Five-axis additive manufacturing and subtractive manufacturing compound machining device

A technology of composite processing, adding and subtracting materials, applied in the direction of additive processing, coating devices, metal processing equipment, etc., can solve the problems of high material requirements, additive manufacturing is not suitable for mass production, and cannot be replaced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

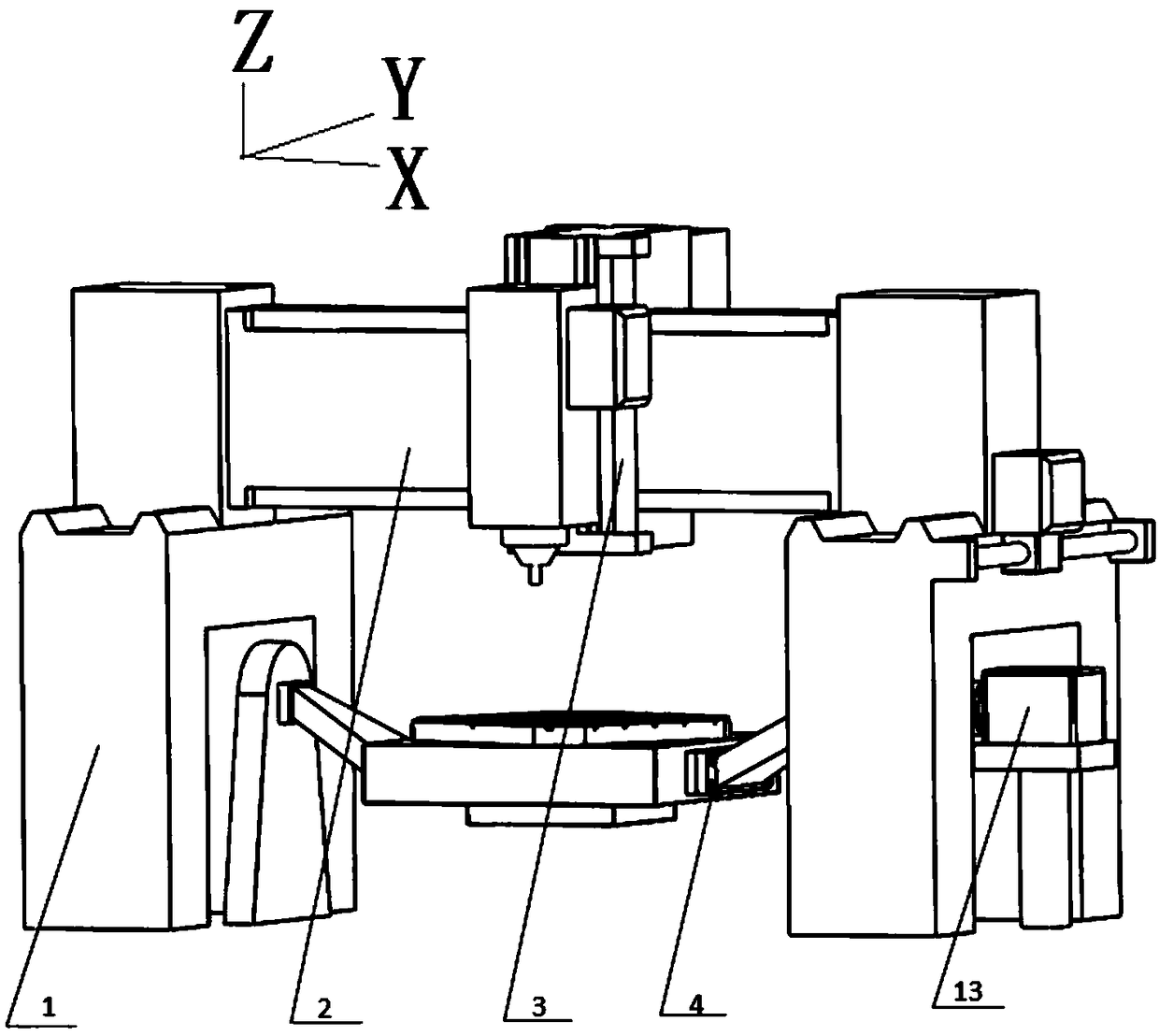

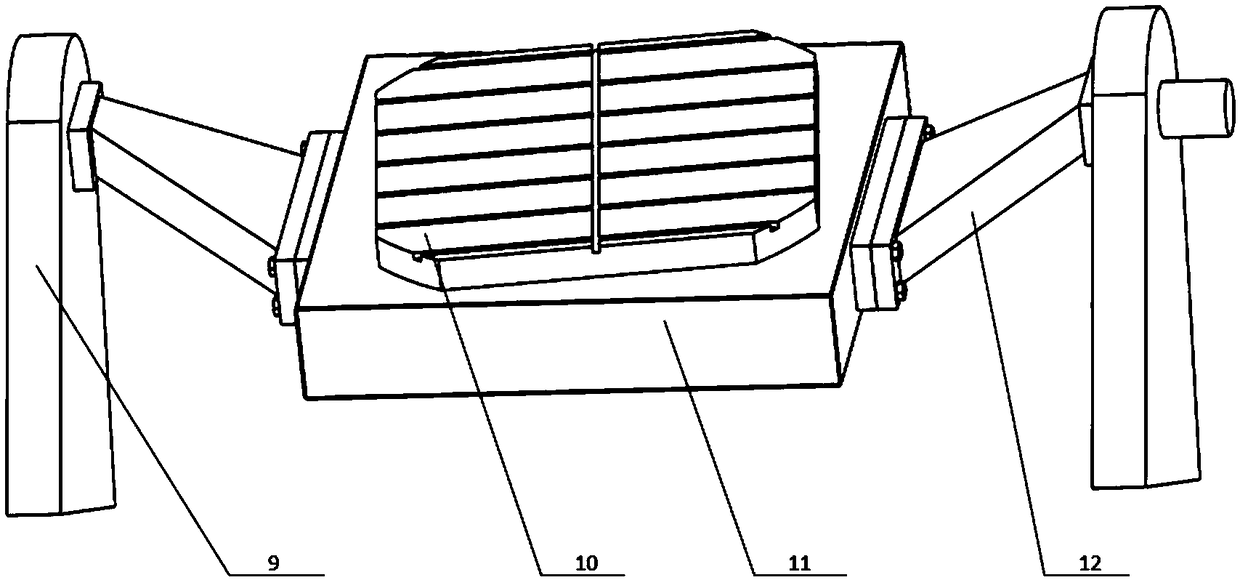

[0026] The five-axis compound processing device for adding and subtracting materials implemented according to the present invention mainly includes a support beam 1 , a beam 2 , a double Z-axis adding and subtracting material module 3 , and a cradle-type workpiece tray 4 .

[0027] The two ends of the beam 2 are erected on the support beam 1 on both sides respectively. The support beam 1 on both sides is fixed on the frame and provides support for the beam 2. The top surface of the support beam 1 is a guide rail, and the beam 2 is driven by a ball screw. On the supporting beam 1, linear feeding in the Y direction is carried out along the guide rail on the top surface of the supporting beam 1 .

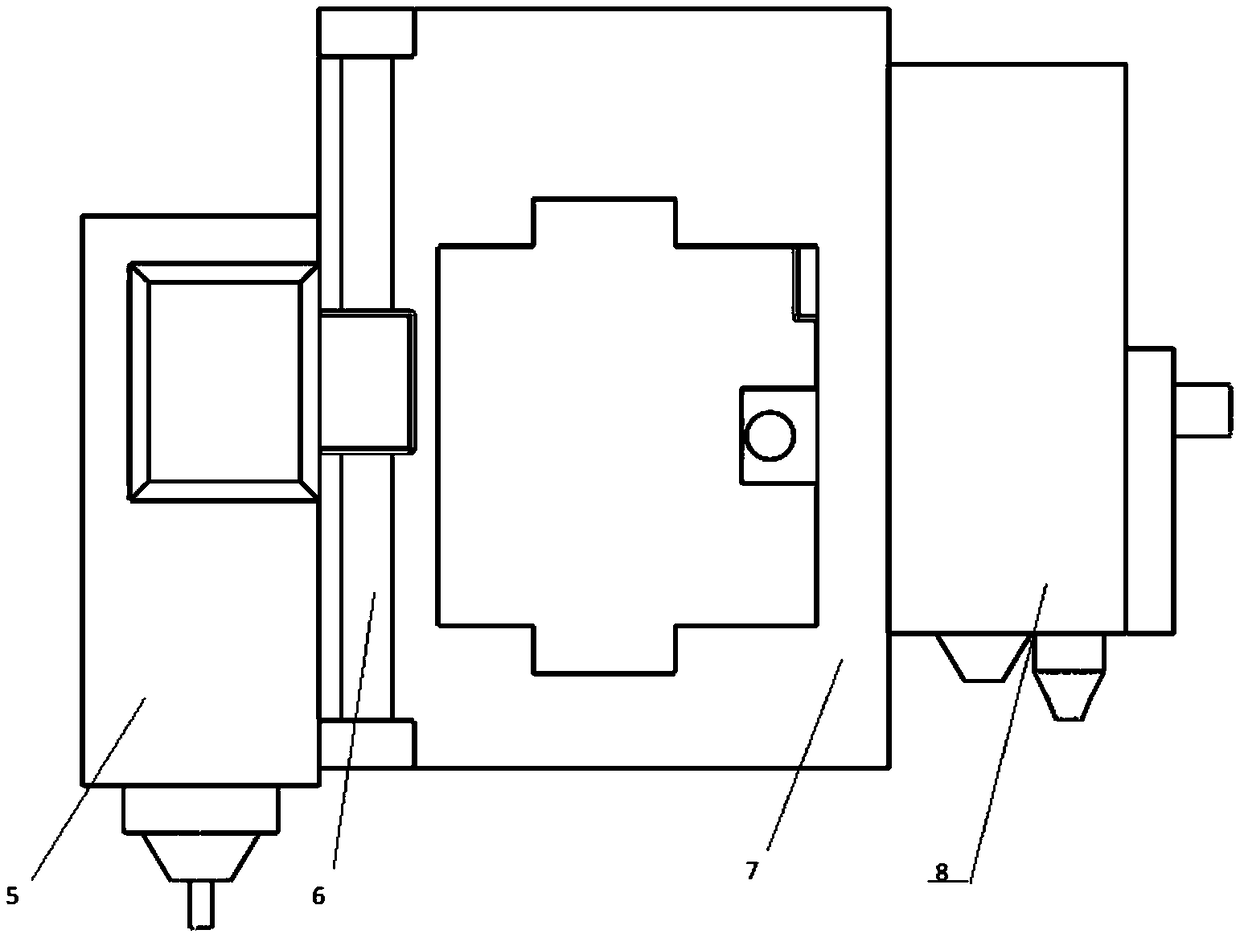

[0028] A guide rail is set on the beam 2 along the horizontal X-axis (the X-axis and the Y-axis are perpendicular to each other and on the same plane, and both are perpendicular to the Z-axis). The material reduction module 3 can perform linear feeding in the X-axis direction along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com