Nickel or nickel base alloy electrode sheet type resistor and method of producing the same

A technology of nickel-based alloy and manufacturing method, applied in resistance manufacturing, non-adjustable metal resistors, resistors, etc., can solve problems such as chip resistor failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

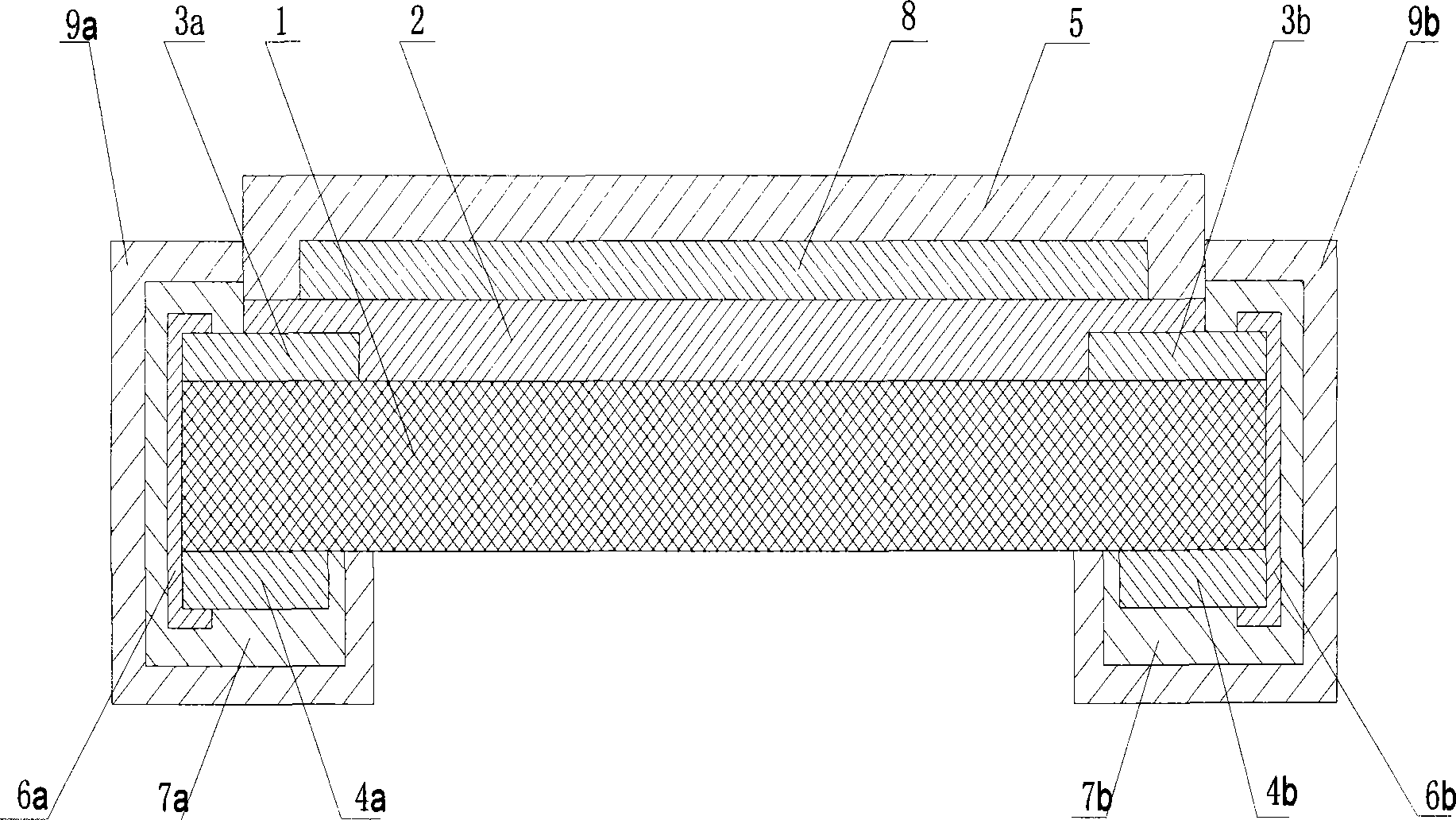

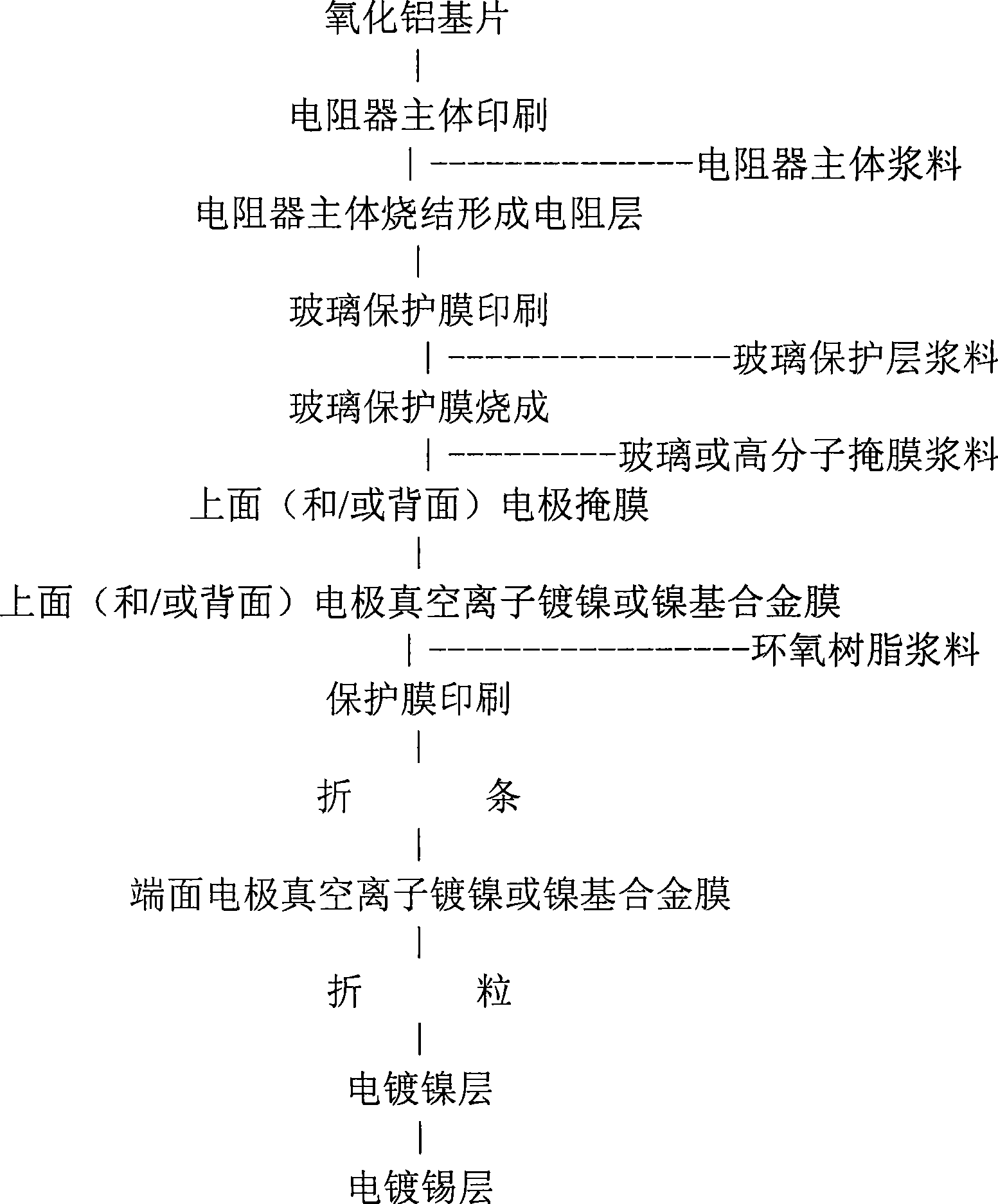

[0031] figure 2 It is a cross-sectional view of a nickel or nickel-based alloy electrode thick-film chip resistor according to Example 1 of the present invention. In this figure, 1 is the insulating substrate of the present invention, 2 is the resistance layer of the present invention, 3a, 3b are the electrode layers at both ends of the front side of the present invention, and the resistance layer 2 is made of ruthenium oxide paste by screen printing Materials are printed on the insulating substrate 1 and sintered. After that, the mask patterns of the electrode layers 3a and 3b at both ends of the front and the electrode layers 4a and 4b at both ends of the back are formed by screen printing. The alloy method is to form the electrode layers 3a, 3b at both ends on the upper side, and the electrode layers 4a, 4b at both ends on the back, and then form the electrode layers 6a, 6b at both ends of the side by vacuum arc ion plating, and then use the electroplating process to form ...

Embodiment 2

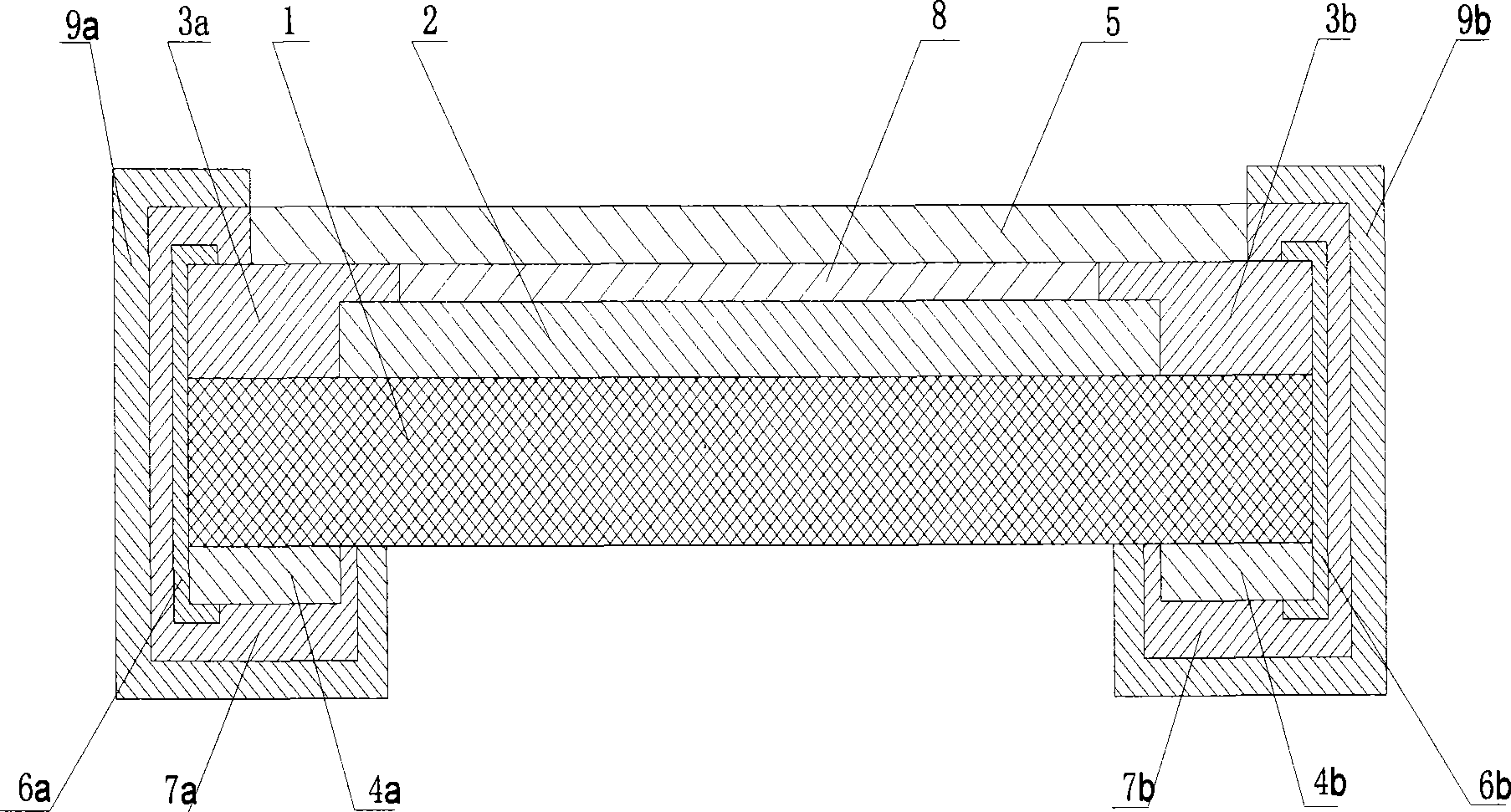

[0045] Figure 4 It is a sectional view of nickel or nickel-based alloy thick film chip resistor of embodiment 2 of the present invention, Figure 5 It is the manufacturing flow chart of the nickel or nickel-based alloy thick film chip resistor of the embodiment 2 of the present invention.

[0046] Since the manufacture of the chip resistor directly adopts nickel or nickel-based alloy as the electrode material, the nickel plating process in Example 1 can be omitted, and the electrode layer 3a, 3b on the upper surface and the end electrode layer 6a can be formed directly by electroplating. , 6b, the surface of the back electrode layer 4a, 4b is directly tin-plated as a solder layer.

Embodiment 3

[0048] Image 6 It is the sectional view of the nickel or nickel-base alloy thin film chip resistor of embodiment 3, Figure 7 It is the manufacturing flowchart of the nickel or nickel-base alloy thin film chip resistor of embodiment 3

[0049] Combine below Image 6 Figure 7 The manufacturing method of the nickel or nickel-based alloy thin film chip resistor of embodiment 3 is described in detail. The resistance layer 2 of this example no longer uses the film-forming method of screen printing thick film technology, but uses NiCr and / or NiCrSi as the resistance material of the resistance layer to form the resistance layer 2 by vacuum sputtering. First, use a screen printing mask to make a resistance pattern, and then sputter to form a resistance layer; then use screen printing to form a mask pattern of the electrode layers 3a, 3b at both ends on the top, and the electrode layers 4a, 4b at both ends on the back, using vacuum arc The method of ion plating nickel or nickel-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com