Ratchet wrench with jamming-preventing and indicating functions

A ratchet wrench and anti-jamming technology, which is applied in the field of ratchet wrenches, can solve the problems of inability to know the wrench turning direction, wrong turning direction, and increasing processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

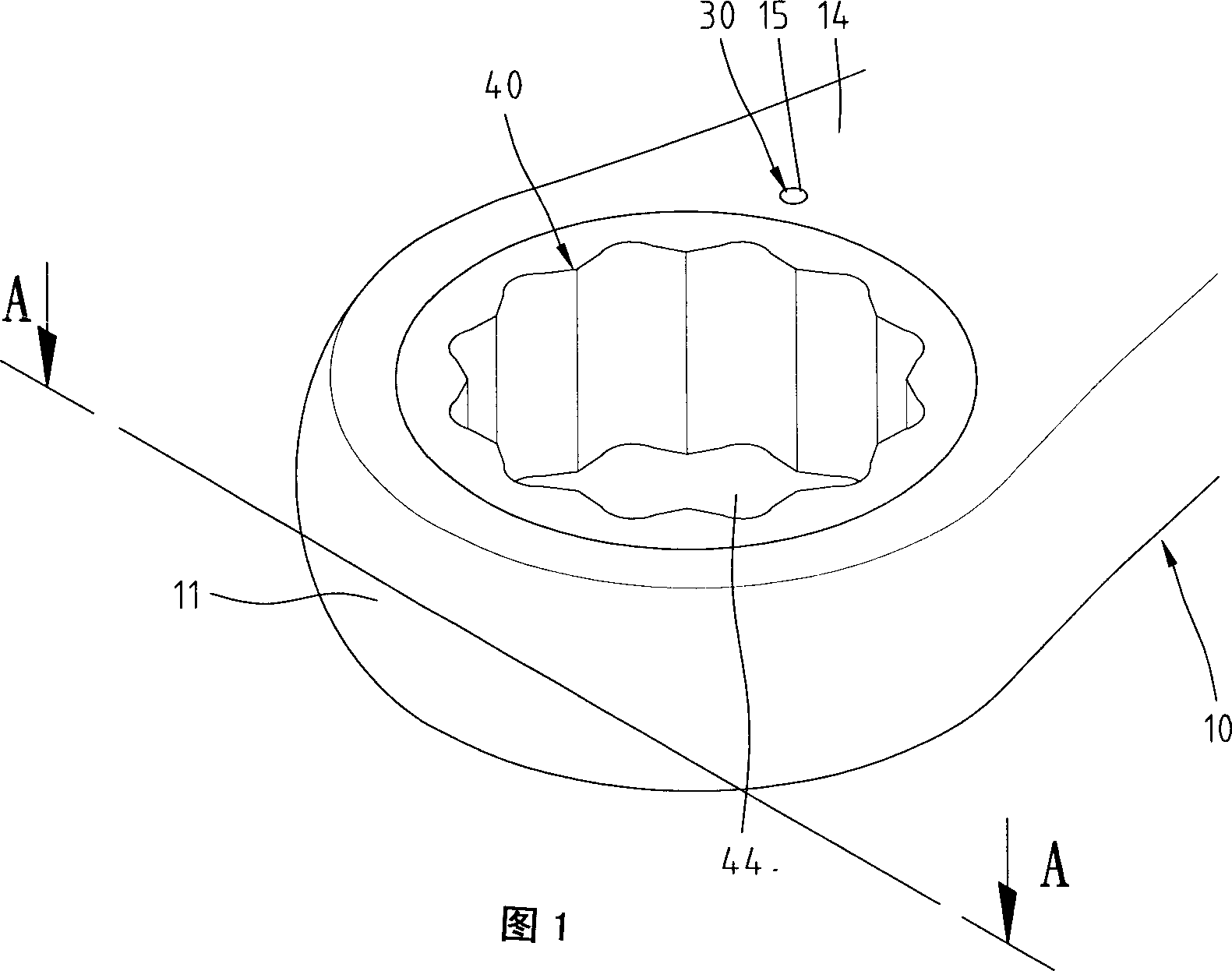

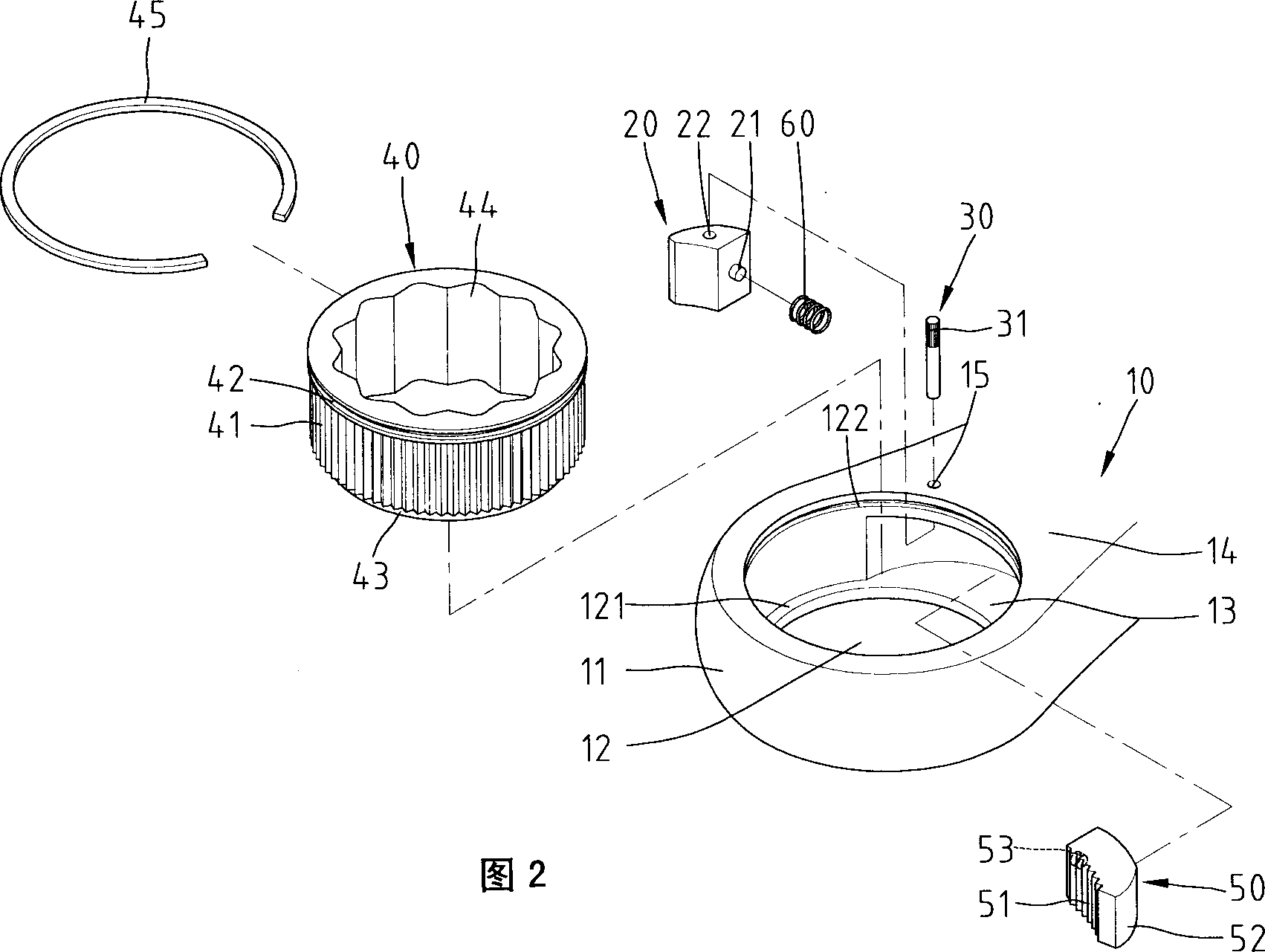

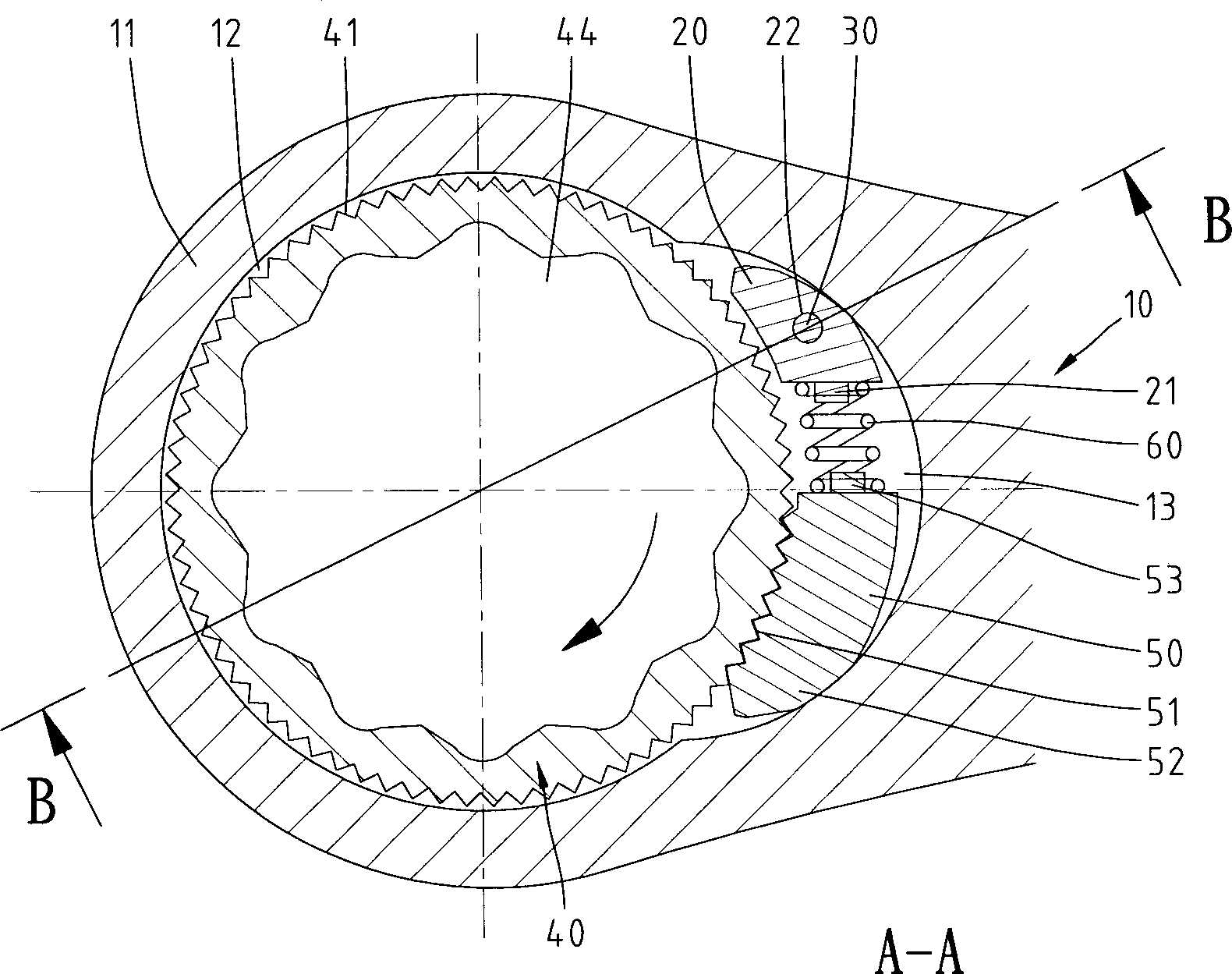

[0050] Please refer to Figure 1 to Figure 9 , the wrench shown in the figure is the structure of the selected embodiment of the present invention, which is for illustration only, and the protection scope of the application is not limited by this structure.

[0051] Please refer to the wrench shown in Figure 2, a ratchet wrench with anti-jamming and marking of the present invention, which includes:

[0052] A wrench body 10, the head 11 at one end of the wrench body 10 is provided with a cylindrical hollow accommodating space 12, one end of the inner wall of the accommodating space 12 is provided with a protruding ring 121, and the other end of the inner wall is ringed A concave ring groove 122 is provided, and a half-moon-shaped accommodating groove 13 is provided at the throat of the wrench body 10. The accommodating groove 13 communicates with the accommodating space 12 and is located in the radial area of one edge of the wrench body 10. 14 is longitudinally provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com