Cold extrusion mold for output shafts and preparation method thereof

An extrusion die and cold extrusion technology, which is applied in the field of I001/1003063905 output shaft cold extrusion die and its preparation, can solve the problems that the concentricity cannot be guaranteed, the machining equipment is expensive, and there are many waste materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

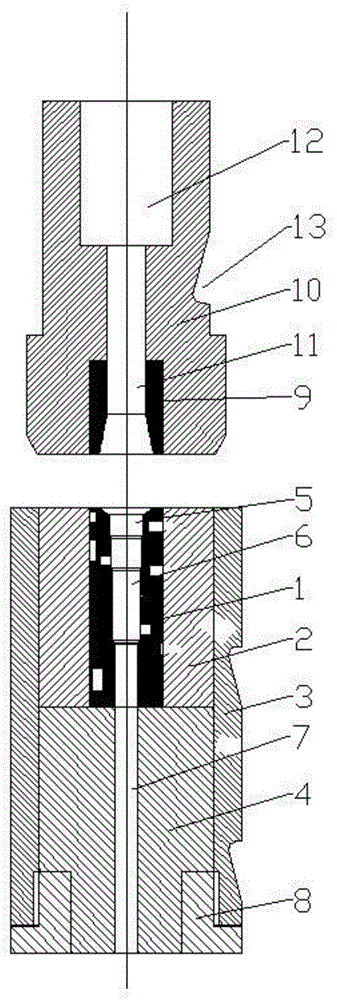

[0021] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the output shaft precision extrusion die described in this embodiment is composed of an upper mold and a lower mold that cooperate with each other, and the lower mold includes a lower mold core 1, a lower mold fixing sleeve 2, a lower mold outer casing 3, and a lower mold base 4. Among them, the main body of the lower mold core 1 is composed of a cylinder with a diameter of 40 mm and a height of 103.7 mm. The center of the top of the main body is provided with an upward-opening shaft head cavity 5. The lower mold cavity 6 is connected; the upper cavity diameter of the lower mold cavity 6 is 16.6mm, and the height is 16.3mm; the middle cavity diameter is 14.9mm, and the height is 37.7mm; the lower cavity diameter is 11.7mm, and the height is 33.5mm ; Adjacent cavities are connected by arc-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com