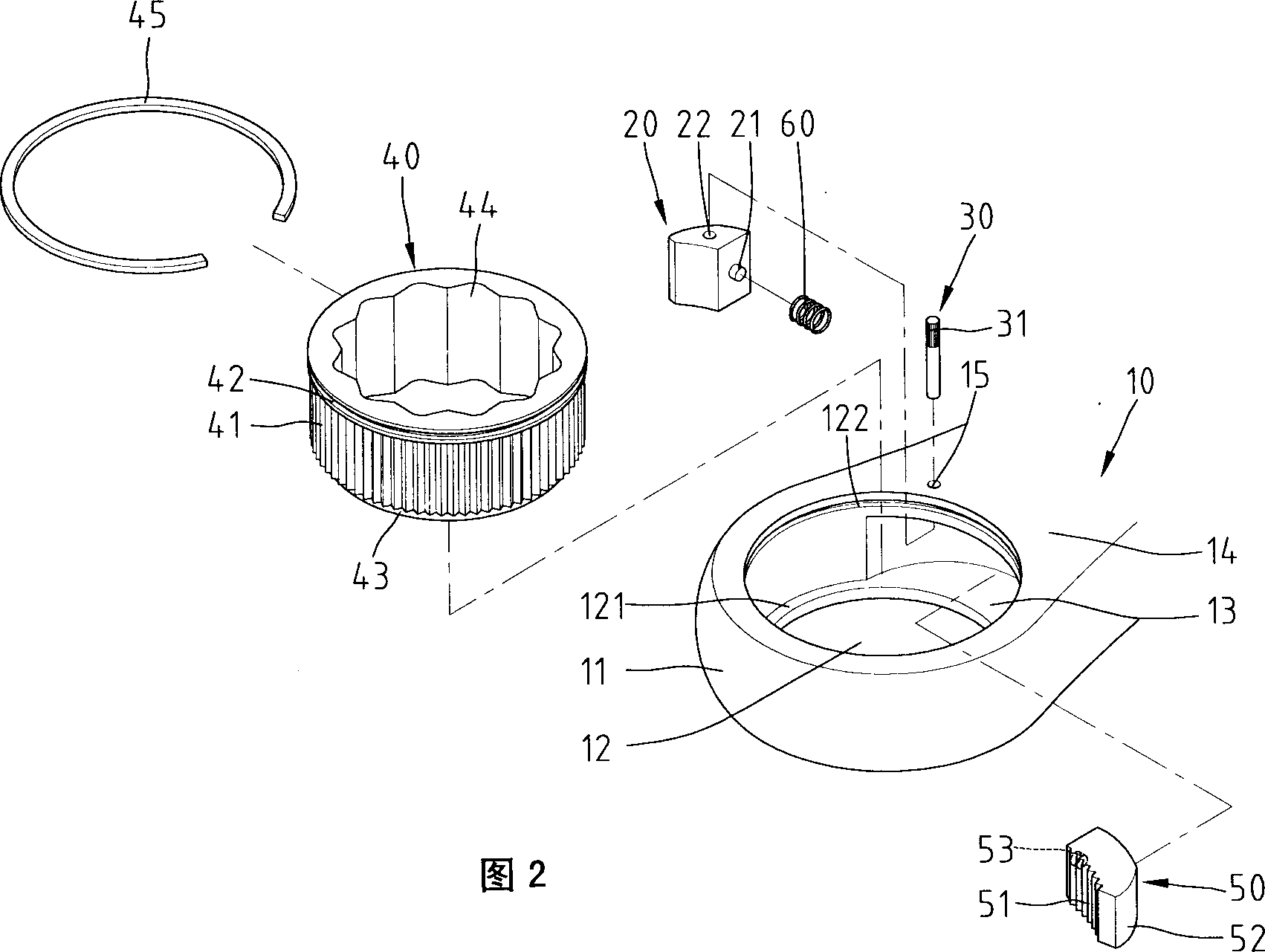

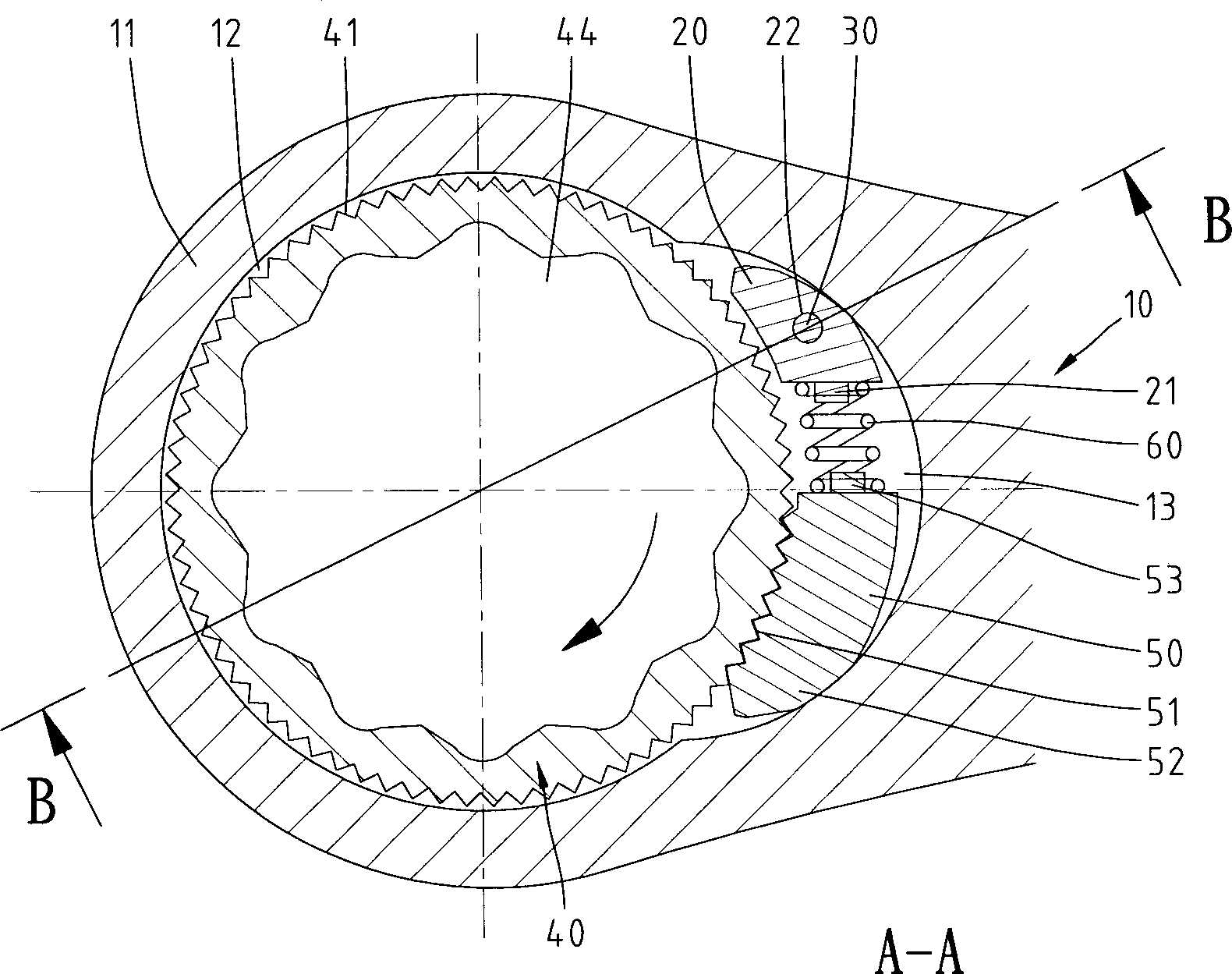

Ratchet wrench with jamming-preventing and indicating functions

The ratchet wrench includes a main body with communicated holding slot and holding space as well as a through hole communicated to the holding slot; a clamping block held in the holding slot; a fixedpart in the through hole and the clamping block to limit the clamping block in the holding slot and to form an indicating mark on one side of the main body; a ratchet wheel with several ratchets; a ratchet block with several ratchets on its one end to mesh with those in the ratchet wheel and capable of being set in the holding slot; and an elastomer between the ratchet block and the clamping block. The turning direction of the wrench can be known via the mark and the ratchet block may be made to separate from the ratchet wheel via pushing the clamping block to prevent jamming.

Owner:林彦文

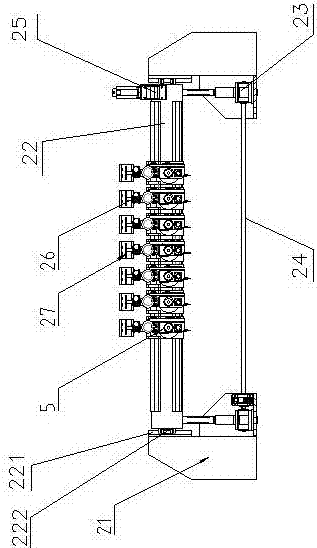

Compound type machining equipment for copper alloy flat wires

The invention discloses compound type machining equipment for copper alloy flat wires. The compound type machining equipment comprises a pay-off rack, multi-pass rolling equipment, online annealing equipment, two-time continuous pressing equipment, online annealing equipment, a tension rack and a finished product wire drawing machine, wherein the finished product wire drawing machine comprises a polycrystalline die, a winding displacement mechanism and a take-up mechanism. The compound type machining equipment disclosed by the invention adopts few machining procedures, is high in production efficiency and high in machining precision; the produced copper alloy flat wires are smooth in surfaces and good in quality.

Owner:WUHU CHUJIANG ALLOY COPPER

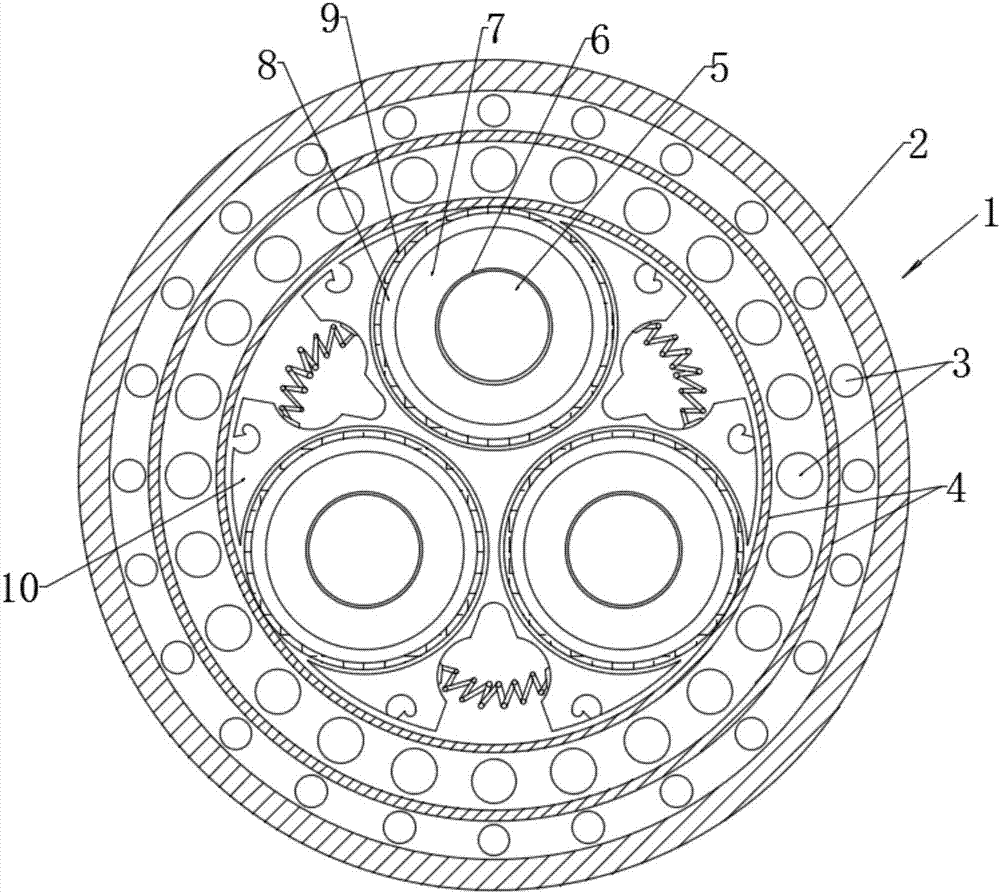

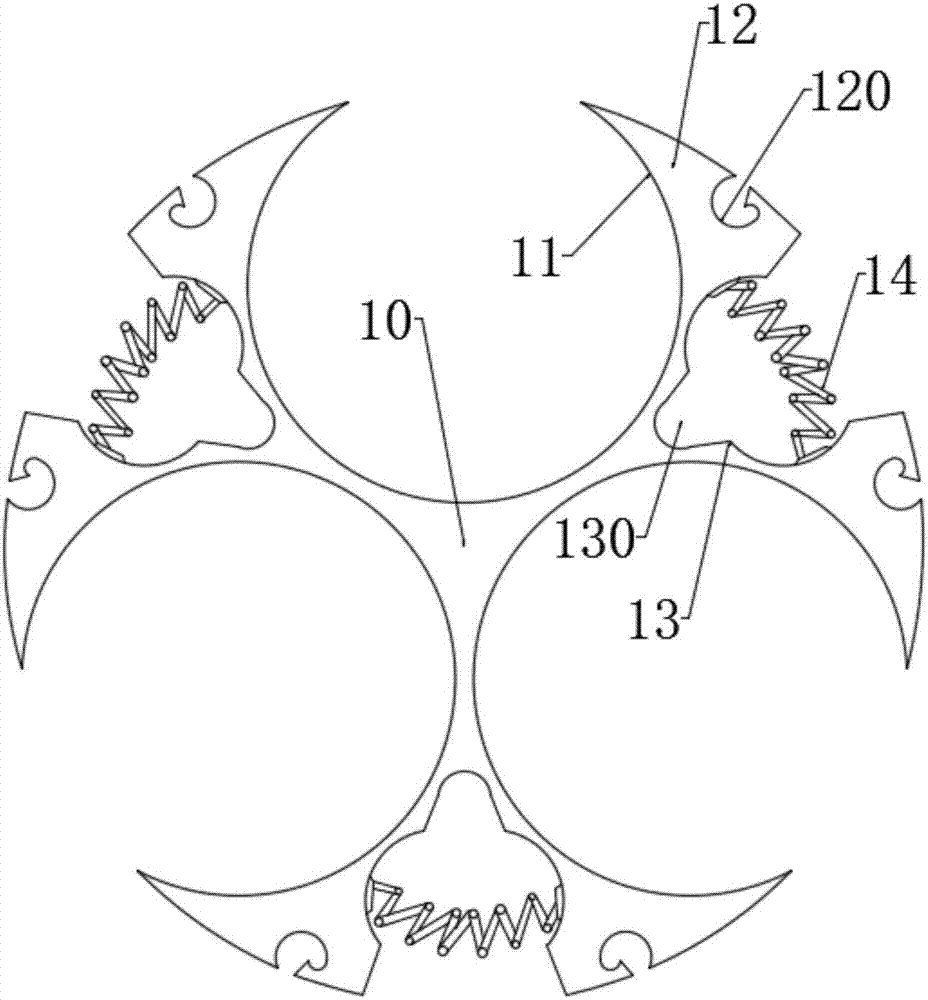

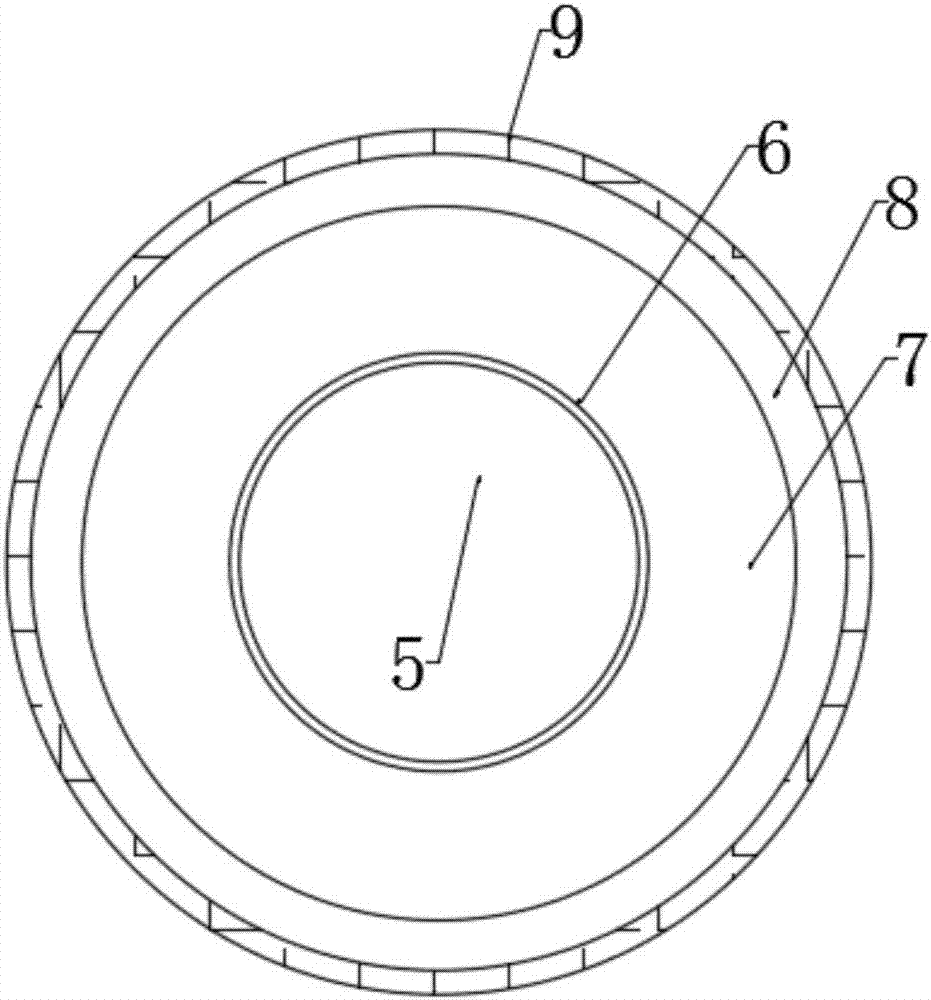

Stable and conveniently assembled and dissembled multiple-conductive-core cable and manufacturing method therefor

ActiveCN107195372ASmall space volumeReduce weightClimate change adaptationInsulated cablesEngineeringProtection layer

The invention discloses a stable and conveniently assembled and dissembled multiple-conductive-core cable. The cable comprises an outer protection layer and cable inner core conductors arranged in an inner cavity of the outer protection layer. The invention also discloses a manufacturing method for the stable and conveniently assembled and dissembled multiple-conductive-core cable; the method comprises the following steps of S1, preparing a traction rope, the outer protection layer and the cable inner core conductors of a to-be-threaded cable; S2, fixing and tightening one end of the traction rope at one ends of the cable inner core conductors, meanwhile, enabling one end with a hook to be penetrated through the inner cavity of the outer protection layer; S3, fixing the hook by a drawbench or a traction apparatus, and performing traction operation on the cable inner core conductors; and S4, controlling the traction speed to be not greater than 3m / min until the threading of the cable inner core conductors is completed. A rotary wheel mounting groove and an auxiliary rotary wheel apparatus are arranged in the inner cavity of the outer protection layer, so that convenience in the cable threading process can be well ensured, and structural completeness can be guaranteed; the method is applicable to design of a relatively short cable; and after maintenance, the safety is relatively high and is not affected.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

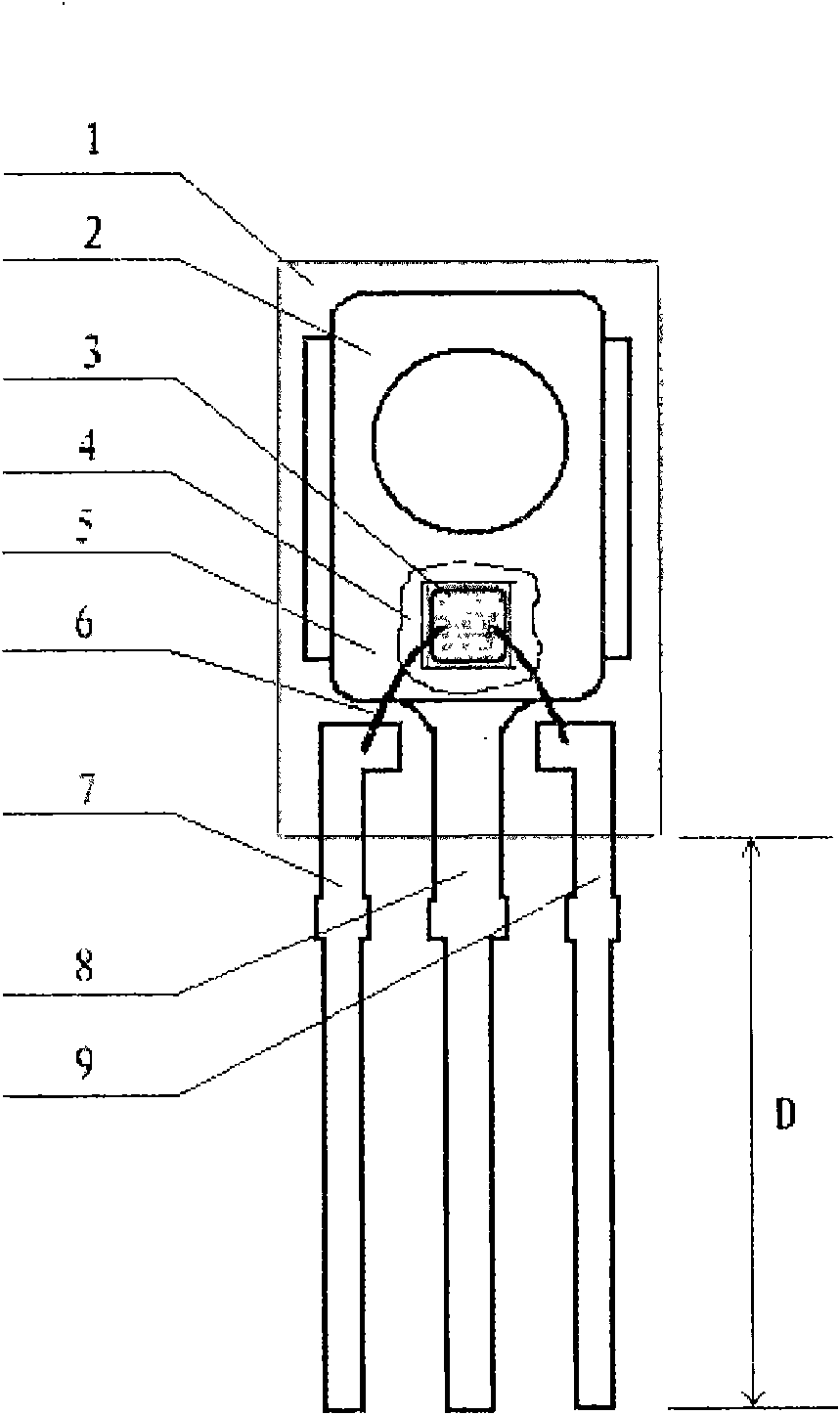

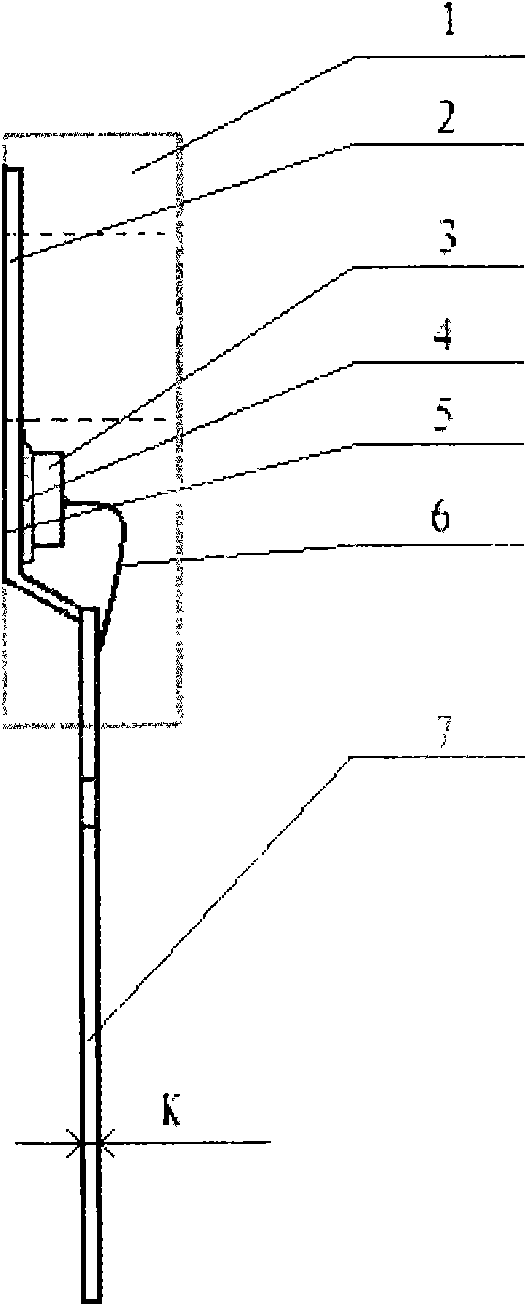

High-power transistor

InactiveCN101661919ASave materialReduce volumeSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical element

The invention discloses a high-power transistor, which comprises a wafer, a lead frame, leads, pins and a plastic sealing body, wherein the upper part of the lead frame automatically generates a radiating fin, while the lower part of the lead frame automatically generates a collector pin; both sides of the collector pin are provided with an emitter pin and a base pin at intervals; the lead frame is thin with the thickness of between 0.38 and 0.42 mm; and the pins are short with the length of between 6 and 7 mm, and are made of KFC copper materials containing iron of 2 to 5 percent. The high-power transistor has the characteristics of small size, raw material saving, low cost, high power, simple processing, reliable work and long service life, and can be widely used as a key electrical element in televisions, audio equipment, electronic instruments and equipment and electronic light source.

Owner:四川大雁微电子有限公司

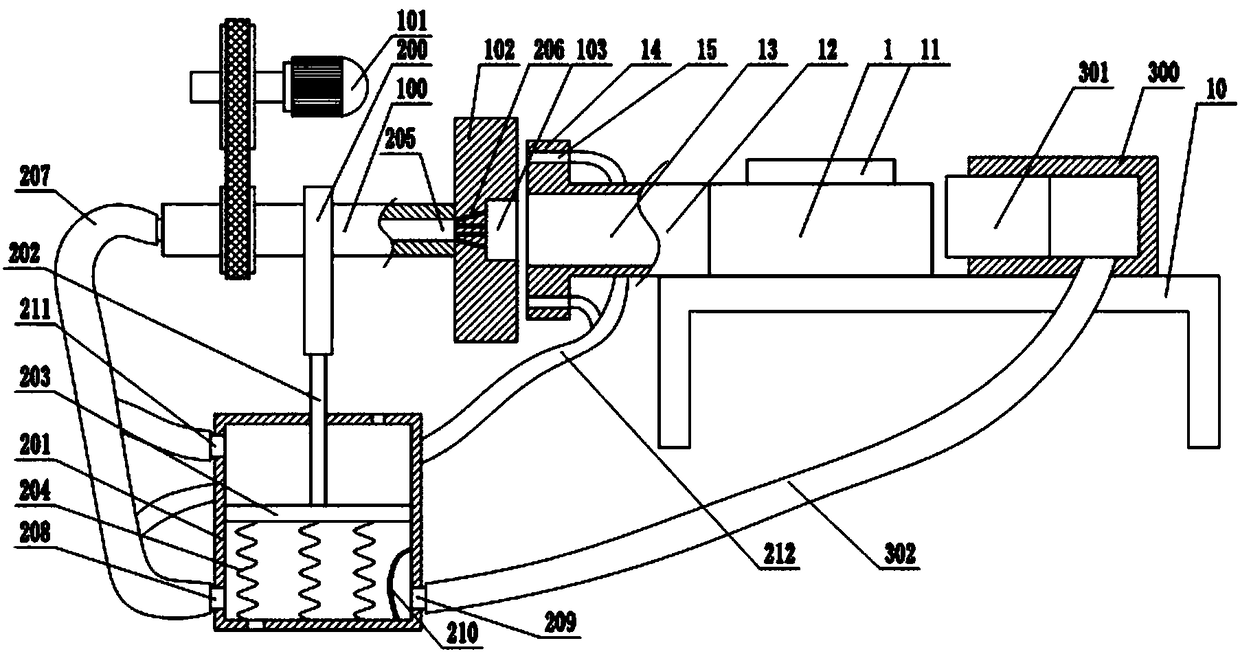

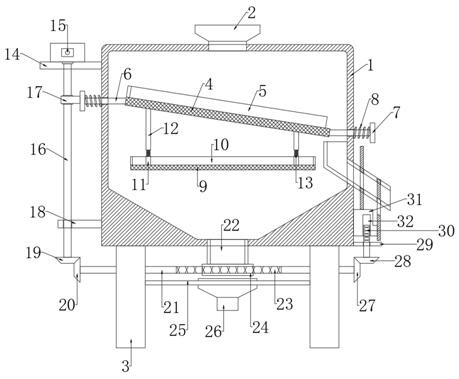

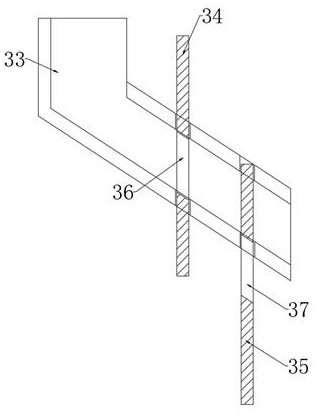

Medicine particle and medicine powder separation and recovery device

ActiveCN112536226AQuantitative dischargeReduce transferSievingGas current separationDrive motorBiomedical engineering

The invention discloses a medicine particle and medicine powder separation and recovery device. The medicine particle and medicine powder separation and recovery device comprises a box body, wherein two supporting plates are fixedly connected to the bottom of the box body, a first screen and a second screen are arranged in the box body, the first screen is located above the second screen, and thefirst screen and the second screen are connected through four connecting mechanisms. and the first screen is obliquely arranged, rectangular rods are fixedly connected to the two ends of the first screen, the two rectangular rods penetrate through the box body and are slidably connected with the box body, fixing blocks are fixedly connected to the opposite ends of the two rectangular rods, and first springs are fixedly connected between the two fixing blocks and the box body. The medicine particle and medicine powder separation and recovery device is reasonable in structure, double screening of medicines can be achieved through one driving motor, besides, screened medicines can be quantitatively discharged, and therefore, workers can directly pack and contain the medicines conveniently, secondary containing is not needed, transferring of the medicines is reduced, and pollution to the medicines can be reduced.

Owner:YANTAI YUHUANGDING HOSPITAL

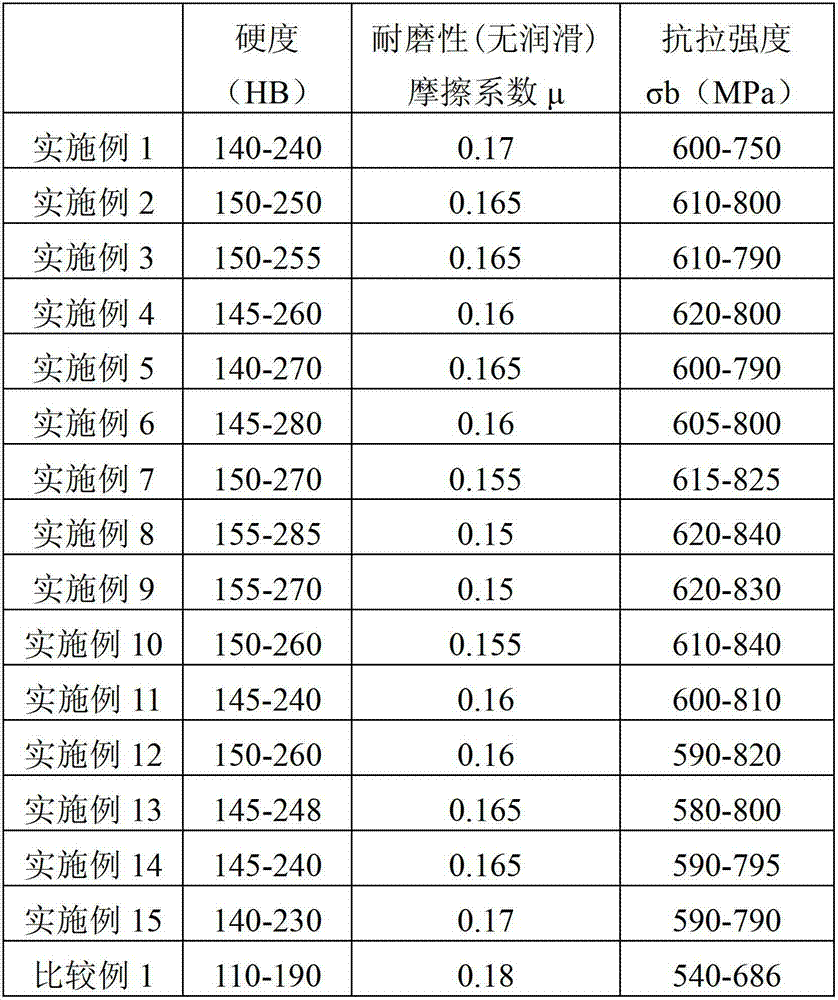

High-strength corrosion-resistant copper-based alloy bar for ocean engineering and preparation method thereof

The invention relates to a high-strength corrosion-resistant copper-based alloy bar for ocean engineering. The alloy bar comprises the following components: aluminum accounting for 13% to 23% of the total weight of the alloy bar, iron accounting for 3% to 17% of the total weight of the alloy bar, tin accounting for 0.5% to 8% of the total weight of the alloy bar, zinc accounting for 1% to 15% of the total weight of the alloy bar and the balance of copper. The invention further relates to a preparation method of the high-strength corrosion-resistant copper-based alloy bar for the ocean engineering. According to the method, proper amount of the tin, the zinc and other elements are added on the basis of the traditional copper-based alloy; and the content of the aluminum is increased properly, thereby enhancing the compressive strength, the corrosion resistance and the like of the alloy. As a result, the performance of a bar material QAL9-4 made of the alloy is enhanced. Relative to the preparation method of the bar material QAL9-4, as the method provided by the invention is used, the only requirement is to squeeze the bar material without being forged, but the obtained mechanical performance is equal to that of the bar material being forged. Therefore, the method provided by the invention has the advantages that the machining processes are reduced; the production efficiency is improved; and the production cost is lowered.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

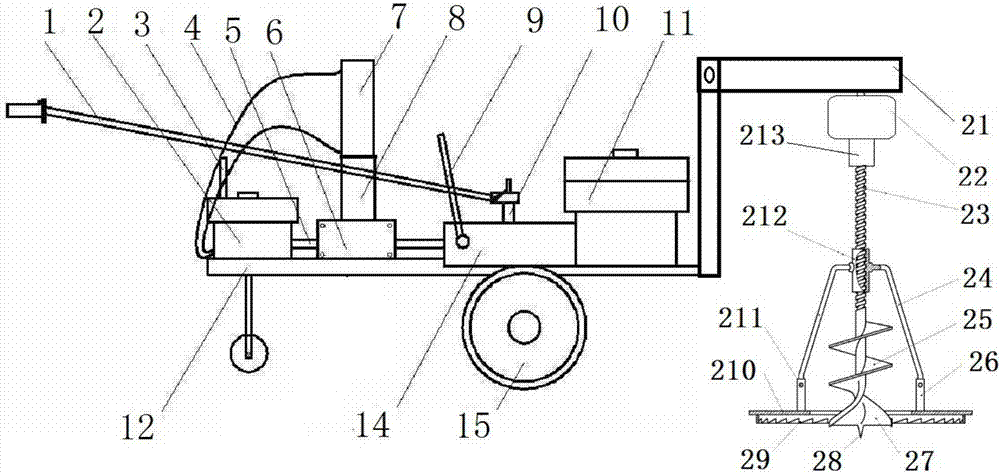

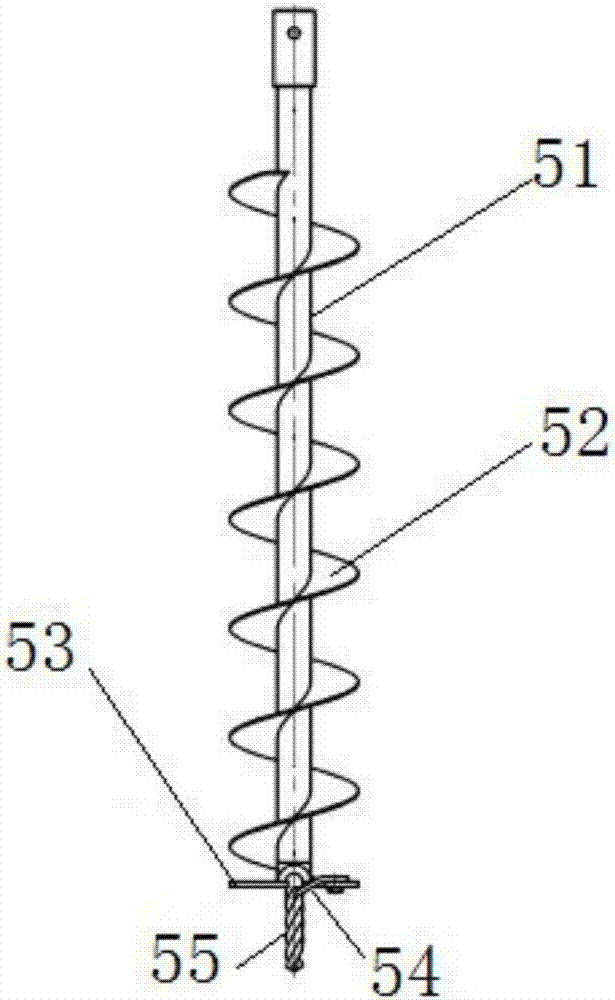

Garden green plant growing facility

InactiveCN107241940AImprove aestheticsReduce processing proceduresPlantingFurrow making/coveringOil pressureEngineering

The invention discloses a garden green plant growing facility which comprises a machine frame, wherein the middle part of the machine frame is provided with a worm-gear-type traveling control transmission case; a lower traveling control is installed below the traveling control transmission case; a vertical hydrocylinder is installed above the traveling control transmission case; the rear side of the traveling control transmission case is provided with an oil pressure unit; the front side of the traveling control transmission case is provided with a movable transmission case; the front side of the movable transmission case is provided with a gasoline engine; the traveling control transmission case and oil pressure unit are connected with the movable transmission case by a drive shaft; and the front end of the machine frame is provided with a hole digging device. The garden green plant growing facility reduces the complicated processing procedure, lowers the working difficulty and manufacturing cost, and improves the aesthetic degree of the hole digger; and when the facility is wound by plants or other things, a ground auger is required for reverse rotation, thereby withdrawing the facility by the reverse rotation through the power transmission of the ground auger.

Owner:上海璞现空间设计有限公司

Asphalt mixture additive and preparation method thereof

ActiveCN104559258APerformance is easy to controlImprove road performanceBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt mixture additive and a preparation method thereof. The asphalt mixture additive comprises the following components in parts by mass: 10-20 parts of a polymer, 5-10 parts of a cross linker, 10-20 parts of padding, 0.5-2 parts of a smog inhibitor, 1-2 parts of a plasticizer, 0.1-1 part of an antioxidant and 50-70 parts of matrix asphalt, wherein the matrix asphalt is one of Shell 70#, Shell 90#, SK70# or SK90#. Compared with the prior art, the asphalt mixture additive has the advantages that the anti-rutting performance and water damage resistance of an asphalt mixture can be significantly improved, the low-temperature cracking resistance and ageing resistance of asphalt concrete can be effectively improved, and the service life of asphalt roads is prolonged; meanwhile, the asphalt mixture additive can substitute about 15-25% of asphalt raw materials in the asphalt mixture, so that the production temperature is reduced to 140 DEG C, then the smoking phenomenon in the production and spreading processes is effectively reduced, and the asphalt mixture additive is energy-saving and environment-friendly; and the production method is simple, low in cost and suitable for industrialized production.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

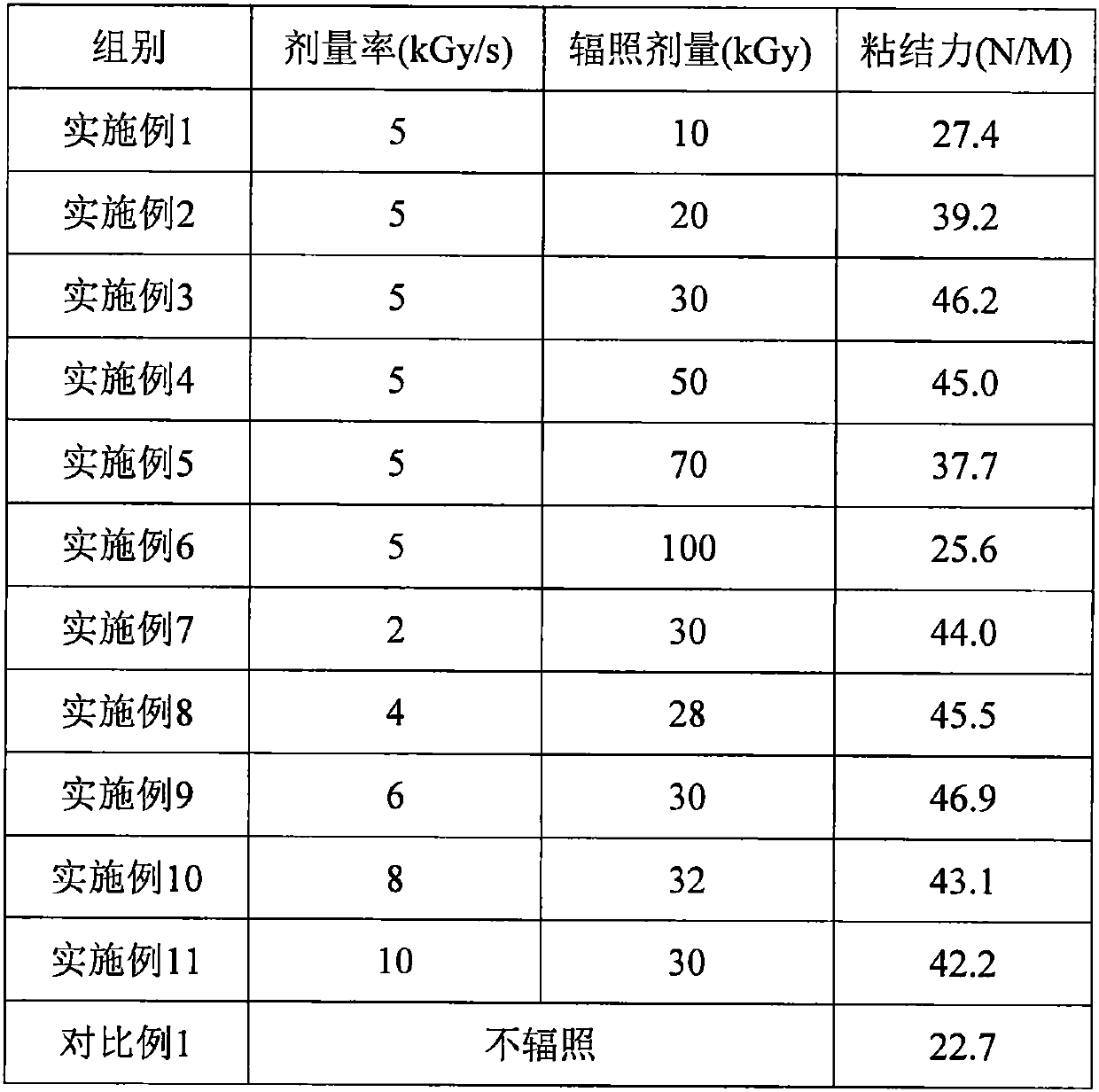

Method for improving electrolytic solution resistance of binder in lithium battery negative electrode sheet by irradiation

InactiveCN111600075AStable thicknessThe circulatory system is beneficialCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The invention discloses a method for improving electrolytic solution resistance of a lithium battery negative electrode binder through irradiation, and belongs to the technical field of lithium batteries. The method comprises the following steps: preparing a lithium battery containing a negative electrode taking sodium carboxymethyl cellulose (CMC-Na) and styrene-butadiene rubber emulsion (SBR) asbinders; and placing the whole battery on an under-beam device of an electron beam irradiation accelerator, and irradiating the whole lithium ion battery, wherein the irradiation dose is 10 to 100 kGy, the irradiation dose rate is 2-10 kGy / s, and in the negative electrode, CMC-Na and SBR can generate intramolecular and intermolecular chemical cross-linking so as to improve the electrolytic solution resistance of the binders CMC-Na and SBR in the negative electrode sheet, reduce the swelling of the binders CMC-Na and SBR in the electrolytic solution, reduce the thickness expansion rate of thenegative electrode sheet in the battery circulation process, improve the capacity retention rate of the battery and prolong the service life of the battery. The process is simple and easy to implement, low in cost and suitable for consumer electronic lithium batteries and power type lithium batteries.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

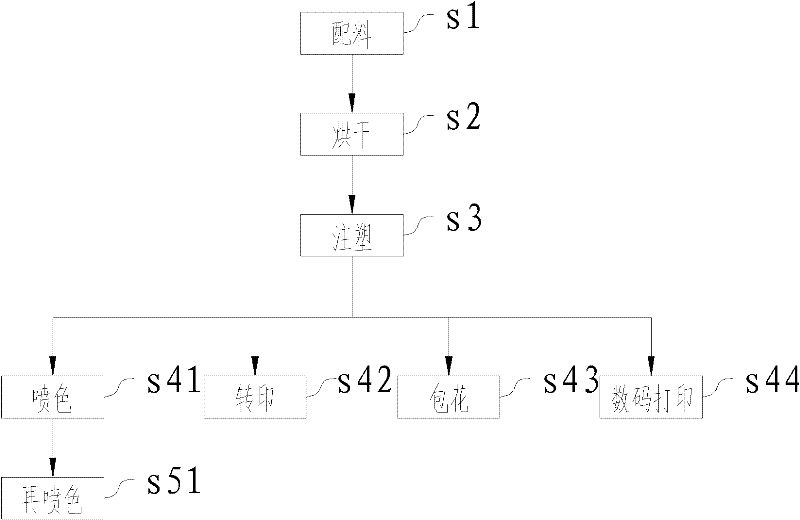

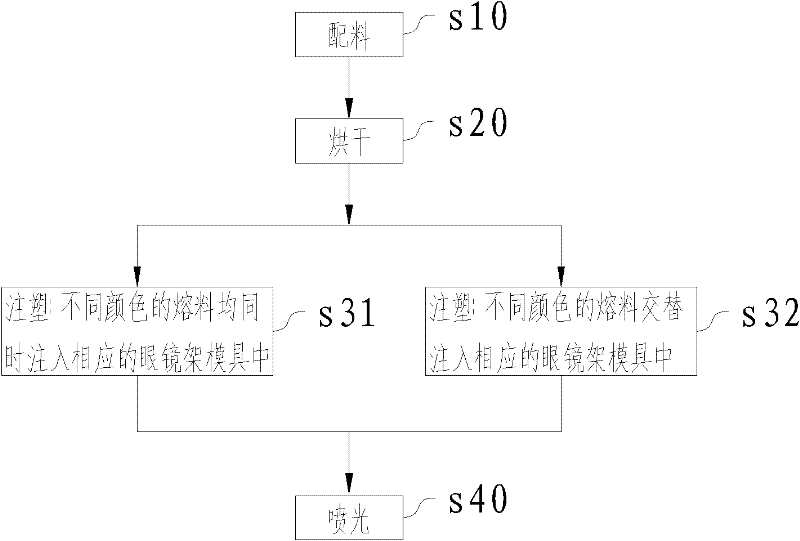

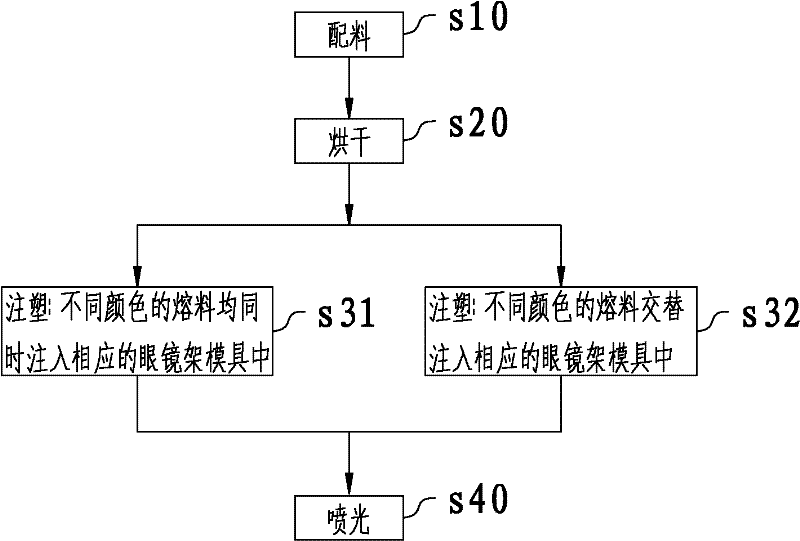

Processing method for spectacle frame

InactiveCN102218799AReduce processing proceduresReduce color sprayFramesDigital printingComputer vision

The invention relates to the processing field of spectacles, in particular to a processing method for a spectacle frame, which comprises the steps as follows: materials and paints with different colors are respectively combined into melt with different colors; the melt with different colors is dried; and the melt with different colors after being dried is injected into a corresponding spectacle frame die for cooling and solidifying. Compared with the steps of the prior art for processing multi-color figure spectacles, the working procedures like color spraying, color respraying or transferring, figure packing and digital printing are omitted in the processing method for spectacle frame; in this way, the processing procedures of the spectacle frame are reduced and the processing process is simpler, thereby improving the processing efficiency.

Owner:瑞安东大眼镜有限公司

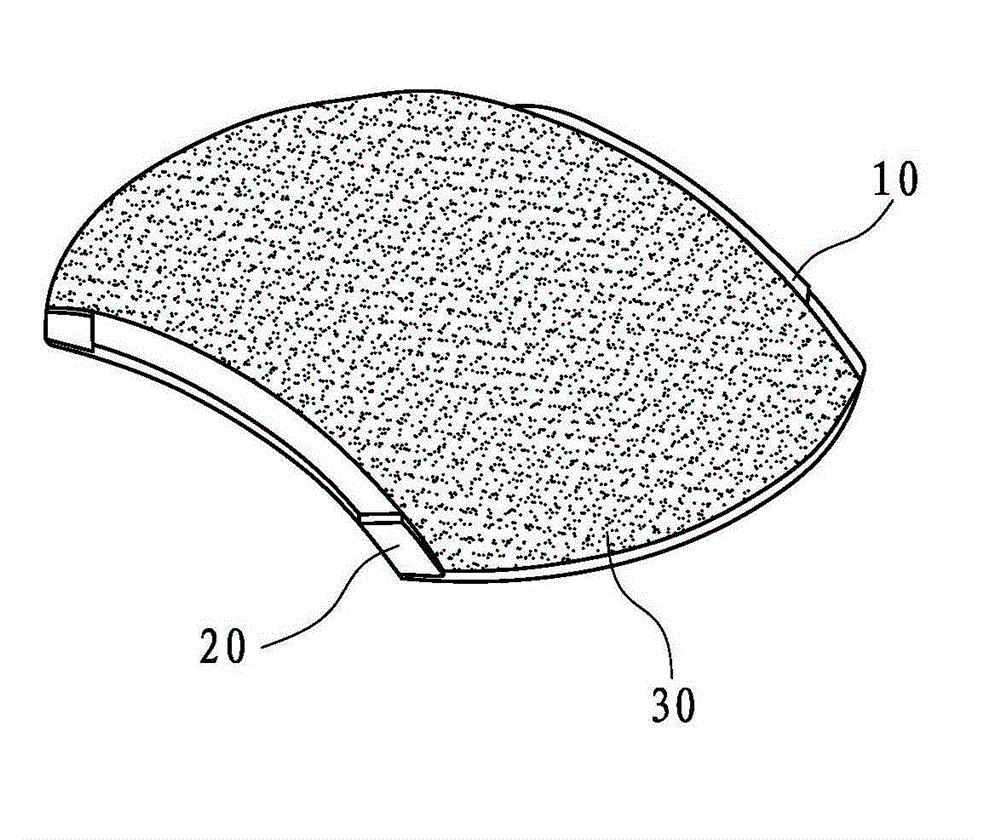

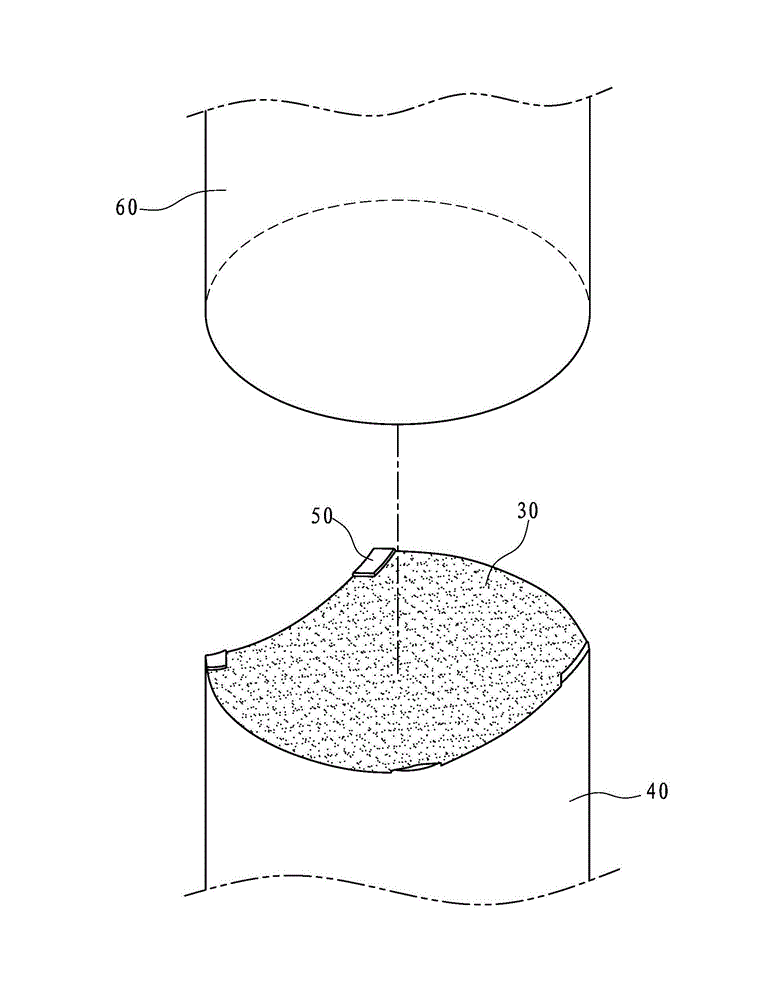

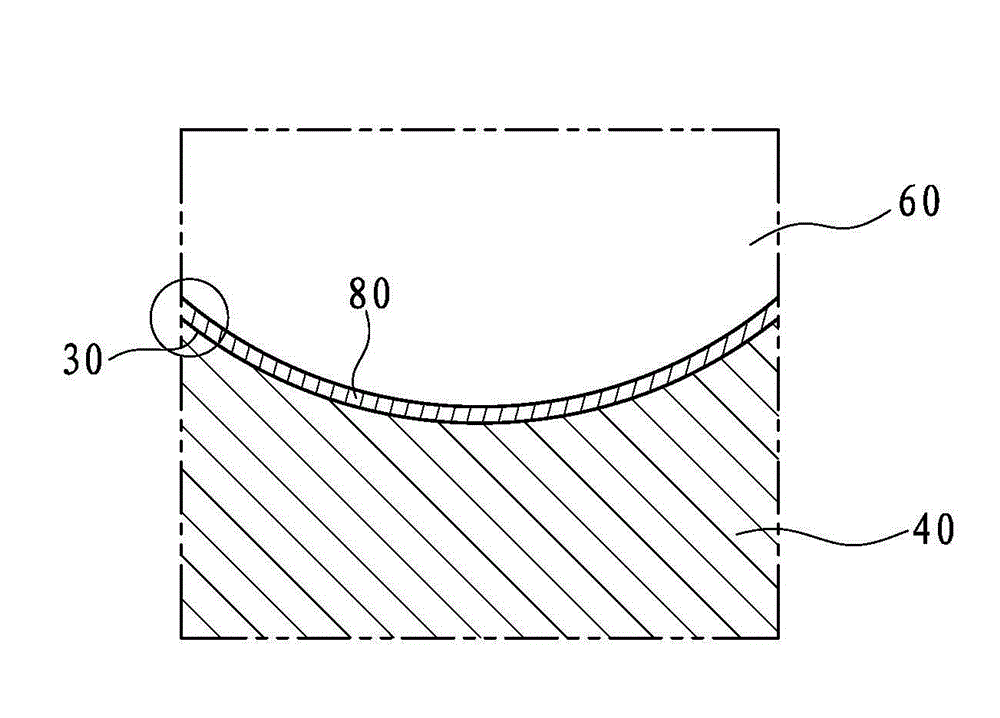

Nylon polarized lens and forming mold thereof

InactiveCN102749724AIncrease profitAvoid glue flushingOptical articlesOptical partsOptoelectronicsMaterials science

The utility model discloses a nylon polarized lens which comprises a nylon material layer and a polarized film, wherein a positioning part for positioning the polarized film is formed at each of the four corners of the nylon material layer, and buffering grooves are arranged at the end surface of two opposite edges of the nylon material layer. A forming mold for preparing the nylon polarized lens comprises an upper mold and a lower mold. The top end face of the lower mold is an arch concave face, and a buffering rib for molding a lens buffering slot and a positioning part for positioning the polarized film are formed on the top end face of the lower mold; and the bottom end face of the upper mold is an arch convex face, and the upper mold approaches the lower mold to form a mold chamber for molding the lens. The nylon polarized lens and the forming mold are suitable for manufacturing a polarized lens which has a thin mode and expensive materials, and improve the yield and the product quality.

Owner:XIAMEN HONGTAI ELECTRONICS OPTICAL C O

Printed circuit board and method of manufacturing the same

InactiveUS20130112471A1Low costReduce processing proceduresRadiation applicationsPretreated surfacesPrinting inkEngineering

Disclosed herein is a printed circuit board and a method of manufacturing the same. The printed circuit board includes preparing a base substrate; forming a pattern layer for forming via holes on the base substrate by printing ink for forming via holes; forming an insulating layer on the base substrate including the pattern layer for forming via holes; and removing the pattern layer for forming via holes.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Vacuum freeze-drying processing method of fresh ginsengs

InactiveCN108634157AExtended shelf lifeGuaranteed freshnessFood preservationFreeze-dryingAdditive ingredient

The present invention discloses a vacuum freeze-drying processing method of fresh ginsengs. The vacuum freeze-drying processing method comprises steps of material selecting, deep washing and screening, instant high temperature sterilizing, pre-freezing, one-step vacuum freeze drying, moisture preventing and packaging. The processed fresh ginsengs are subjected to the instant high temperature sterilizing and one-step vacuum freeze drying to maximally retain nutrients of ginsenosides, polysaccharides, flavonoids, vitamins, etc., and to enable many easily volatile and heat-sensitive natural ingredients originally unique to the fresh ginsengs to both be very well preserved. Besides, the shapes of the original fresh ginsengs are preserved; the ginsengs are unique in smell and fresh in color, and have characteristics of being clean and sterile, eaten directly, and crisp in mouthfeel; and the whole processing method optimizes technological processes, shortens processing processes, effectivelyimproves processing efficiency, reduces production costs, and effectively extends the shelf life of the fresh ginsengs.

Owner:广东天葆堂健康科技产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com