Sewing machine rotating shuttle frame and manufacturing method thereof

A technology for sewing machines and rotary hooks, applied to sewing machine components, sewing machine ring mechanisms, sewing equipment, etc., can solve the problems of complex processing and waste of materials, and achieve the effects of reducing wear, reducing processing procedures, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

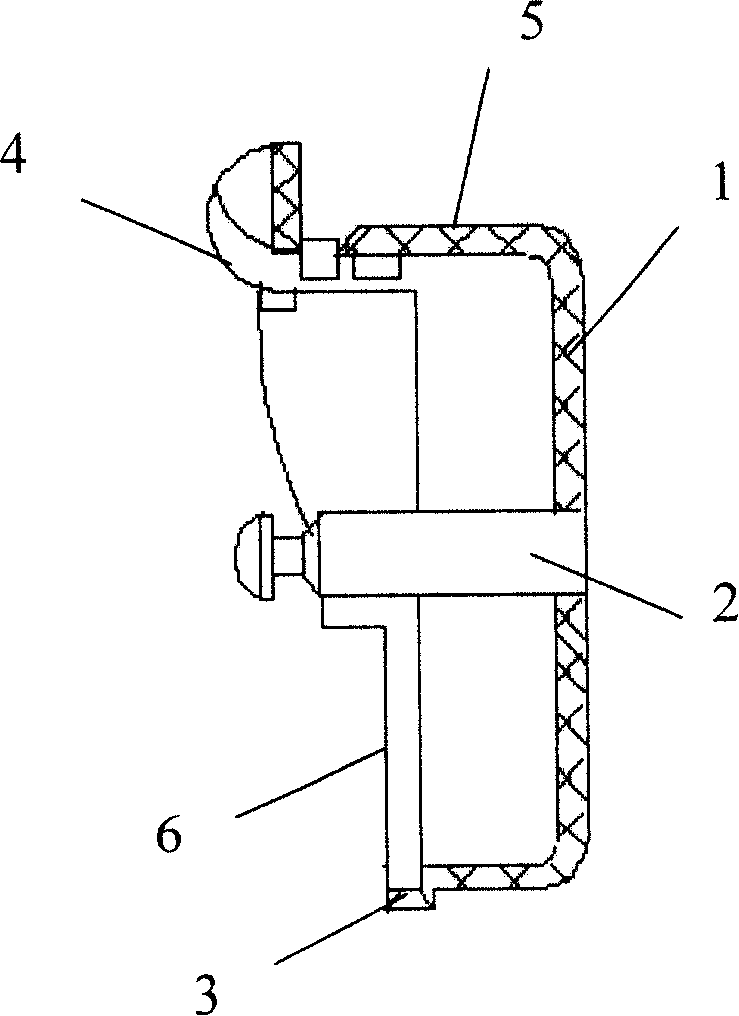

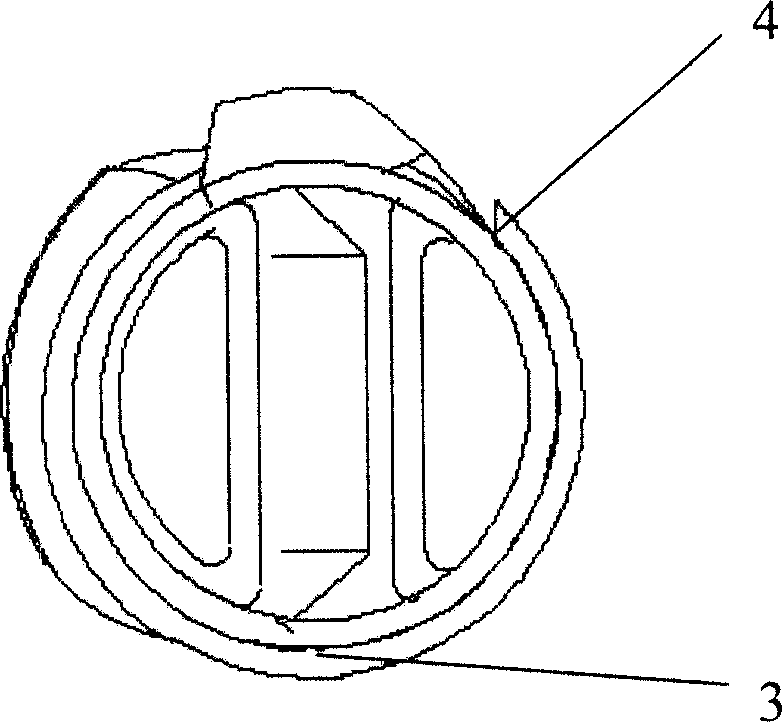

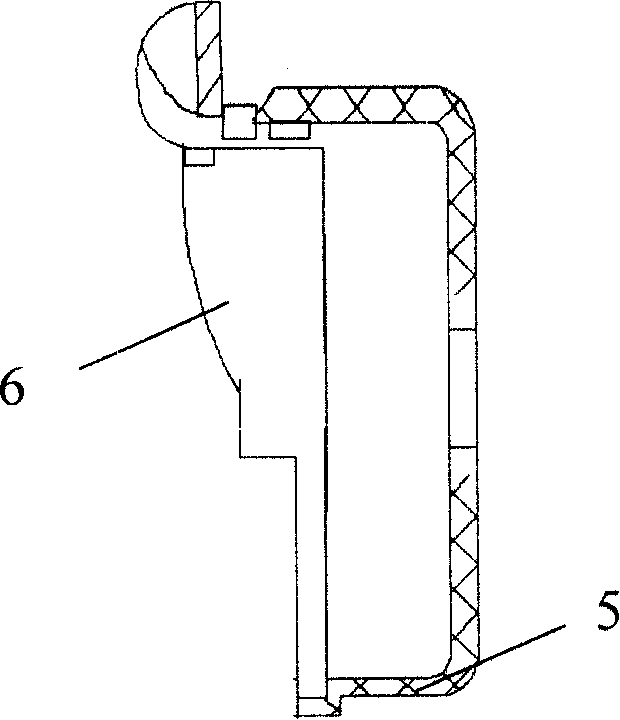

[0012] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the shuttle frame in the sewing machine rotary hook of the present invention is composed of a housing, wherein the housing is formed by connecting a first cylindrical housing 6 and a second cylindrical body 5, and the first cylinder An open convex track 3 is provided on the outer circumference of the housing 6, and a branching hook 4 is arranged in a section of the open convex track 3. One end of the second cylinder 5 is closed, and the first cylinder The other end of the housing 6 is connected and fixed to the other end of the second cylinder 5. The axial direction of the first cylindrical housing 6 coincides with the axial direction of the second cylindrical body 5. The first cylindrical housing 6 is made of plastic or nylon , or ceramic material, the second cylinder 5 is made of metal material, a solid metal bobbin handle 2 is arranged on the axis line in the second cylinder 5, and one end of the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com