Equipment for fixing bars when being cut by saws

A fixed rod and sawing technology, which is applied in the field of mechanical processing, can solve the problems of potential safety hazards and affecting processing efficiency, and achieve the effects of improving clamping stability, safety, and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

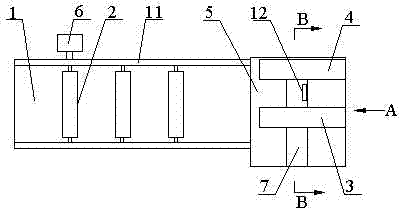

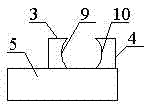

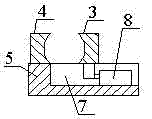

[0030] Such as Figure 1~Figure 3 As shown, the equipment used to fix the bar during sawing includes a workbench 1, a rotating shaft 2, a movable clamping block 3, a fixed clamping block 4, a clamping table 5 and a motor 6, and a plurality of rotating shafts 2 are rotated and arranged on On the workbench 1, the output end of the motor 6 is connected to the rotating shaft 2, the clamping platform 5 is arranged on the front end of the workbench 1, a chute 7 is opened on the clamping platform 5, and the fixed clamping block 4 is fixed on the side of the clamping platform 5. On one side, the movable clamping block 3 is arranged opposite to the fixed clamping block 4, and the bottom of the movable clamping block 3 is slidingly arranged in the chute 7; it also includes a hydraulic cylinder 8 fixed in the chute 7, and the expansion and contraction of the hydraulic cylinder 8 End is connected with the bottom of movable clamping block 3.

[0031] When working, the motor 6 drives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com