Granularity-controllable sodium citrate refining process and implementing device

A sodium citrate, particle size technology, applied in the refining process of sodium citrate and the field of realization equipment, can solve the mismatch between the production speed of crystal nuclei and the growth speed of crystal nuclei, and the easy occurrence of crystals of different sizes and heavy crystals Unable to control and other problems, to achieve the effect of high recrystallization yield, simplified production operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

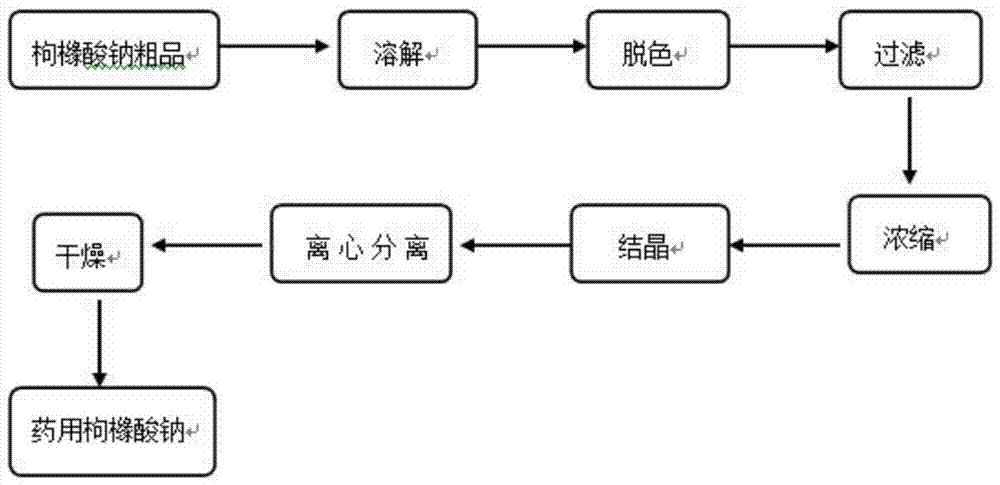

[0046] The refining process of the sodium citrate of the present embodiment adopts the seed crystal crystallization mode, comprises the following steps:

[0047] S1. Dissolving: Dissolve 10kg of crude food-grade anhydrous sodium citrate in 12L of water, and raise the temperature of the feed solution to 90°C;

[0048] S2. Decolorization: add activated carbon with a mass percentage of 0.3% to the solution obtained in S1, stir at a constant temperature of 90°C for 0.5h, and filter to obtain a fine filtrate;

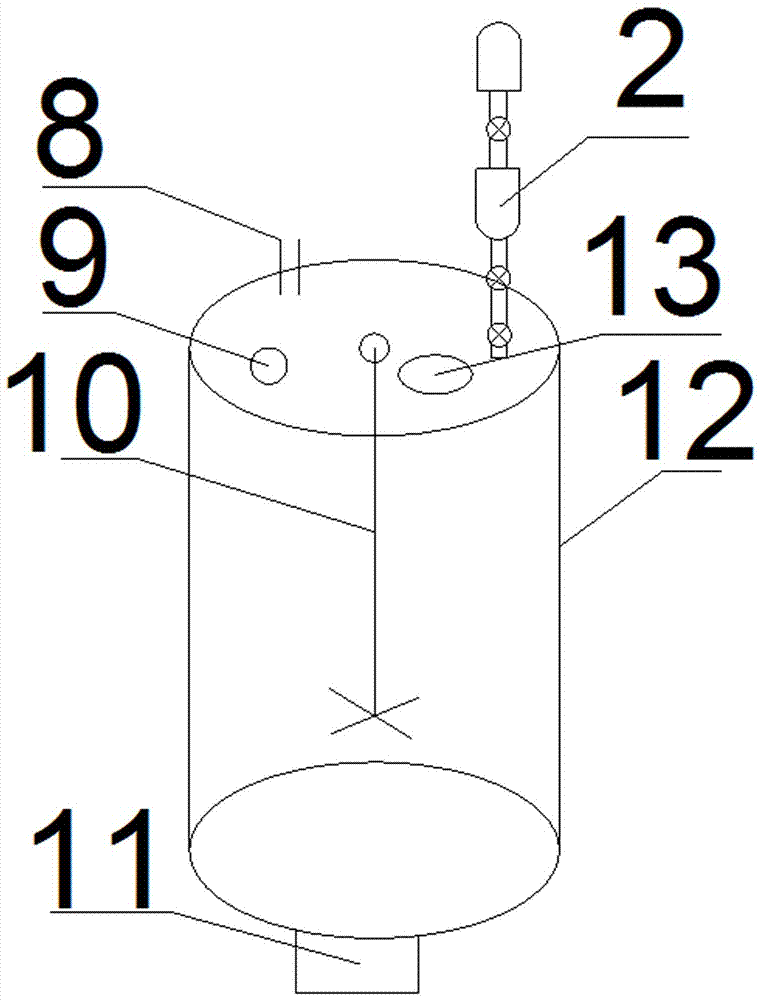

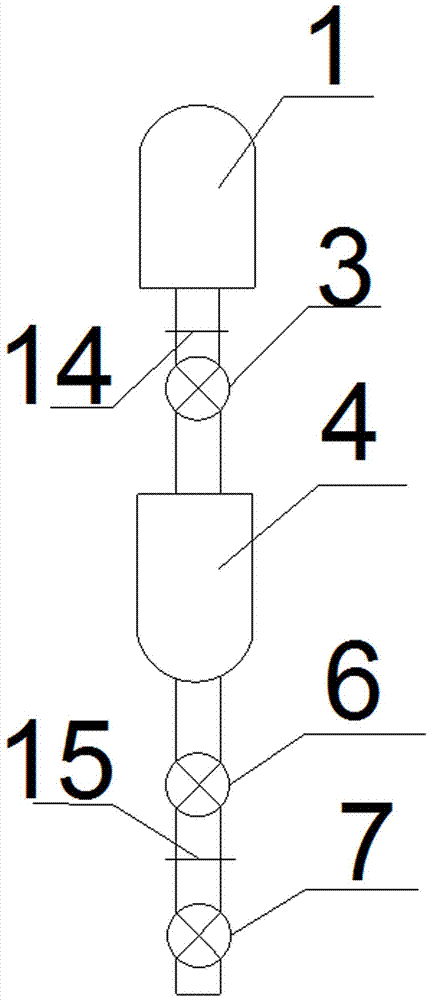

[0049] S3. Concentration and crystallization: depressurize the fine filtrate obtained in S2 to -0.08MPa, stir at a speed of 33r / min, concentrate to a viscous liquid with a specific gravity of 1.34g / ml, and add 5g of seed crystals using a seed crystal register , continue to concentrate for 0.5h, cool the feed liquid at a cooling rate of 10°C / h, cool to 55°C, stir at a speed of 13r / min, and crystallize for 5h to obtain wet granules of sodium citrate;

[0050] S4. Separation a...

Embodiment 2

[0051] The steps of embodiment 2 are the same as those of embodiment 1, except that the specific gravity of the viscous liquid in step S3 is 1.25 g / ml.

Embodiment 3

[0052] The steps of embodiment 3 are the same as those of embodiment 1, except that the specific gravity of the viscous liquid in step S3 is 1.36 g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com