Longitudinal cutting device of paper cutter and control method of longitudinal cutting device

A technology of a slitting device and a paper cutter, which is applied in the control of using feedback, transportation and packaging, and sending objects, etc., can solve the problems of easily damaged tool rest, inconvenient adjustment, etc., to reduce labor intensity, improve adjustment accuracy, The effect of high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

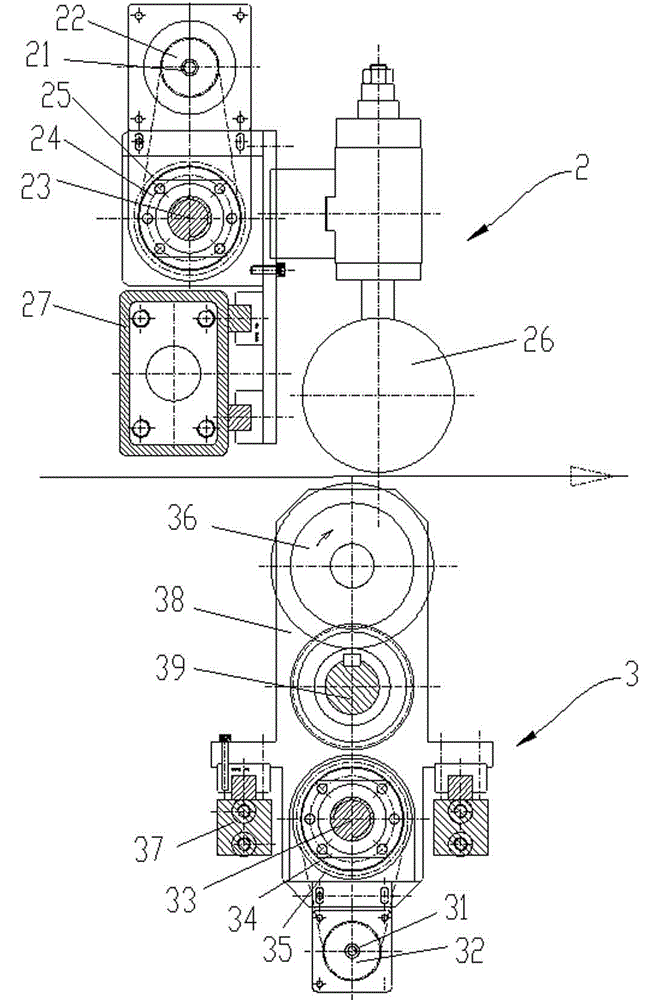

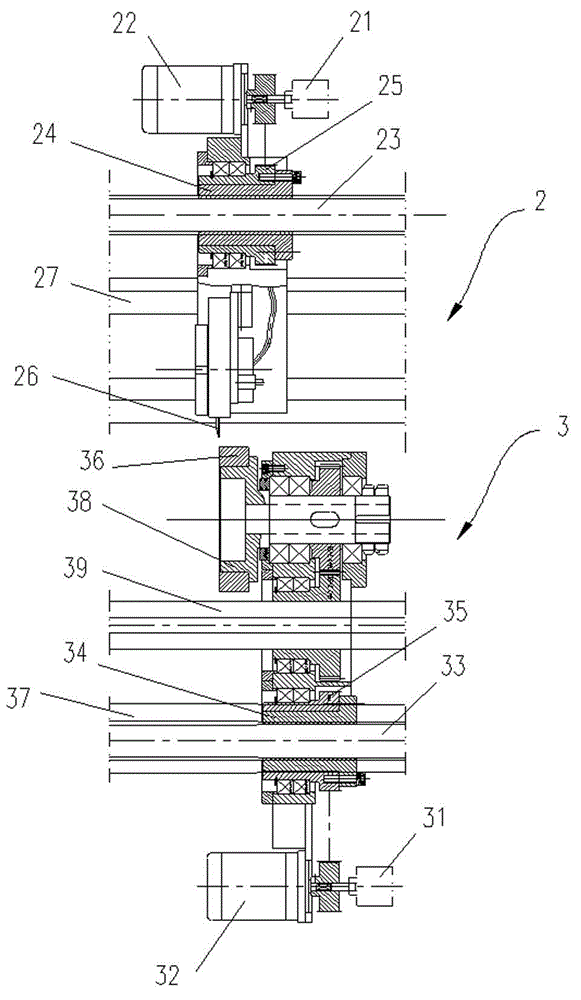

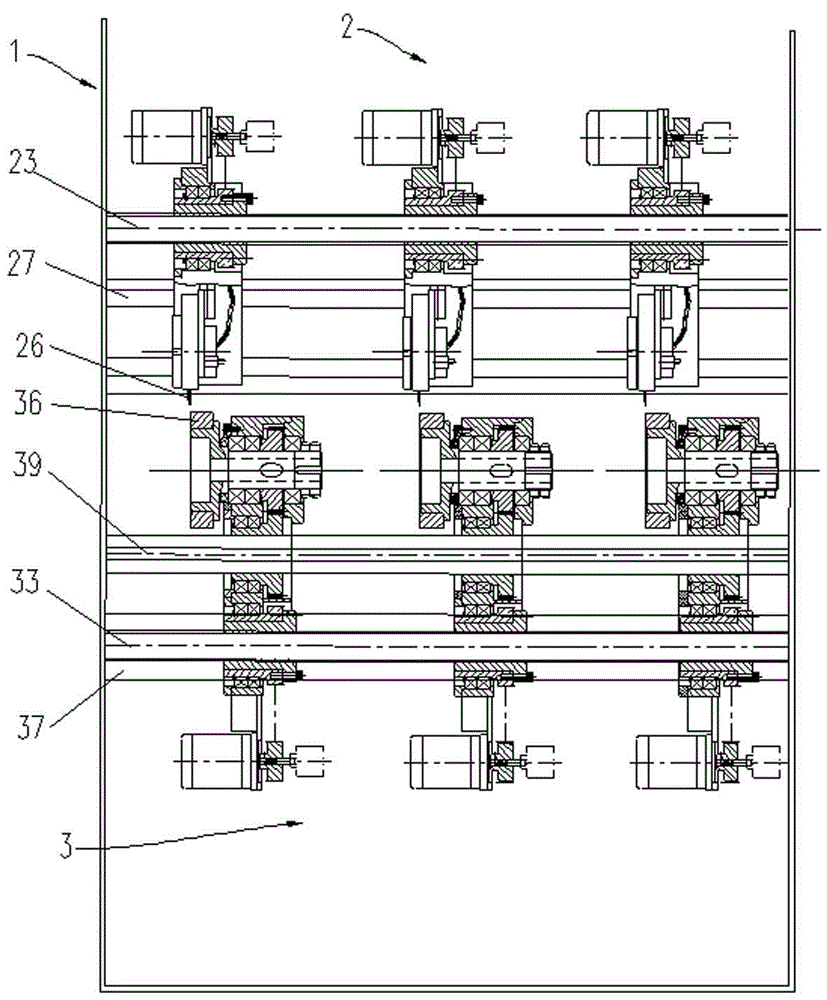

[0031] Refer to attached figure 1 As shown in -3, a slitting device of a paper cutter, including:

[0032] Rack 1; and

[0033] The upper cutter device 2 includes an upper motor 22 with an upper encoder 21, an upper ball screw 23 extending perpendicular to the conveying direction of the paper and fixedly arranged on the frame 1, and an upper ball screw 23 arranged on the upper ball screw 23 and The upper nut 24 driven and rotated by the upper motor 22, the upper sleeve 25 sleeved on the upper nut 24, the upper cutter 26 fixedly arranged on the upper sleeve 25 and located above the paper surface, and the upper nut 24 opposite to the upper ball During the rotation of the screw mandrel 23, the upper bushing 25 slides along the conveying direction perpendicular to the paper, and the upper encoder 21 is used to detect the position of the upper cutter 26 and convert the position data into a digital signal; and

[0034] An upper control device, which is used to receive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com