High-power transistor

A technology of high-power transistors and wafers, which is applied to electric solid-state devices, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problems of low lead frame thickness requirements, increased processing steps, and high product costs, so as to improve product competition. Strength, volume reduction, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

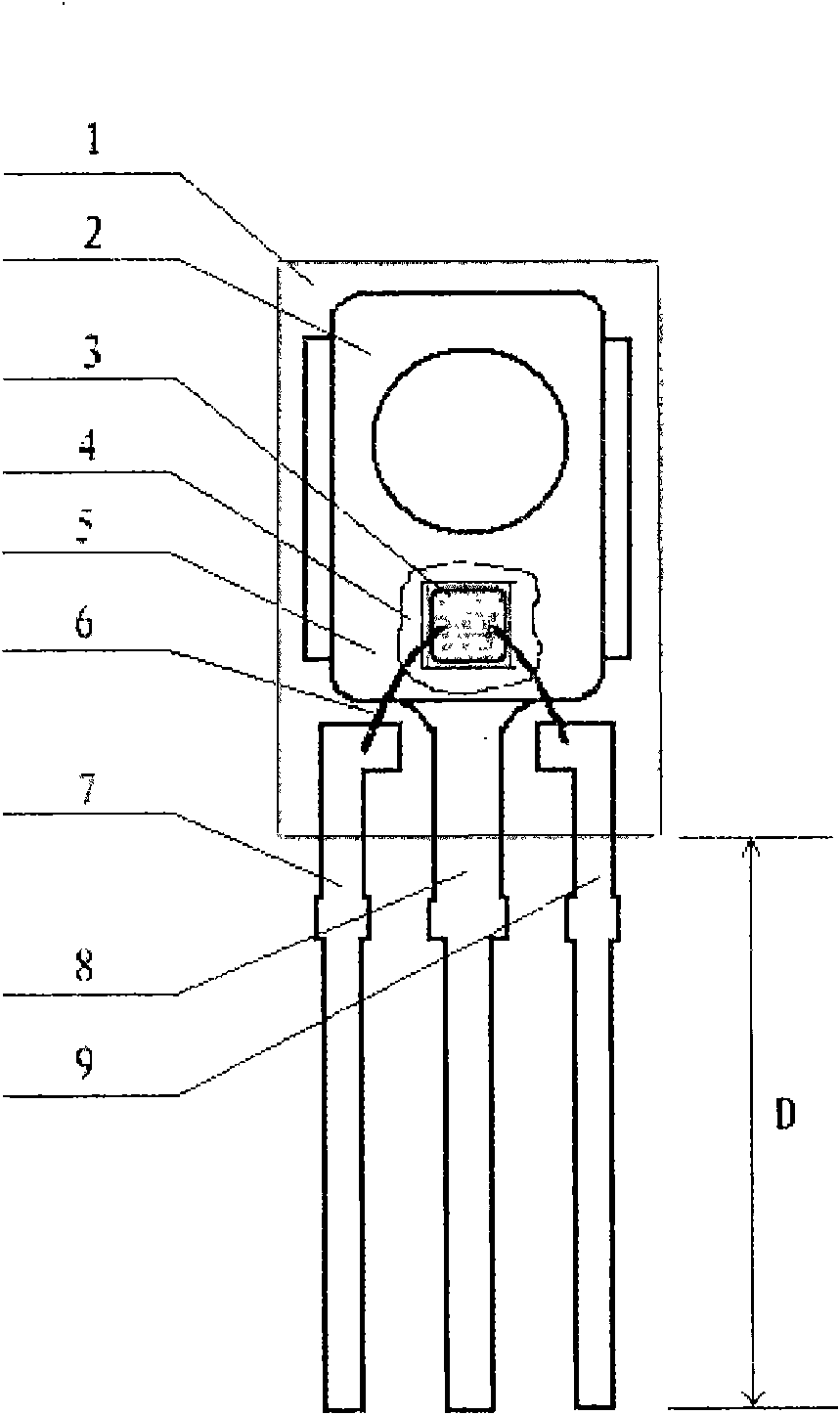

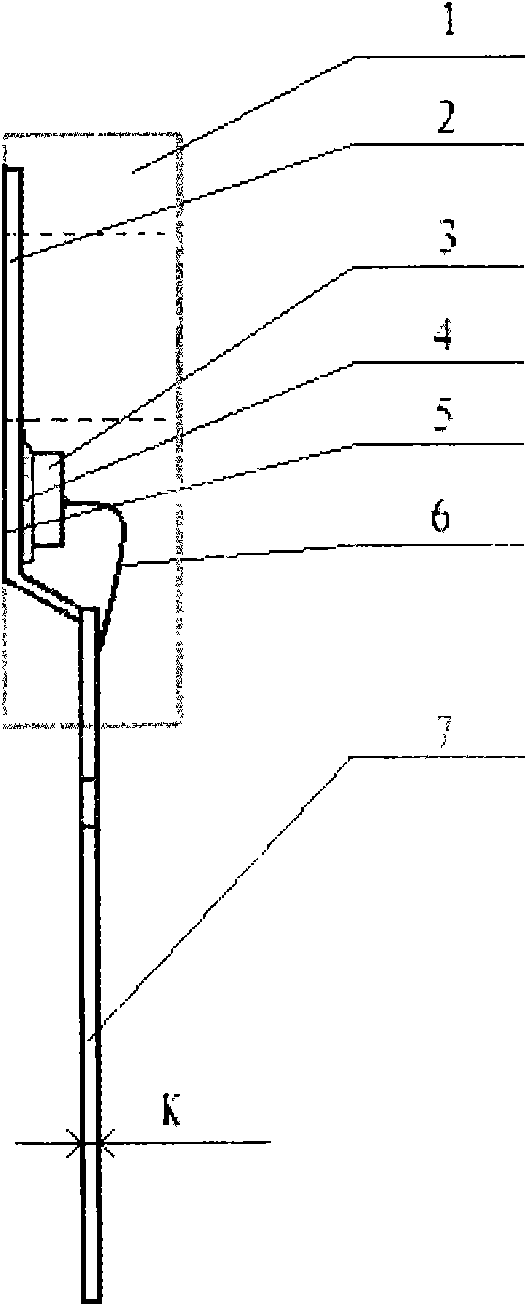

[0015] Depend on figure 1 and figure 2 As known, the present invention includes a plastic package 1 , a chip 3 , a lead frame 5 , and leads 6 . The upper self-generated heat sink 2 of the lead frame 5, the lower self-generated collector pin 8, the emitter pin 7 and the base pin 9 are arranged at intervals on both sides of the collector pin 8, and the chip 3 is bonded by the solder layer 4. Fixed on the lead frame 5, the emitter pin 7 and the base pin 9 are connected to the chip 3 through the lead wire 6, the lead wire 6 can be made of gold wire or copper wire, and the above-mentioned structure is packaged with the plastic package body 1 to form a high power transistors. The collector 8 on the lead frame 5 is the same length D as the emitter pin 7 and the base pin 9, see figure 1 , D is 6-8mm, the optimum is 6.45mm, the material of lead frame 5 and pins 7, 8, and 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com