Method for soaking water-proof zipper in waterproof material

A waterproof zipper and waterproof material technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high manufacturing cost, the inability to integrate the zipper tape, and the separation of the waterproof film and the zipper tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

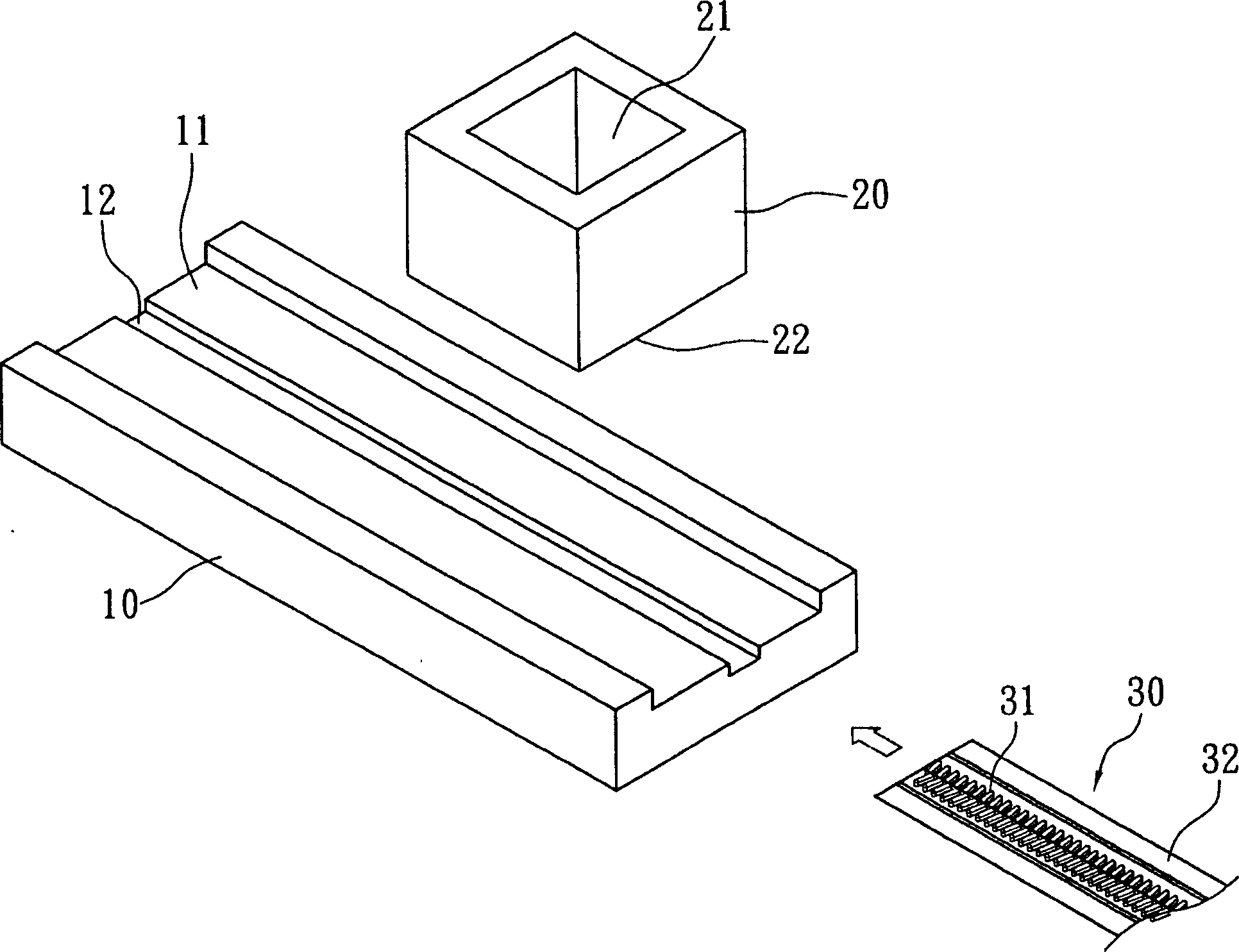

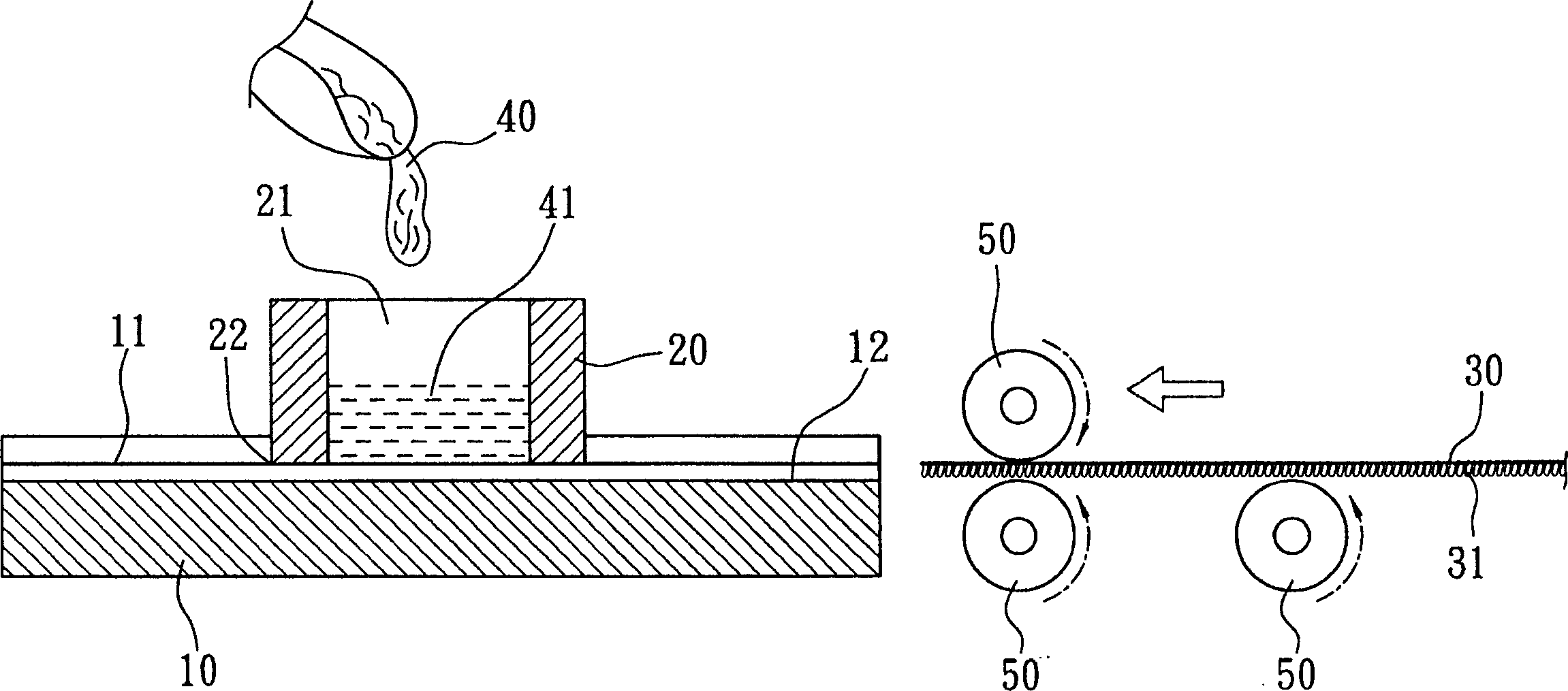

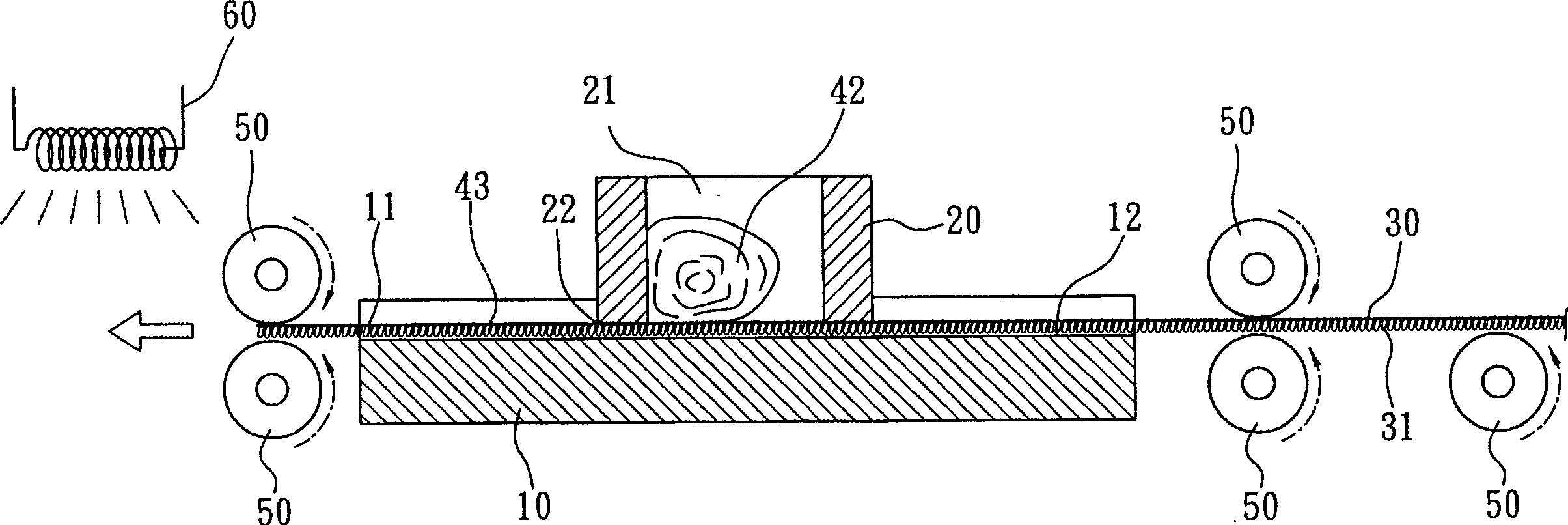

[0019] see figure 1 , figure 2 and image 3 , the present invention is a method for making a waterproof zipper to infiltrate a waterproof material. The method includes main technical means such as "thickening", "casting" and "waterproof film layer", which can improve the service life of the waterproof zipper and can Reduce its processing procedures to reduce manufacturing costs.

[0020] And a preferred embodiment of the present invention, please refer to figure 1 , figure 2 As shown, the manufacturing device is provided with a lower mold 10 and an upper mold 20. The lower mold 10 is provided with a positioning groove 11 and a groove 12 on the plate body. The ideal space arrangement lower groove 12 is located in the positioning groove 11 in the center, and the positioning groove 11 can carry the zipper tape 30 to slide on it, and the recess of the groove 12 can accommodate the zipper elements 31 to fill in and place, so that the cloth tape 32 of the zipper tape can be fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com