Adjusting device for upper knife holder and upper circular knife of upper knife shaft of splitting machine, and preparation method

A technology of slitting machine and tool holder, which is applied in metal processing and other directions, can solve the problems of easy loosening, low fit, and increase the diversity of upper tool holder parts, so as to improve the cutting accuracy, improve the tightening relationship, and improve the The effect of slitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

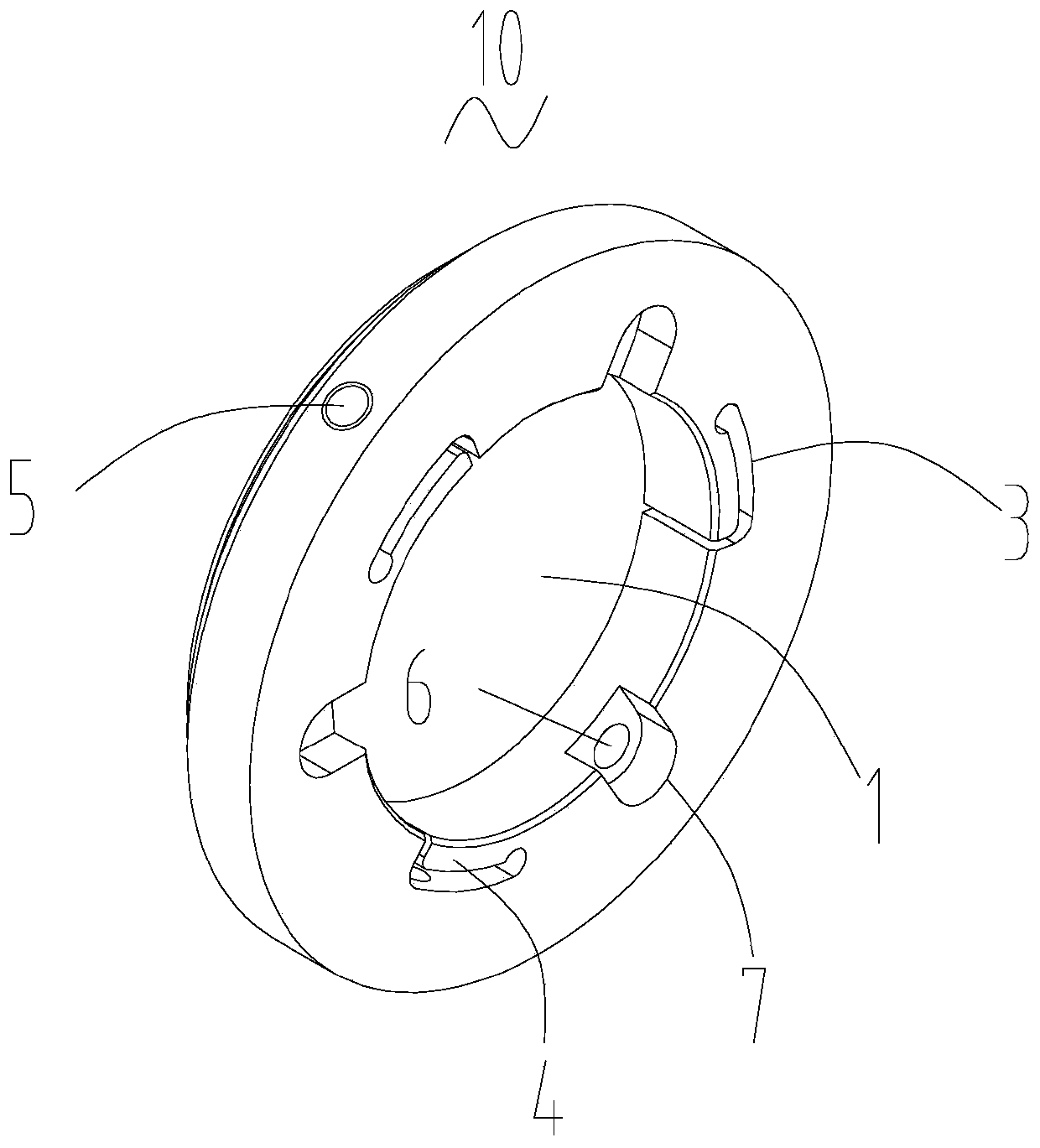

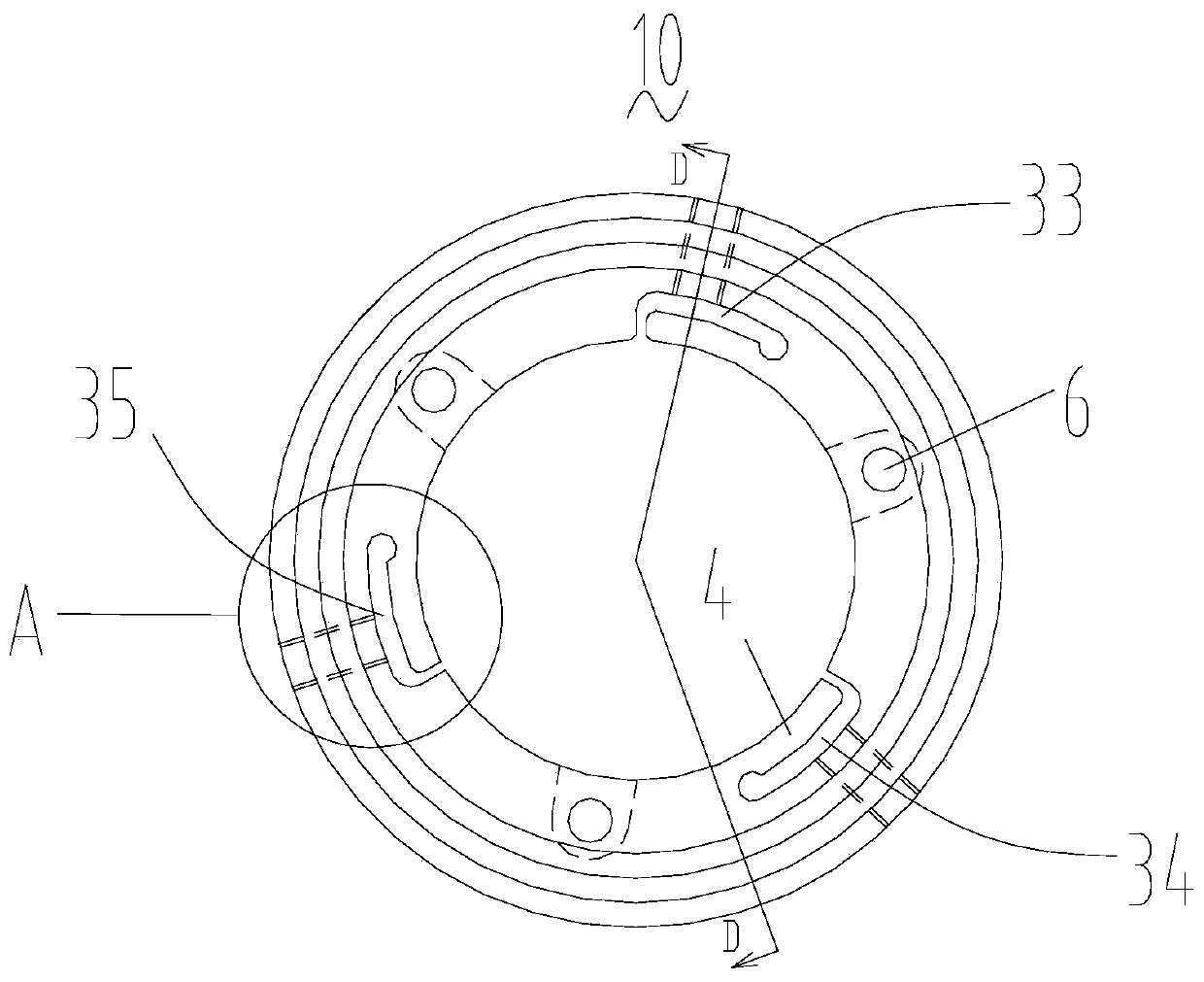

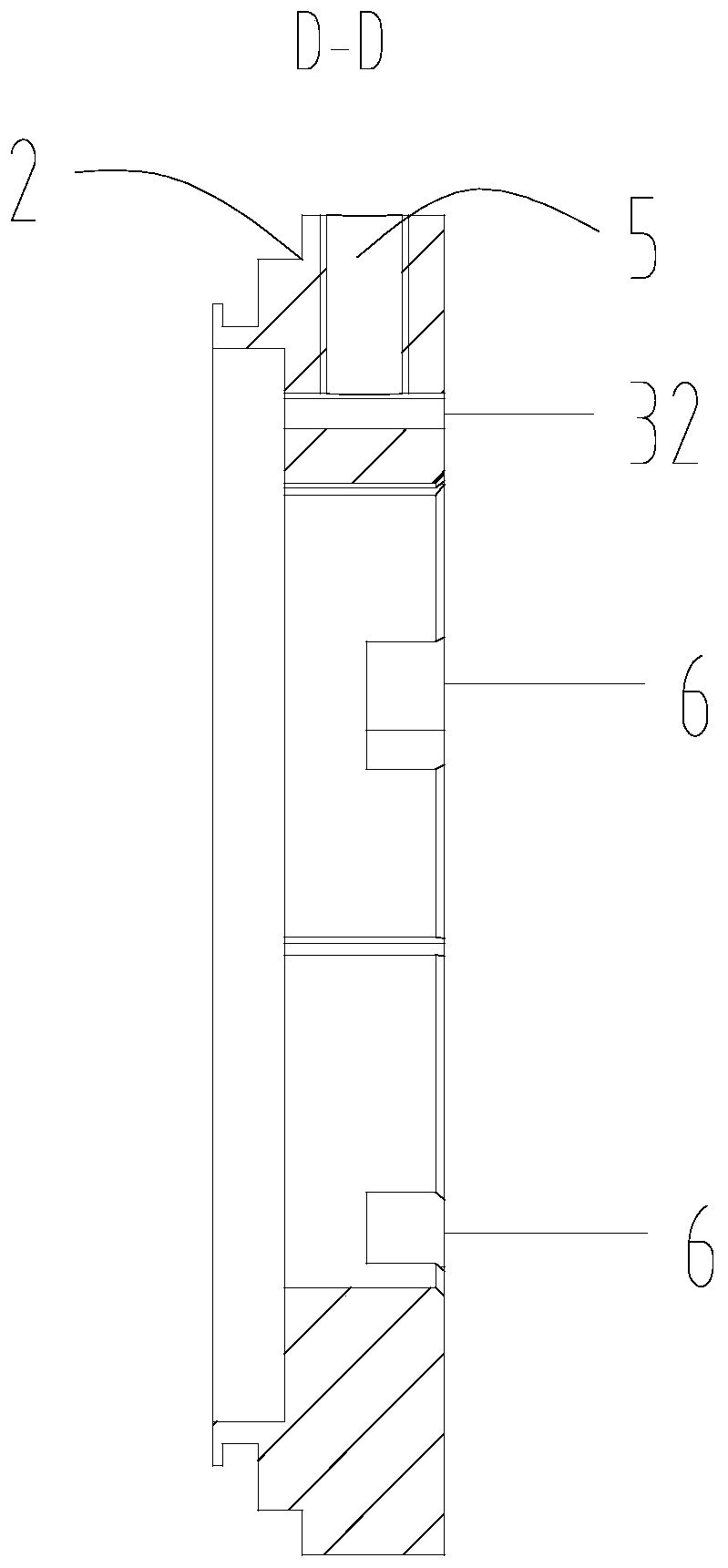

[0032] Such as Figure 1-7 As shown, the present invention provides an upper knife holder 10 of the upper knife shaft of the slitting machine, which includes a round hole 1 matched with the upper knife shaft and a card slot 2 for engaging the upper round knife. The upper knife holder 10 is close to At least one locking slit 3 is provided in the side area of the upper knife shaft. By setting the locking slit, a locking block that is integrally formed with the upper knife holder 10 and perfectly matched with the upper knife shaft is formed on the upper knife holder 10. 4. Instead of the existing separately set fixed block, on the one hand, the degree of cooperation between the upper tool holder 10 and the upper tool shaft is greatly improved, thereby effectively improving the locking degree and firmness of the upper tool holder 10 and the upper tool shaft; on the other hand On the one hand, the processing steps of the upper tool holder 10 are effectively reduced, and the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com