Printing method and equipment for test paper

A technology of printing equipment and printing method, applied in printing, printing press, letterpress printing and other directions, can solve problems such as increasing the cost of test paper, and achieve the effect of reducing production cost, simplifying process, and printing accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

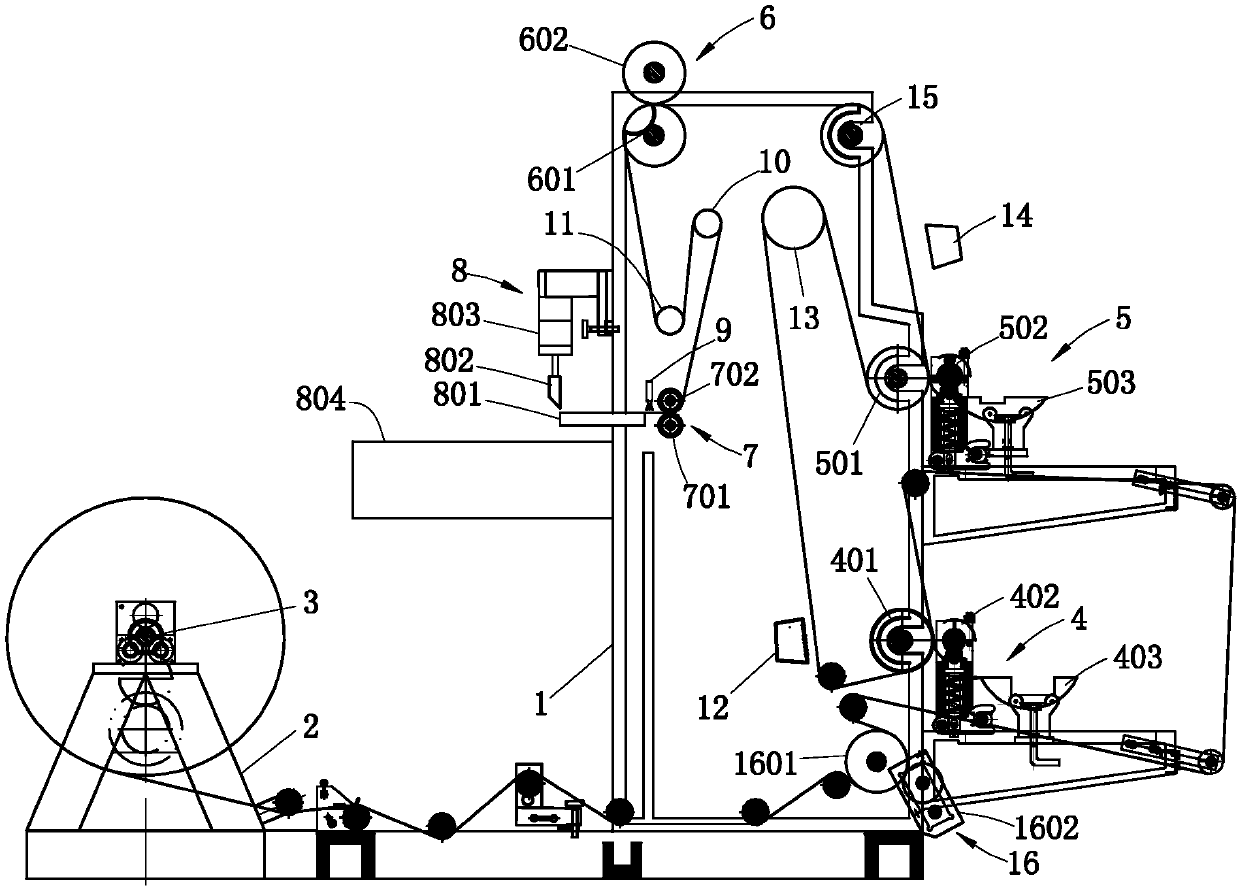

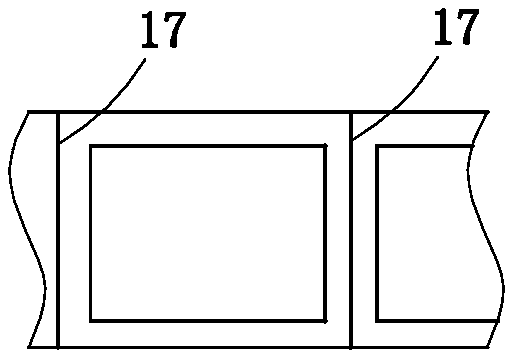

[0039] Such as figure 1 As shown, the present invention provides a kind of test paper printing method, comprises the following steps of implementing in sequence: (1) unwinding, paper roll is placed on the uncoiling roller 3, and uncoiling roller 3 is rotated and installed on the uncoiling support 2; (2) For printing, the front printing mechanism 4 and the reverse printing mechanism 5 are arranged on the frame 1 downstream of the unwinding support 2, the front printing mechanism 4 is located below the reverse printing mechanism 5, and the paper tape is wound through the front printing mechanism 4 and the reverse printing mechanism 5 in sequence , when printing the reverse side of the test paper, the identification tape 17 is printed in the middle of the blank space between the adjacent test papers, and the identification tape 17 is printed on the paper tape format position such as image 3 As shown; (3) traction, the top of the frame 1 is provided with a traction mechanism 6, u...

Embodiment 2

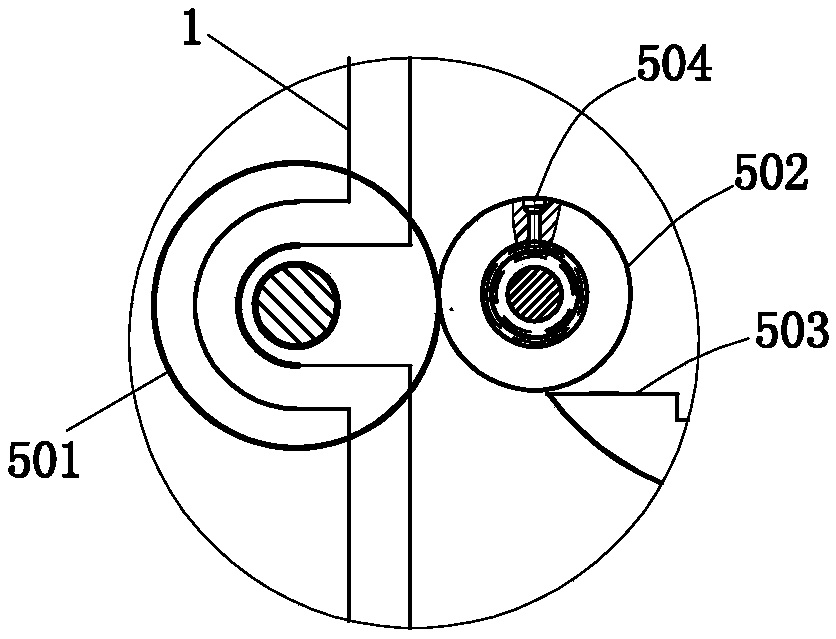

[0047] Such as figure 1 As shown, the present invention provides a kind of examination paper printing equipment, comprises frame 1, is characterized in that: the bottom of frame 1 is fixedly installed with uncoiling support 2, uncoiling support 2 is rotatably installed with uncoiling roller 3, and uncoiling roller 3 connects the first A power unit; along the paper tape transmission direction, the downstream of the unwinding roller 3 is provided with a front printing mechanism 4, and the downstream of the front printing mechanism 4 is provided with a reverse printing mechanism 5, and the reverse printing mechanism 5 is located above the front printing mechanism 4, and the reverse printing mechanism The downstream of 5 is provided with a traction mechanism 6, and the traction mechanism 6 is arranged on the top of the frame 1. Under the traction of the traction mechanism 6, the paper tape is sequentially wound by the unwinding roller 3 through the front printing mechanism 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com