Air cylinder pushing type device for cutting carbon fiber prepreg and method

A carbon fiber prepreg, push-type technology, applied in metal processing and other directions, can solve the problem of low cutting accuracy, and achieve the effects of increasing device flexibility, improving reliability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

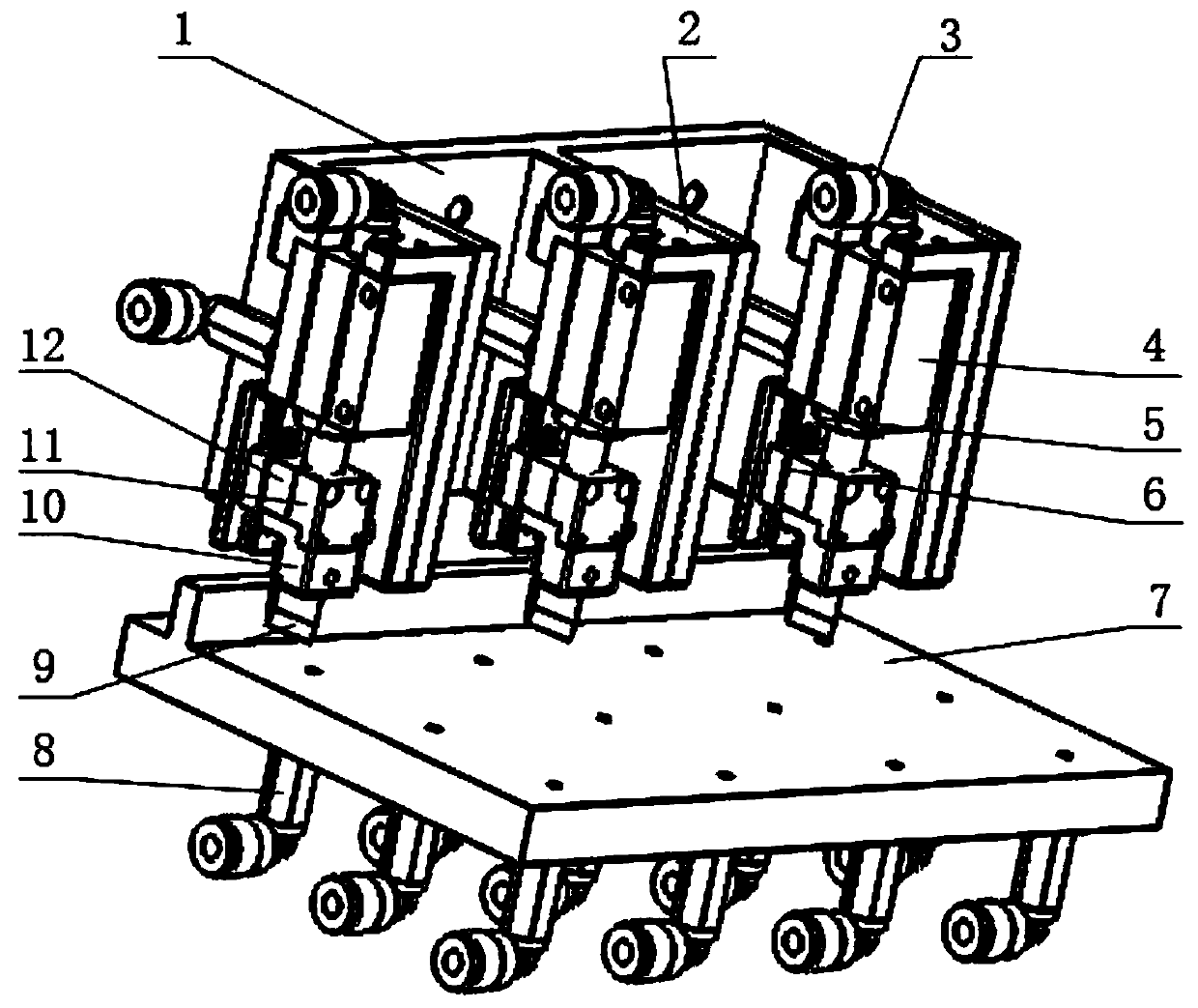

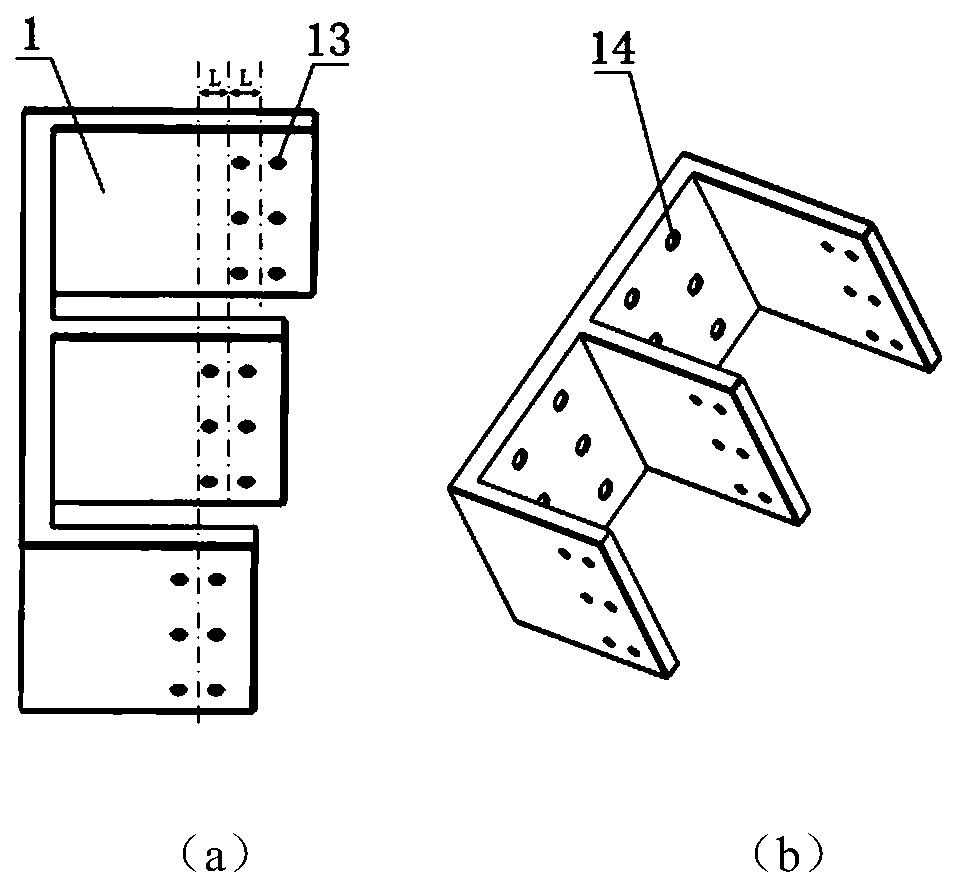

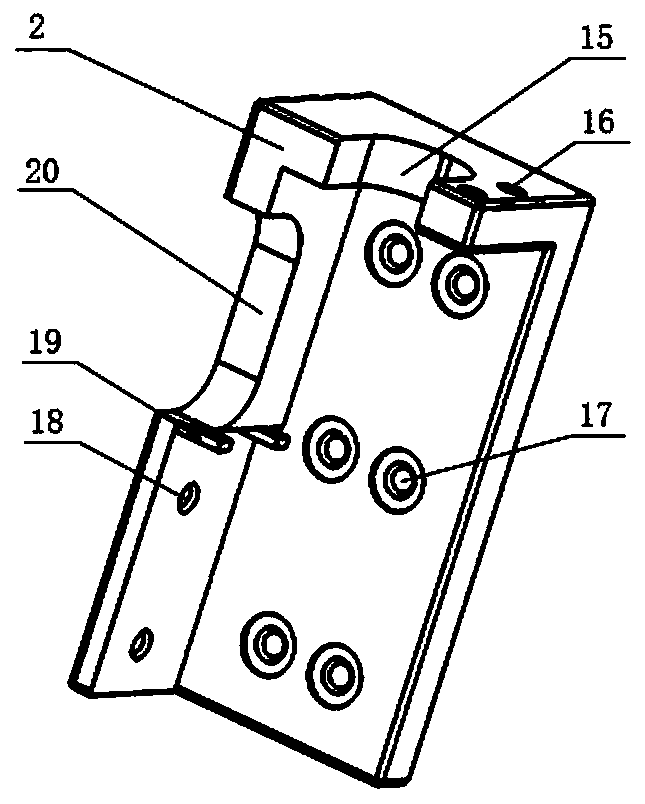

[0038] see figure 1 , the device of the cylinder pushing type slitting carbon fiber prepreg of the present invention includes components such as a component mounting plate 1, a cylinder guide rail connector 2, a cylinder 4, a slitting knife 9 and a slitting anvil 7; wherein, see figure 2 , The component mounting plate 1 is provided with several bosses of different lengths. The present invention takes three bosses as an example for illustration, and the number of bosses can be determined according to specific conditions. Each boss is provided with some boss holes 13, the boss holes 13 on each boss are dislocated with the boss holes 13 on the adjacent boss, and the boss holes 13 on each boss are aligned with the adjacent boss holes. The distance between the boss hole 13 on the adjacent boss along the length direction of the boss is L, and the width of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com