Separation joint construction structure and construction method of roof ground and table top layer

A technology for separation joints and countertops, which is applied in the direction of roof covering, roof, floor, etc., can solve the problems of foundation layer damage and inconvenient construction of separation joints, and achieve the effects of saving time, improving construction efficiency and simplifying construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

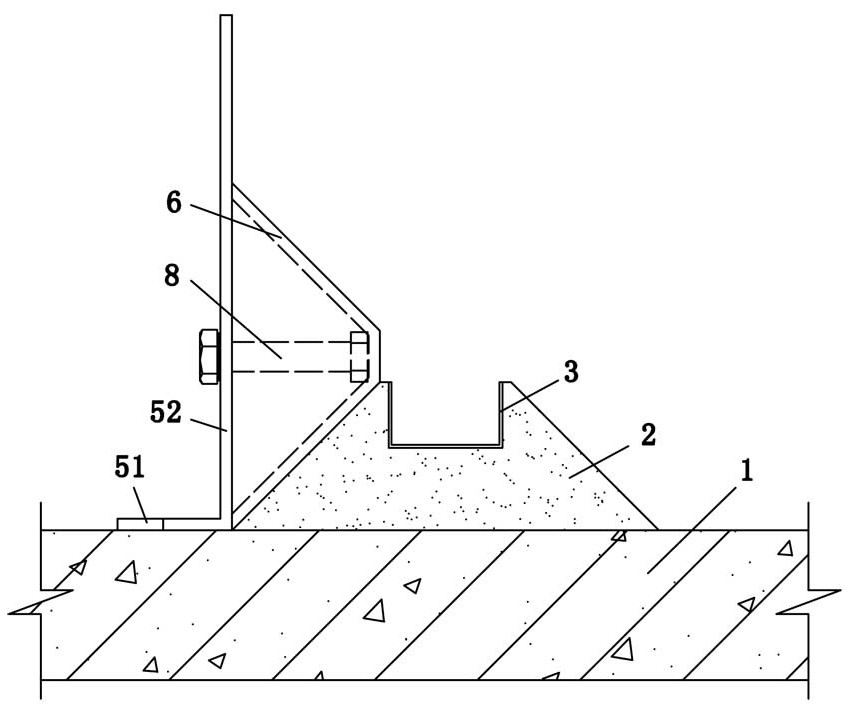

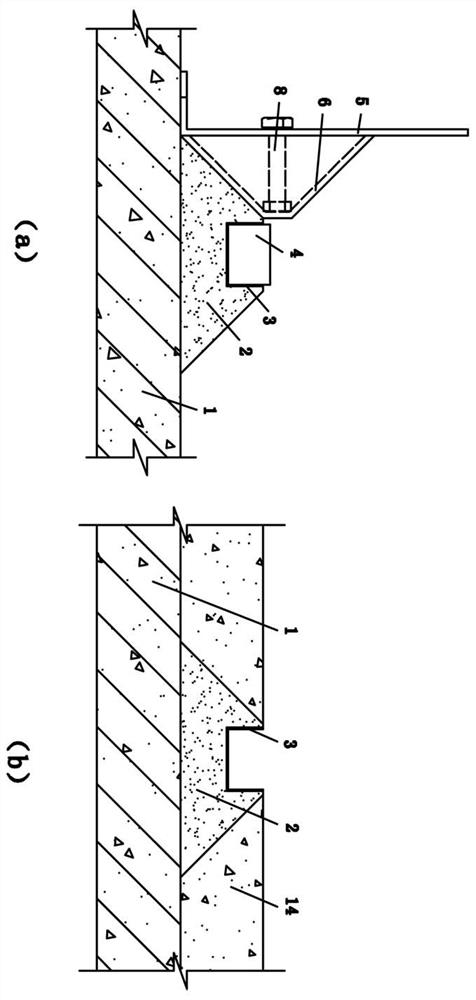

[0038] Such as Figure 1~Figure 2 As shown, a construction structure for the separation joints of the roof floor and the stand surface layer includes a base layer 1, and a mortar layer 2 is arranged on the base layer 1, and the mortar layer 2 is a layer structure formed by cement mortar. The ratio of cement mortar in the mortar layer 2 is 1:1, and the cross section of the mortar layer 2 is isosceles trapezoidal. The upper bottom of the mortar layer 2 formed by masonry has a length of 20mm and a bottom angle of 45°, and the lower bottom of the mortar layer 2 is bonded to the base layer 1.

[0039] The upper bottom surface of the mortar layer 2 is embedded with a PVC partition strip 3 to form a partition, and a sponge strip 4 is arranged inside the partition strip 3, and the function of the sponge strip 4 is to prevent blocking.

[0040] A side flat seat is provided on one side of the mortar layer 2, and the side flat seat includes an "L"-shaped vertical plate 5 and a standard ...

Embodiment 2

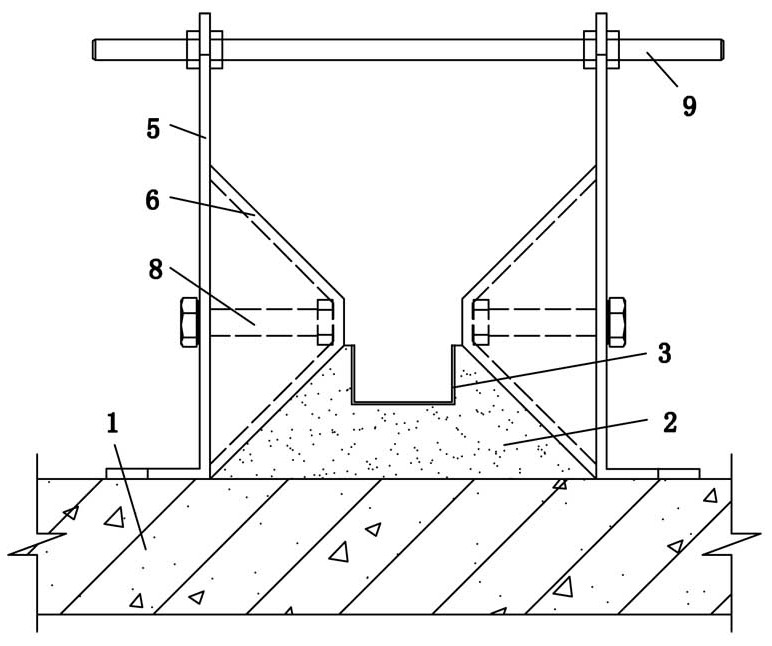

[0054] Such as Figure 3~Figure 9 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that: the side flat seats are arranged symmetrically on both sides of the mortar layer 2, and the side flat seats on both sides are attached to the clamping place. The mortar layer 2 is provided with a counterweight on the side flat seat. Specifically, the counterweights are distributed on the horizontal section 51, and the counterweights can be made of bricks, stones, concrete blocks and other construction materials that are easily obtained, and the horizontal section 51 is pressed by the counterweights, thereby realizing the flat seat on the opposite side. The fixing of the counterweight is not shown in the figure.

[0055] In this embodiment, the distance between the side flat seats on both sides is adjustable and connected, which can match mortar layers 2 of different sizes. Specifically, screw rods 9 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com