Automatic slitting machine for auxiliary material of flexible circuit board

A technology of flexible circuit and board accessories, applied in metal processing and other directions, can solve the problems of only cutting out, thickness limitation, etc., and achieve the effect of high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

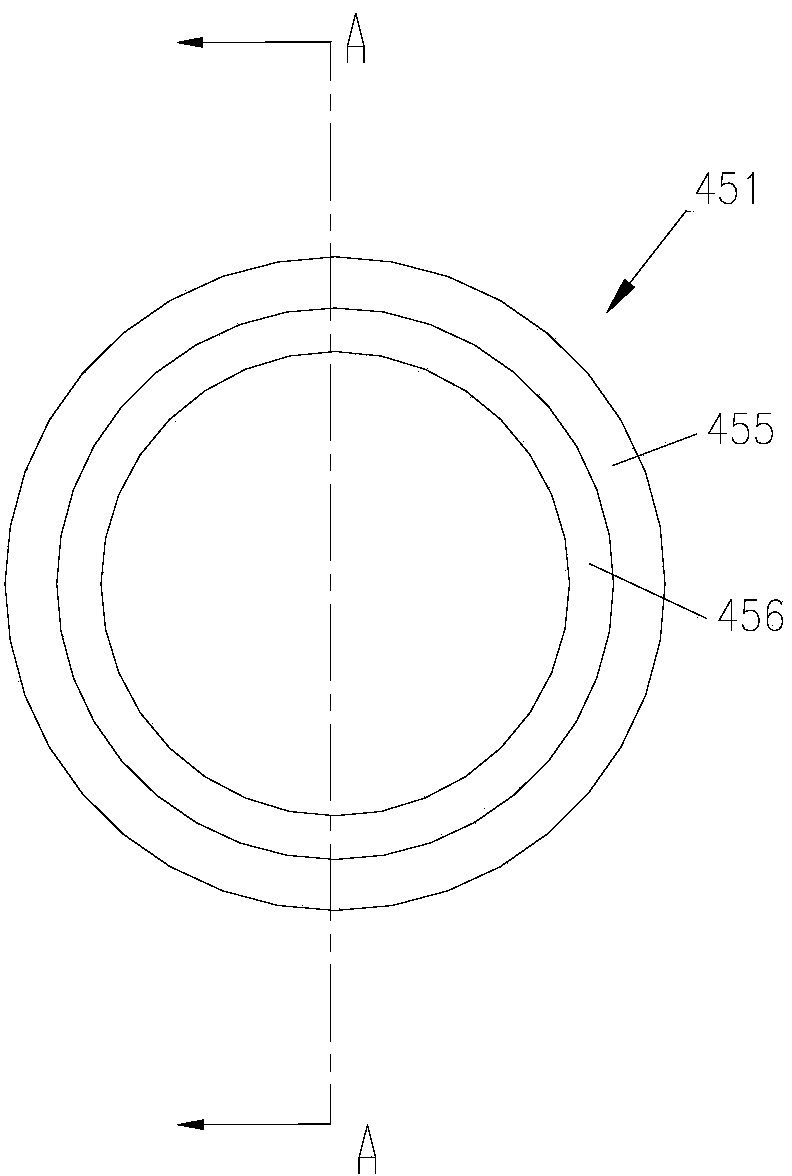

[0038] The invention provides an automatic cutting machine for auxiliary materials of flexible circuit boards, such as Figure 20 As shown, it includes a base 1 and a control device, and the base 1 is provided with a power unit, a driving device, a discharging mechanism 2, a feeding mechanism 3, a cutting mechanism 4 and a receiving mechanism 5, such as Figure 15 As shown, the cutting mechanism 4 includes a knife shaft 41 and a knife set 42 through which the knife shaft 41 passes through. The knife set 42 includes an upper knife set 43 and a lower knife set 44. The upper knife set 43 consists of several Each unit knife set 45 is composed of an annular upper spacer 46a arranged between every two adjacent unit knife sets 45 , and the unit knife set 45 includes a card seat 451 , an upper annular circular knife 452 and a snap ring 454 . The lower knife group 44 is composed of several lower annular circular knives 441 and an annular lower spacer 46b arranged between every adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com