Method for manufacturing paper-plastic composite bag with window

A production method and paper-plastic composite technology, which are used in box making operations, rigid/semi-rigid container manufacturing, papermaking, etc., can solve problems such as difficulty in control, increased machine cost, and discontinuity in the processing process, and save the process of slicing. , The effect of reducing processing procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The production process of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] refer to Figure 5 Shown, the manufacture method of a kind of paper-plastic composite window bag provided by the present invention comprises the following steps:

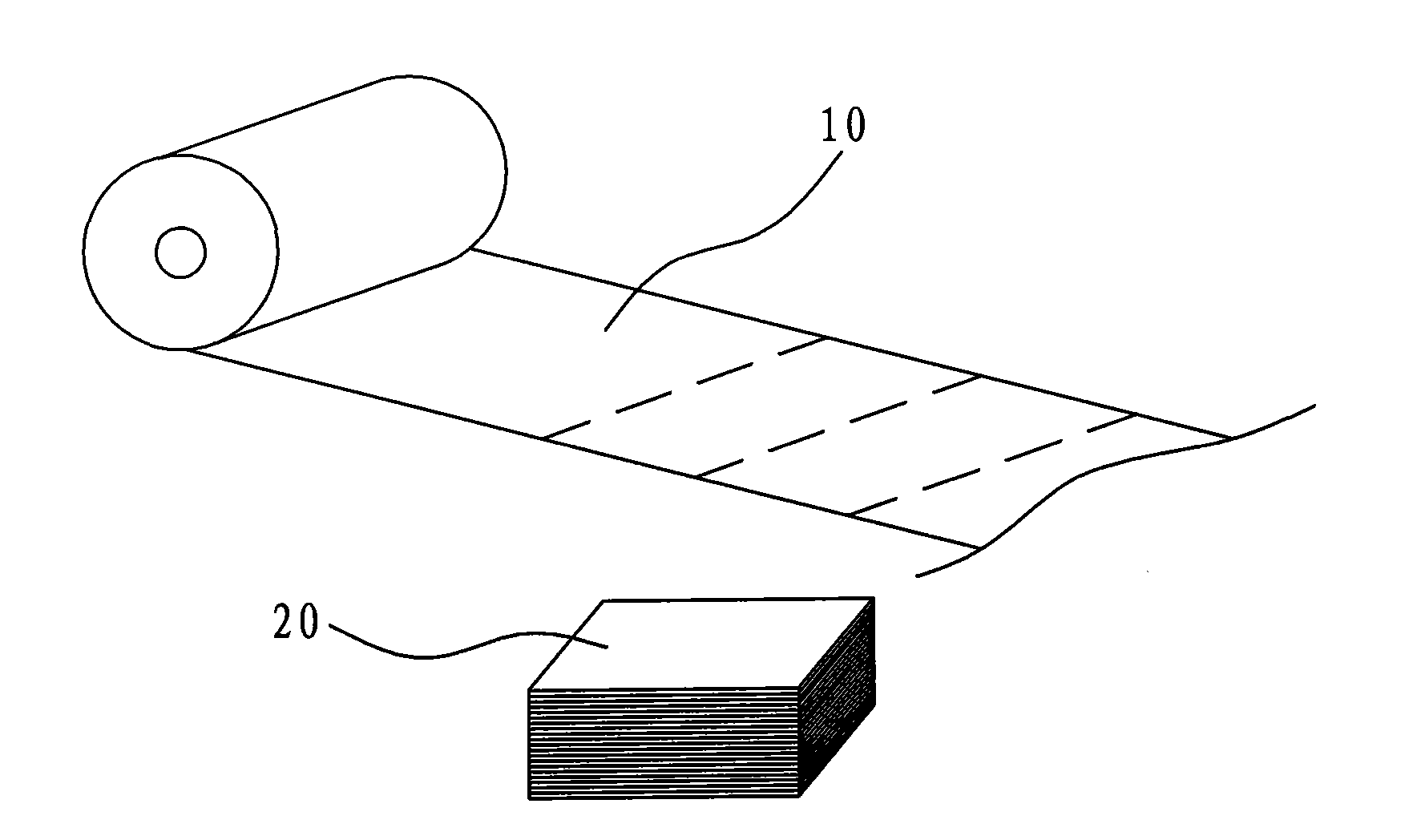

[0036] (1) material preparation: prepare the required paper 1 and transparent plastic film 2, wherein the plastic film adopts degradable film materials, such as PE (polyethylene), PP (polypropylene), etc.;

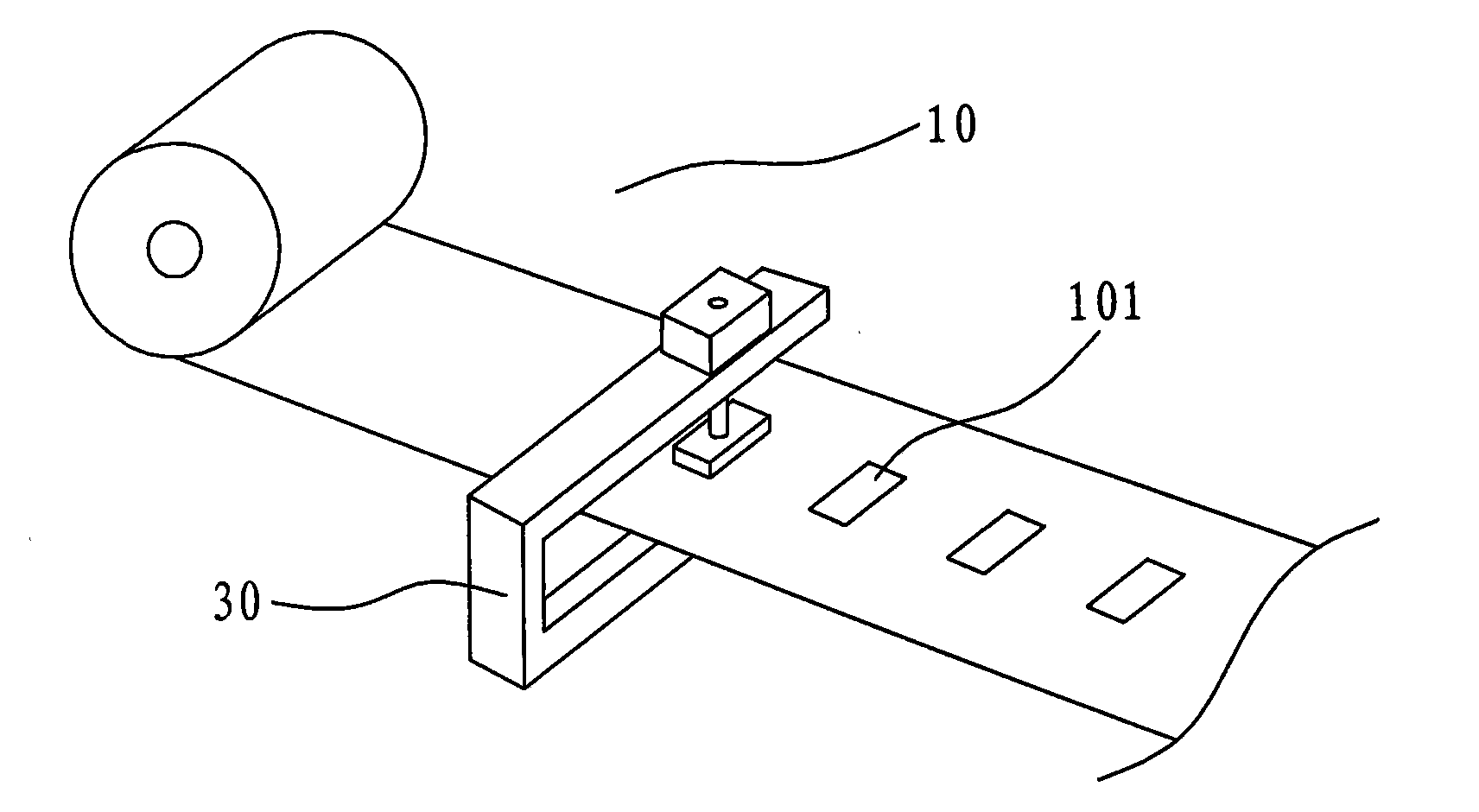

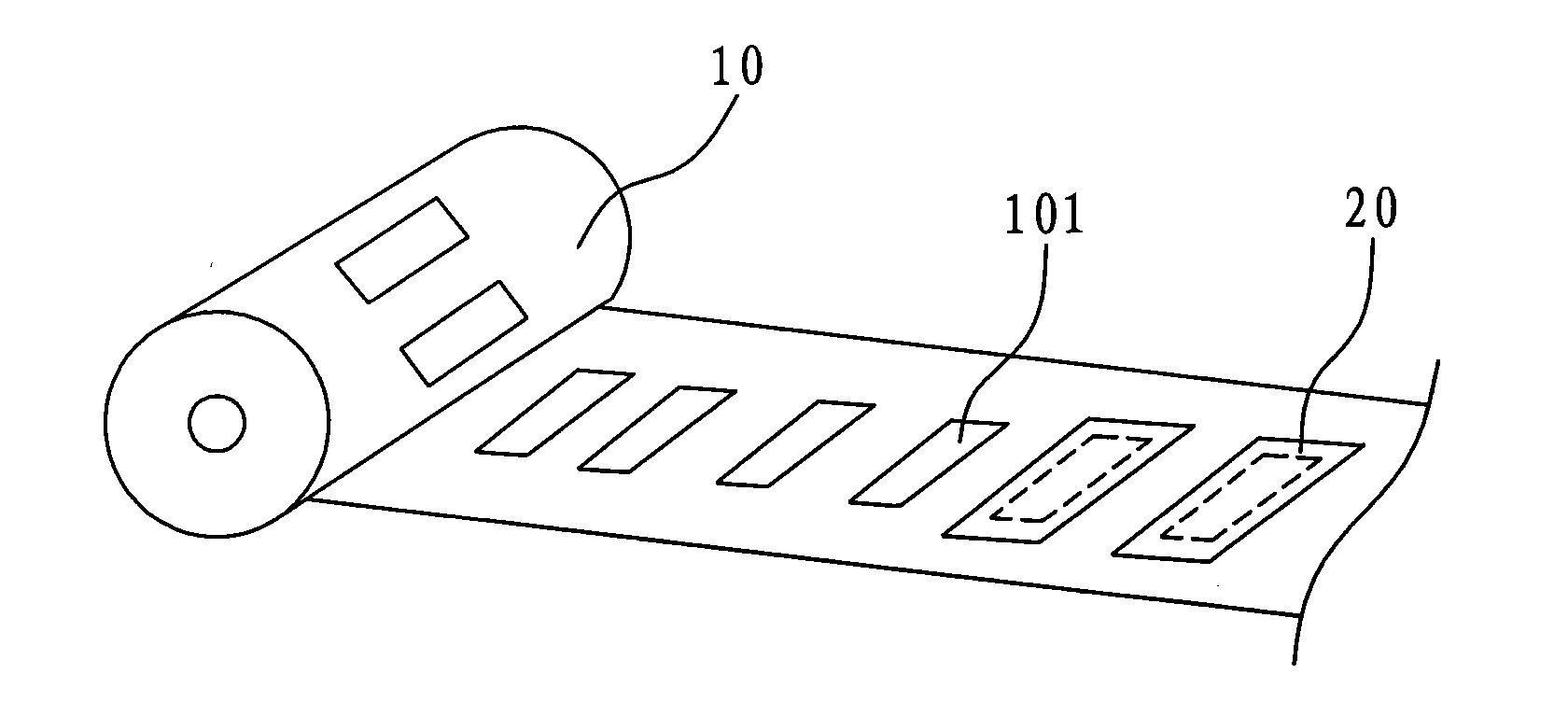

[0037] (2) Cut the paper 1 longitudinally at the desired position to form a window 11 of a predetermined width on a general-purpose cutting device, and then wait to enter the laminator 5. For details, please refer to Image 6 As shown, when the paper 1 passes through the cutting device, the distance between the two cutters 3 is adjusted to the width required by the window 11, so that when the rolled paper 1 passes through the cutting device, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com