Method for manufacturing mobile phone camera fixing device

A mobile phone camera, fixing device technology, applied in branch equipment, telephone structure, telephone communication and other directions, can solve the problems of loss of camera protection, mobile phone camera frame falling off, mobile phone fixing trouble, etc., to achieve obvious reinforcement effect, good fixing effect, The effect of reducing weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

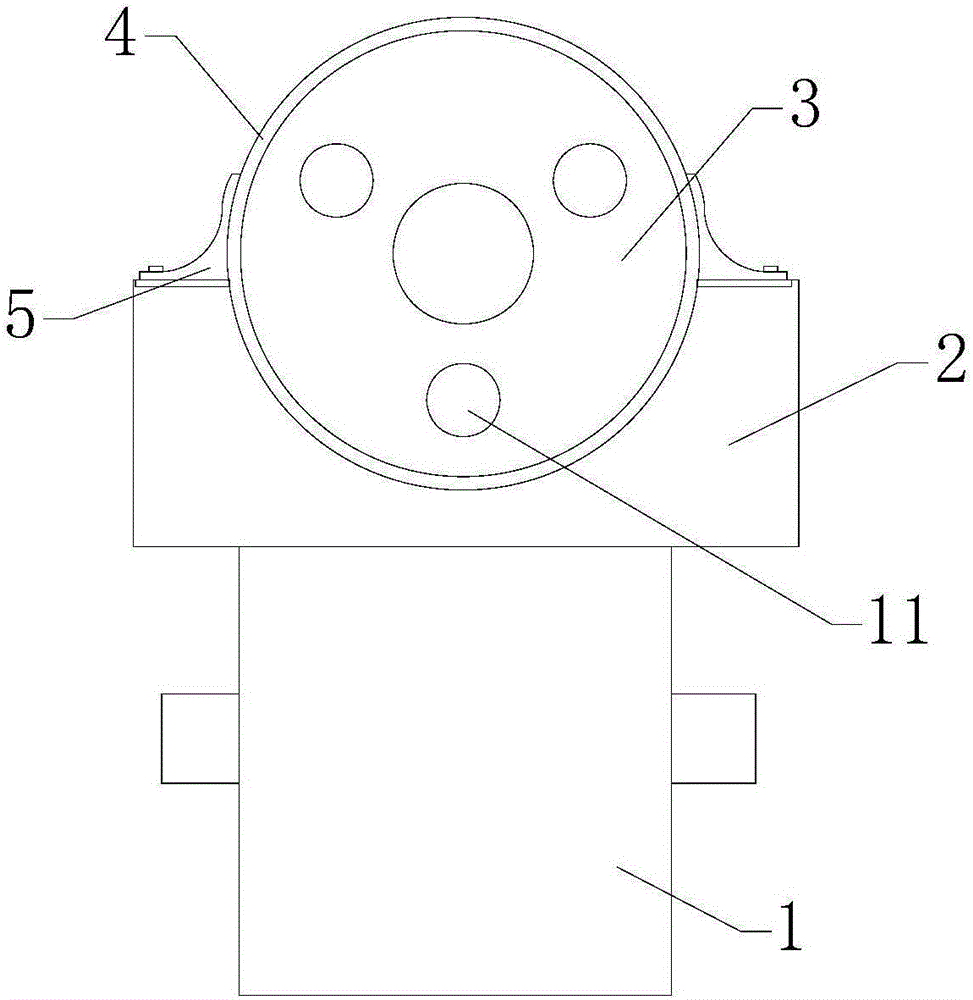

[0023] Such as figure 1 Shown, a kind of preparation method of mobile phone camera fixing device comprises substrate 1, fixing base 2 and mounting base 4, described base plate 1 top is provided with fixing base 2, described fixing base 2 is provided with mounting base 4, The mounting seat 4 is provided with an inner cavity 3, and a bottom plate 6 is arranged behind the inner cavity 3, and the bottom plate 6 is installed on the fixing seat 2;

[0024] The inner cavity 3 is provided with a suction cup 11, and the suction cup 11 is installed on the inner wall of the bottom plate 6. The edge of the mounting seat 4 is provided with a rubber edge, and the inner diameter of the rubber edge is smaller than the inner diameter of the mounting seat 4. , the outer diameter of the rubber edge is equal to the outer diameter of the mounting seat 4.

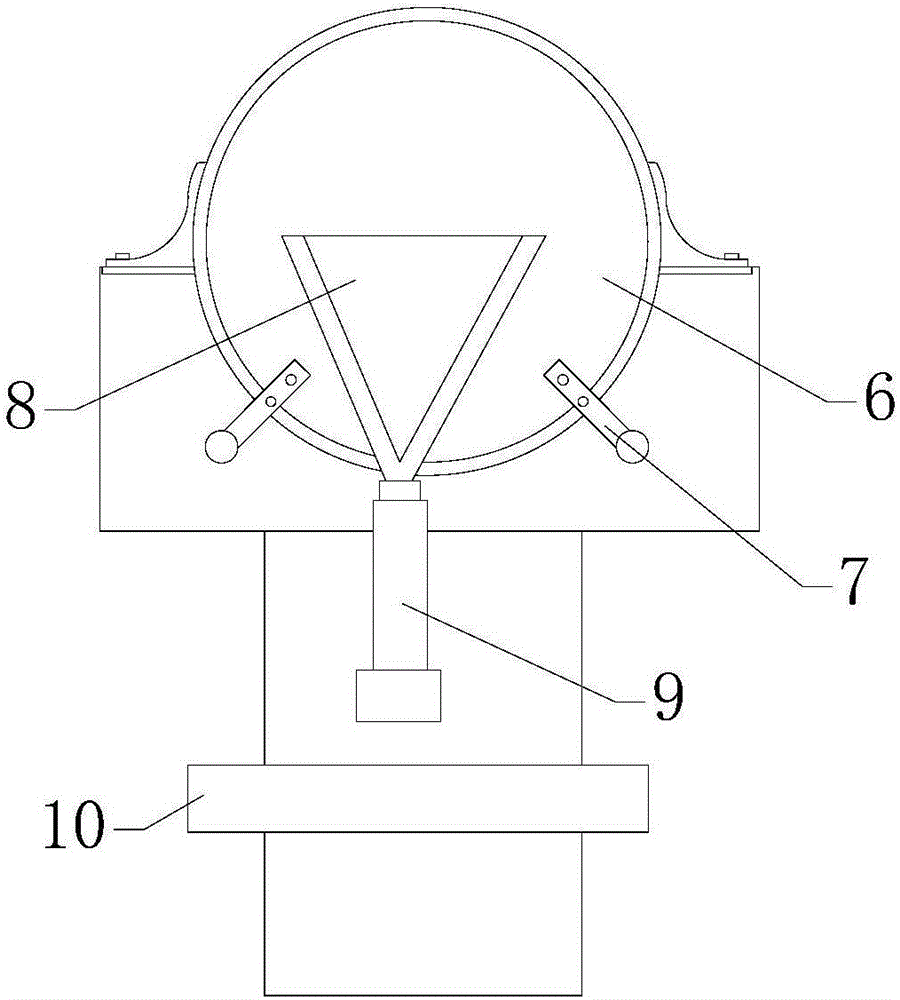

[0025] The outer wall of the bottom plate 6 is provided with a connecting clip 7, and the connecting clip 7 is fixed on the mounting seat 4 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com