Chemical mechanical polishing equipment

A technology of chemical machinery and equipment, applied in the field of semiconductor manufacturing technology, can solve the problems of shortened life, reduced reliability of semiconductor devices, metal short circuit, etc., to achieve the effect of ensuring yield, avoiding short circuit or failure, and ensuring reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

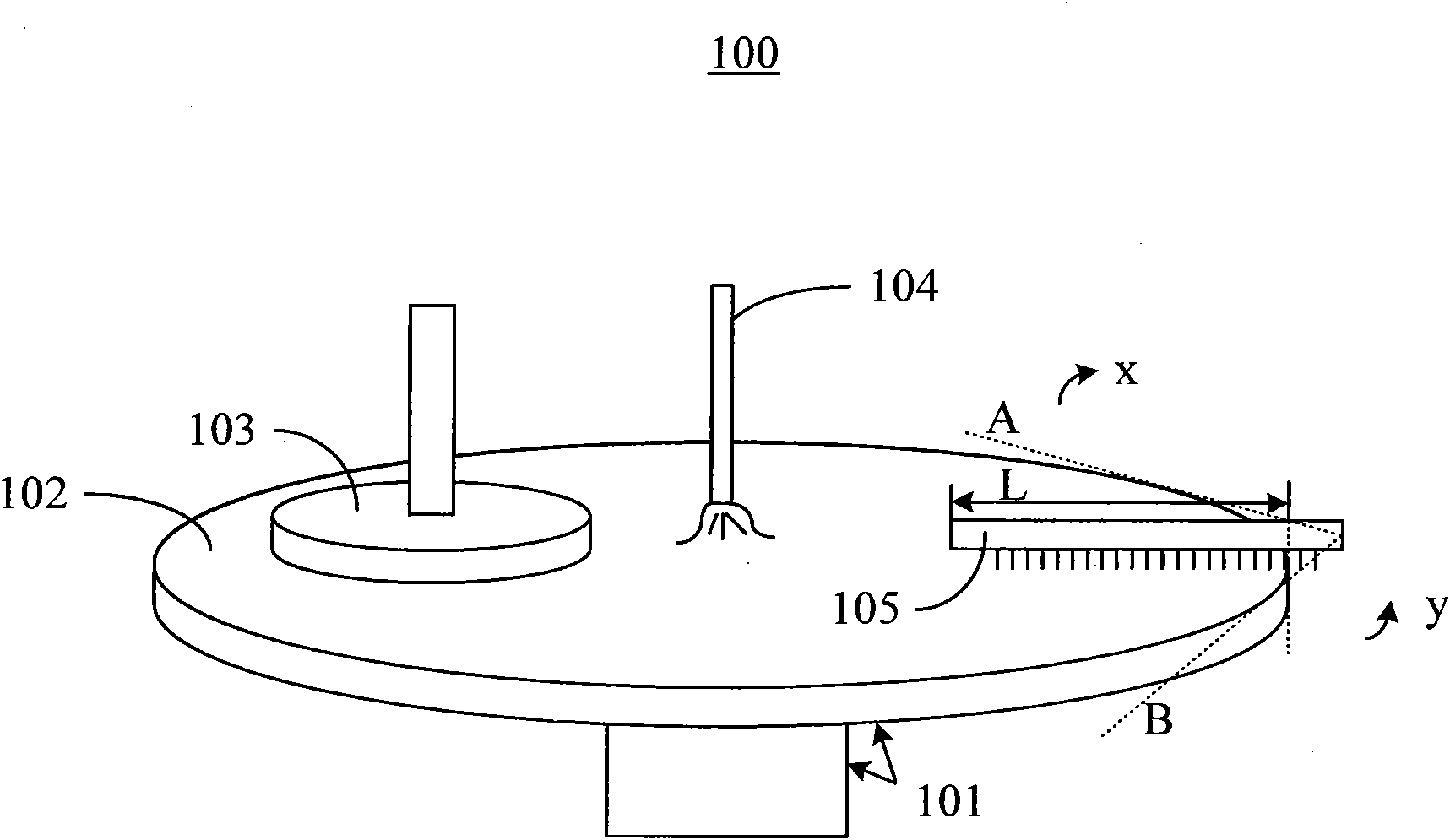

[0027] Such as figure 1 As shown, the chemical mechanical polishing equipment 100 comprises a rotary table 101, a polishing pad 102 fixed on the surface of the rotary table 101, a polishing head 103 for fixing the wafer and pressing the wafer on the surface of the polishing pad 102, and spraying the polishing slurry on the surface of the polishing pad 102. Abrasive spray head 104, abrasive pad cleaning member 105 and drive components (not shown). The chemical mechanical polishing equipment 100 grinds the wafer through the relative movement between the rotary table 101 and the polishing head 103 under the action of the polishing slurry. Since the chemical mechanical polishing equipment 100 described here has a similar structure and component composition with the widely used chemical mechanical polishing equipment, except for the polishing pad cleaning part 105 and the driving part (not shown), for the sake of simplicity, the General components such as the rotary table 101 , th...

no. 2 example

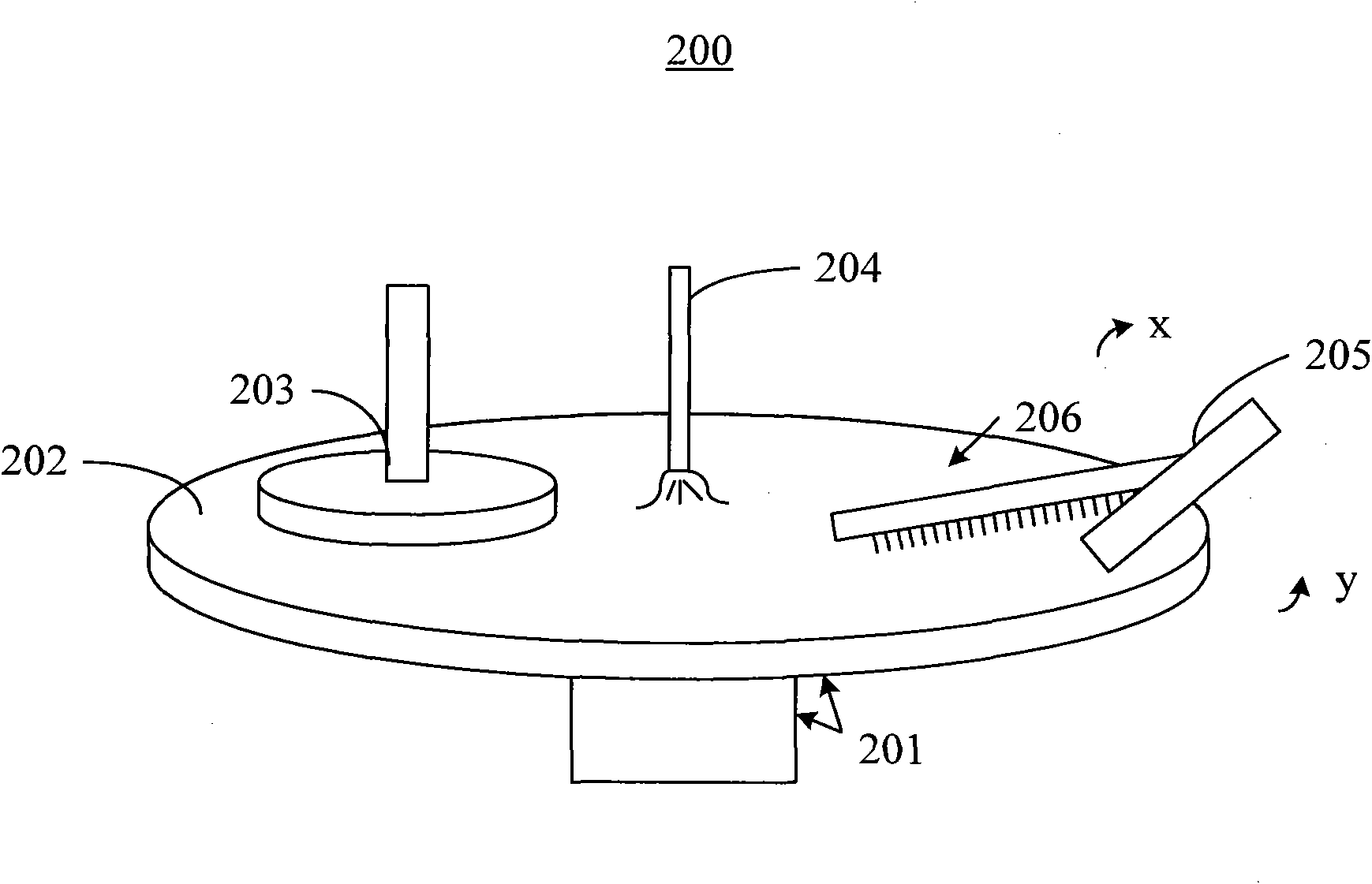

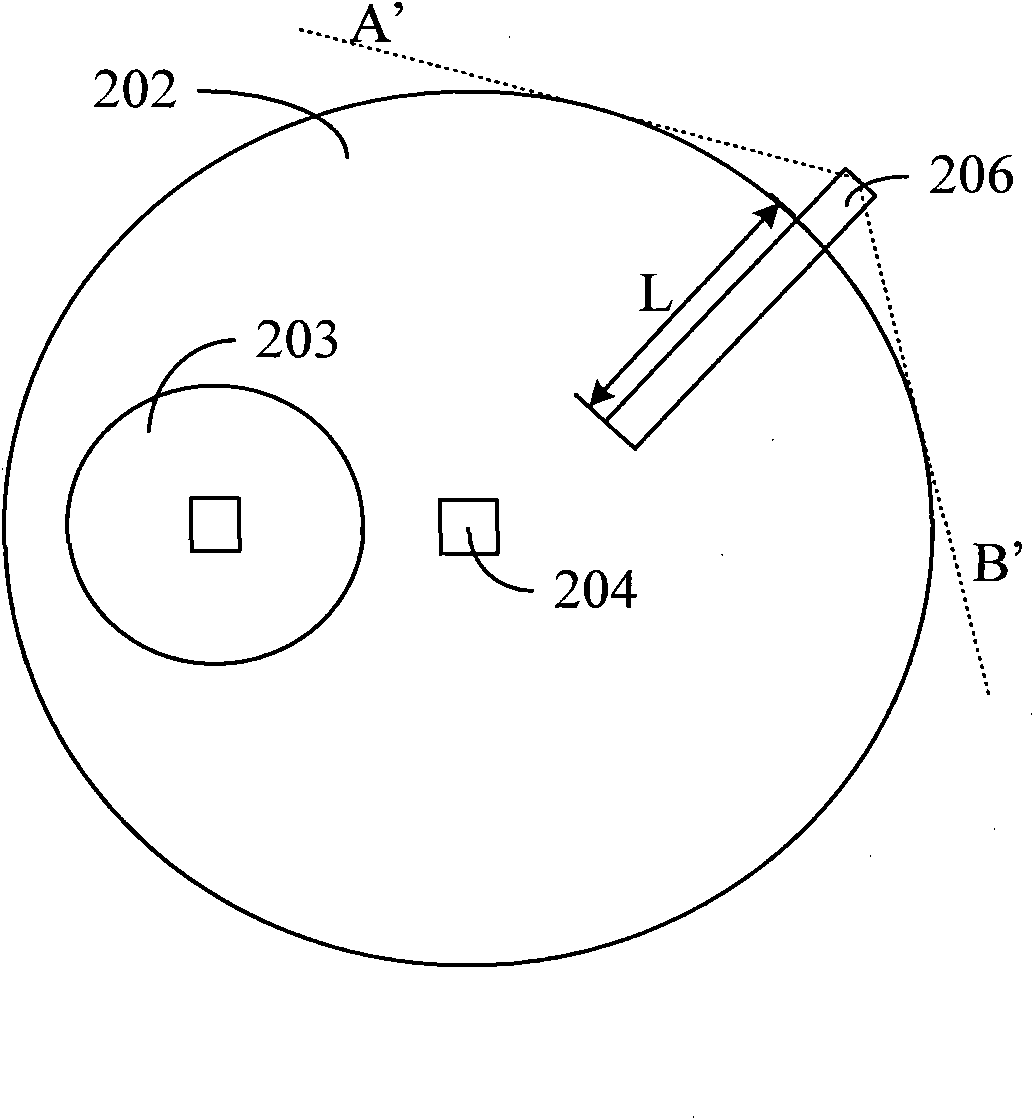

[0036] Such as Figure 2A As shown, the chemical mechanical polishing equipment 200 includes a rotary table 201, a polishing pad 202 fixed on the surface of the rotary table 201, a polishing head 203 for fixing the wafer and pressing the wafer on the surface of the polishing pad 202, and spraying the polishing slurry on the surface of the polishing pad 202. Abrasive spray head 204, pad conditioning arm 205, pad cleaning member 206 and drive components (not shown). The chemical mechanical polishing equipment 200 polishes the wafer through the relative movement between the rotary table 201 and the polishing head 203 under the action of the polishing slurry. Since the chemical mechanical polishing equipment 200 described here has a similar structure and parts composition with the widely used chemical mechanical polishing equipment, except the polishing pad trimming arm 205, the polishing pad cleaning part 206 and the driving parts, in order to describe simply, General components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com