Method for preparing large-size complex silicon nitride ceramic

A silicon nitride ceramic, complex shape technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problem that direct writing technology cannot prepare large-sized silicon nitride ceramic materials, etc., to save raw materials, The effect of reducing production cycle and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

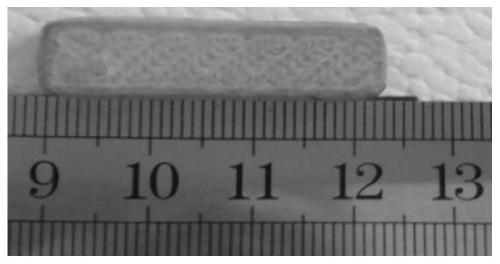

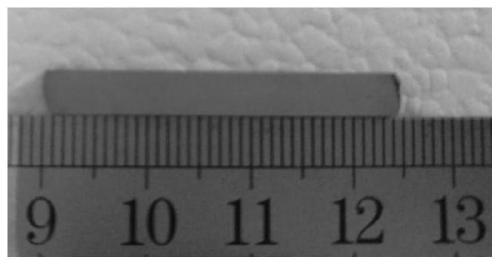

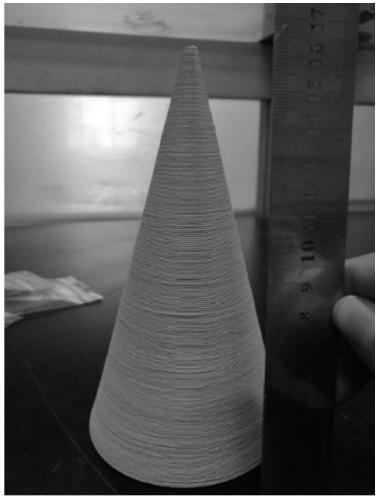

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode 1: In this implementation mode, a method for preparing silicon nitride ceramics with large size and complex shape is carried out according to the following steps:

[0028] 1. Weighing:

[0029] Weigh 30-55 parts of silicon nitride powder, 0.2-5 parts of ammonium polyacrylate, 0.2-5 parts of polyethylene glycol, 3-10 parts of nano-alumina, 3-10 parts Nano yttrium oxide and 45-70 parts of deionized water;

[0030] 2. Mixing:

[0031] Mix 30 to 55 parts of silicon nitride powder, 3 to 10 parts of nano-alumina and 3 to 10 parts of nano-yttrium oxide to obtain the primary mixed raw material, and use absolute ethanol as the ball milling medium for the initial mixing The raw materials are ball-milled for 12h-48h, dried and sieved to obtain the ball-milled raw materials. The ball-milled raw materials are mixed with 45-70 parts of deionized water, 0.2-5 parts of ammonium polyacrylate and 0.2-5 parts of polyethylene glycol Alcohol mixed, and using ...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle size of the silicon nitride powder described in step 1 is 0.5 μm˜20 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the silicon nitride powder in Step 1 is 0.5 μm˜5 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com