Nylon polarized lens and forming mold thereof

一种偏光镜片、成型模具的技术,应用在其他家里用具、光学、光学部件等方向,能够解决镜片厚等问题,达到减少加工程序、利用率提高、避免冲胶现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

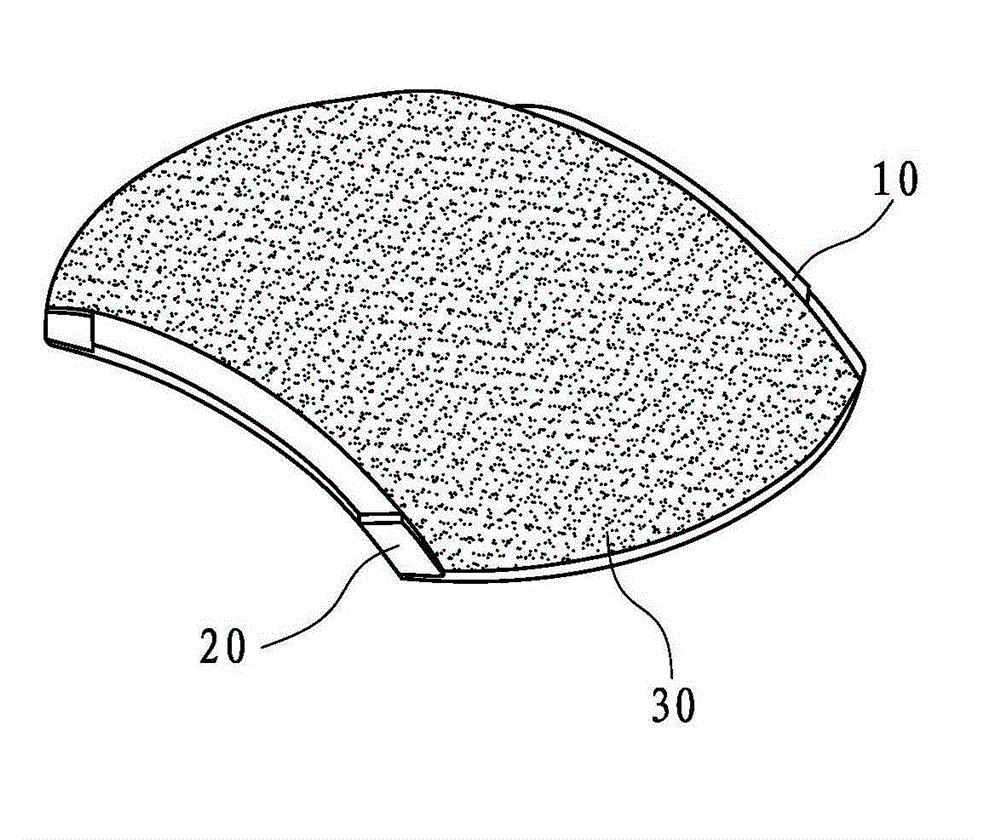

[0042] Such as Figure 8 Shown is the first embodiment of a nylon polarizing lens disclosed in the present invention, which is composed of a nylon material layer 100 and a polarizing film 30 . A positioning part for positioning the polarizing film 30 is respectively formed at four corners of the nylon material layer 100. There are many specific forms of the positioning part. Figure 8 The positioning portion shown is the concave portion 20 , and a polarizing film 30 is combined on the outer surface of the area surrounded by the four concave portions 20 . The key of the present invention is that buffer grooves 1 are provided on the end faces of the two opposite sides of the nylon material layer 100 .

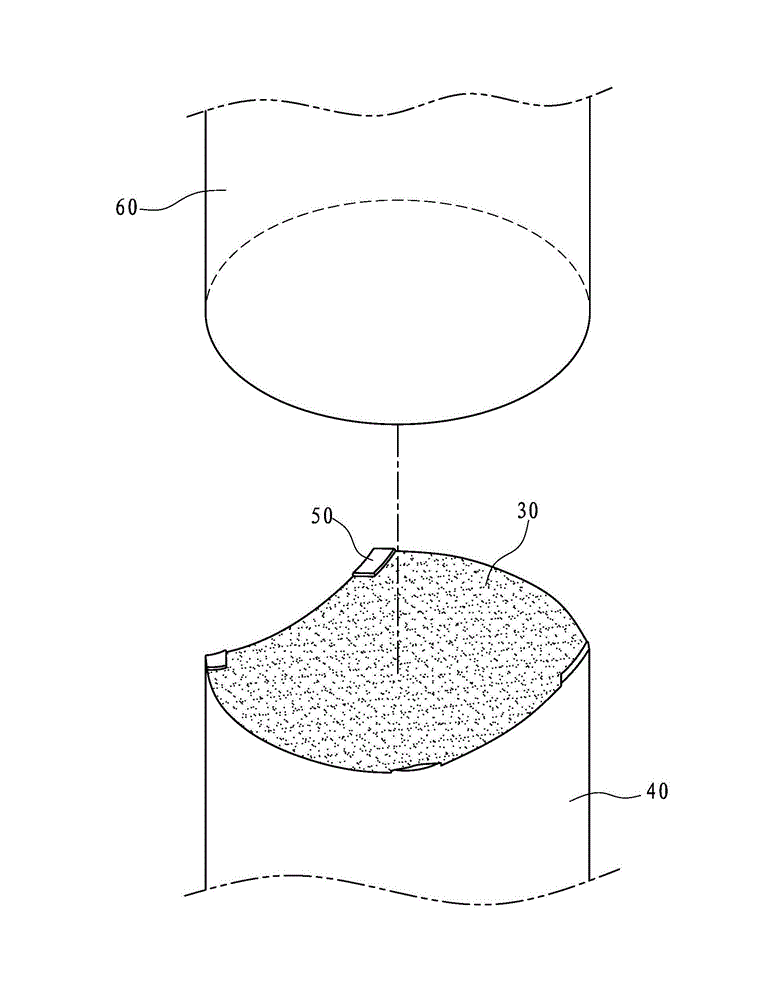

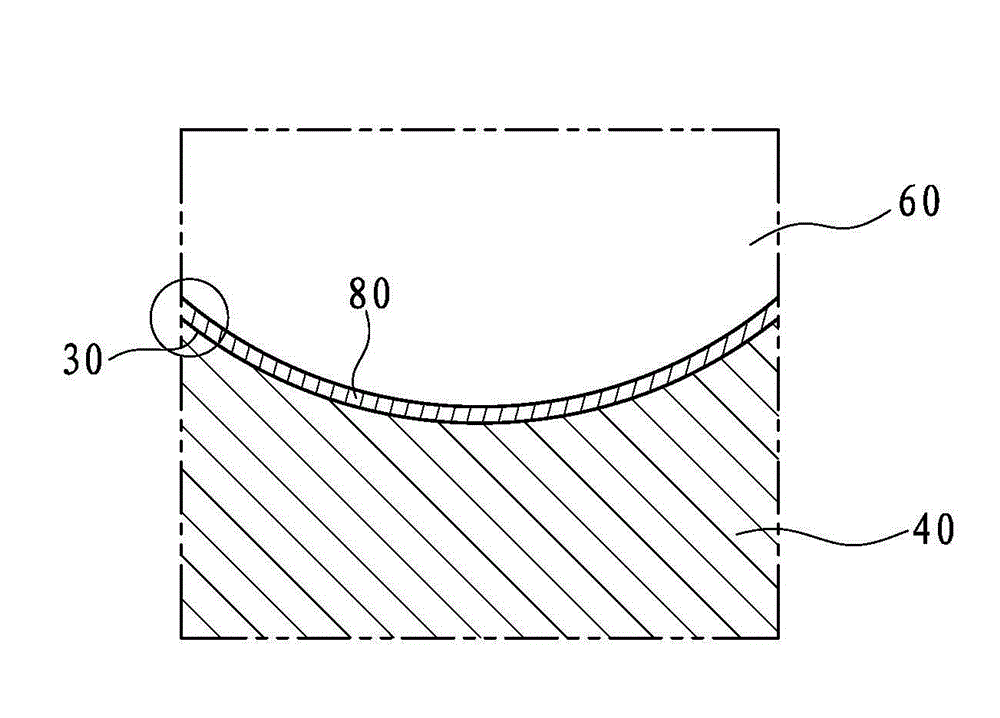

[0043] Cooperate Figure 9 and Figure 10 As shown, the forming mold for preparing the above-mentioned nylon polarized lens is composed of an upper mold 60 and a lower mold 40 . The top end surface of the lower mold 40 is an arc concave surface, and a buffer rib 2 is formed o...

Embodiment 2

[0046] Another example Figure 11 Shown is the second embodiment of a nylon polarizing lens disclosed in the present invention, which is composed of a nylon material layer 100 and a polarizing film 30 . Form a positioning portion for positioning the polarizing film 30 at four corners of the nylon material layer 100 respectively, and this embodiment positioning portion forms aperture 3 at four corners of the nylon material layer 100, and aperture 3 is for the die described later The positioning pin penetrates through to position the polarizing film 200 . The key of the present invention is that buffer grooves 1 are provided on the end faces of the two opposite sides of the nylon material layer 100 .

[0047] In this embodiment, the two opposite sides of the nylon material layer 100 extend to both sides to form a positioning plane 4, and four corners of the outer surfaces of the two positioning planes 4 are respectively formed with protruding top feet 5, which can be supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com