Compression-resisting sealing flange

A technology for sealing flanges and flanges. It is used in flange connections, pipe/pipe joints/pipe fittings, through components, etc. It can solve the problem of low bonding between flanges and flanges and easy extrusion of gaskets. Compression piece, poor pre-tightening effect, etc., to achieve the effect of good fixing effect, lower operating cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

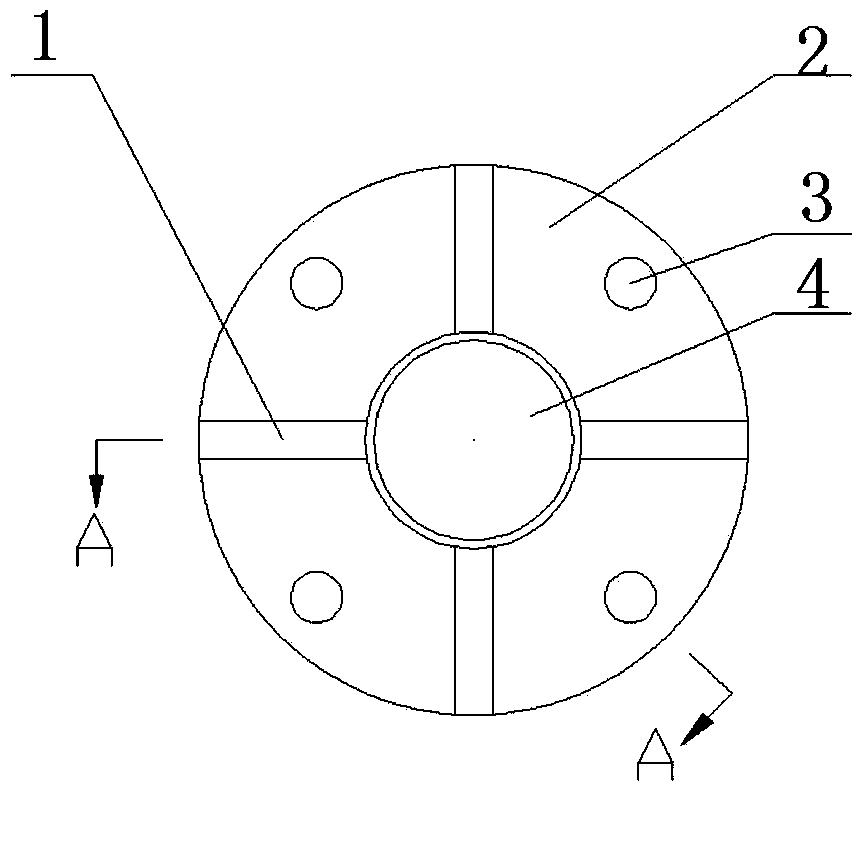

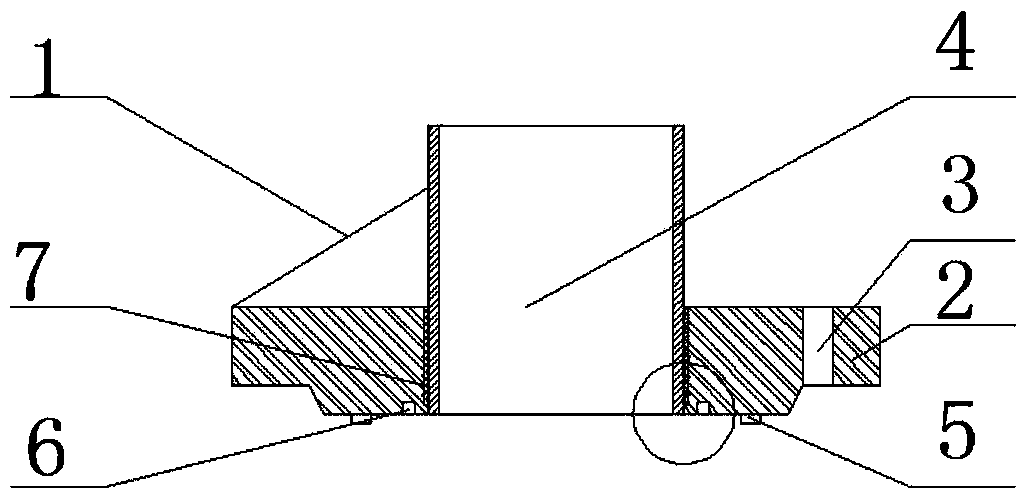

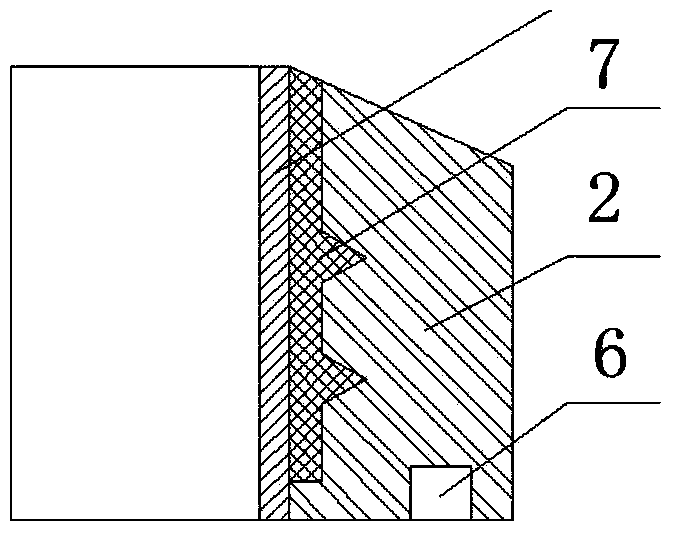

[0019] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 , 2 , 3, there is a sealing groove 6 on the flange body 2, and the sealing groove 6 and the gasket 5 cooperate with each other to make the sealing effect very good. Fixed connection, good fixing effect, good sealing effect, and suitable for high-pressure operation, the annular groove 7 is opened on the inner side of the flange, and there are three annular grooves 7 on the flange body 2, and the annular groove 7 is concentric with the pipe 4 as the center Distributed in a circle, the cross-sectional shape of the annular groove 7 is an isosceles triangle. The flange body 2 is provided with reinforcing ribs 1 to strengthen the connection between the flange and the pipeline 4, so that the pressure resistance is strong, the sealing effect is good, and it is difficult to leak, which is suitable for harsh working occasions. The flange can not only be operated u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com