Automobile ABS magnetoelectric wheel speed sensor

A wheel speed sensor and magnetoelectric technology, applied in the field of auto parts, can solve the problems of low stability of the adjustment height of the leather connecting cloth, damage to the magnetic poles, magnets and coils, mud pollution, etc., to achieve good fixing effect and prevent normal The effect of signal transmission, reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

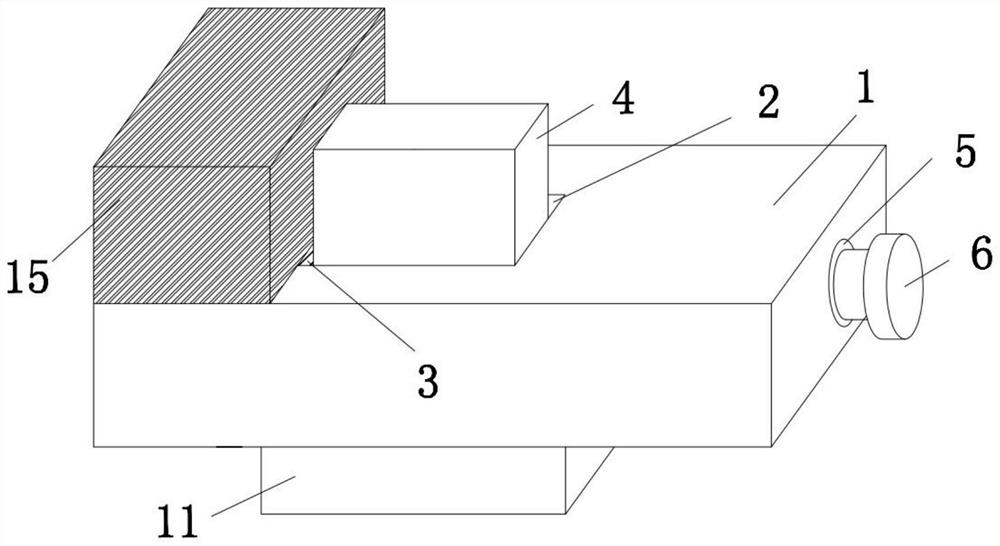

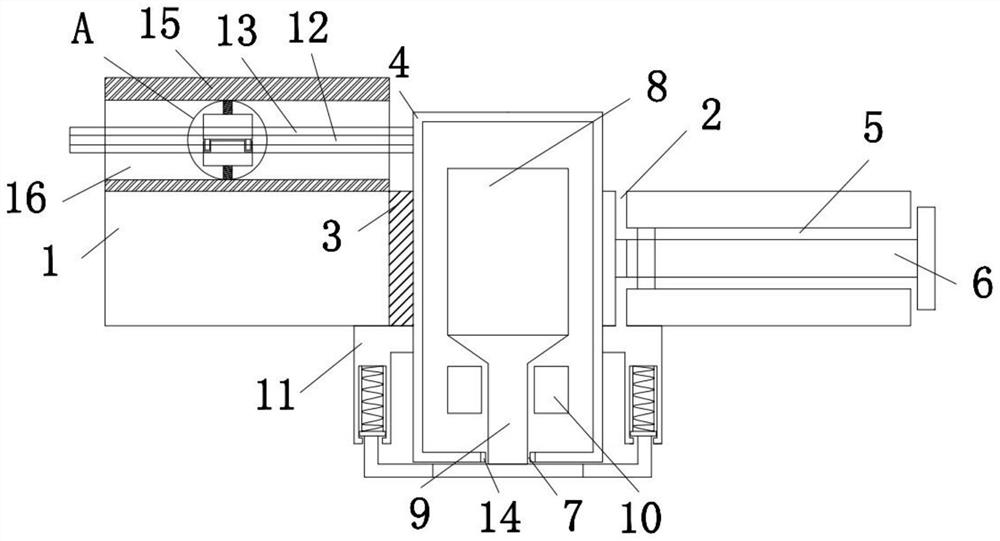

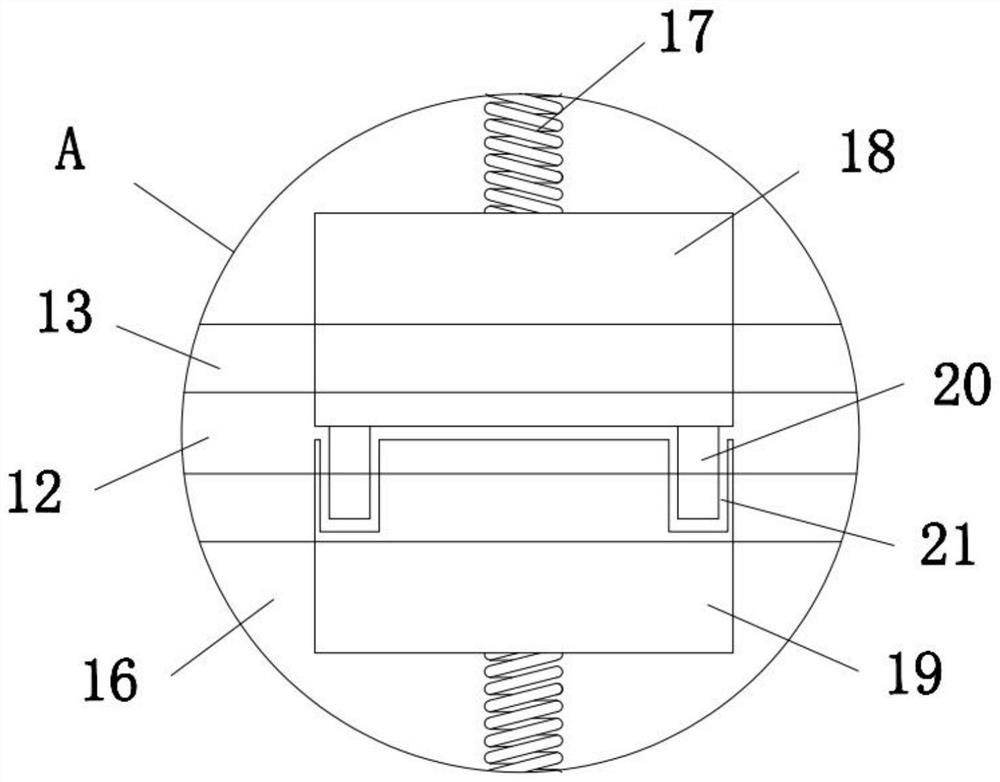

[0039] see Figure 1-Figure 3 , an automobile ABS magnetoelectric wheel speed sensor, comprising a fixed plate 1, the top of the fixed plate 1 is provided with a first through hole 2, the left inner wall of the first through hole 2 is fixedly connected with a first rubber pad 3, the first A sensor body 4 is placed inside the through hole 2, and a threaded hole 5 is provided on the right side of the fixed plate 1. The first through hole 2 communicates with the threaded hole 5, and the internal thread of the threaded hole 5 is connected to the limit assembly 6, which The left side of 6 is attached to the sensor body 4, and the bottom of the sensor body 4 is provided with a second through hole 7. The inside of the sensor body 4 is provided with a magnet 8, and the bottom of the magnet 8 is provided with a magnetic pole 9. The bottom of the magnetic pole 9 is located at Inside the second through hole 7, the outside of the magnetic pole 9 is provided with an induction coil 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com