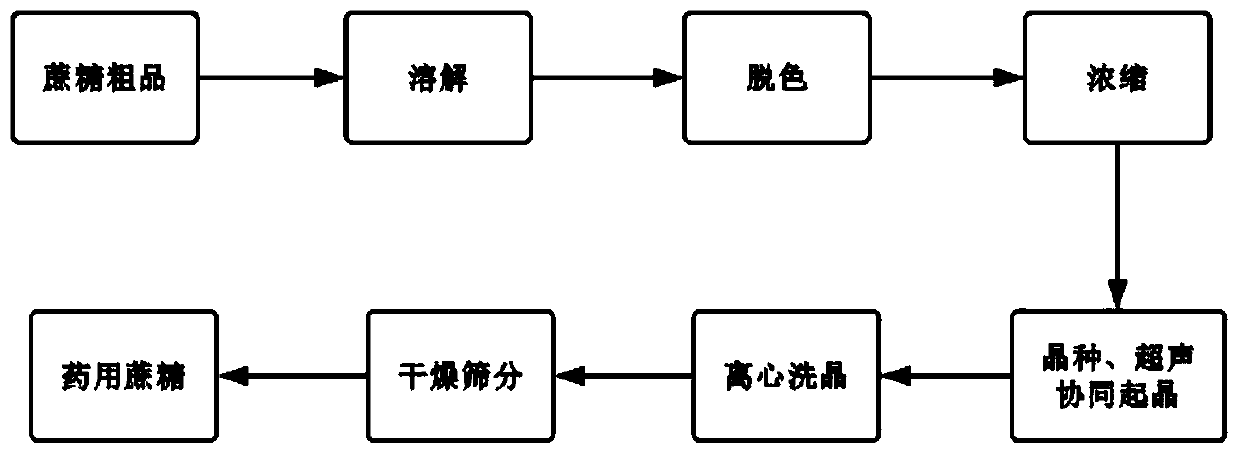

Novel granularity-controllable sucrose refining method

A refining method and technology for sucrose, applied in the field of sucrose refining, can solve the problems of sucrose powder crystal form destruction, poor fluidity of sugar powder, easy agglomeration, etc., and achieve the effects of effective particle size control, low cost and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

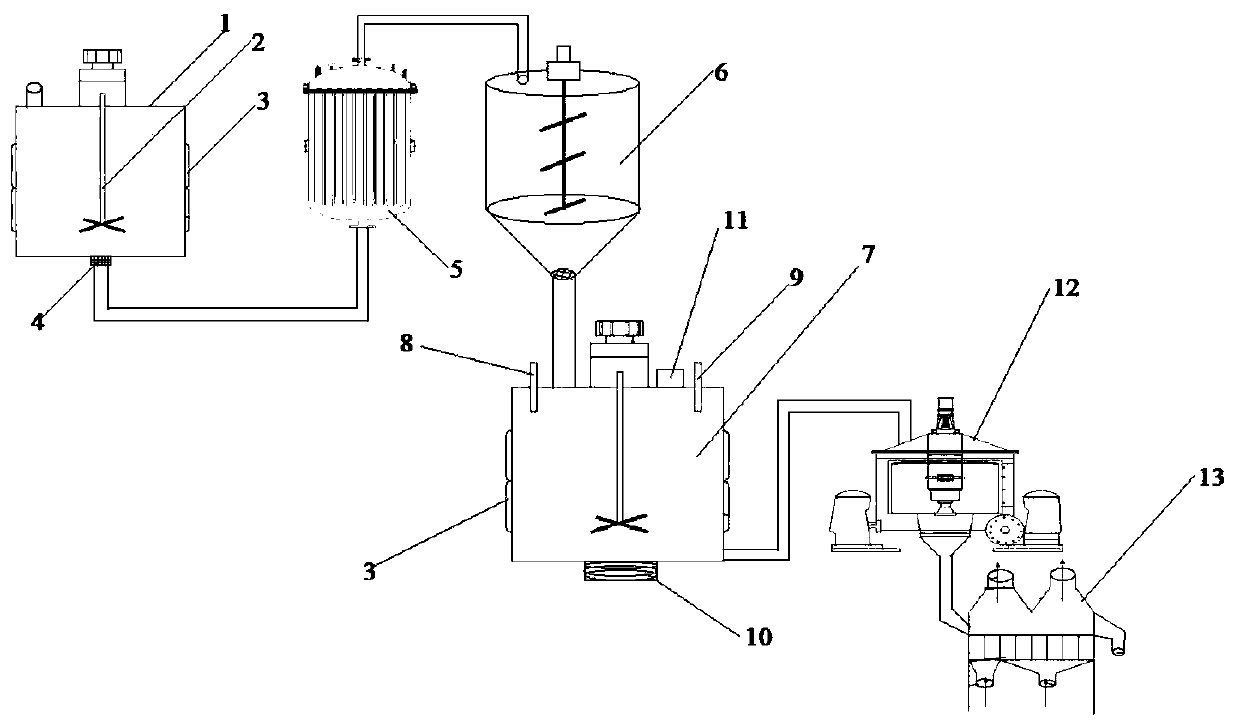

[0030] This embodiment provides a novel production device for refining sucrose with controllable particle size.

[0031] A new production system for refining sucrose with controllable particle size includes a dissolution tank 1, a titanium rod filter 5, a fine filtrate tank 6, a concentration tank 7, a centrifuge 12 and a fluidized vibrating machine 13. The discharge port of described dissolving tank 1 connects the feed port of titanium rod filter 5, and the discharge port of titanium rod filter 5 is connected with the feed port of fine filtrate tank 6, and the discharge port of fine filtrate tank 6 is connected with concentrated The feed port of the tank 7 is connected, the discharge port of the concentration tank 7 is connected with the centrifuge 12, and the centrifuge 12 is connected with the inlet of the fluidized vibrating machine 13.

[0032] The upper part of the dissolving tank 1 is provided with a feed inlet, and the interior is provided with a stirrer 2 , and a stea...

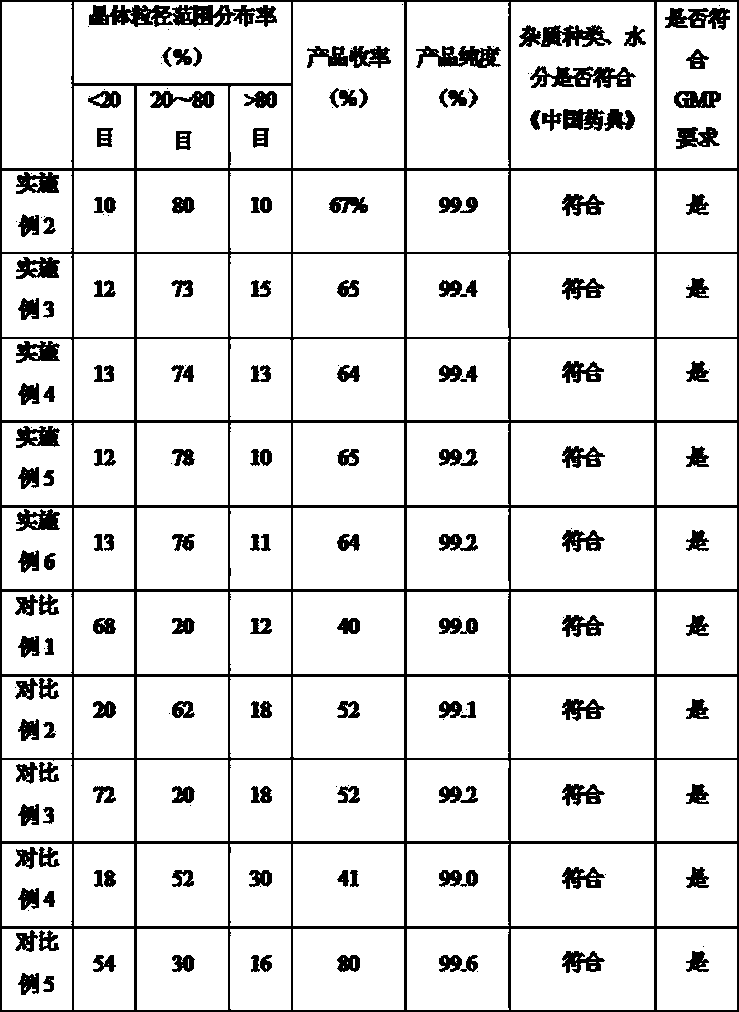

Embodiment 2

[0036] This embodiment provides a novel controllable particle size sucrose refining method, the preparation steps are:

[0037] S1. Dissolving and decolorizing: Dissolve 10kg of food-grade sucrose in 4kg of deionized water, add 8g of activated carbon for decolorization, stir at a constant temperature of 80°C until the sucrose is dissolved, and filter to obtain a fine sucrose filtrate.

[0038]S2. Concentrated crystallization: Stir the sucrose filtrate obtained in S1 at 28r / min, depressurize to -0.09~-0.07Mpa, concentrate at 70~80°C until the sugar Brix is 90°Bx, add 20g of seed crystals, and simultaneously Turn on the ultrasonic wave, adjust the frequency to 1620 Hz to stimulate the crystallization for 25 minutes, and obtain the crystallization solution.

[0039] S3. Separation and purification: Centrifuge the crystallization solution obtained in S2 at 1000~1200r / min into coarse crystal grains and mother liquor, add the coarse crystal grains to purified water, stir, and cent...

Embodiment 3

[0042] This embodiment provides a novel controllable particle size sucrose refining method, the preparation steps are:

[0043] S1. Dissolving and decolorizing: Dissolve 10kg of food grade sucrose in 5kg of deionized water, add 10g of activated carbon for decolorization, stir at a constant temperature of 85°C until the sucrose is dissolved, and filter to obtain a fine sucrose filtrate.

[0044] S2. Concentrated crystallization: Stir the sucrose filtrate obtained in S1 at 35r / min, reduce the pressure to -0.09~-0.07Mpa, concentrate at 70~80°C until the sugar Brix is 87°Bx, add 30g of seed crystals, and simultaneously Turn on the ultrasonic wave, adjust the frequency to 1700 Hz to stimulate the crystallization for 20 minutes, and obtain the crystallization solution.

[0045] S3. Separation and purification: Centrifuge the crystallization solution obtained in S2 at 1000~1200r / min into coarse crystal grains and mother liquor, add the coarse crystal grains to purified water, stir,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com