Patents

Literature

44results about How to "Solve the problem of misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

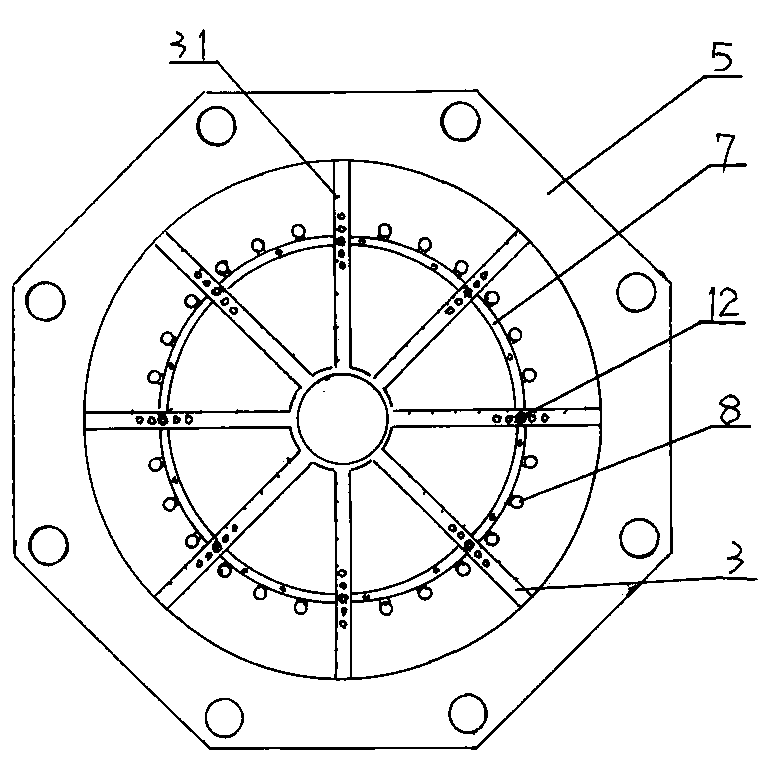

Two-dimensional point range type laser Doppler speed measurement device

ActiveCN103777034ARealize measurementSolve the problem of misalignmentDevices using time traversedElectromagnetic wave reradiationRotary stageBeam splitter

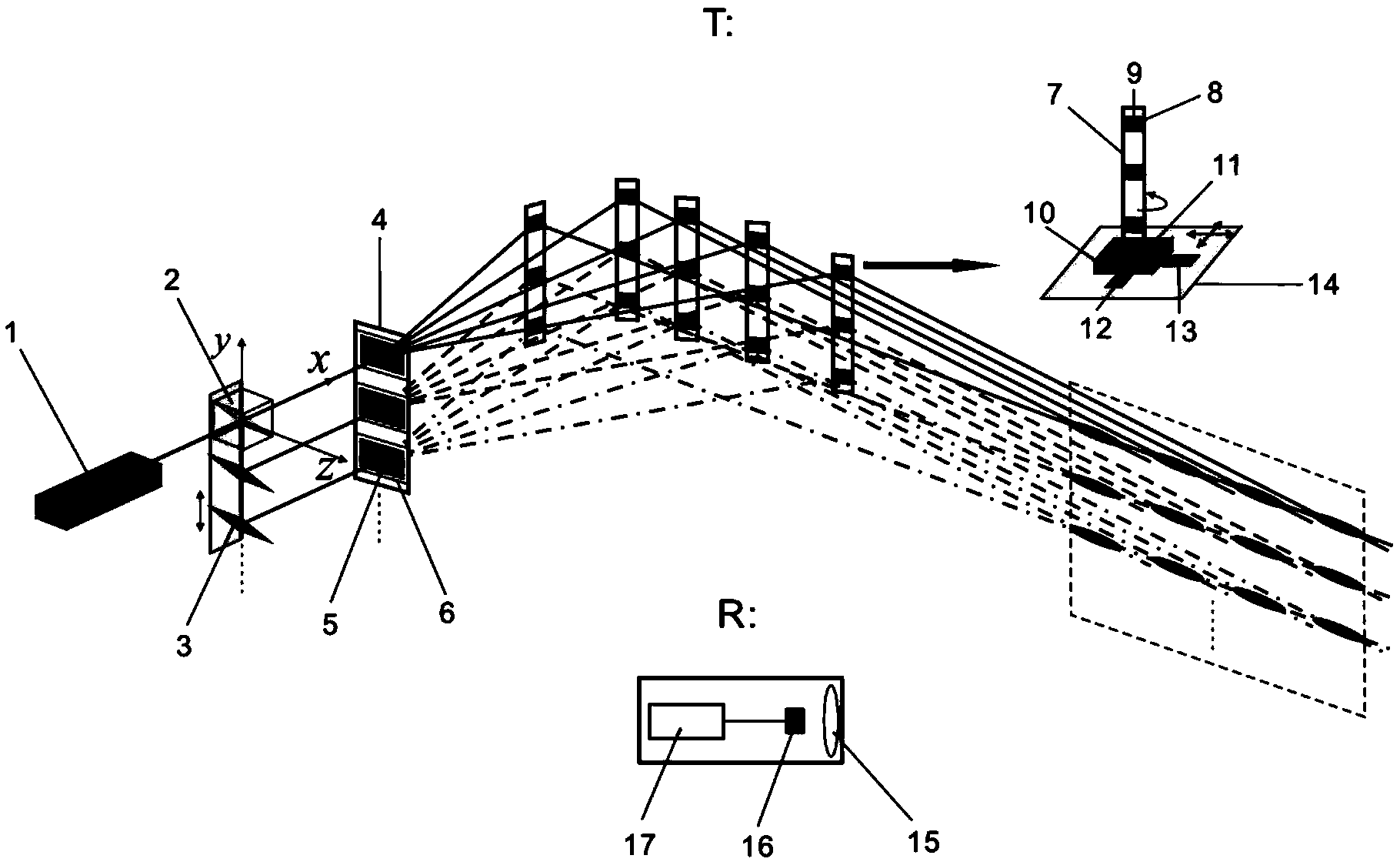

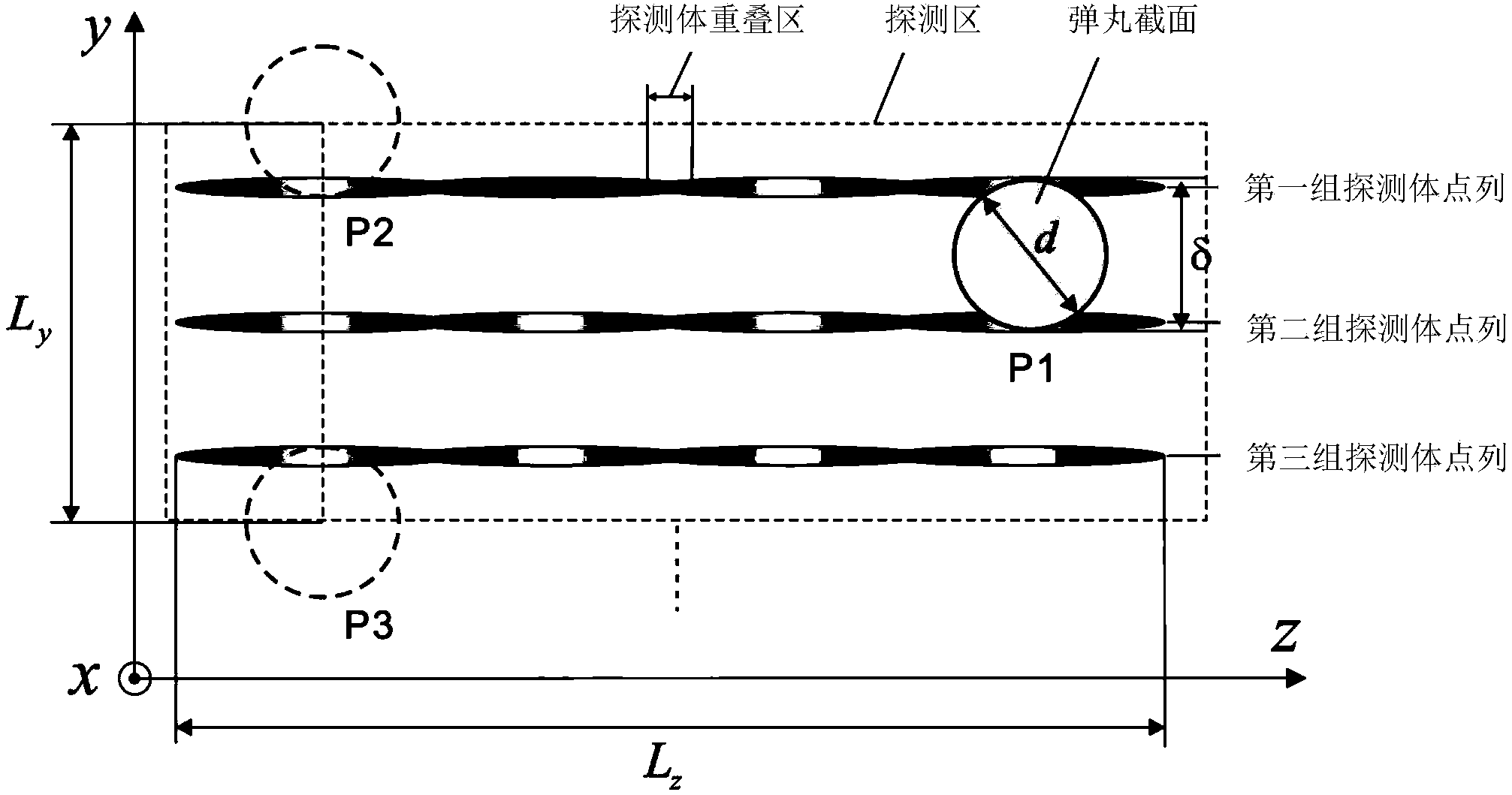

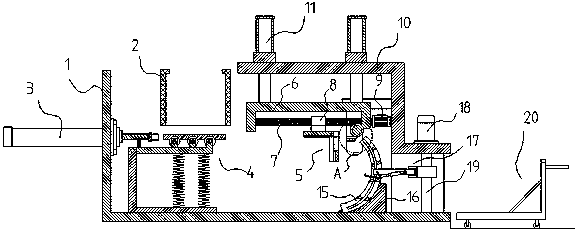

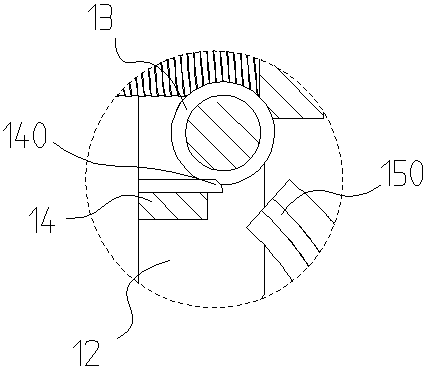

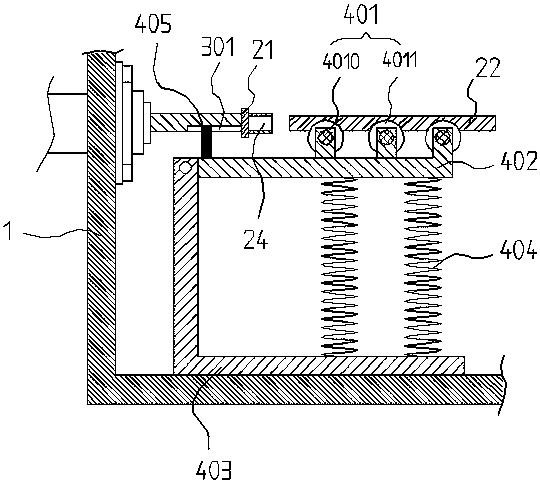

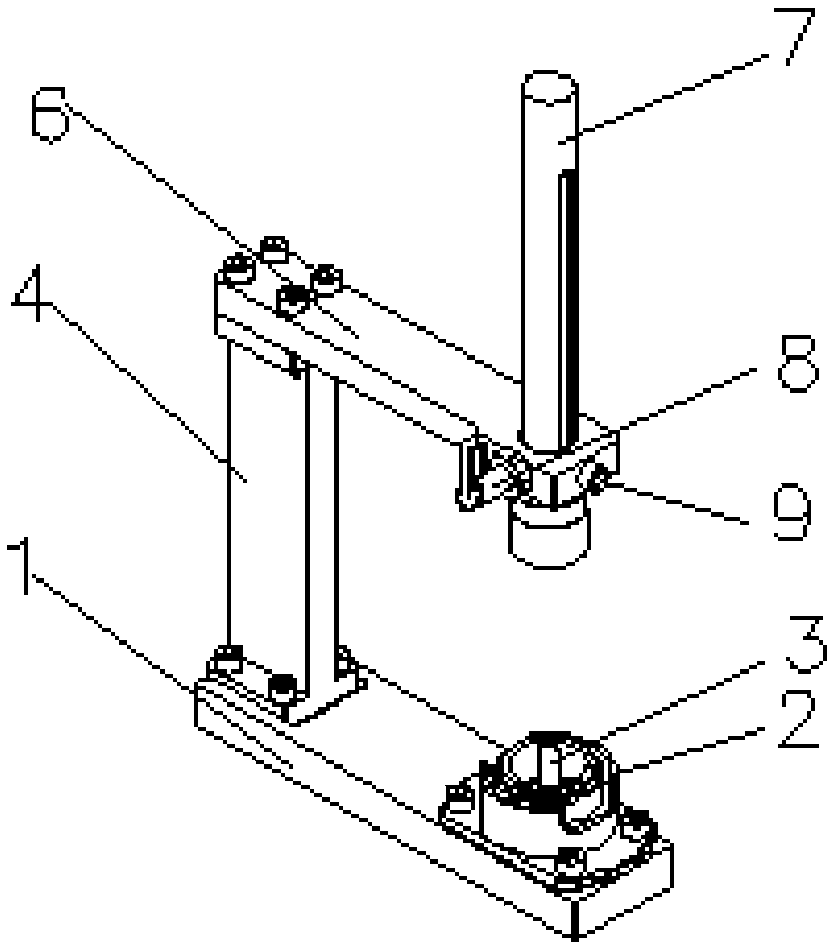

The invention discloses a two-dimensional point range type laser Doppler speed measurement device. The two-dimensional point range type laser Doppler speed measurement device comprises an emitting module and a receiving module. The emitting module comprises a single-frequency laser source (1), a beam splitter prism (2), a mobile beam splitting plate (3), a transmission type diffraction grating (5), a grating frame (6), a grating frame moving guide rail (4), a reflecting mirror (8), a reflecting mirror bracket (9), a reflecting mirror bracket moving guide rail (7), a horizontal moving table (10), a rotary table (11) and a vertical moving guide rail (12). The receiving module comprises a receiving lens (15), a probe (16) and a signal processing module (17), and is separated from the entire device. The two-dimensional point range type laser Doppler speed measurement device has the advantages of being capable of achieving measurement of the instantaneous speed of projectiles, solving the problem of misalignment caused by ballistic deflection when a single-point differential type Doppler system carries out measurement, and being high in system measurement accuracy, stable in structure and easy to adjust.

Owner:TIANJIN UNIV

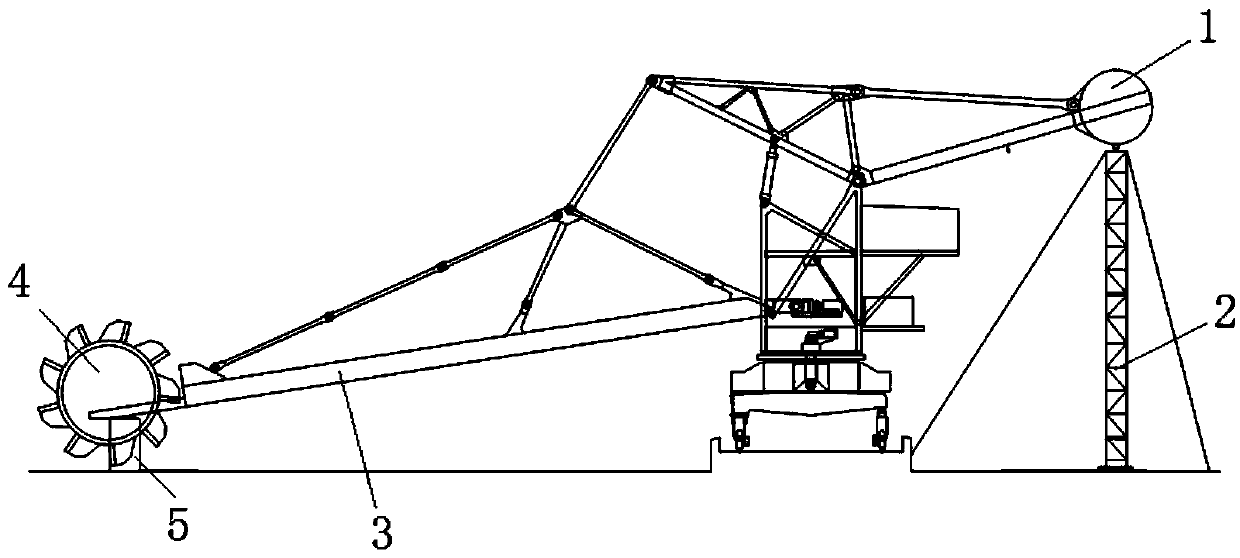

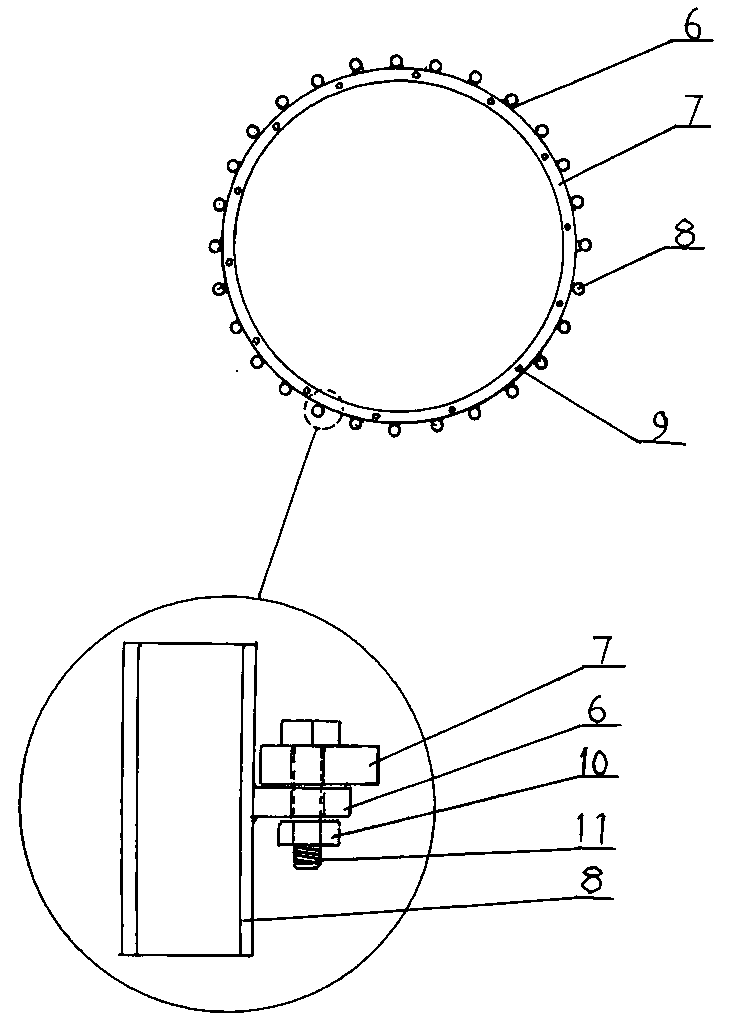

Replacement method of revolving bearing of material taking machine

ActiveCN104259738ARealize replacement workSolve the problem of misalignmentMetal working apparatusPower cableReplacement method

The invention discloses a replacement method of a revolving bearing of a material taking machine. The replacement method comprises the following steps: (1) a counterweight bracket is mounted; (2) an arm frame of the material taking machine and a counterweight are adjusted; and an arm frame bracket is arranged; (3) a gear ring protective cover, a central power cable and a central carriage are removed; a bearing bracket is welded; and a platform is built; (4) a jacking bracket is reinforced; and a jacking jack is placed; (5) a guide sleeve and an anti-tilting bracket are welded; (6) a bearing inner ring bolt is disassembled; and the upper body of the material taking machine is jacked; and (7) a plate is paved; a roller is placed; and a bearing is extracted out. The replacement method of the revolving bearing of the material taking machine, provided by the invention, is safe and effective, and effectively reduces the cost and difficulty of replacing the revolving bearing.

Owner:NORTHEASTERN UNIV

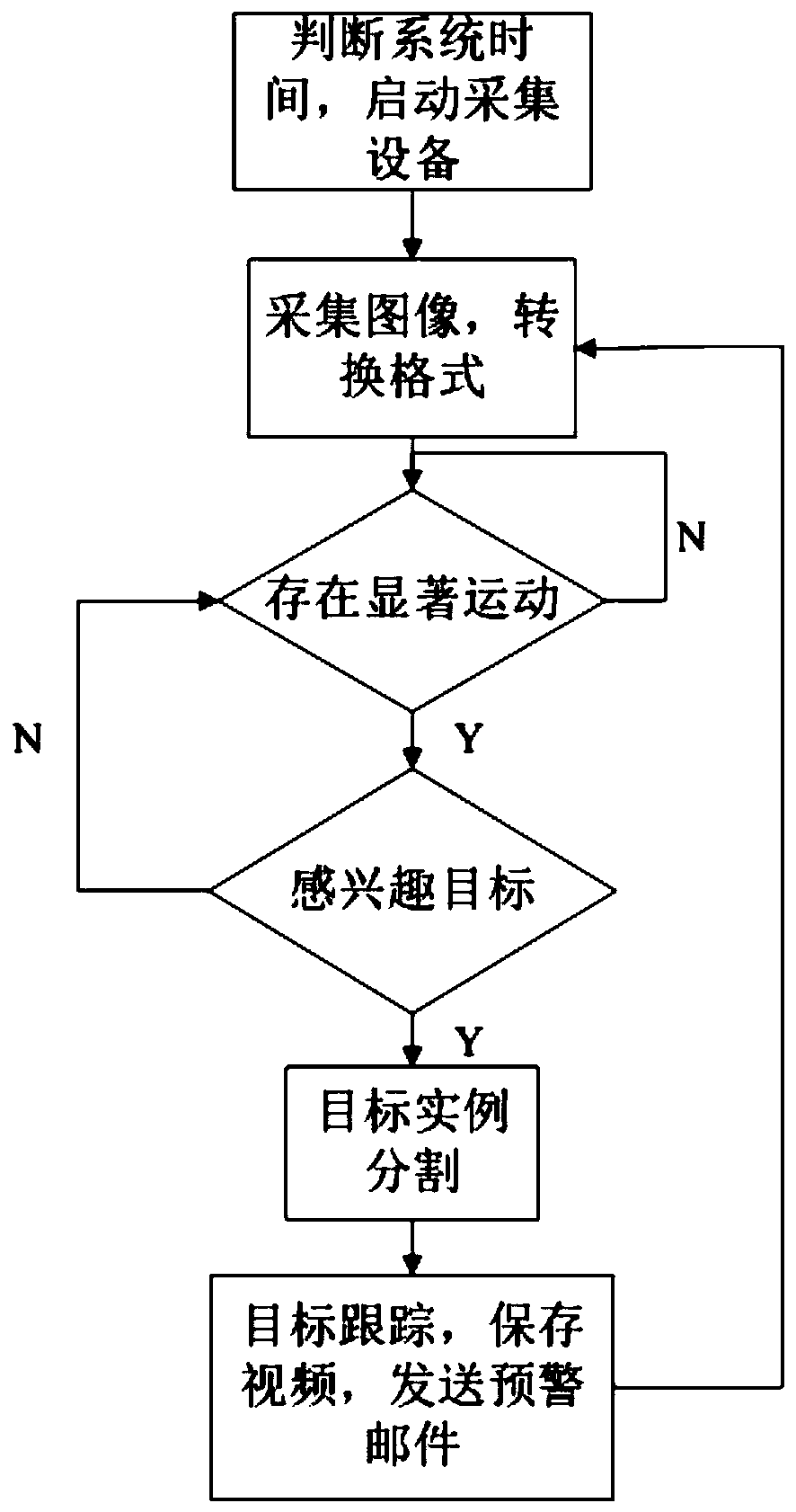

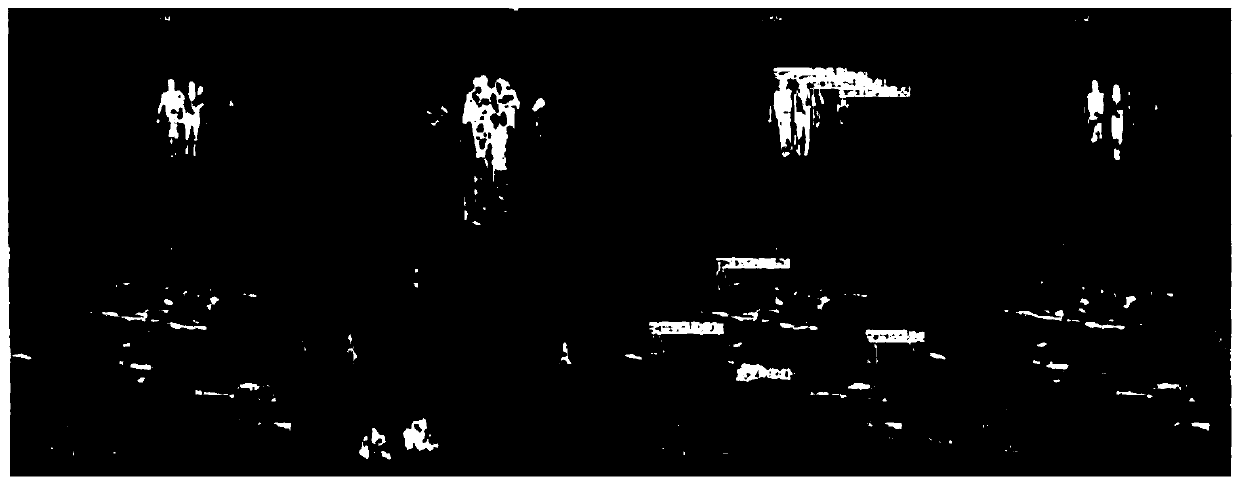

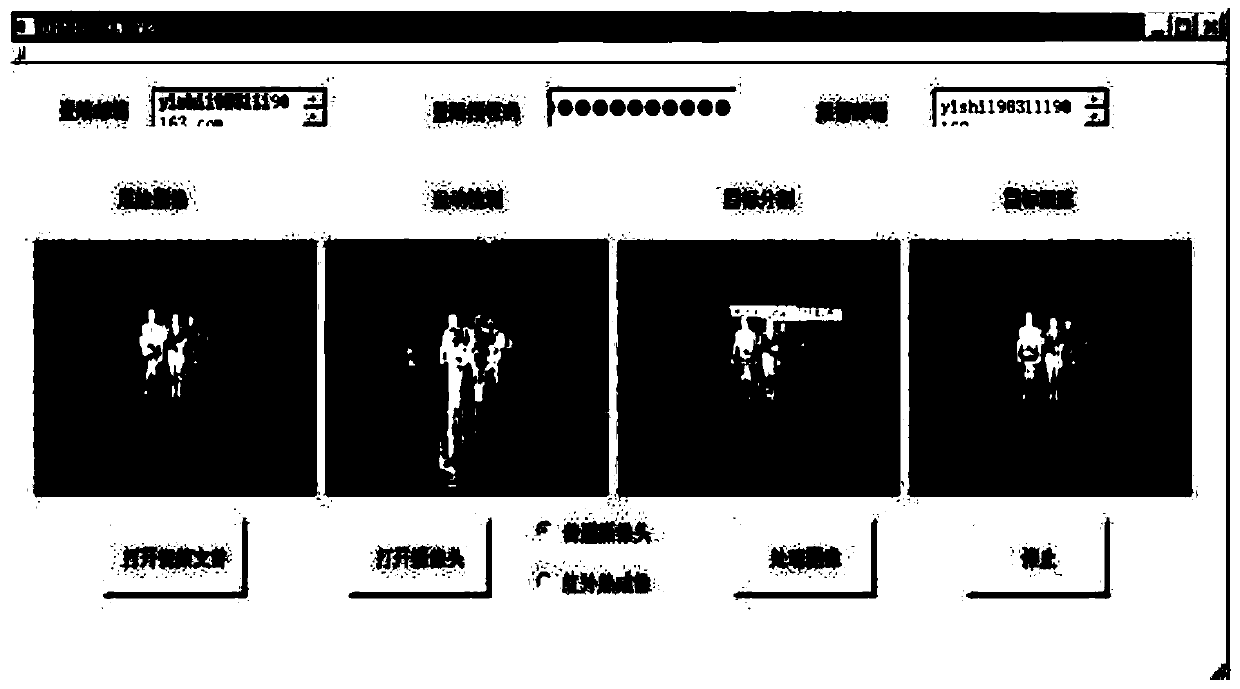

The invention discloses an AI thermal imaging all-weather intelligent monitoring method

InactiveCN109948474AImprove accuracyRealize 24/7 monitoringImage analysisCharacter and pattern recognitionThermographic cameraSmart surveillance

The invention discloses an AI thermal imaging all-weather intelligent monitoring method, which comprises a control module and comprises the following steps: S1, extracting the working time of a systemby the control module, and starting a high-definition camera or a thermal imager according to a preset time threshold section H; S2, the control module obtains thermal imaging or high-definition camera video data, and transcodes thermal imaging AV format video output into video images; S3, performing motion detection on the video image by using a motion detection algorithm; Setting a remarkable motion detection threshold, and judging whether the current motion is remarkable or not, so as to filter out false detection caused by noise and light and shadow changes; Meanwhile, the detected movingtarget is subjected to screenshot; And S4, performing interested target segmentation on the detected video image with significant motion by using an instance segmentation algorithm to determine whether the target causing the current motion is a monitoring target interested in the system, and entering the next step if the segmentation result is the interested target.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

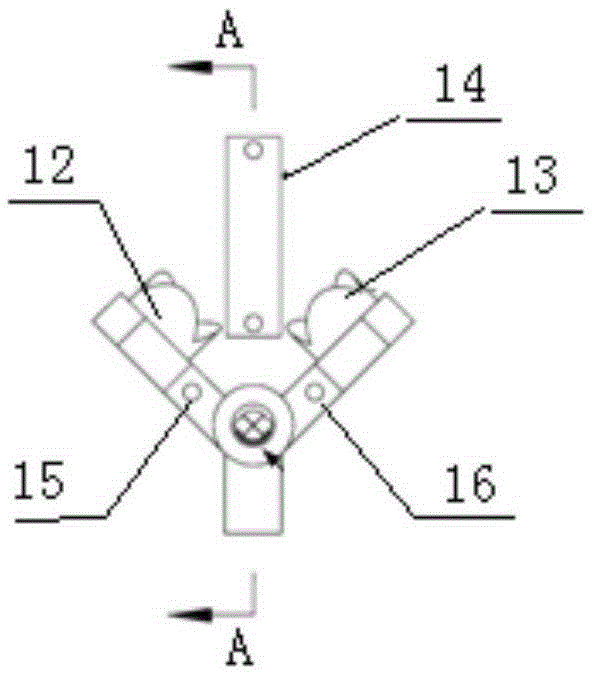

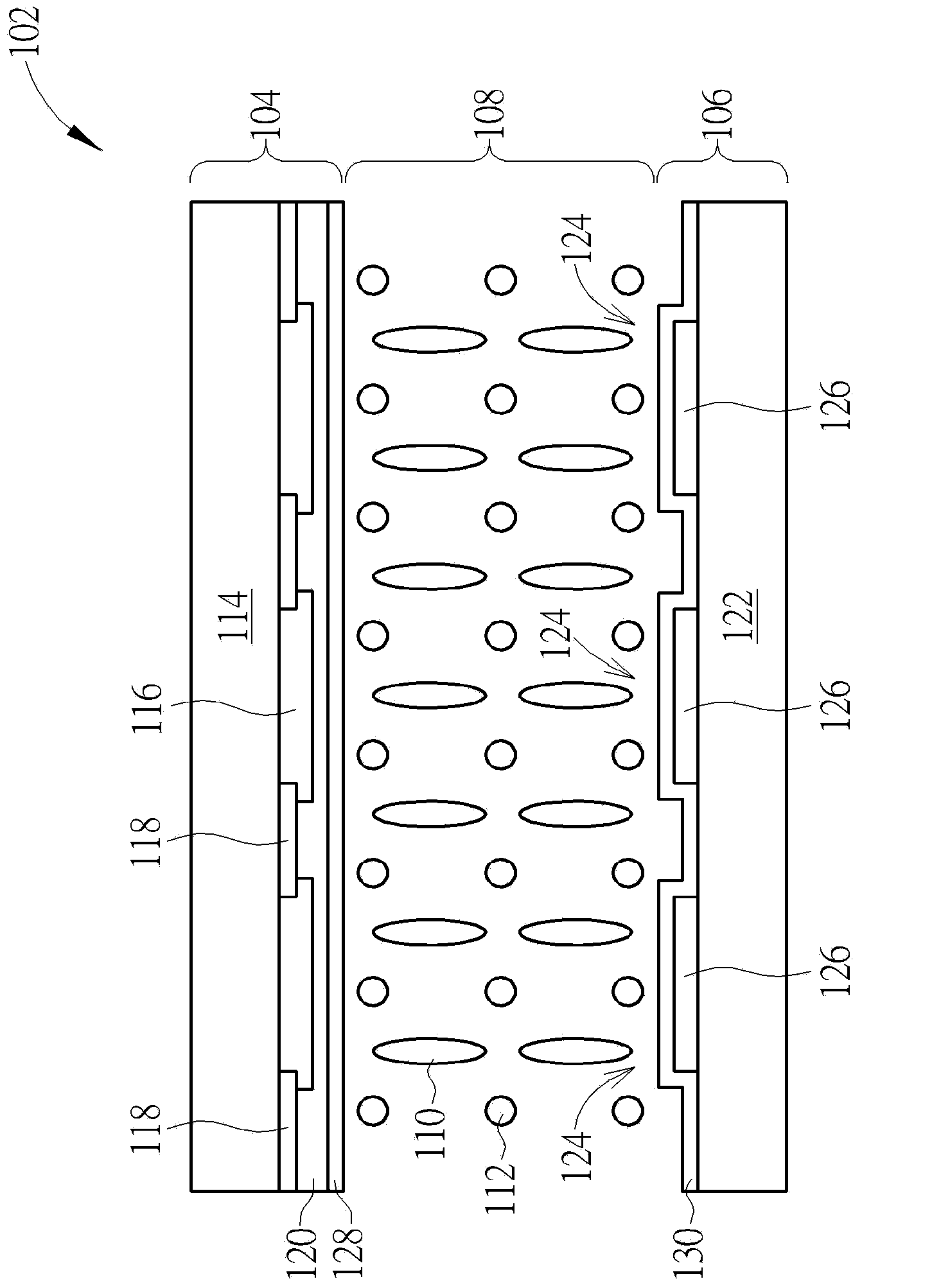

Bridge pile foundation on-site-binding reinforcement cage deviation control formwork and construction method thereof

PendingCN110468831ASolve the problem of misalignmentStrong enduranceBulkheads/pilesRebarBuilding construction

The invention belongs to a bridge pile foundation on-site-binding reinforcement cage deviation control formwork and a construction method thereof. The bridge pile foundation on-site-binding reinforcement cage deviation control formwork includes a fixed plate panel, a fixed plate supporting frame, a fixed reinforcement cage positioning plate, a mobile reinforcement cage positioning plate, a reinforcement cage positioning arc plate and a reinforcement sleeve assembly. The construction method includes the steps that the bottom of the on-site-binding reinforcement cage in a column is fixed by thefixed reinforcement cage positioning plate and reinforcement sleeves, the top of the on-site-binding reinforcement cage in the column is fixed by the mobile reinforcement cage positioning plate and the reinforcement cage positioning arc plate and reinforcement sleeves, and construction of various column bodies with different diameters is completed by changing the diameters of the mobile reinforcement cage positioning plate and the reinforcement cage positioning arc plate, and the positions of the reinforcement sleeves corresponding to the diameter of the variable diameter reinforcement cage. The bridge pile foundation on-site-binding reinforcement cage deviation control formwork can effectively control, correct and is suitable for the deviation of the on-site-binding reinforcement cage ofpile foundations with different diameters and has the advantages of simple structure, high construction speed, good quality, low production and use cost, less time and labor, and wide applicability.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

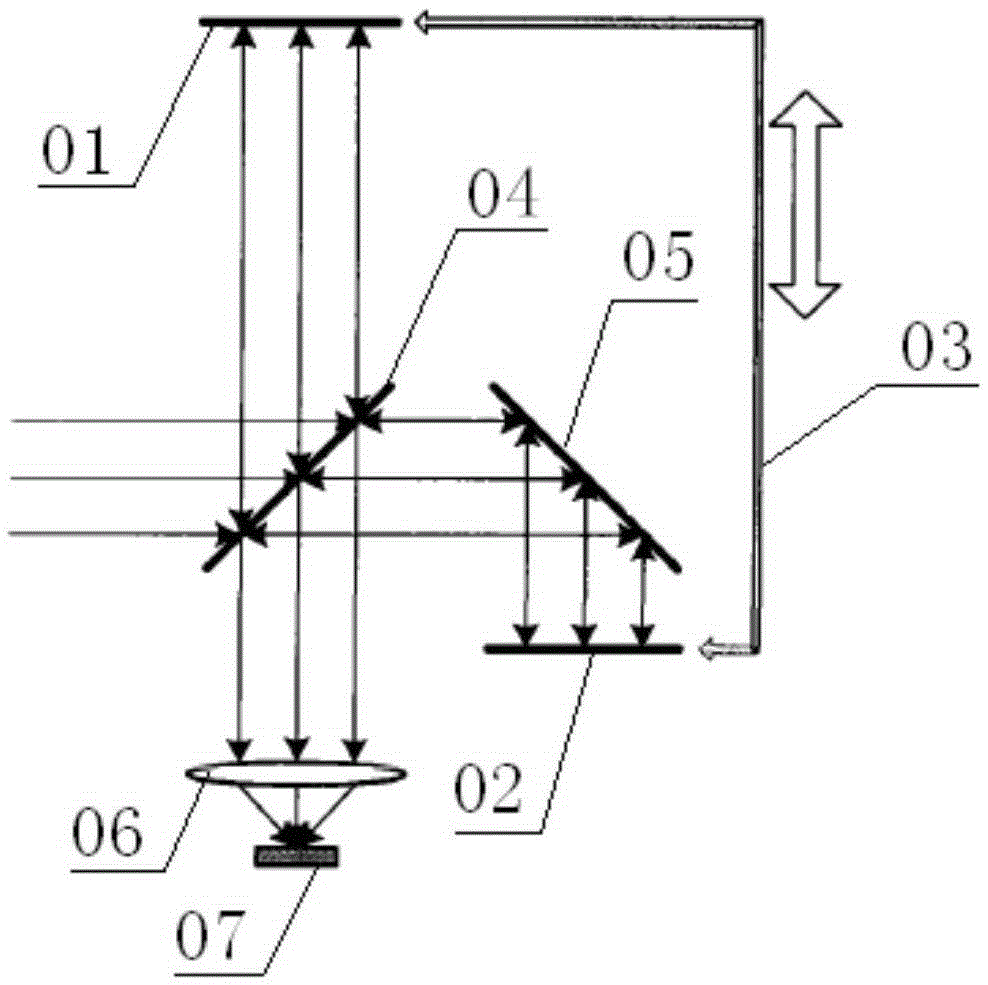

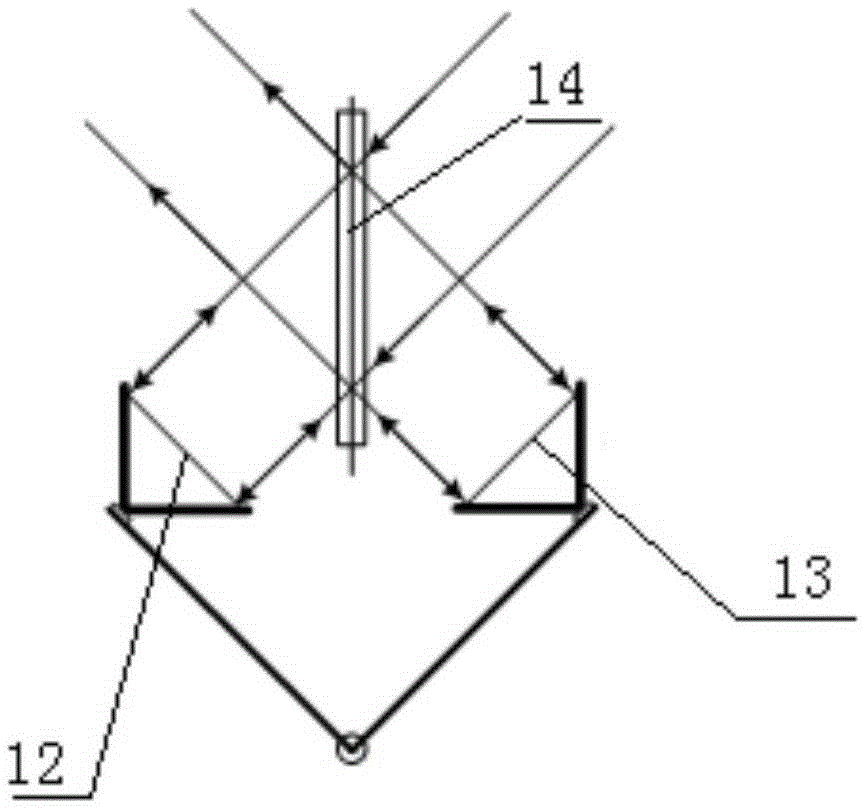

Interference device and spectrometer comprising same

InactiveCN105387935AImplement tilt correctionSolve the problem of misalignmentInterferometric spectrometryBeam splitterPlane mirror

The invention discloses an interference device and a spectrometer comprising the interference device. The interference device comprises a housing, a swing arm, a first solid angle mirror, a second solid angle mirror and a beam-splitter mirror, wherein the swing arm is swingably arranged to the housing through a pivot, and the swing arm comprises a first arm portion and a second arm portion, which are fixedly together; the first solid angle mirror is arranged to the first arm portion; the second solid angle mirror is arranged to the second arm portion; and the beam-splitter mirror is arranged between the first solid angle mirror and the second solid angle mirror, and splits the light rays into a first light beam and a second light beam, the first light beam being irradiated to the first solid angle mirror, and the second light beam being irradiated to the second solid angle mirror to enable the reflected first light beam and the second light beam to have interference. The interference device having the structure above can solve the problem that inclination of a plane mirror of an interferometer in the prior art cannot be corrected, and the problem of no-collimation can be prevented.

Owner:BEIJING SDL TECH

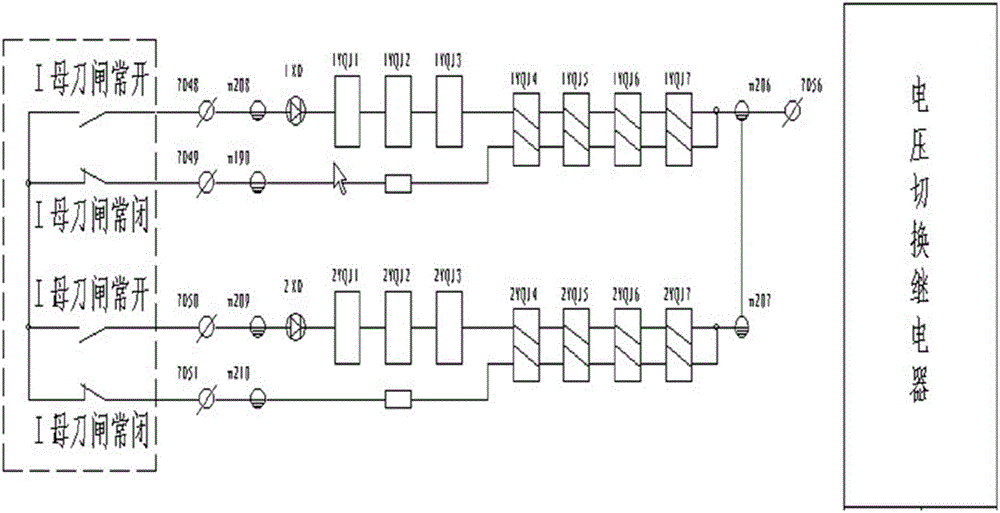

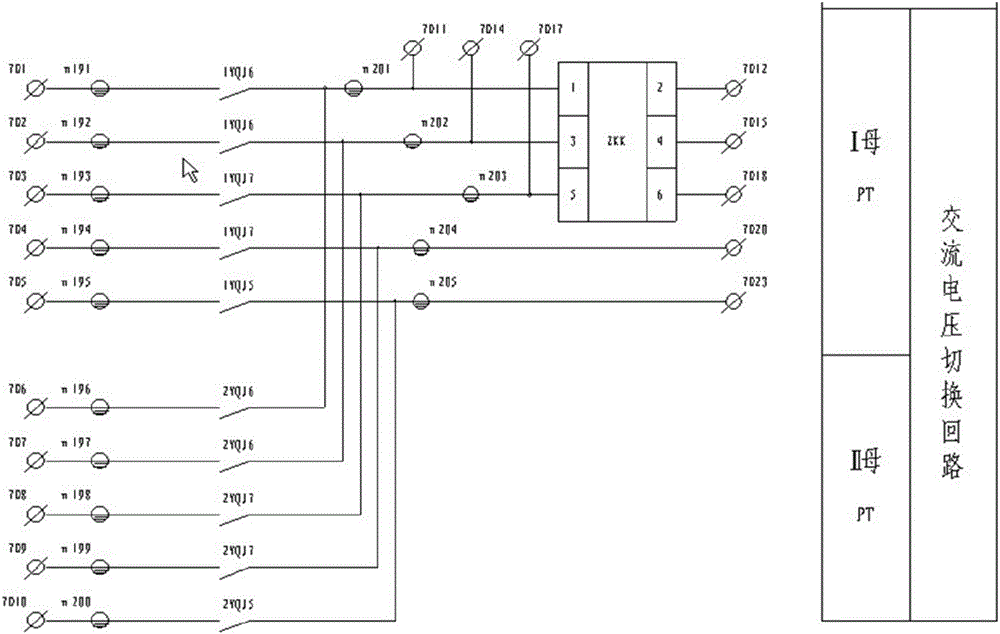

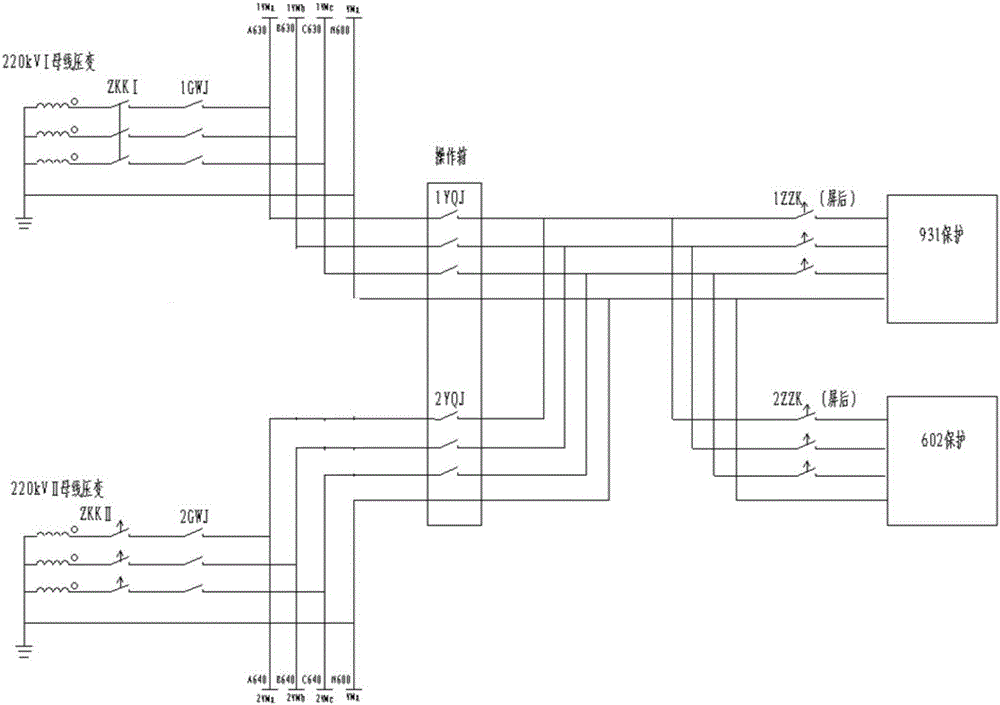

Double-bus line protection method and device of integrating voltage switching

ActiveCN106532656ASolve the problem of misalignmentEasy wiringEmergency protective circuit arrangementsEngineeringZero voltage switching

The invention discloses a double-bus line protection method and device of integrating voltage switching. The bus voltage of double buses directly enters a protection device sampling circuit; meanwhile, the position of a line knife switch is switched into the protection device as a switch-in quantity; an auxiliary contact of using the line knife switch directly enters the protection device for judgment of voltage switching; the protection device selects the bus voltage through logic judgment according to the position of the knife switch; and when the auxiliary contact of using the line knife switch is abnormal, the bus voltage can be selected by adopting a manually strong setting method. Through the design mode, the problem that false coordination can exist in the bus voltage is thoroughly solved; a special voltage switching device is omitted in line protection; the investment is reduced; meanwhile, connection of the protection device is simplified; and the reliability of the protection device is improved.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO

High-speed double-width wall paper linking line slitting photogravure press

ActiveCN104760406ASolve the problem of misalignmentRotation speed synchronizationRotary intaglio printing pressPhotogravurePrinting press

The invention discloses a high-speed double-width wall paper linking line slitting photogravure press. The high-speed double-width wall paper linking line slitting photogravure press comprises a frame; a left supporting base and a right supporting base are arranged on the frame; a cutter shaft rotated in relative to the frame and two space adjusting screw rods are mounted between the left supporting base and the right supporting base; one end of the cutter shaft is connected with a cutter shaft motor, and three lower cutters are installed on the cutter shaft, and three cutters include a left lower cutter, a right lower cutter and a middle lower cutter; the side of the lower cutter is provided with a pneumatic cutter matched up with the lower cutter; two space adjusting screw rods are screwed with linking plates, one end of each of the linking plate is connected with the left lower cutter or the right lower cutter, and the other end is connected with the pneumatic cutter matched up with the left lower cutter or the right lower cutter; the pneumatic cutter is installed on the cutter shaft. The structure needs not perform the secondary slitting by the slitter, thus the production efficiency is improved; the space adjusting screw rods are adjusted so as to adjust the slitting width, and the operation is convenient; the high-speed double-width wall paper linking line slitting photogravure press can effectively solve the problem of slitting misalignment of the double-width press due to the different flexibilities, and also prevent products from rough edges.

Owner:江门市智睿包装机械有限公司

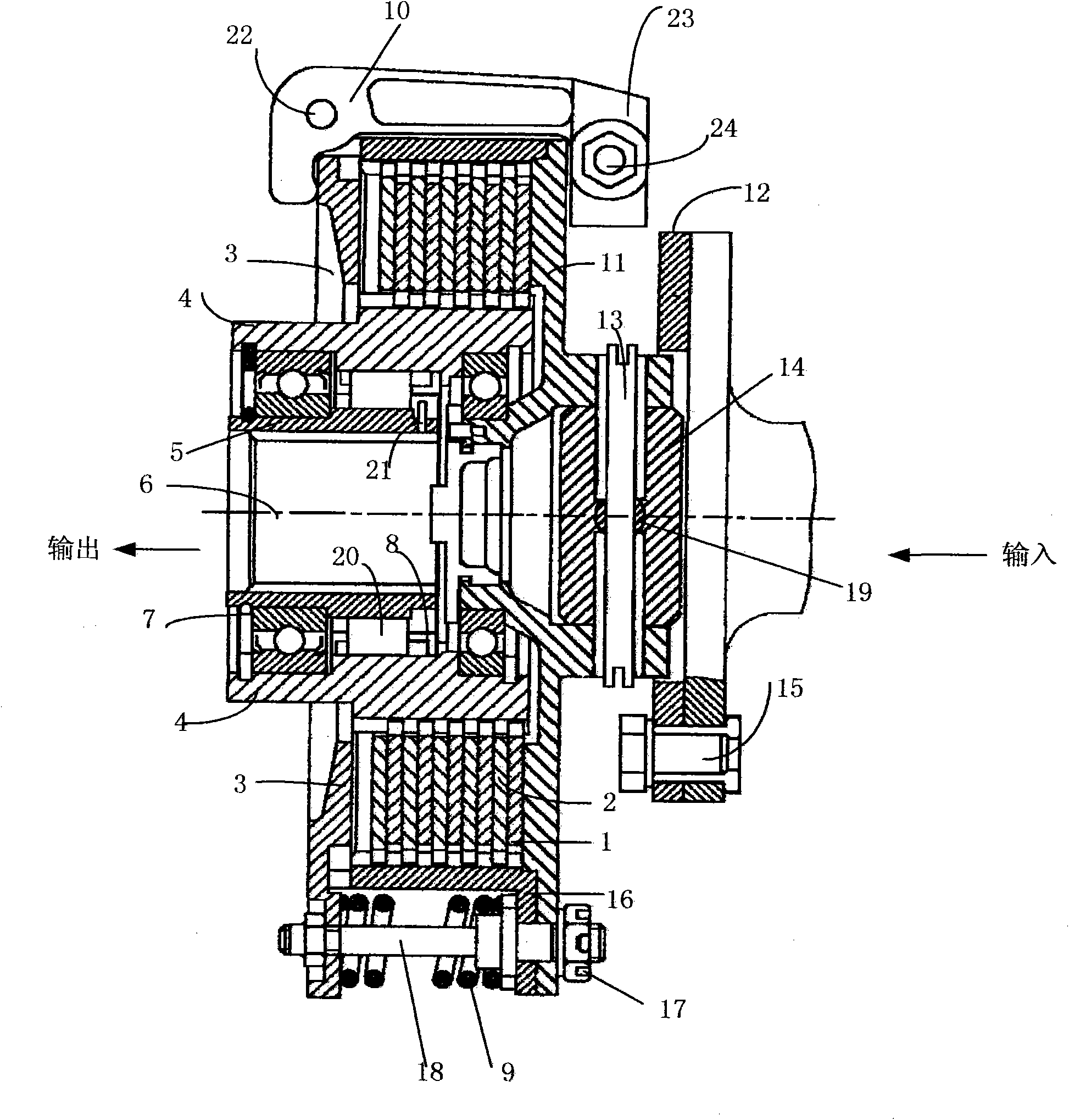

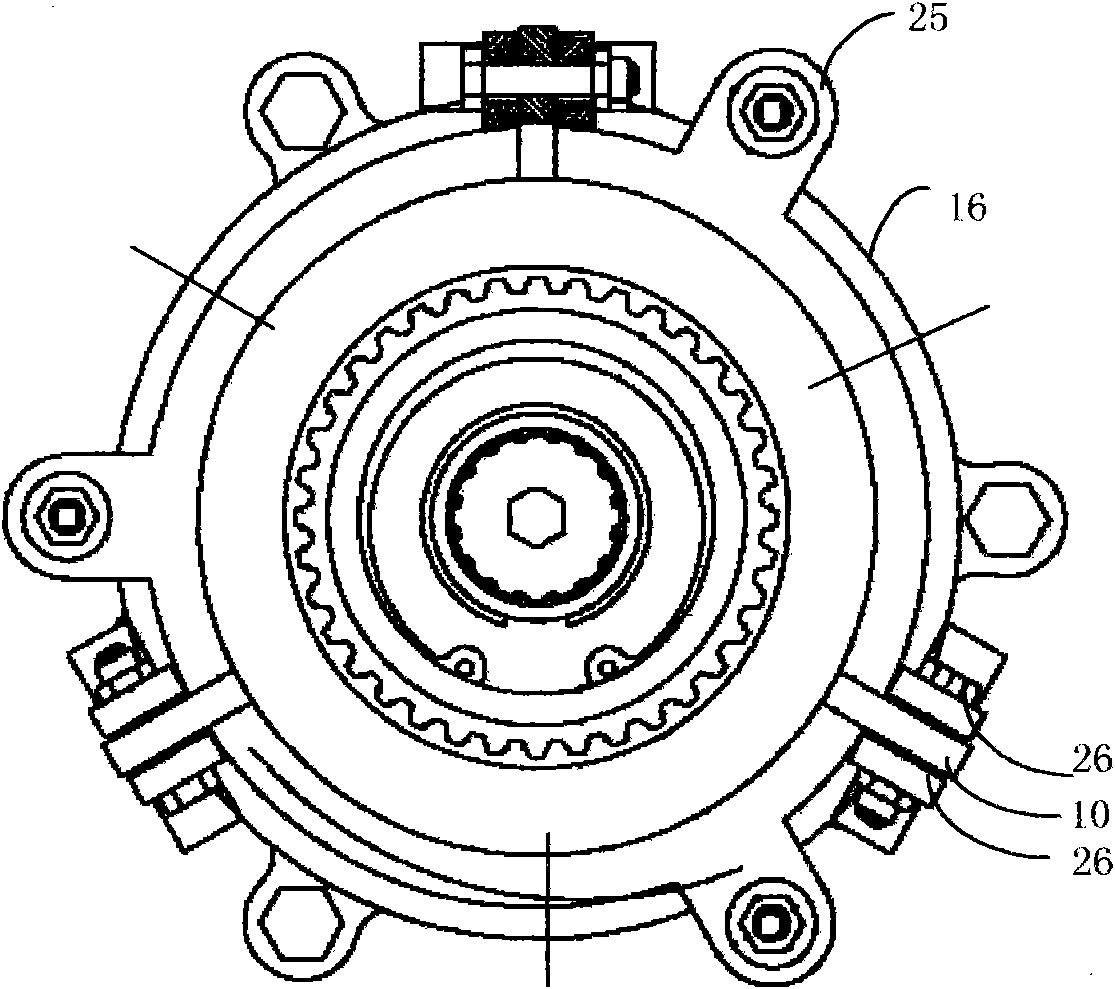

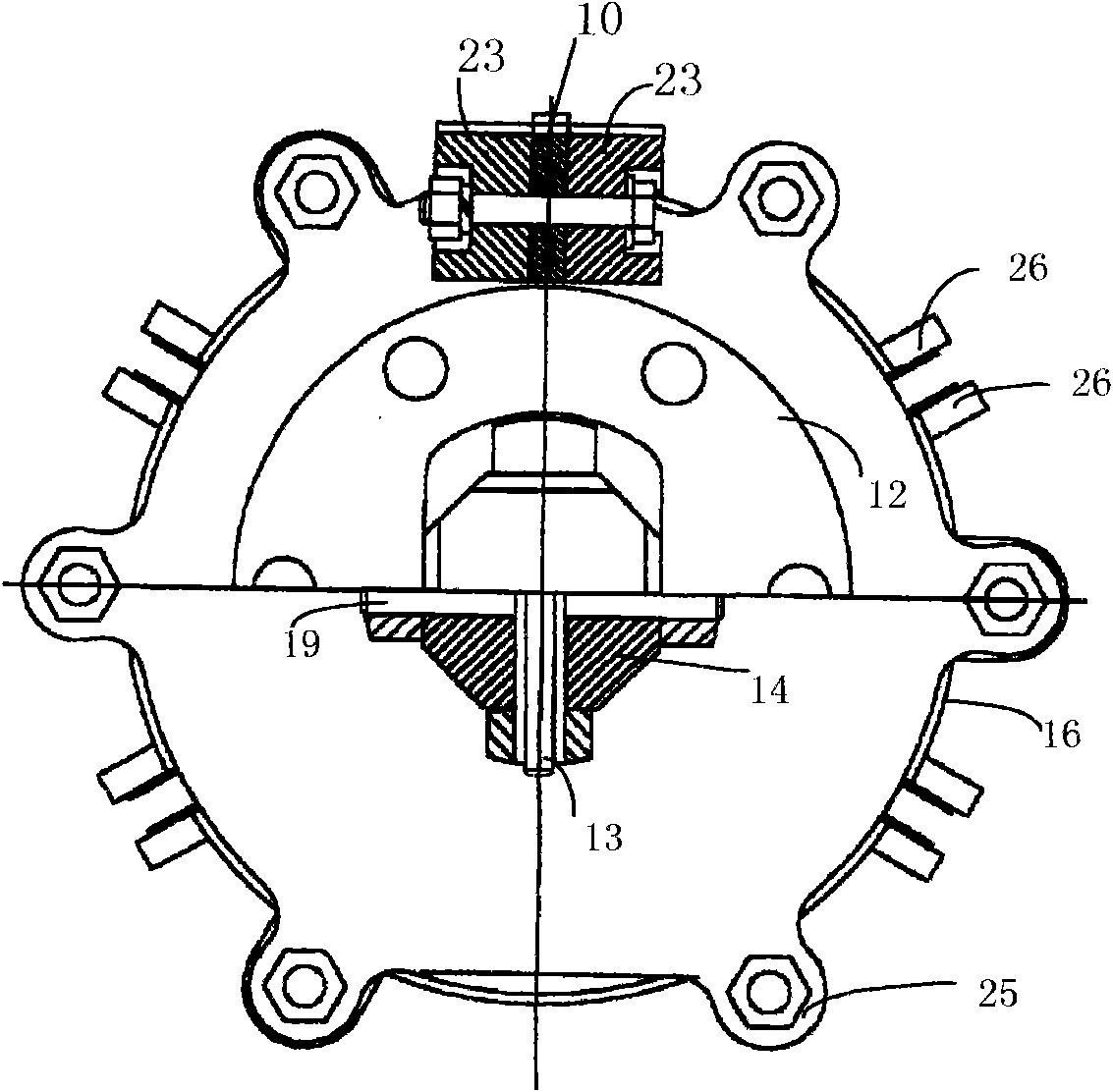

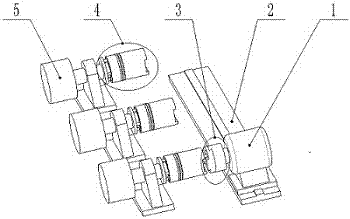

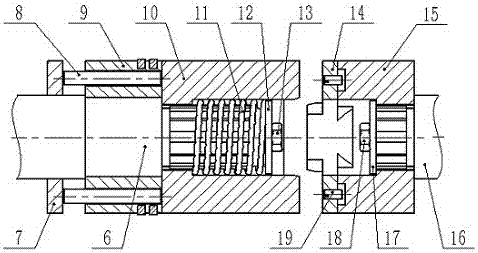

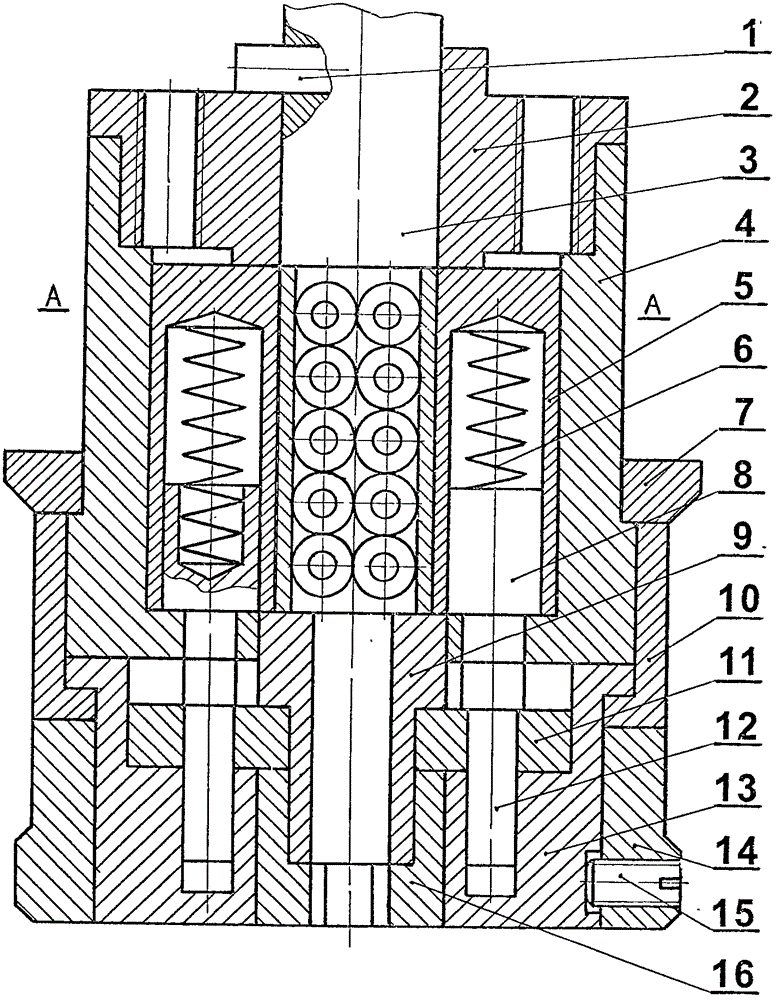

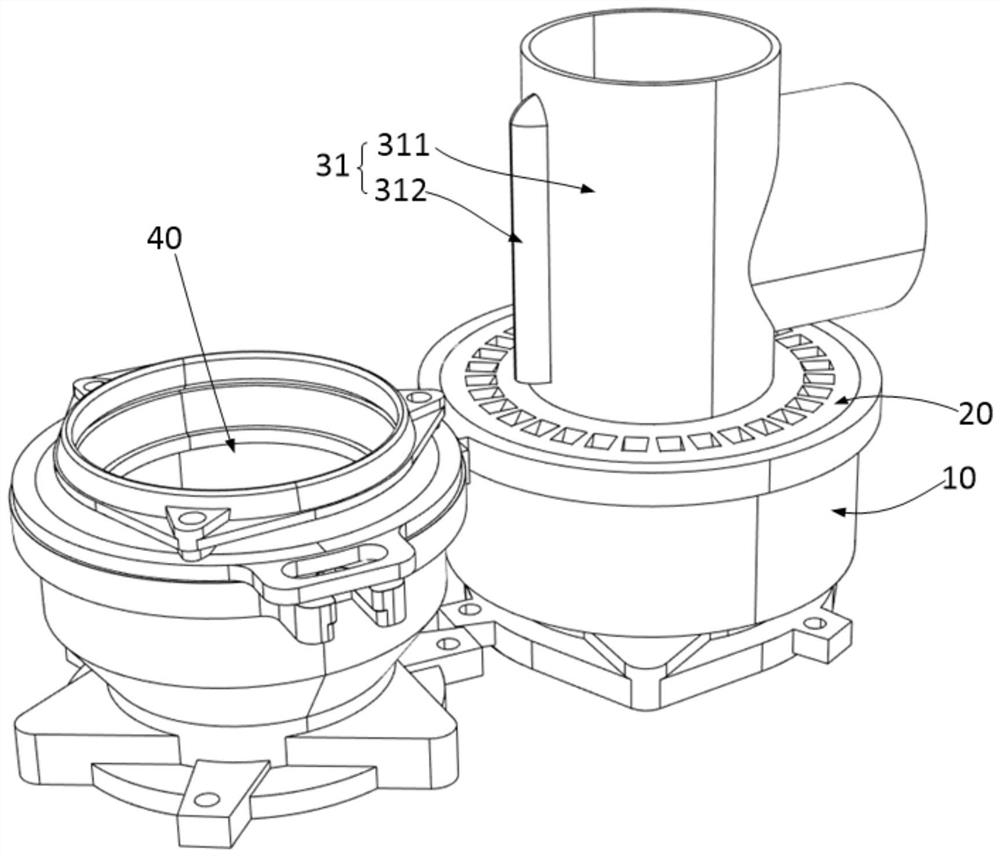

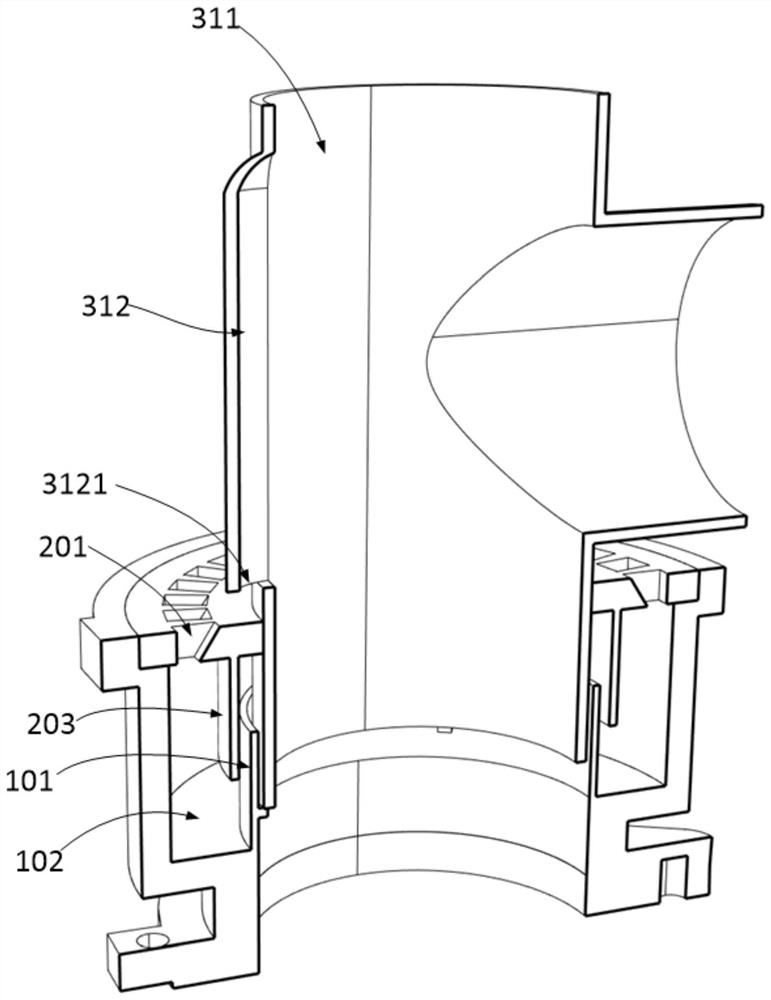

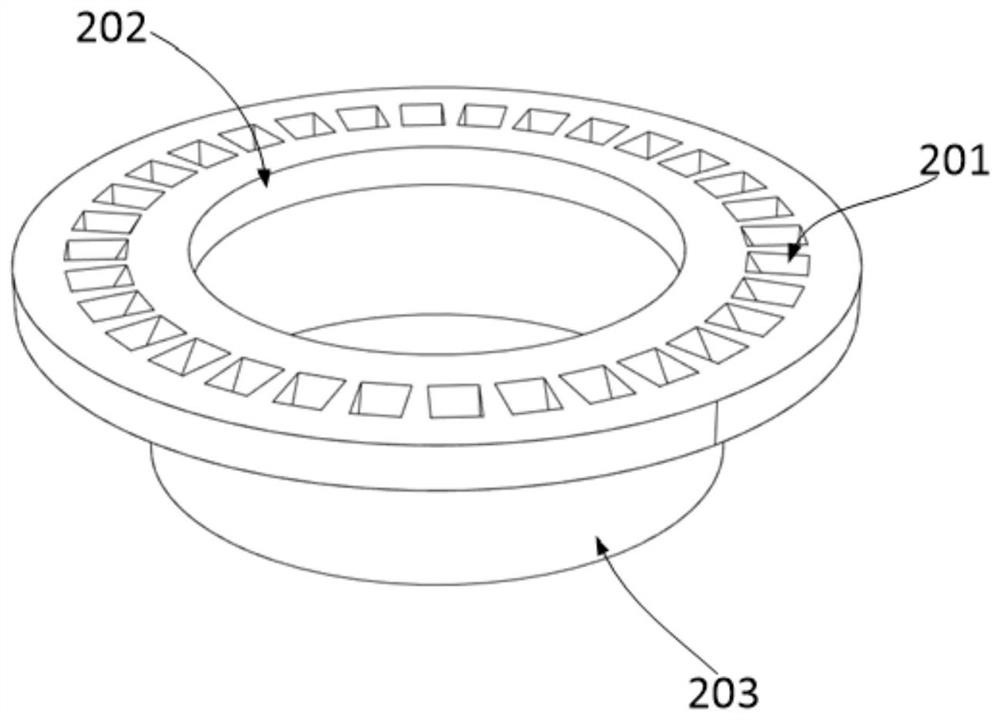

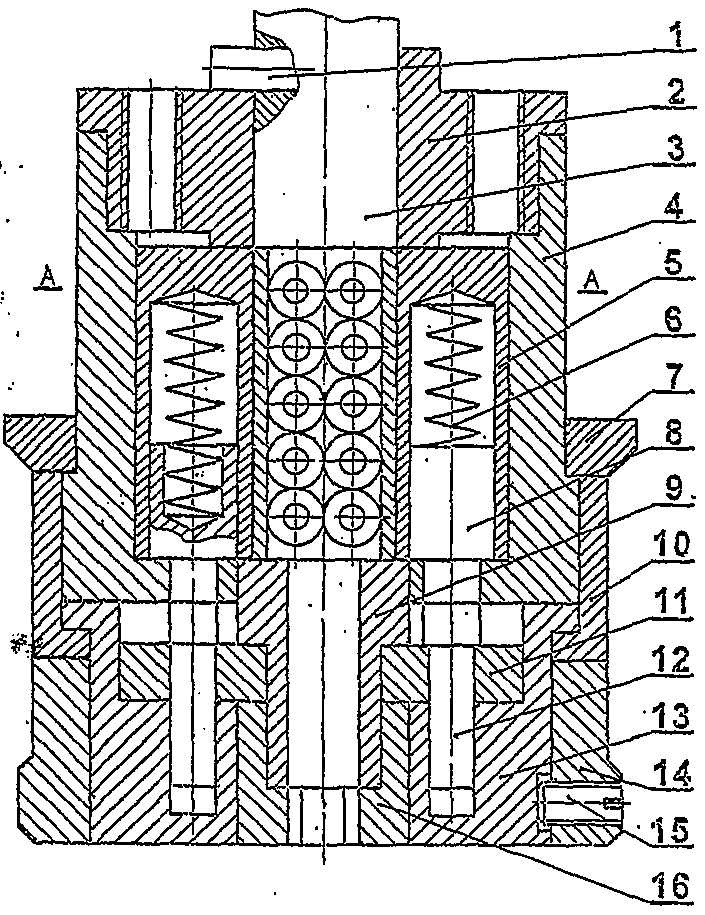

Multifunctional clutch

The present invention provides a multifunctional clutch, comprising an inner ring, an outer ring, a friction piece, a centrifugal block, a star wheel, a flange plate and a hinge coupler. The hinge coupler comprises a pin rod, a coupler shaft fork, a cross block and a plug pin; the clutch is connected with an output shaft through the hinge coupler; five driving friction pieces and five driven friction pieces are mounted between the inner ring and the outer ring; the inner ring is connected with the star wheel through two single-row radial ball bearings; a return spring is mounted between the star wheel and the retaining check ring; ten cylindrical rollers with retainers are used for loosening or tightening when clutching; the outer ring is provided with six centrifugal blocks; the outer ring input end is connected with the coupler shaft fork; a screw is mounted at the end part of the coupler shaft fork; the screw is sleeved with a return pressure spring; the output end is provided with a pressure plate; the coupler shaft fork is connected with the flange plate through the pin rod and the plug pin; and the flange plate is fixedly connected with the power source through six bolts and mounting holes. The clutch is featured with simple size, compact structure and simple adjusting, and integrating the friction clutch, the overrunning coupler and the hinge coupler into one.

Owner:BEIHANG UNIV

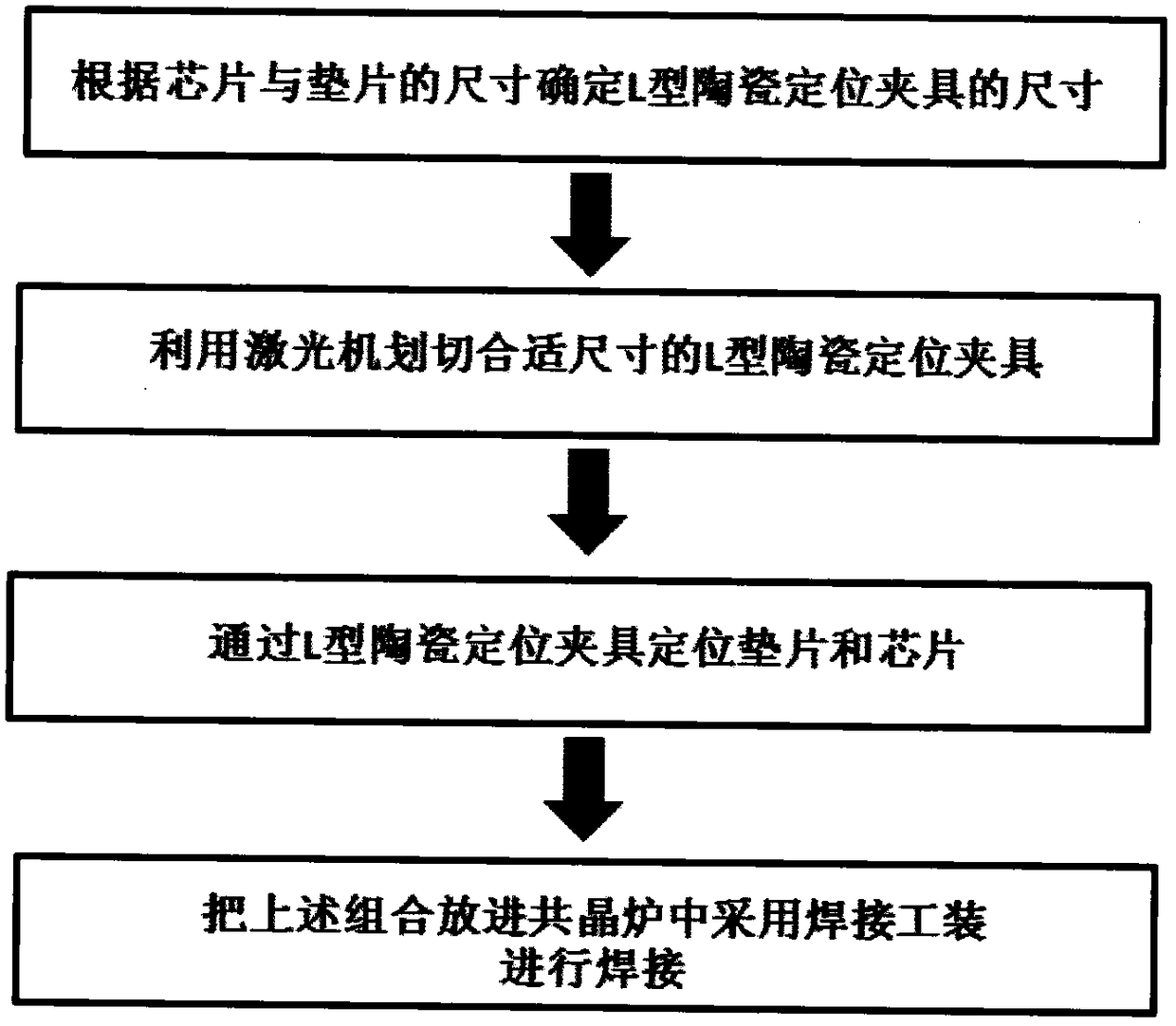

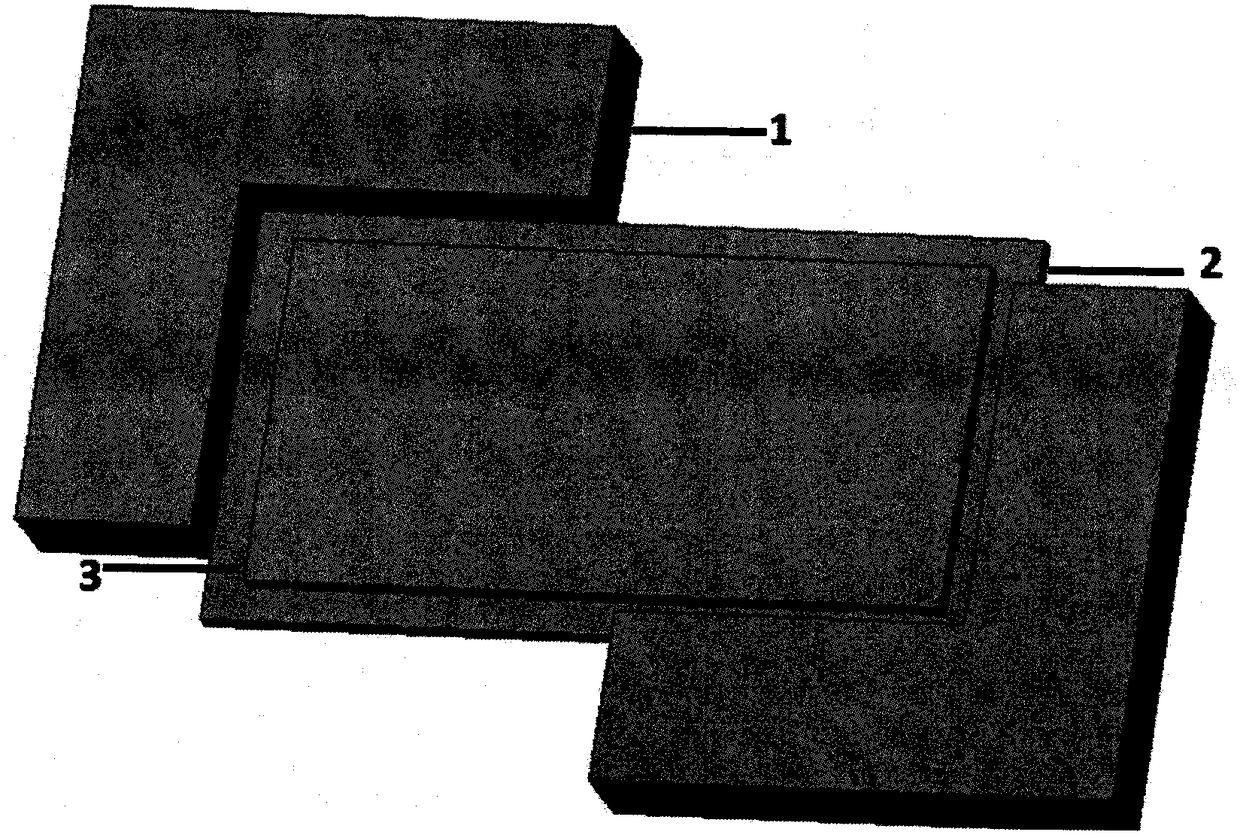

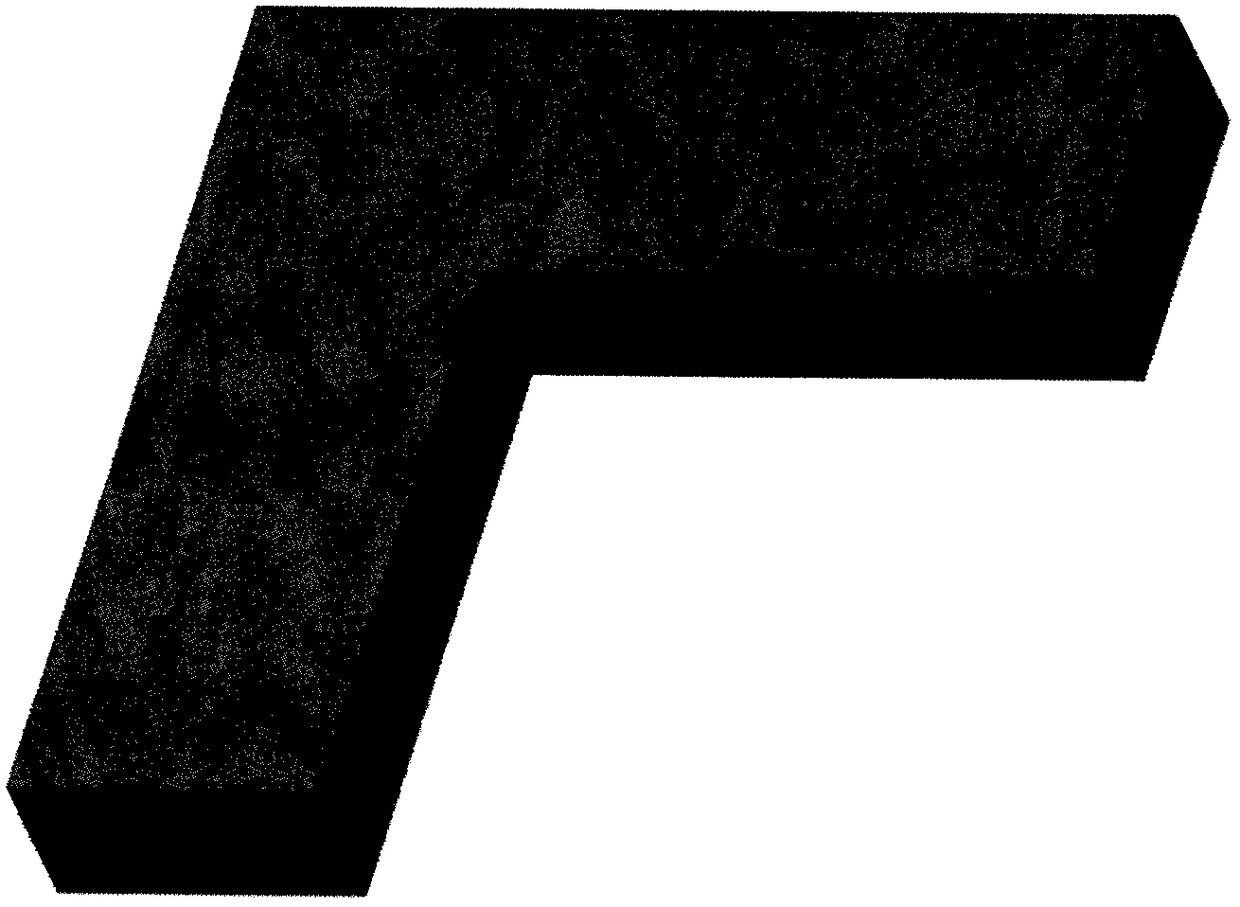

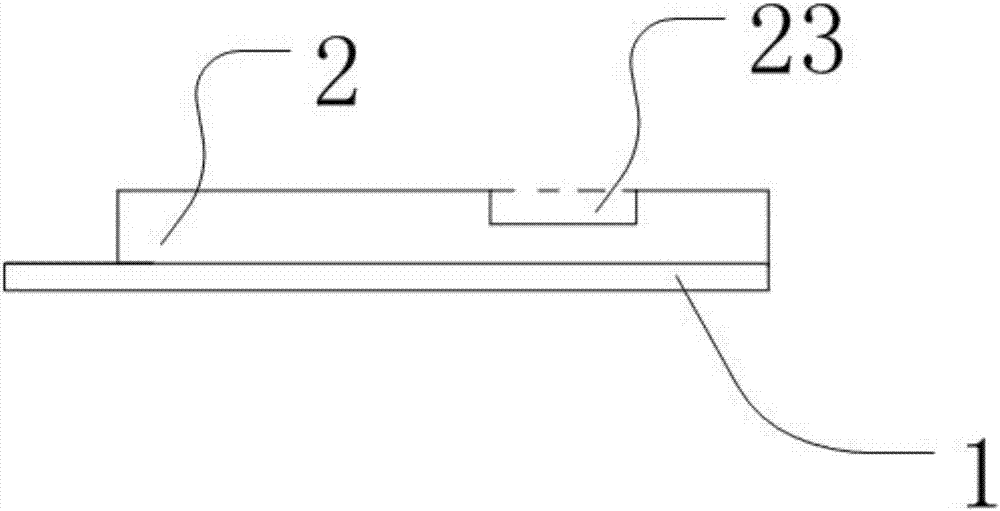

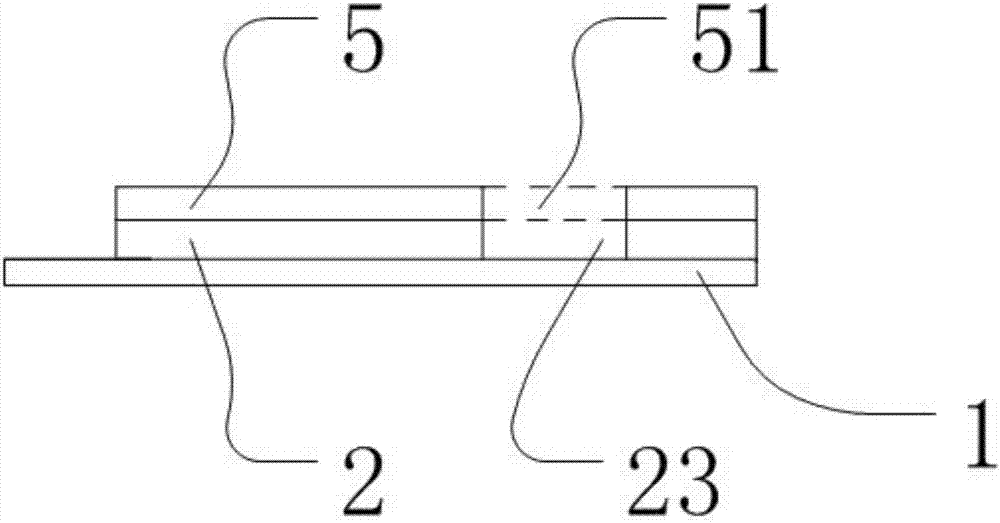

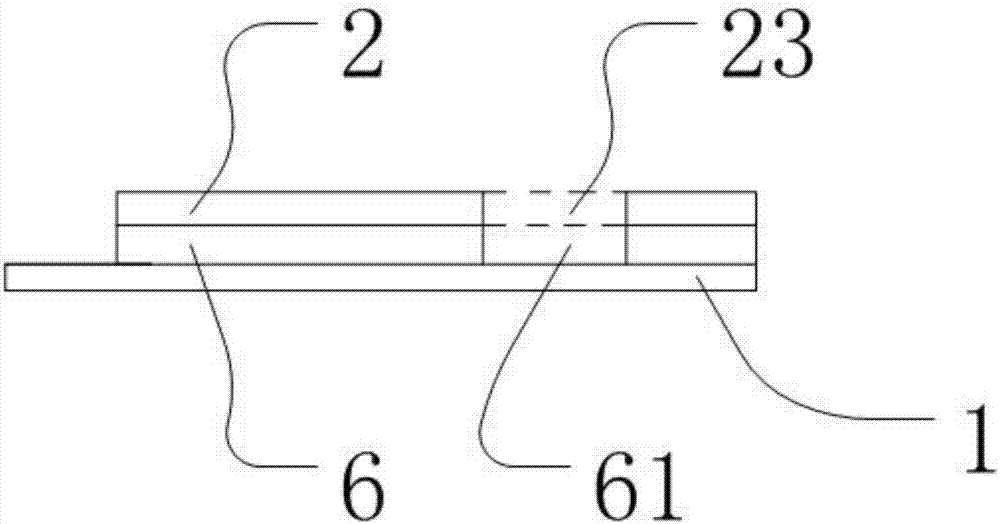

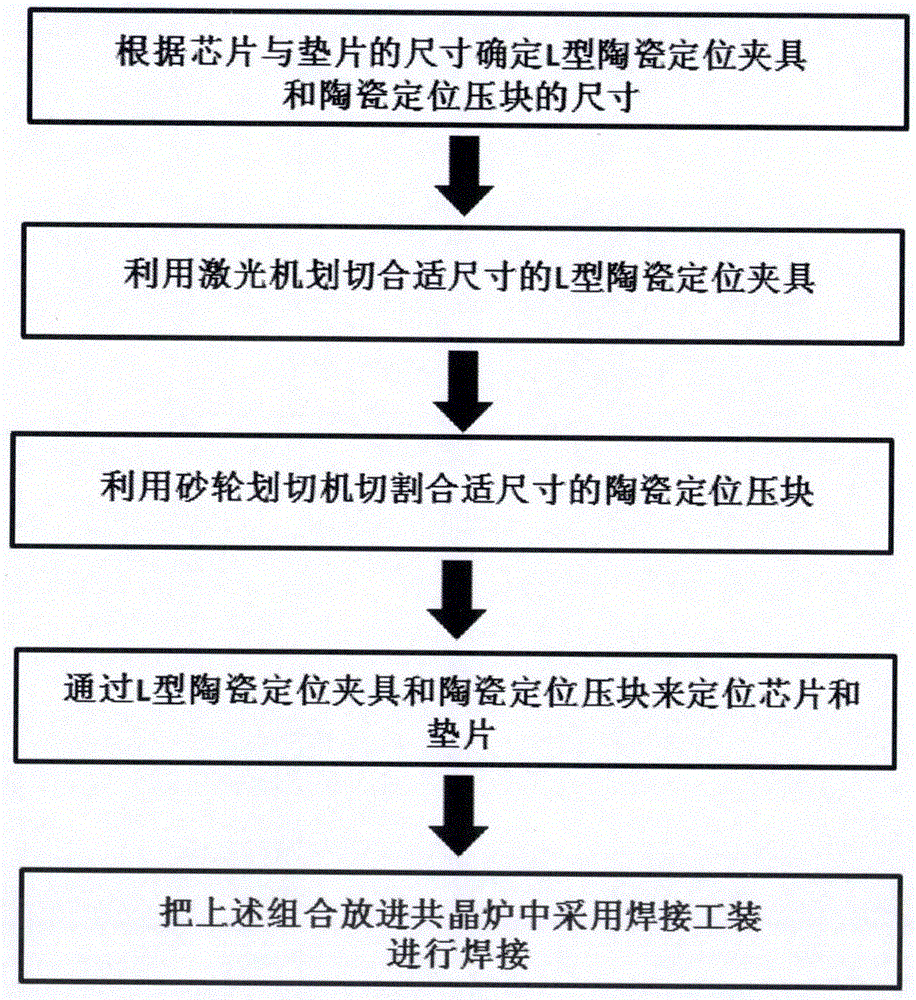

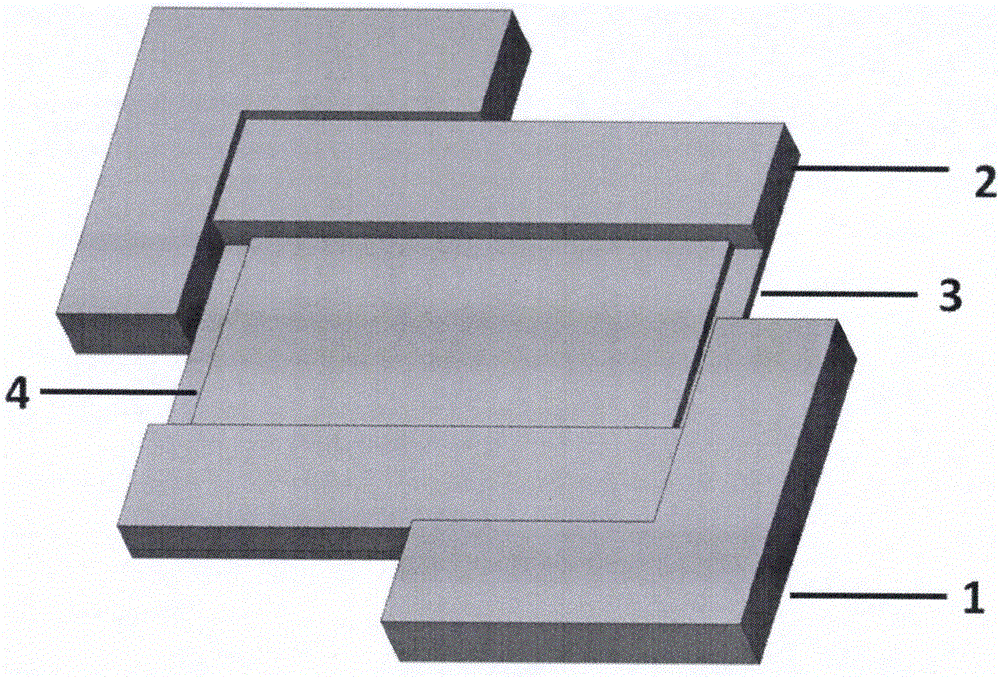

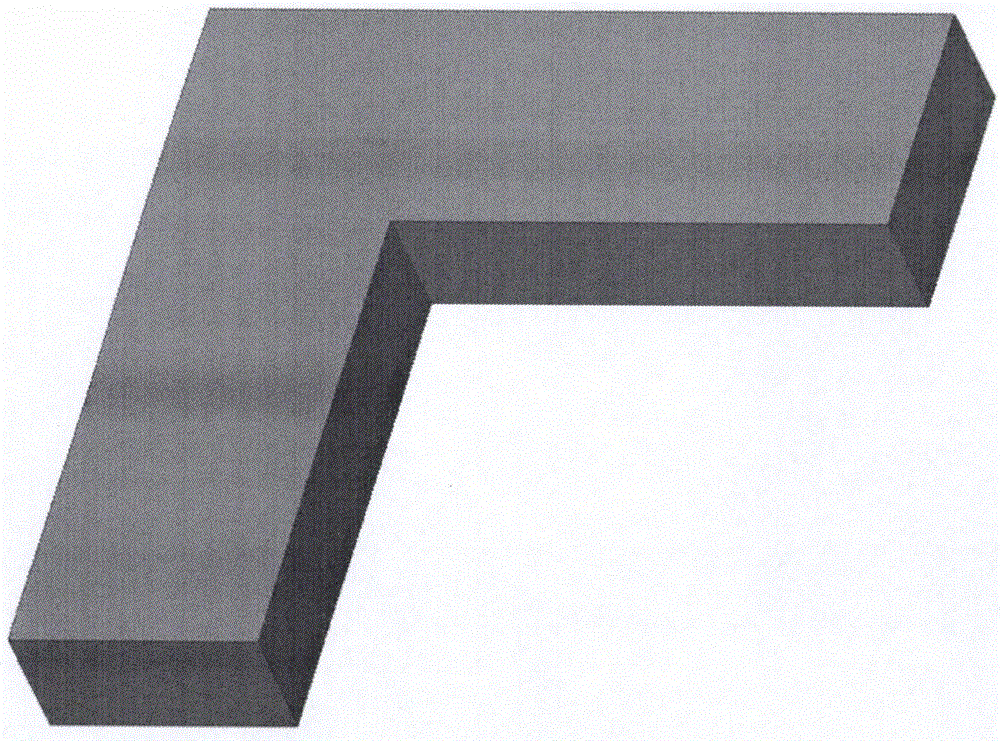

A chip eutectic welding method

ActiveCN106024645BSolve the problem of misalignmentSimple methodSemiconductor/solid-state device manufacturingSoldering auxillary devicesSolderingDislocation

The present invention proposes a chip eutectic welding method, comprising the following steps: step (a), determining the size of the L-shaped ceramic positioning fixture according to the size of the gasket; step (b), using a laser machine to cut the corresponding size L-shaped ceramic positioning fixture; step (c), in the process of positioning the chip, first adopt the L-shaped ceramic positioning fixture to fix the gasket, then put the soldering piece on the gasket, and finally put the chip on the soldering piece; step (d) After the chip is fixed by the positioning fixture, put it into the vacuum eutectic furnace and use the welding tool for eutectic welding. In the chip eutectic welding method of the present invention, the L-shaped ceramic positioning fixture is prepared by a laser machine, which effectively solves the problem of misalignment between the chip and the pad during eutectic welding. The method is simple, low in cost, and strong in feasibility; Ceramics are used as the base material, which can provide effective mechanical support and have a wide range of applications.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

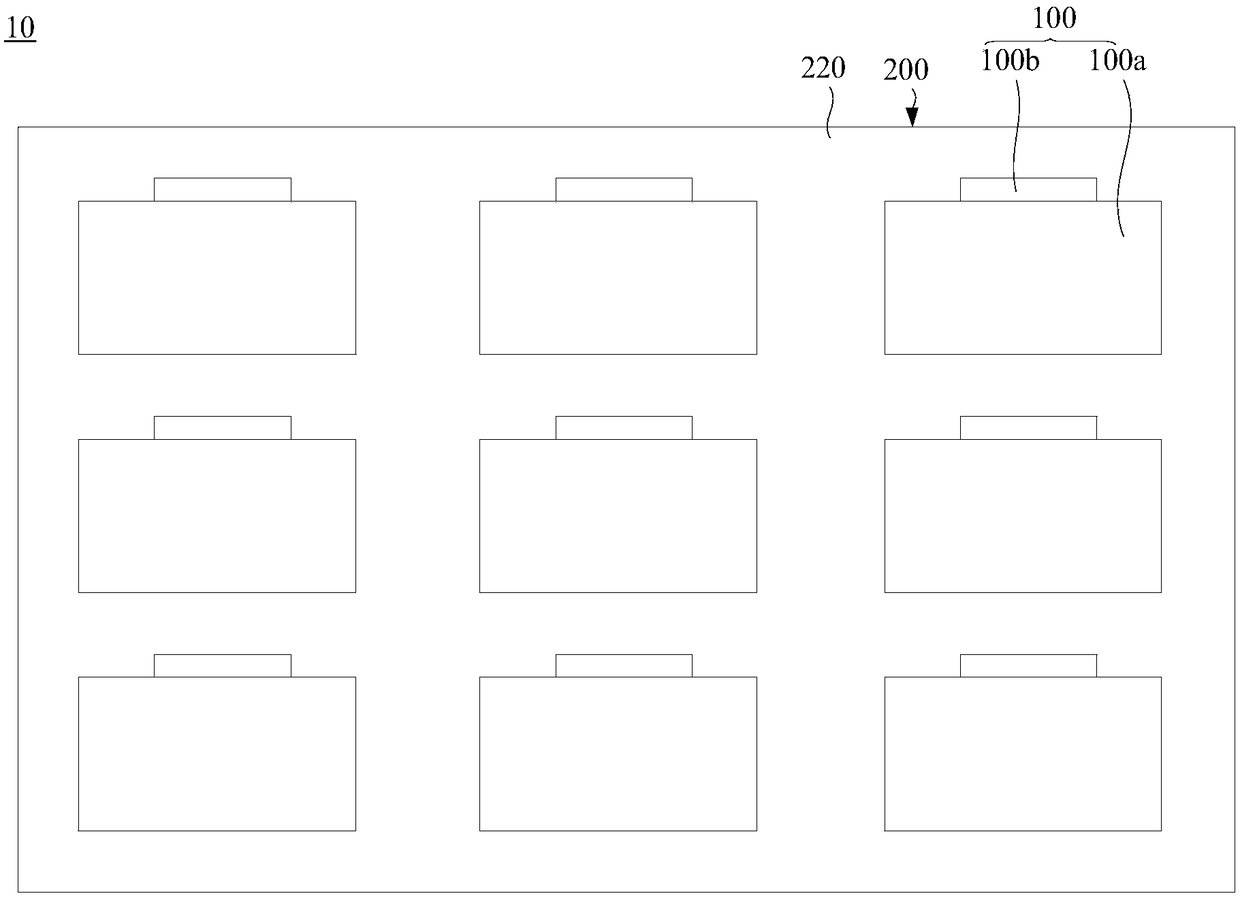

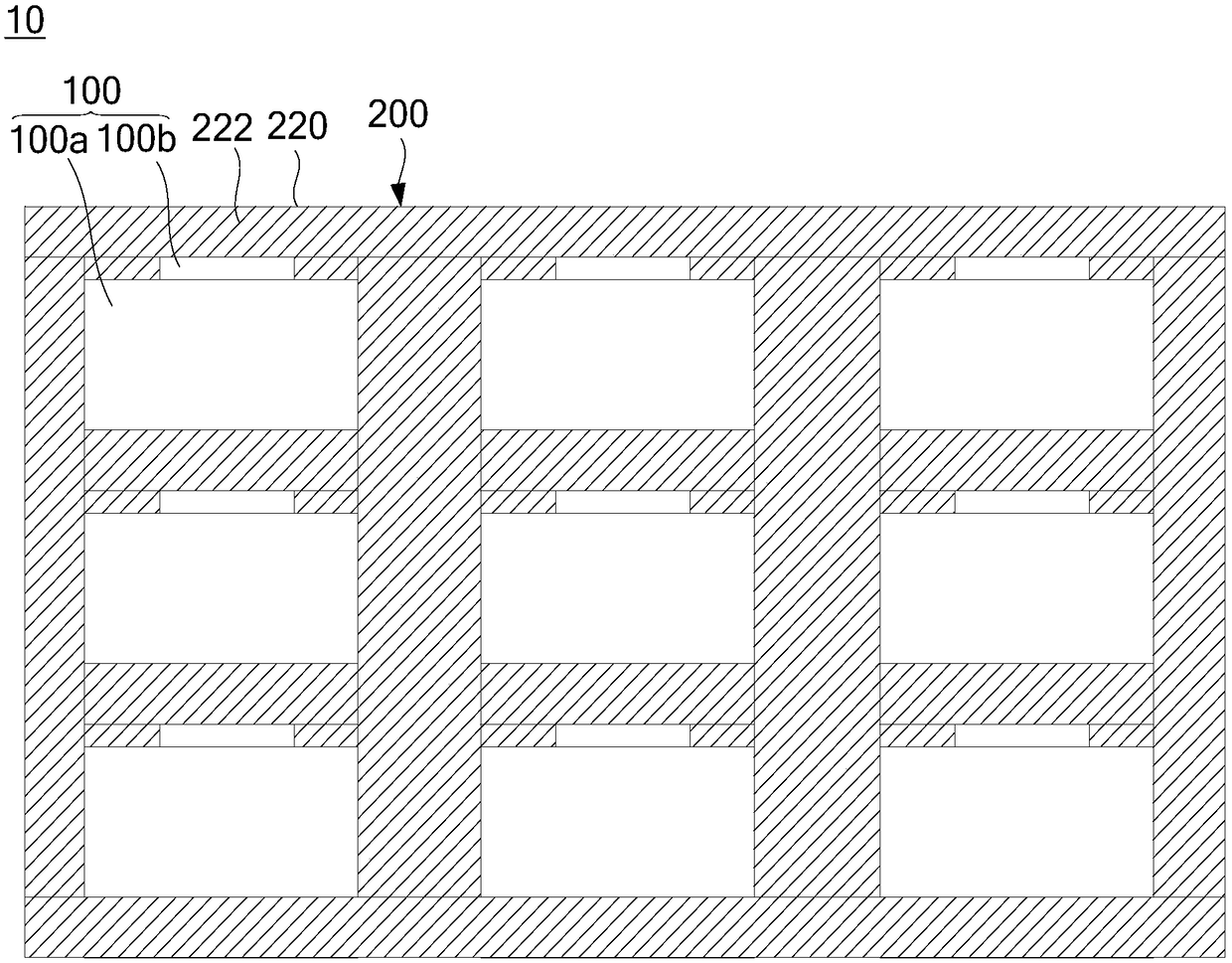

Display panel and making process thereof, and display device

ActiveCN106950758ASolve the problem of misalignmentGood show tasteSolid-state devicesNon-linear opticsDisplay deviceEngineering

The invention discloses a display panel and a making process thereof, and a display device; the display panel comprises a substrate and an electrode layer arranged on the substrate; the electrode layer is provided with a first defect position and an electrode repair layer; the transparent conductive repair layer covers on the first defect position. The transparent conductive repair layer can directly repair the first defect position on the electrode layer, thus allowing the electrode layer to restore normal works, solving the orientation adverse problems, providing better display quality, improving repair success rate, and preventing discard problems caused by overlarge defects.

Owner:HKC CORP LTD +1

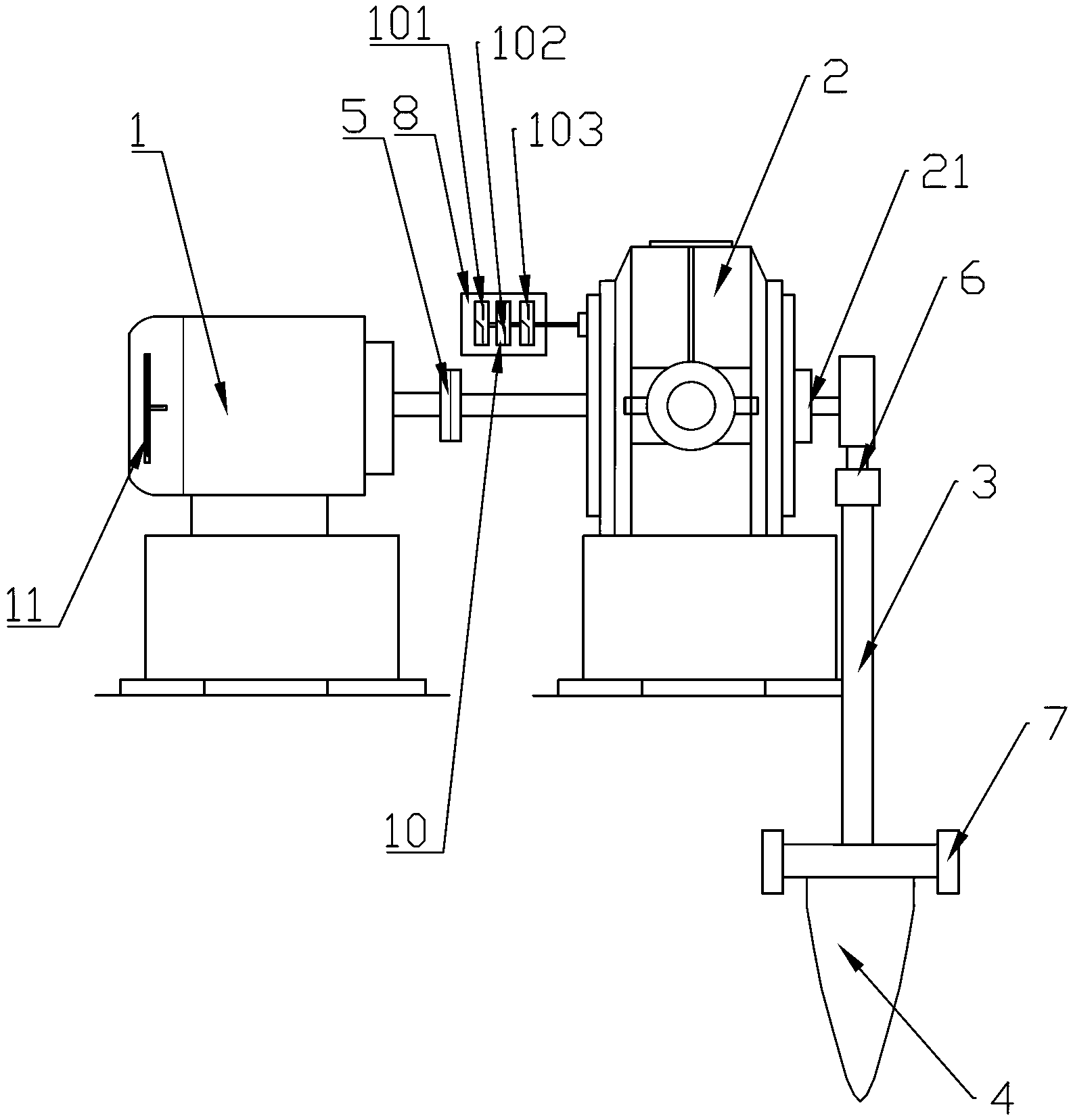

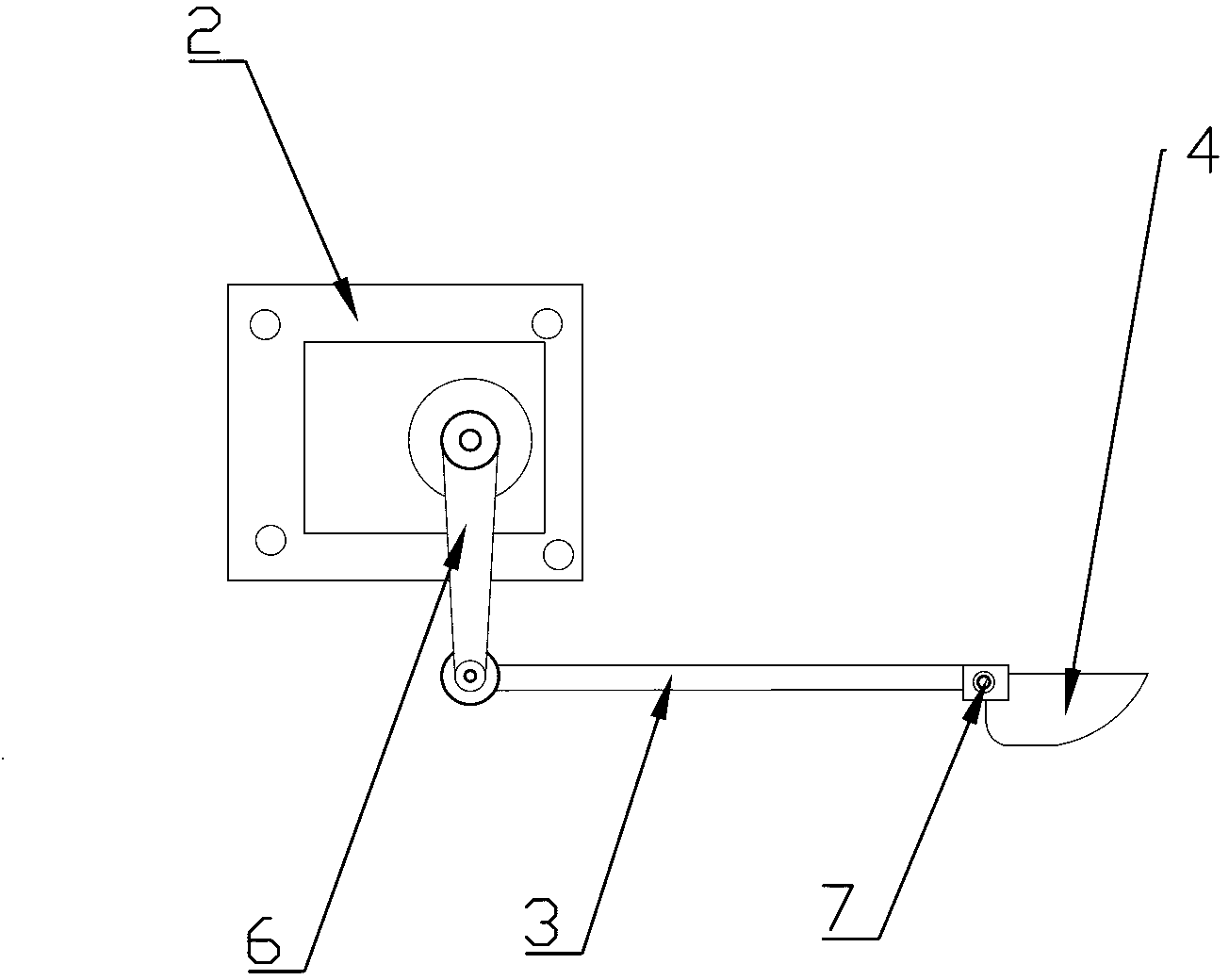

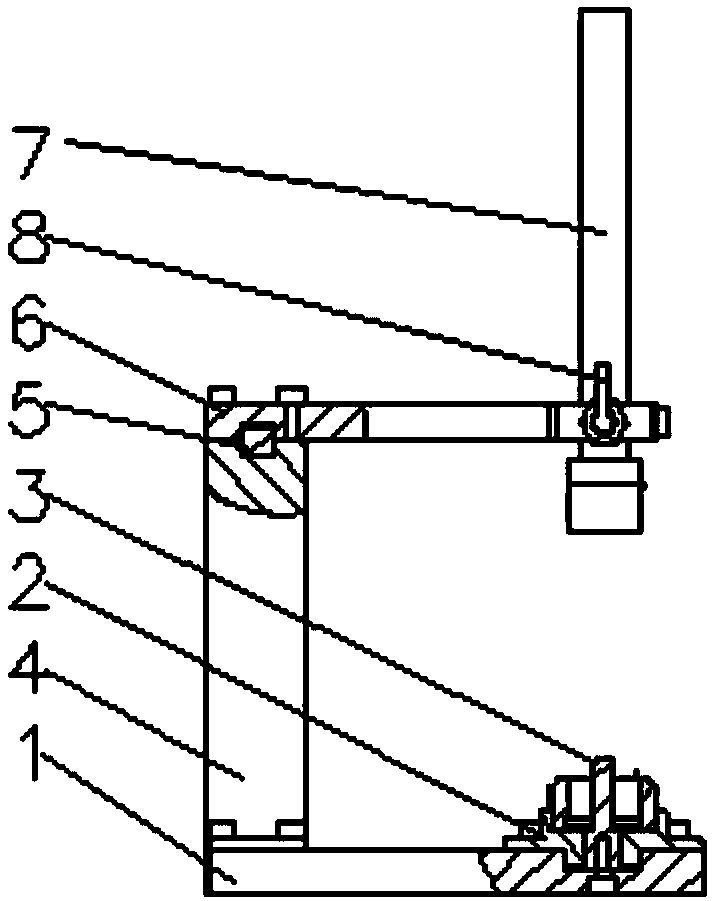

Protective device making swing chute mouth being accurately located

InactiveCN103318831AEnsure safetySolve the problem of misalignmentLiquid transferring devicesElectric machineryEngineering

The invention discloses a protective device making a swing chute mouth being accurately located. The protective device comprises a motor, a speed reducer, a push rod and the swing chute mouth. The motor is connected to the speed reducer through a coupling wheel, one end of a low-speed shaft of the speed reducer is connected to one end of the push rod through a push rod driving mechanism, the other end of the push rod is connected with the swing chute mouth through a chute mouth driving bearing, a travel switch protective box is fixedly arranged at the other end of the low-speed shaft, the travel switch protective box is coaxially connected with the low-speed shaft through a hard connection fixing piece, a travel switch is arranged inside the travel switch protective box, and the travel switch is connected to the motor. The low-speed shaft of the speed reducer is connected with the travel switch, the low-speed shaft and the travel switch are always operated at same angular speed, the swing chute mouth can be accurately located at the preset position, the situation that the swing chute mouth does not go beyond the largest set position, the problem that the swing chute mouth and the mouth of a torpedo ladle are not accurately aligned is thoroughly solved, and safety of tapping iron is effectively guaranteed.

Owner:JIGANG GRP

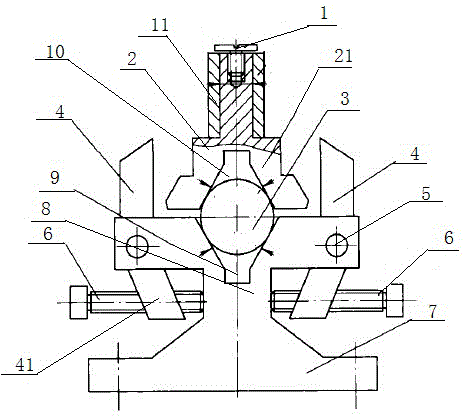

Shaft type milling fixture

InactiveCN103551886ASolve the problem of misalignmentGood symmetryAutomatic control devicesMeasurement/indication equipmentsSteel ballEngineering

The invention provides a shaft type milling fixture, comprising a base, a part fixture body integrally connected with the base, and a tool setting fixture body opposite to the part fixture body; a first V-shaped groove is arranged in the part clamp body; a second V-shaped groove opposite to the first V-shaped groove is arranged in the tool setting fixture body; the space formed by the first V-shaped groove and the second V-shaped groove can be used for placing a steel ball. The shaft type milling fixture disclosed by the invention is manly used in the key seating procedure of shaft type parts on textile machinery, the tool setting fixture body and the part fixture body are highly precisely matched, so the problem of center misalignment in the key seating procedure of the shaft type parts is solved, a key seat made by the fixture is high in symmetry, the production efficiency of the shaft type parts is improved, and the quality of the shaft type parts is ensured.

Owner:WUJIANG XILI MACHINERY FACTORY

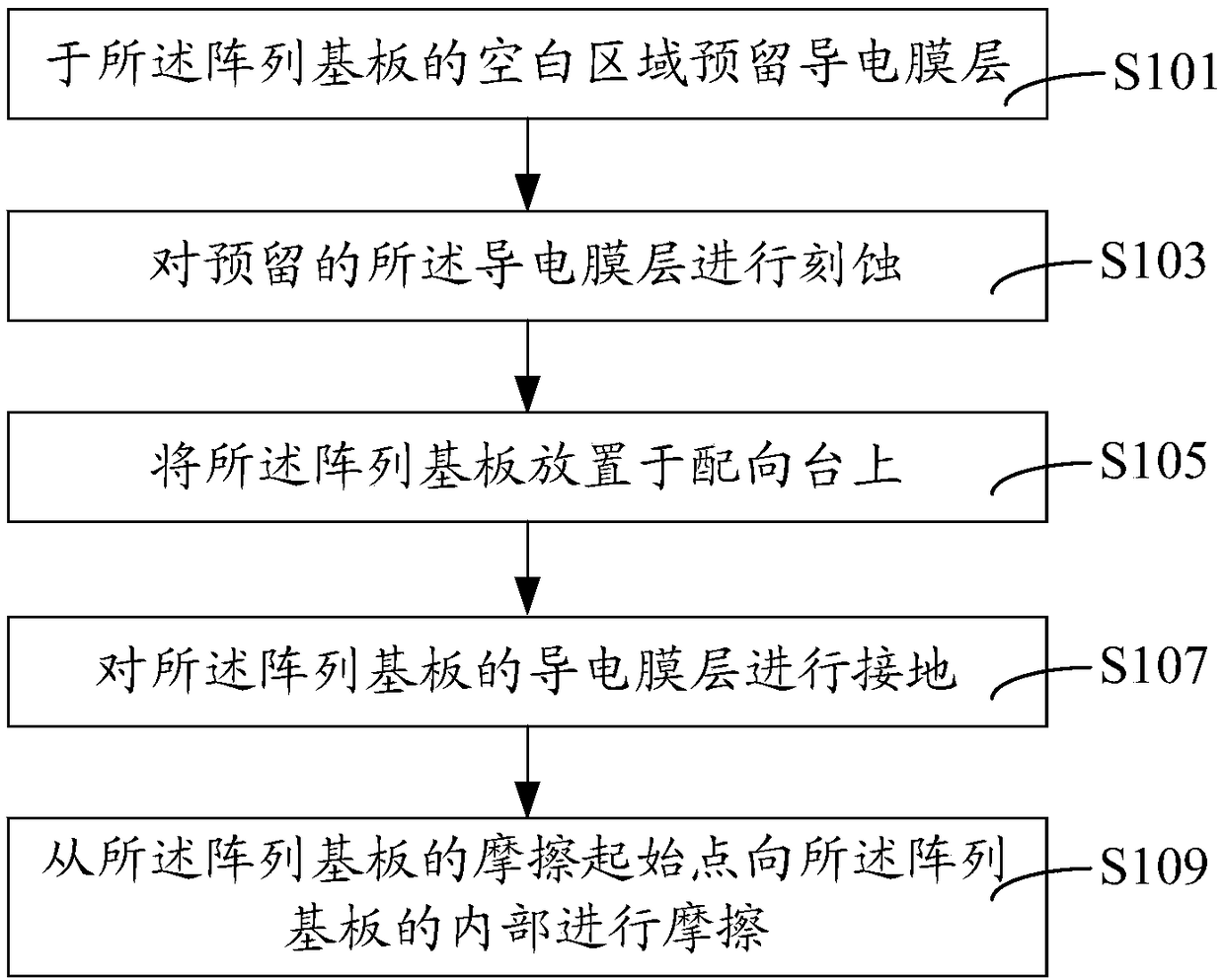

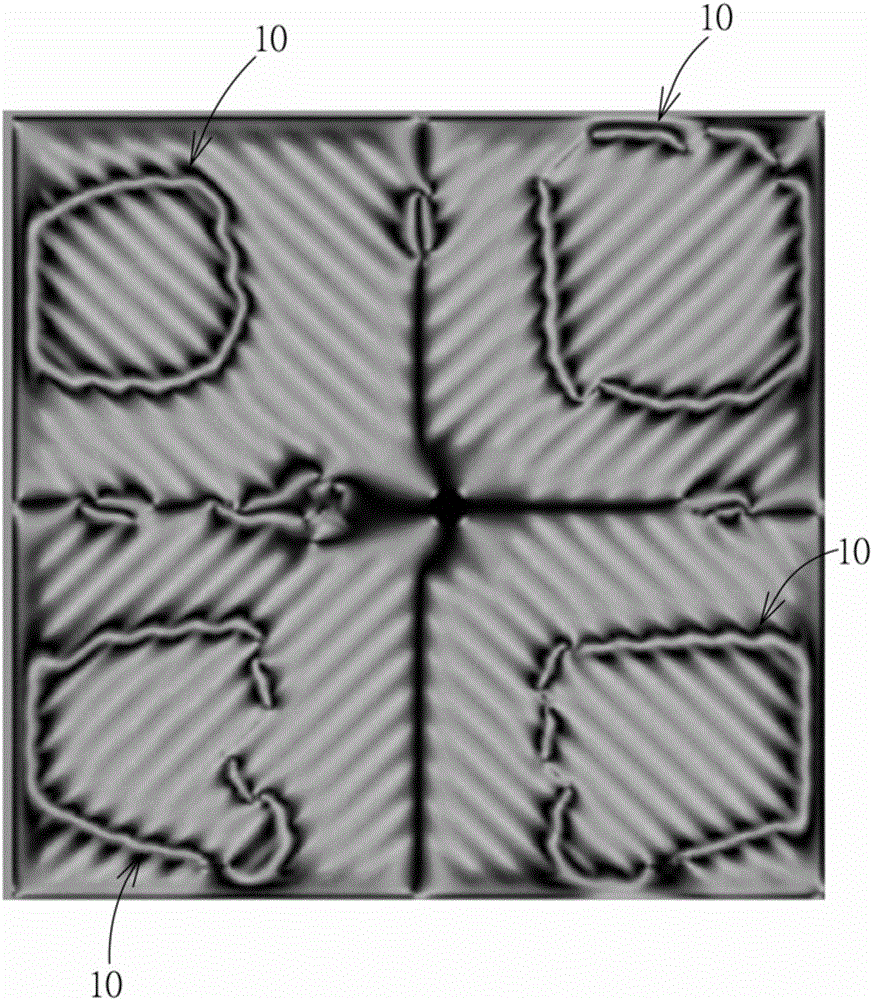

A method of friction alignment and a liquid crystal display device

InactiveCN108169962AAvoid material wasteReduce the differenceNon-linear opticsIntegrated circuitLiquid-crystal display

The invention relates to a method of friction alignment and a liquid crystal display device. The method of friction alignment is used for friction alignment of an array substrate which comprises graphical areas and a blank area isolating the graphical areas. Each graphical area comprises a graphical area body and an integrated circuit control position next to the graphical area body. The method offriction alignment comprises the steps of: providing an array substrate and pre-arranging a conducting film layer in a blank area of the array substrate; etching the pre-arranged conducting film layer to form a pattern on the conducting film layer; placing the array substrate on a alignment table; connecting the conducting film layer of the array substrate to the ground; performing friction froma friction start point of the array substrate towards the inside of the array substrate. The conducting film layer of the array substrate is grounded in advanced, so that generation of static electricity of the conducting film layer of the array substrate in a friction process can be prevented, damage by static electricity to the array substrate during friction alignment can be prevented and the yield rate of manufacture of liquid crystal display devices can be guaranteed.

Owner:TRULY HUIZHOU SMART DISPLAY

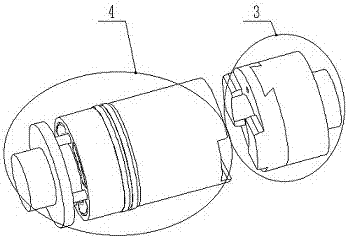

Split electromagnetic coupling

ActiveCN107327515AWork reliablyEasy to operateMagnetically actuated clutchesElectromagnetic couplingDrive shaft

The invention discloses a split electromagnetic coupling. The split electromagnetic coupling comprises a coupling input unit and a coupling output unit, wherein a movable half-coupling of the coupling output unit is capable of being engaged with a slide block of the coupling input unit under the action of an engagement device, movement and power of a transmission shaft II are transferred to a transmission shaft I, a return device is capable of returning the movable half-coupling, and the transmission shaft I and the transmission shaft II are disengaged, so that the coupling input unit is capable of moving relative to the radial direction of the coupling output unit; and the slide block of the coupling input unit is capable of moving in the radial direction of the movable half-coupling and a fixed half-coupling during a transmission process, so that a coaxiality error of the transmission shaft I and the transmission shaft II is compensated. The split electromagnetic coupling is capable of meeting the functional need of mechanical equipment with a multi-load time-sharing driver, has capacity of compensating the coaxiality error of the transmission shafts, and is easy to realize automatic engagement and disengagement through adopting a working manner of realizing engagement through electromagnetic drive and realizing disengagement through spring return.

Owner:LIAONING TECHNICAL UNIVERSITY

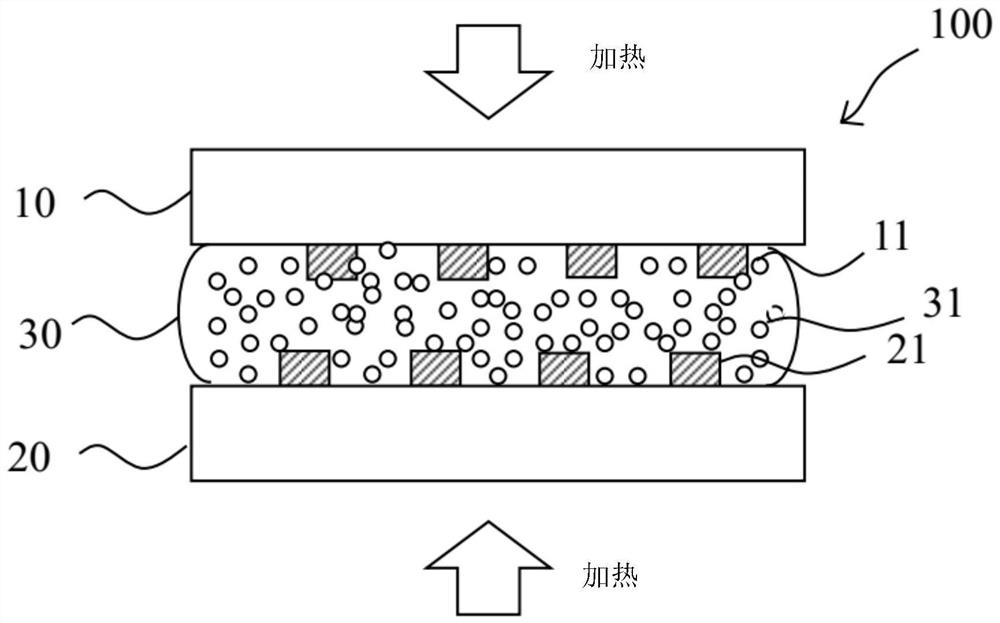

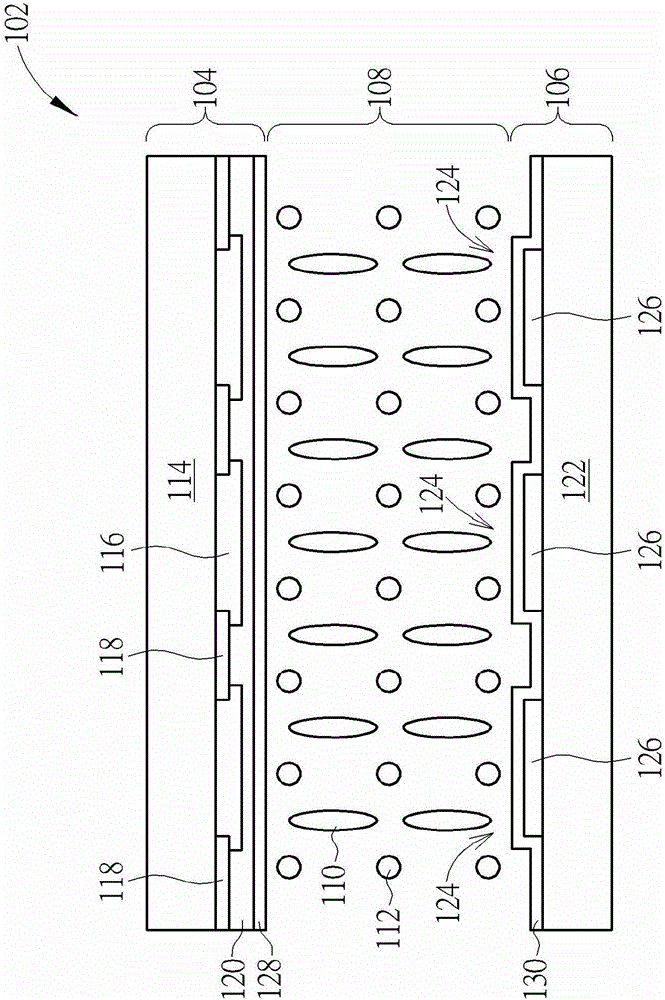

Method of making liquid crystal display panel

InactiveCN104111561AEvenly arrangedSolve the problem of misalignmentNon-linear opticsVoltage referenceEngineering

The invention discloses a method of making liquid crystal display panels. The method comprises the steps of providing an upper substrate, a lower substrate and a liquid crystal layer, providing voltage signals to the lower substrate, and providing reference voltage to the upper substrate. The liquid crystal layer, arranged between the upper substrate and the lower substrate, includes multiple liquid crystal molecules and multiple reactive monomers. The voltage signals have at least one pulse within a working period, and the voltage difference between the peak voltage of the pulse and the reference voltage is 40-45 volts.

Owner:AU OPTRONICS CORP

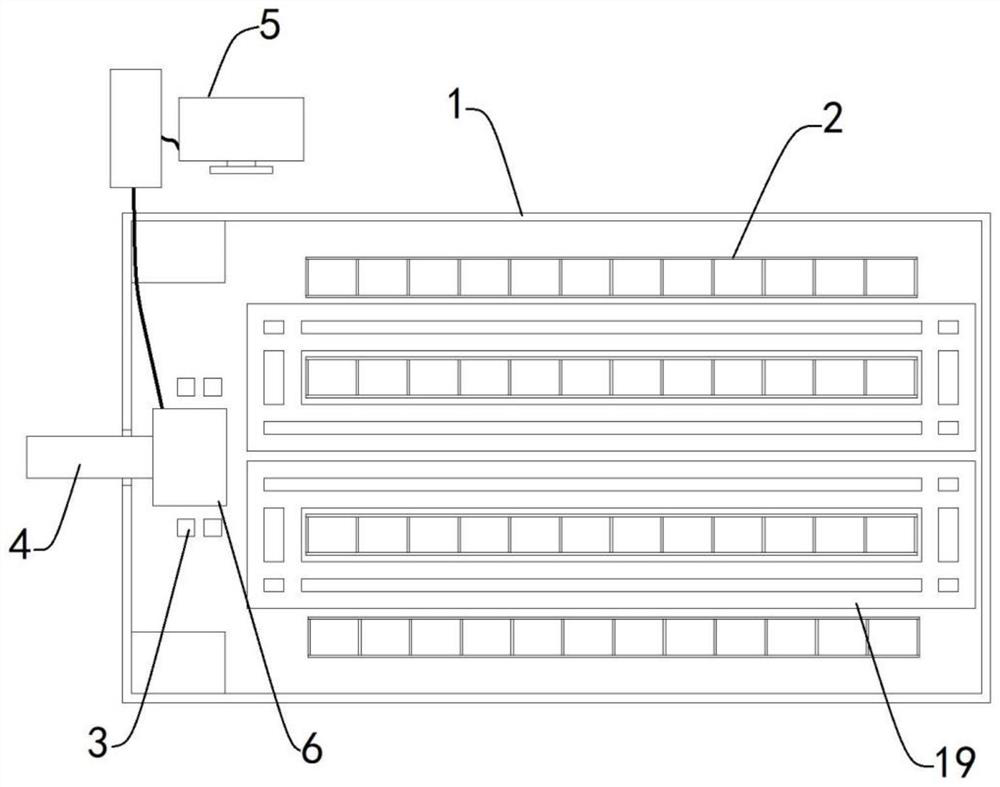

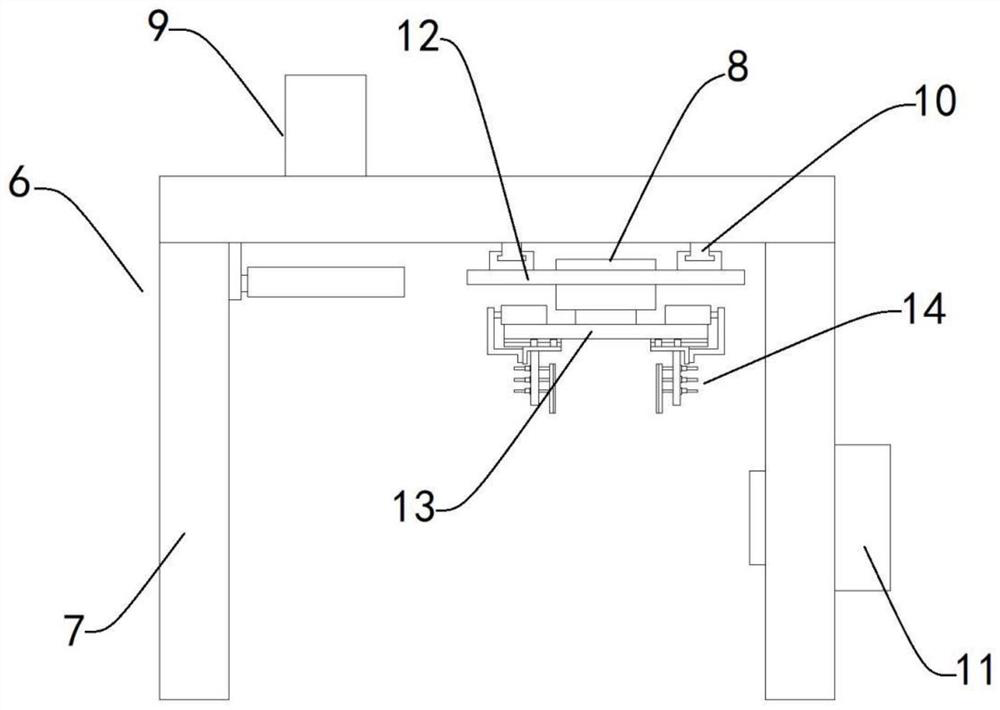

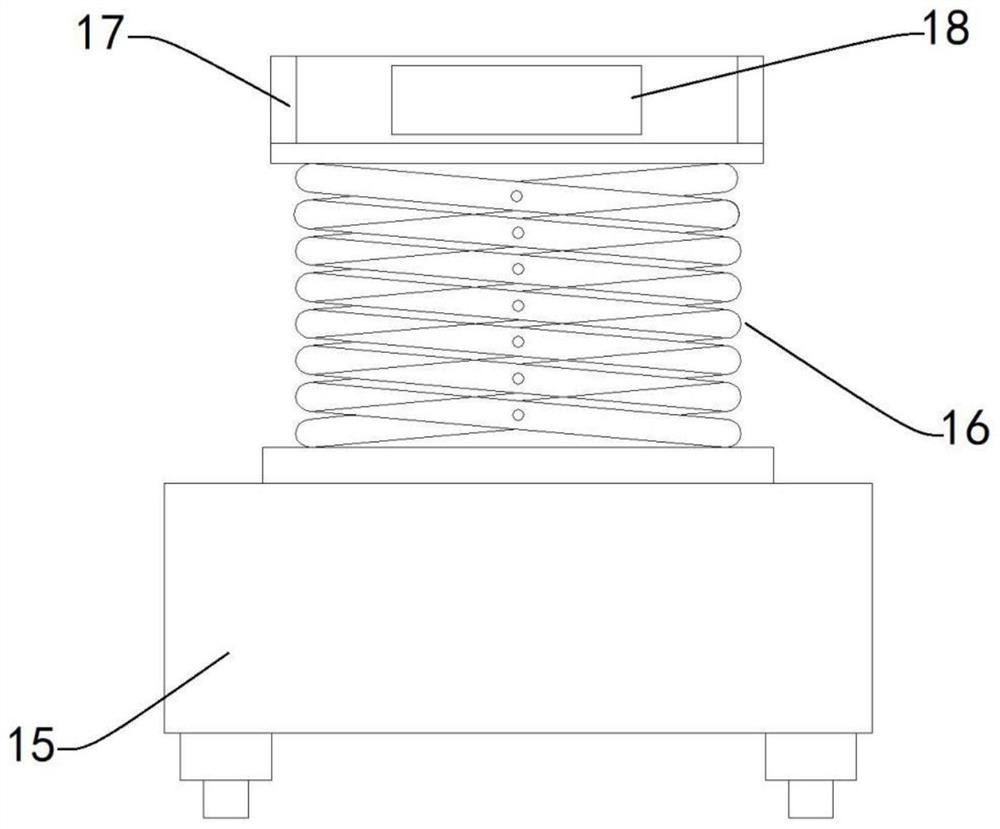

Shoe unmanned intelligent warehousing system

PendingCN113291694AFix the messSolve the problem of misalignmentStorage devicesBarcodeLocal area network

The invention discloses a shoe unmanned intelligent warehousing system which comprises a warehousing bin, a plurality of storage racks, feeding trolleys, a conveying belt, a control center and a scanning device, the two ends of the conveying belt are arranged inside and outside the warehousing bin respectively, one end of the conveying belt is fixedly connected with the scanning device, and the multiple feeding trolleys are arranged on the two sides of the scanning device. The feeding trolleys are connected with the control center through a local area network, the storage racks are fixedly installed in the warehousing bin, the conveying belt is used for conveying materials into the warehousing bin, the scanning device is used for scanning two-dimensional codes or bar codes of products, the products are discharged to the feeding trolleys, and according to the information of the two-dimensional codes or the bar codes, the feeding trolleys transfer the materials to the corresponding positions of the storage racks, split carrying is carried out constantly through the customized shuttle vehicle according to dimension code data of the shoe boxes, warehouse entering and exiting can be carried out at the same time, the problem of disordered placement due to various categories is effectively solved, super-efficient warehouse entering and exiting are carried out, and warehouse entering information is transmitted to the cloud end of the control center.

Owner:苏州灵景智能装备有限公司

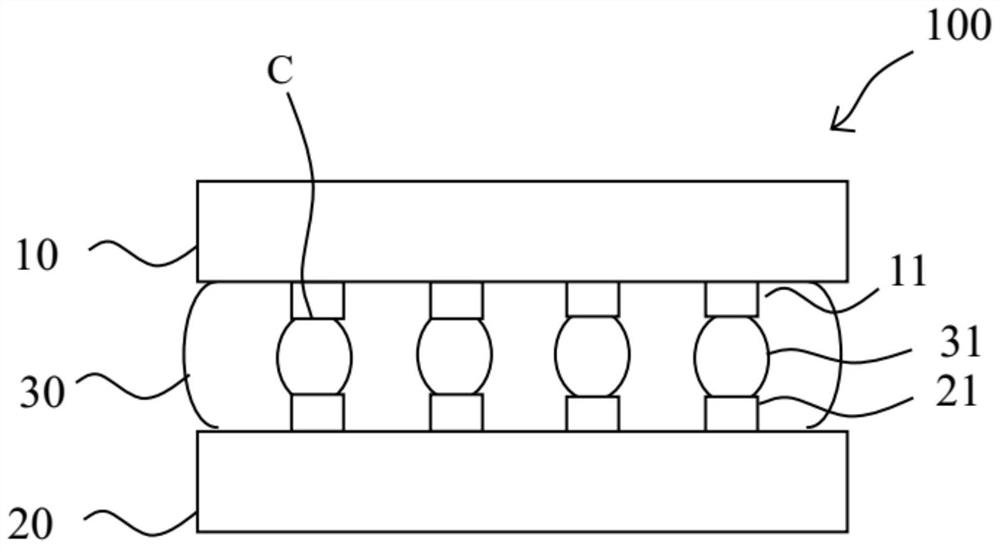

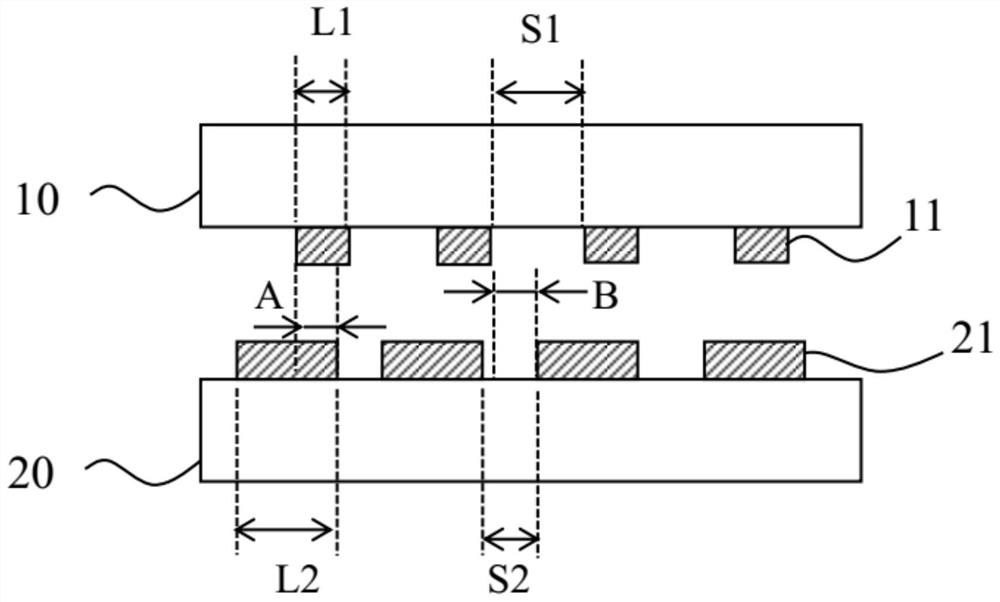

Welded Anisotropic Conductive Film Bonding Structure

ActiveCN111048232BEffective self-alignment functionAvoid large alignment offsetsPrinted circuit assemblingNon-conductive material with dispersed conductive materialAnisotropic conductive filmBonding process

Owner:INTERFACE TECH CHENGDU CO LTD +2

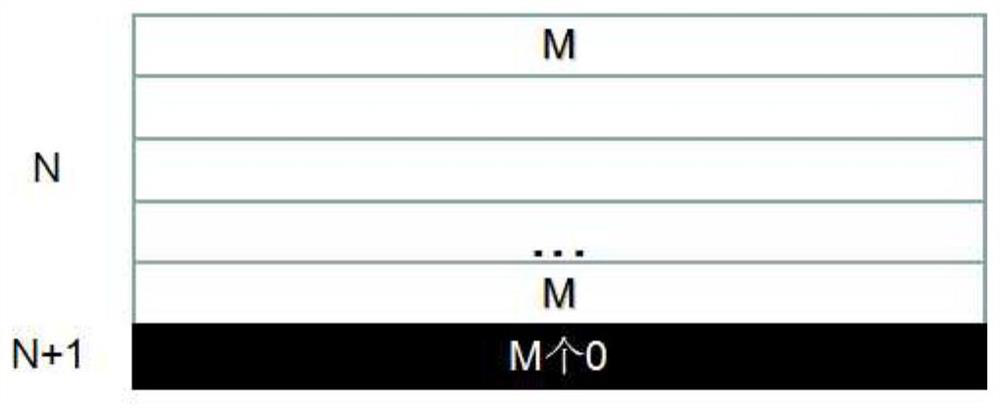

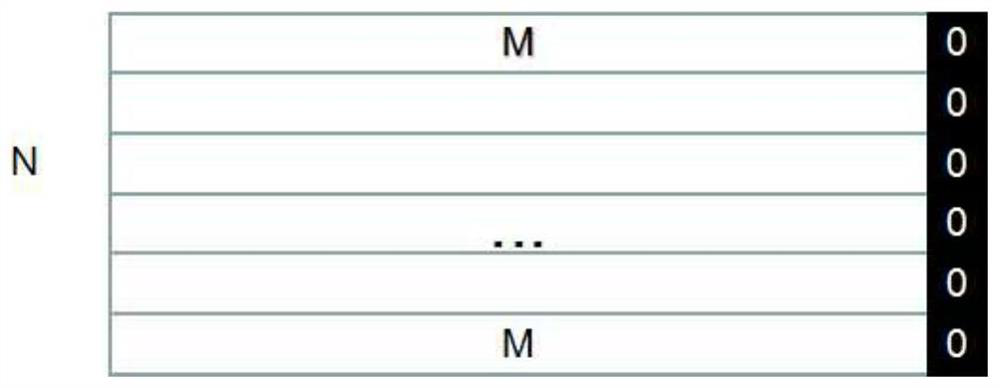

Data access and bounded processing method for deep learning semi-precision operator

PendingCN114218141ASolve the problem of misalignmentReduce occupancyElectric digital data processingAlgorithmTheoretical computer science

The invention discloses a deep learning semi-precision operator data access and bounded processing method, and the method comprises the steps: carrying out the 4B bounded processing of a specific dimension of a multi-dimensional tensor according to the calculation characteristics of an operator in deep learning and the spatial distribution of the tensor, dividing the input data of the four-dimensional tensor into different classes according to the dimensions actually participating in the calculation, and carrying out the calculation of the four-dimensional tensor. Different semi-precision data boundary alignment processing methods are respectively used; specifically, different boundary alignment methods are selected according to the type of an input operator and the calculation dimension of input data. According to the method, the problem that the half-precision operator DMA memory access on the heterogeneous many-core platform is not aligned is solved, the occupation of the memory space can be reduced, the alignment processing time can be effectively shortened, and the alignment processing performance is improved.

Owner:JIANGNAN INST OF COMPUTING TECH

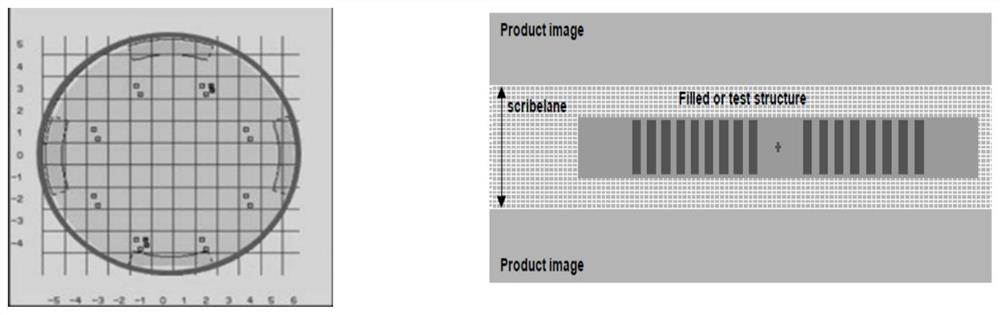

Overlay error compensation method and photoetching exposure method

PendingCN114518693ASolve the problem of misalignmentPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringExposure

The invention relates to the field of semiconductor manufacturing, in particular to an overlay error compensation method and a photoetching exposure method.The overlay error compensation method comprises the following steps that a wafer is provided, and the wafer is provided with an alignment mark; loading the wafer, and measuring a first position of the alignment mark; overturning the wafer by 180 degrees, measuring a second position of the alignment mark, and calculating a position error between the first position and the second position; and calculating the compensation amount of the alignment mark, and then performing compensation. Compared with the prior art, the embodiment of the invention has the advantages that a TIS (Tool-Induced Shift) compensation method is applied to error compensation of the alignment mark, so that the problem of alignment deviation of the alignment mark is solved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

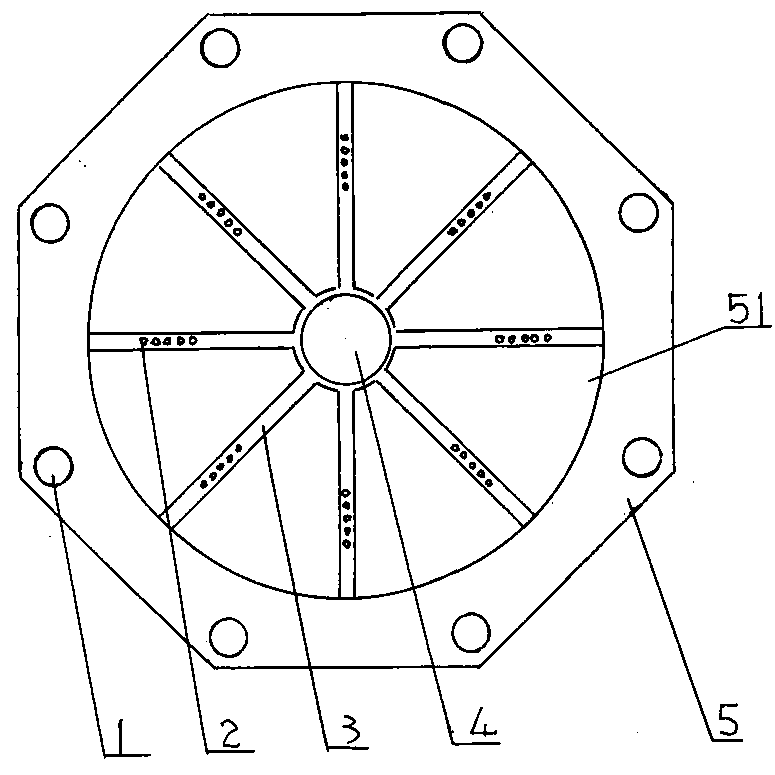

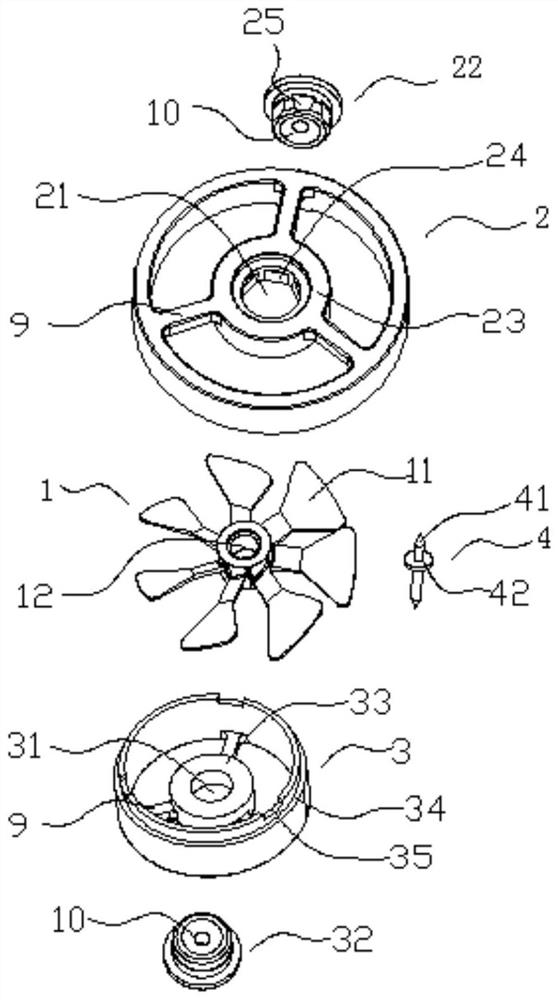

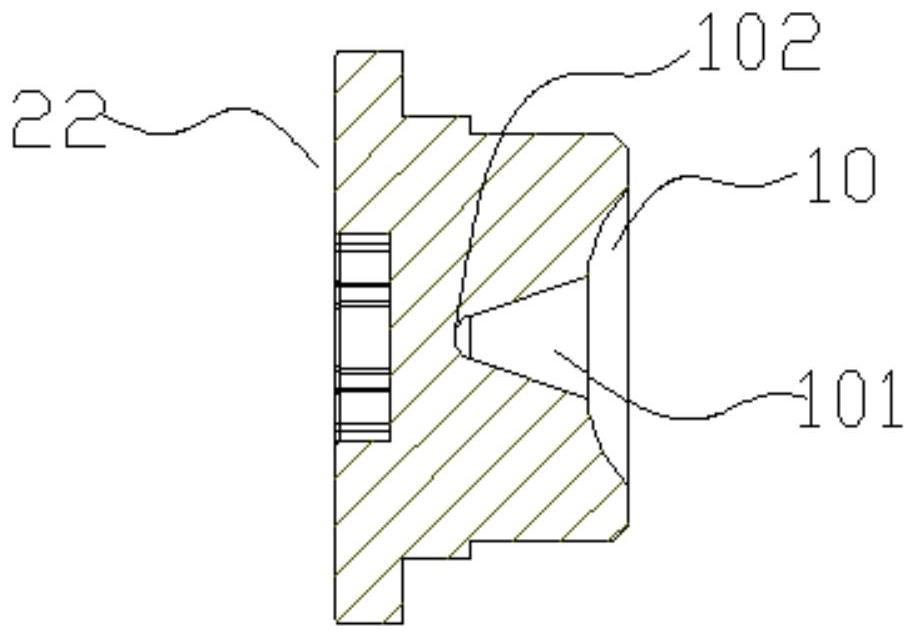

a wind wheel

ActiveCN109723604BLow rotational resistanceReduce resistanceMachines/enginesWind energy generationMarine engineeringStructural engineering

Owner:白士德(珠海)电子科技有限公司

A high-speed double-width wallpaper in-line slitting gravure printing machine

ActiveCN104760406BSolve the problem of misalignmentRotation speed synchronizationRotary intaglio printing pressDouble wallEngineering

The invention discloses a high-speed double-width wallpaper in-line slitting gravure printing machine, which includes a frame, a left support and a right support are arranged on the frame, and a device that can rotate relative to the frame is installed between the left support and the right support. The cutter shaft, the left support and the right support are respectively equipped with spacing adjustment screw rods, one end of the cutter shaft is connected with the cutter shaft motor, and three lower cutters are installed on the cutter shaft, and the sides of the lower cutters are equipped with corresponding Pneumatic cutter, 2 spacing adjustment screw rods are screwed with a linkage plate, one end of the linkage plate is connected to the left lower cutter or right lower cutter, the other end is connected to the pneumatic cutter matched with the left lower cutter or right lower cutter and the pneumatic cutter Sliding mounted above the tool shaft. This structure does not need to add a slitting machine for secondary slitting, which improves production efficiency. The slitting width can be adjusted by adjusting the spacing and adjusting the screw rod. , to prevent the product from producing burrs.

Owner:江门市智睿包装机械有限公司

Method of eutectic soldering of chip in big pad

ActiveCN106024644ASolve the problem of misalignmentSimple methodSemiconductor/solid-state device manufacturingSoldering auxillary devicesSolderingGrinding wheel

The present invention provides a method of eutectic soldering of a chip in a big pad. The method includes the following steps: step (a), determining the size of an L-shaped ceramic location clamp according to the size of the pad; step (b), determining the size of a ceramic locating pressing block according to the sizes of the pad and the chip; step (c), cutting the L-shaped ceramic locating clamp in the corresponding size by using a laser; step (d), cutting the ceramic locating pressing block in the corresponding size by using a grinding wheel cutting machine; step (e), during the process for locating the chip, first fixing the pad by using the L-shaped ceramic locating clamp, then putting the ceramic locating pressing block into the pad, and finally putting a soldering lug and the chip onto the pad; and step (f), after fixing the chip by the locating clamp, putting the chip into a vacuum eutectic furnace to perform eutectic soldering by using a soldering fixture. The method effectively solves a problem of dislocation between the chip and the pad, and the method is easy, and has a low cost and a high feasibility.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

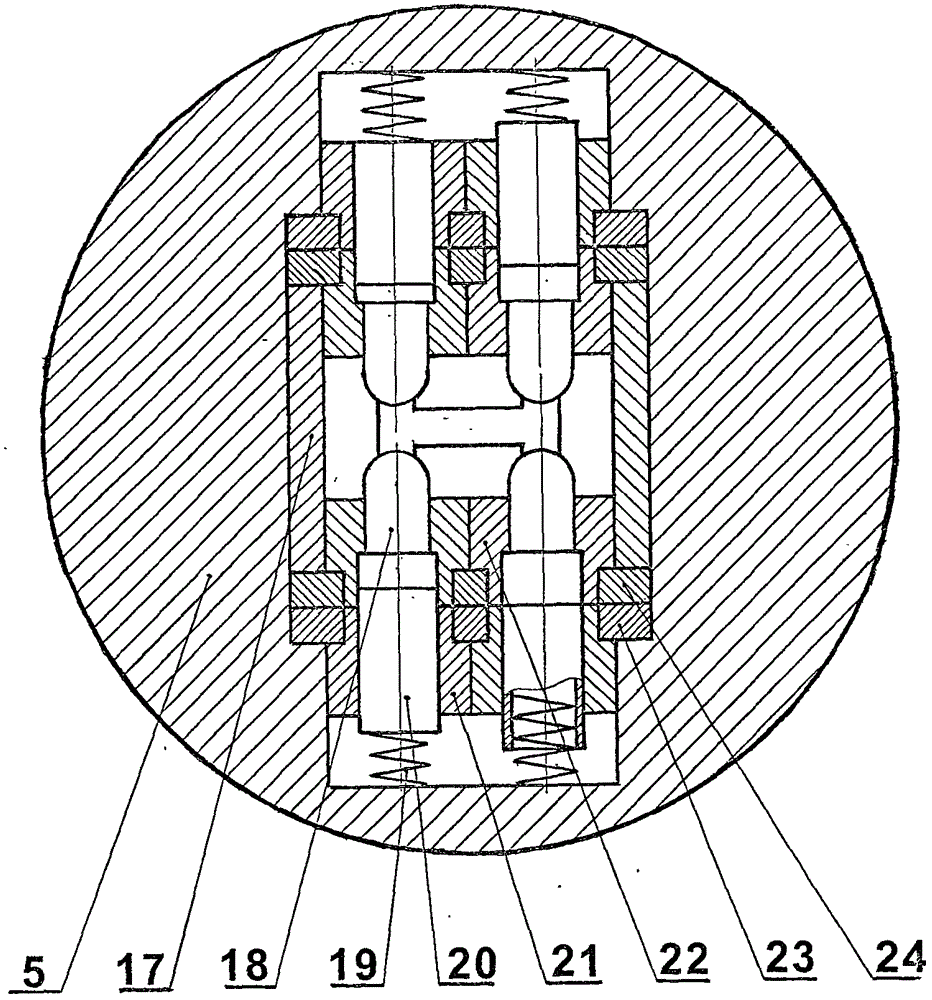

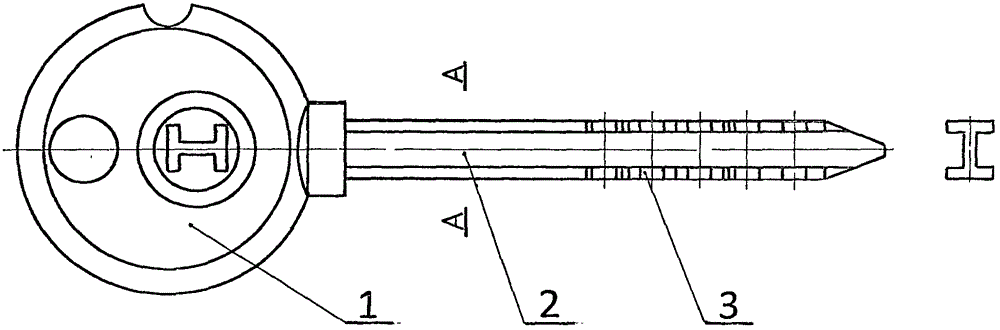

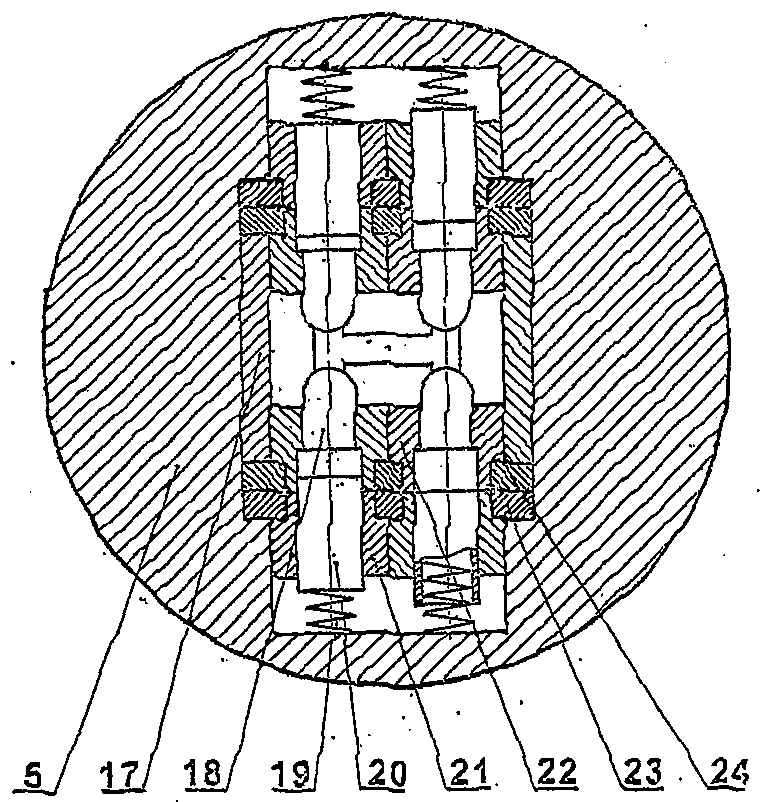

Anti-theft lock core of key and code mixed structure

ActiveCN105781248AEliminate the possibility of openingReduce consumptionKeysPuzzle locksProduction ratePunch press

The invention discloses an anti-theft lock core of a key and code mixed structure. The lock core is composed of a 20-gear marble mechanism, a code mechanism and an H-shaped key. A marble of the anti-theft lock core is designed into 20 gears divided into four rows, each row contains 5 gears, the gear number is the highest record of that of global tumbler locks, and the four-gear sealed marble and the code mechanism are additionally arranged, so that the possibility that the lock core is technically unlocked is completely eliminated. Upper and lower clamping plates of the anti-theft lock core are thin plates which are made of copper materials and can be automatically produced on a high-speed punch with materials (DOBBY punch: the speed is 300 to 1000 times / minute), and stamping is performed by using a die, so that the productivity is increased, and the problem of different axis degrees of marble holes in the upper and lower clamping plates is solved. Shaft parts of the anti-theft lock core are processed on an automatic lathe, so that the full-automatic processing of the parts is realized, the productivity of the lock core is increased by 10 times, the consumption of the copper materials is reduced by 60%, the cost is greatly reduced, and the anti-theft lock core has a high performance-to-price ratio which is the greatest advantage based on the market.

Owner:刘生豹

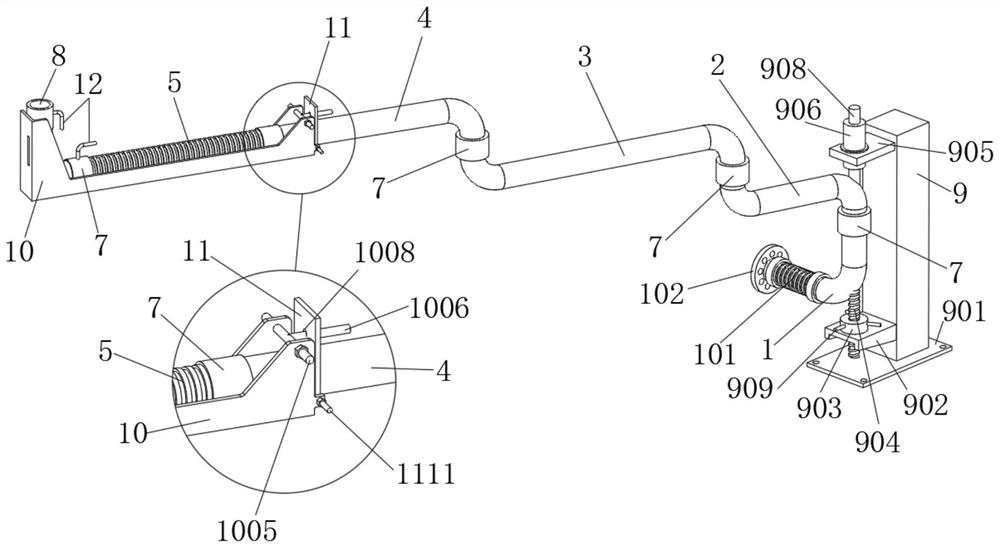

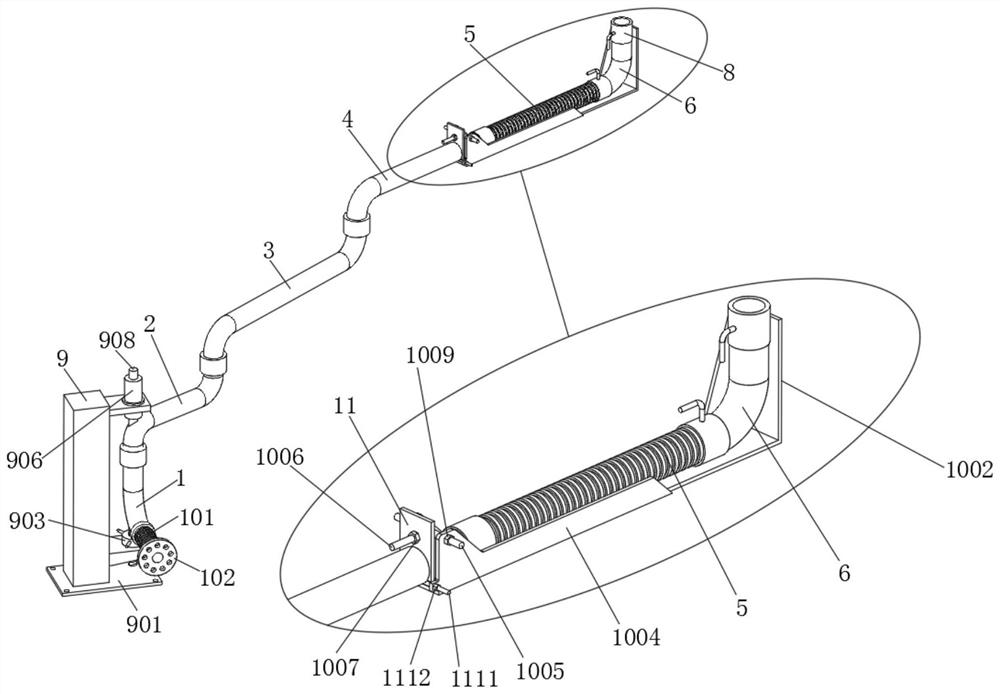

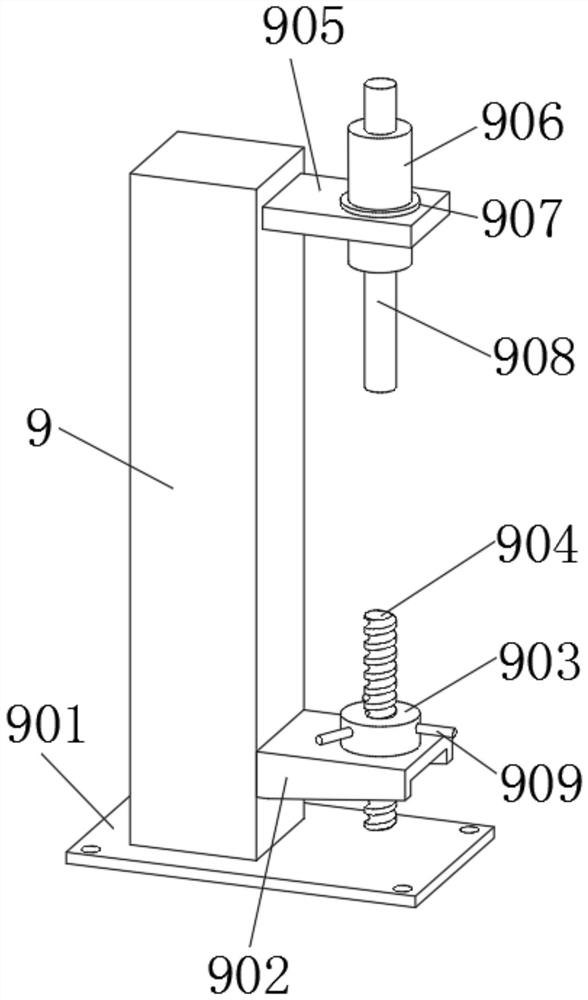

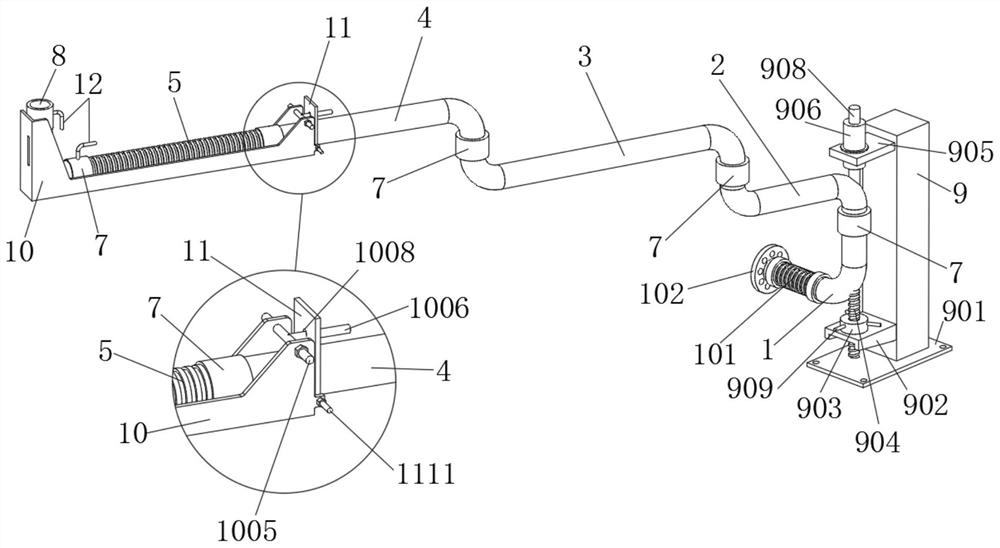

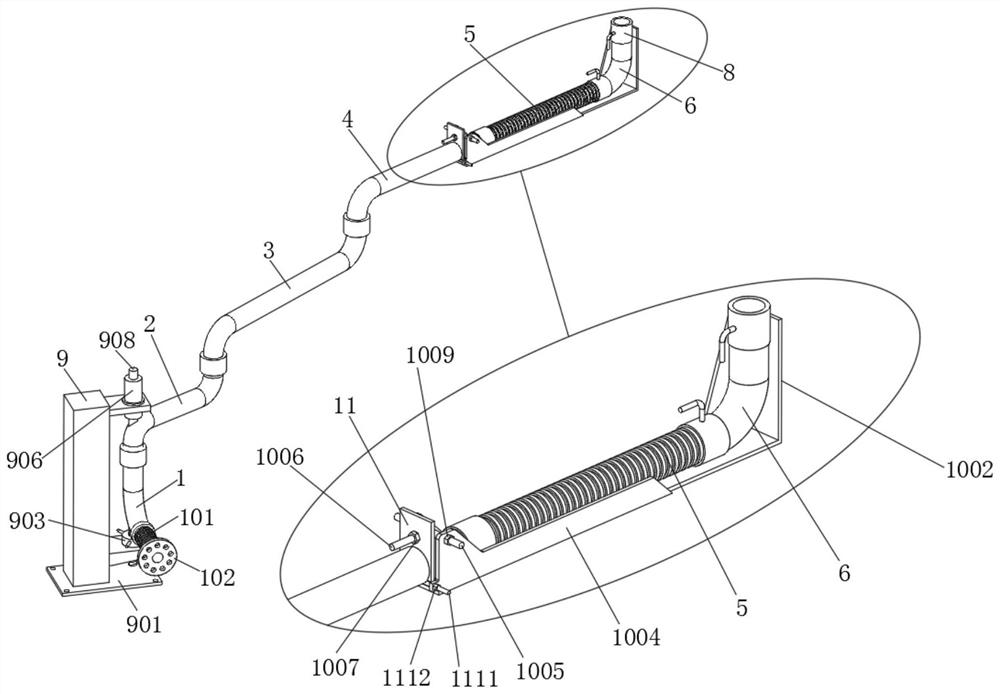

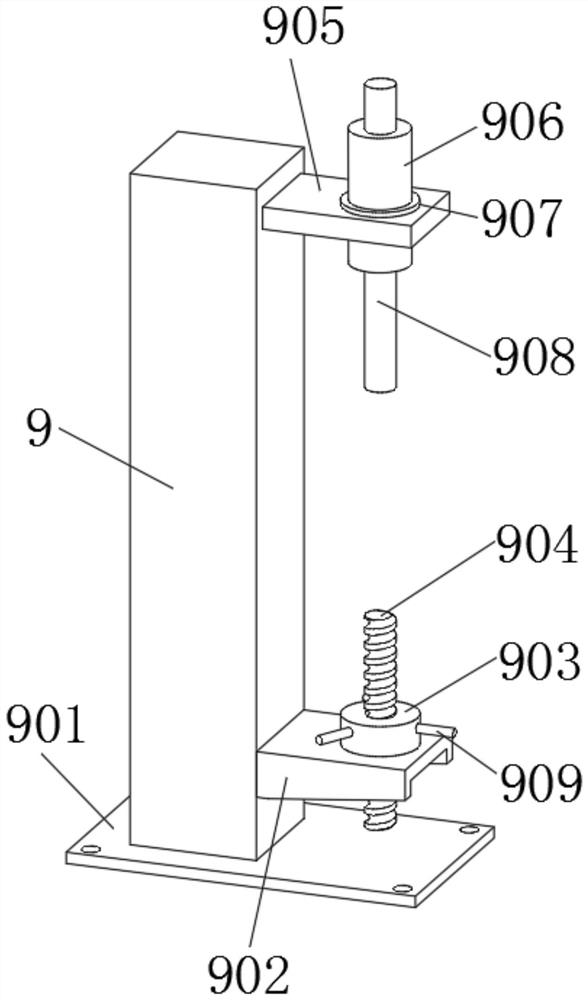

Height-adjustable tank container unloading arm

ActiveCN111908414ASolve the problem of misalignmentHeight adjustableLiquid transferring devicesEngineeringLinear motion

The invention discloses a height-adjustable tank container unloading arm. The height-adjustable tank container unloading arm comprises a combined unloading arm and a supporting mechanism; the combinedunloading arm comprises a lower arm pipe, an inner arm pipe, a middle arm pipe, an outer arm pipe, a metal hose and an upper arm pipe which are sequentially connected through rotary joints; the outerarm pipe is provided with a pitch angle adjustable supporting assembly used for supporting the metal hose; the end part of the lower arm pipe is connected with the hose; the supporting mechanism comprises a supporting stand column, a lower supporting piece is arranged at the lower portion of the side face of the supporting stand column, and an adjusting nut is arranged on the lower supporting piece; the adjusting nut is rotationally connected with the lower supporting piece; an adjusting lead screw is in threaded fit in an internal threaded hole of the adjusting nut; and the top end of the adjusting lead screw is fixedly connected with the outer wall face of the lower arm pipe. According to the height-adjustable tank container unloading arm, the supporting mechanism is arranged, when theadjusting nut is rotated, linear motion of the adjusting lead screw in the vertical direction can be achieved, so that the lower arm pipe is driven to do linear motion in the vertical direction alongwith the adjusting lead screw, and then the effect of adjusting the overall height of the combined unloading arm is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bathroom caisson secondary drainage floor drain pre-embedded system

ActiveCN110878583BReduce leak rateExemption from secondary waterproofingSewerage structuresDomestic plumbingWater storageWater flow

The invention relates to an embedding system for a secondary drainage floor drain of a toilet caisson. The system comprises a first base, a floor drain cover and an upper sewage discharge pipe. The first base is hollow, a circle of water storage wall is arranged in the first base, a cavity for water feeding and storage is formed between the inner wall of the first base and the outer wall of the water storage wall, and the inner side of the water storage wall is provided with a drainage channel. When the water level in the cavity is higher than the height of the water storage wall, water in thecavity can be discharged via the drainage channel. The floor drain cover is embedded in the first base and provided with water inlets for water leakage and an upper connection port, a water seal cover is arranged below the floor drain cover, and the water seal cover extends into the cavity. The upper sewage discharge pipe comprises a main pipe body and a drainage structure located on the main pipe body, the main pipe body penetrates through the upper connection port and is inserted in the water storage wall, and the drainage structure is used for draining water flowing down from the inner wall of the main pipe body into the cavity. According to the embedding system, a small part of water in the sewage discharge pipe is introduced into the floor drain, so that the liquid level of a water seal of the floor drain is sufficient, and the anti-odor effect is achieved.

Owner:深圳市新星联合管道有限公司

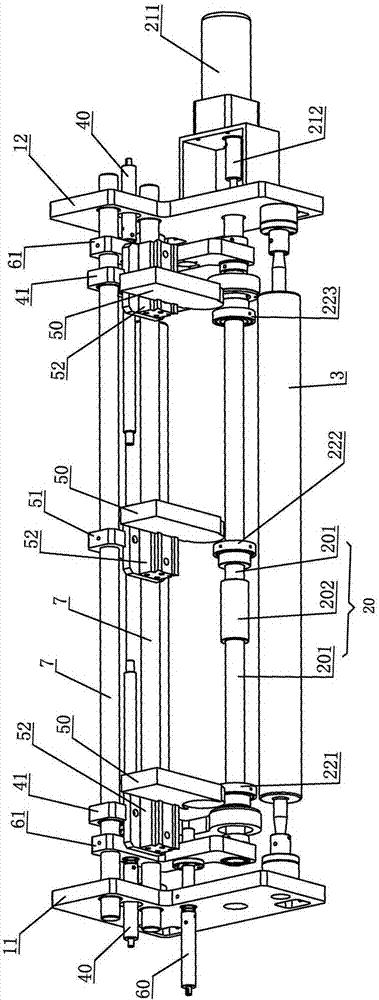

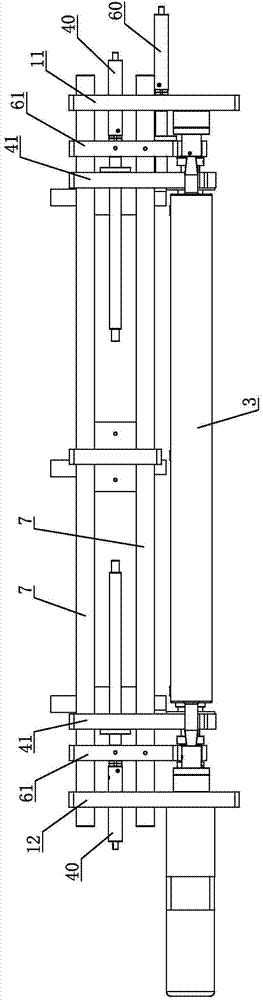

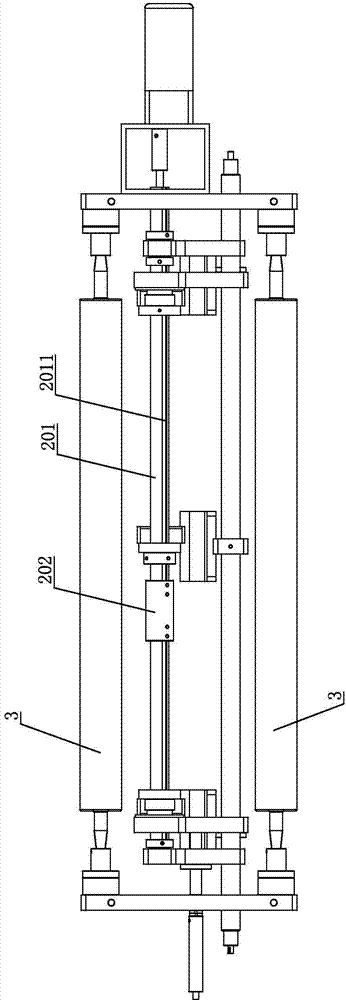

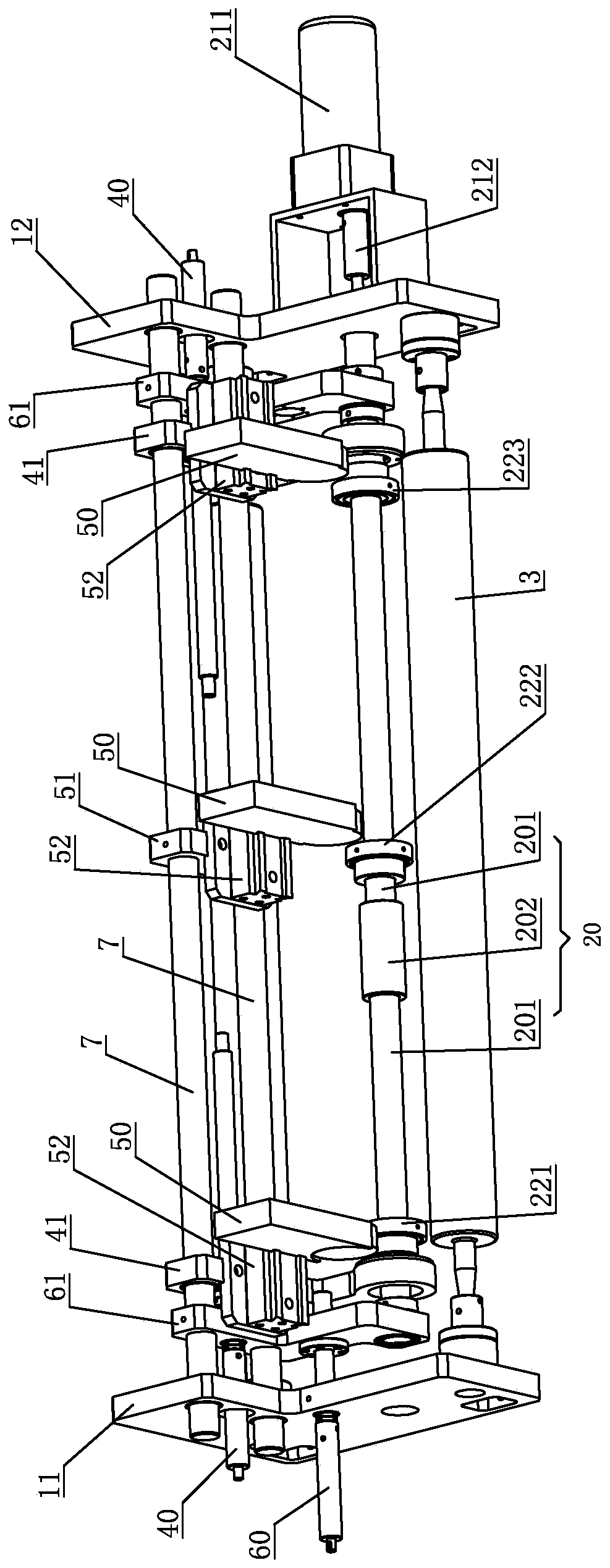

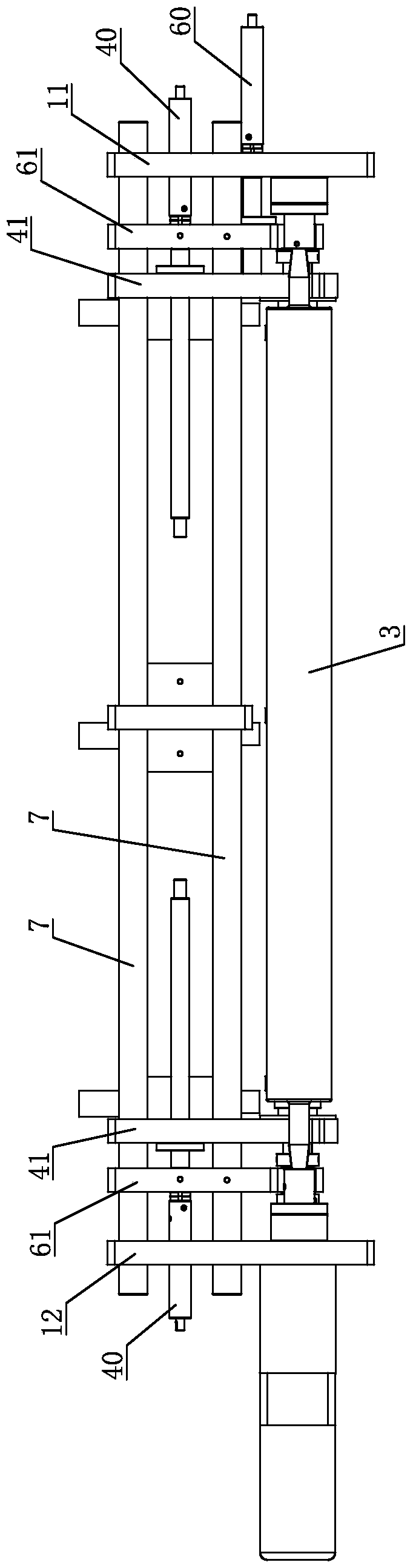

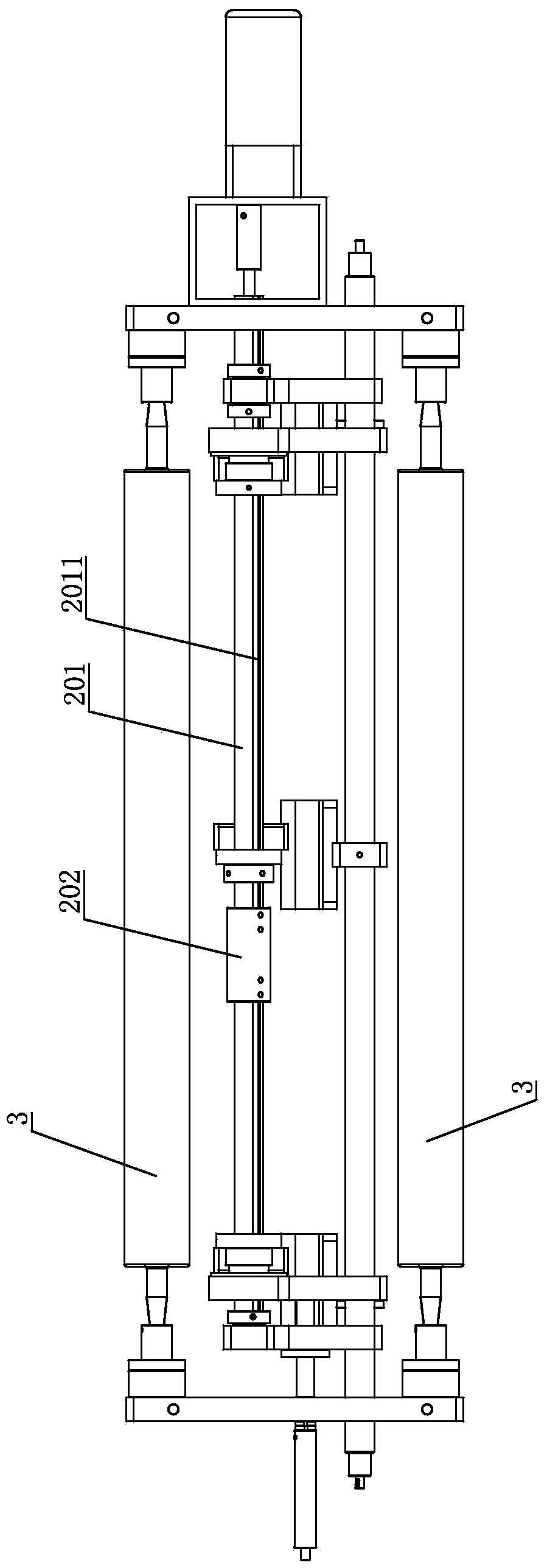

Rod bending, inserting and sleeving machine

InactiveCN108500586AIncrease productivitySolve the problem of misalignmentMetal working apparatusDrive motorEngineering

The invention discloses a rod bending, inserting and sleeving machine which comprises a rack, an automatic discharging mechanism, a material supporting plate mechanism, a material propulsion mechanismand a hydraulic pushing cylinder. The tail end of a piston rod of the hydraulic pushing cylinder is connected with an inserting push plate. An upper bottom plate and a lower bottom plate are arrangedon the rack. Jacking air cylinders are fixed to the upper bottom plate. Push rods of the jacking air cylinders are connected with a connecting frame. A screw is arranged on the connecting frame. Thematerial propulsion mechanism is in threaded connection with the screw through a sliding seat. An upper press roller and a lower press plate are arranged on the lower bottom plate, the upper press roller and a drive motor are connected through a core shaft, annular grooves are formed in the upper press roller, and a bending channel is formed by the annular grooves and an arc passing segment on thelower press plate. According to the aim, the rod bending, inserting and sleeving machine is provided for solving the problems, automatic assembling is adopted, whole assembling is in the faster and more convenient process, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

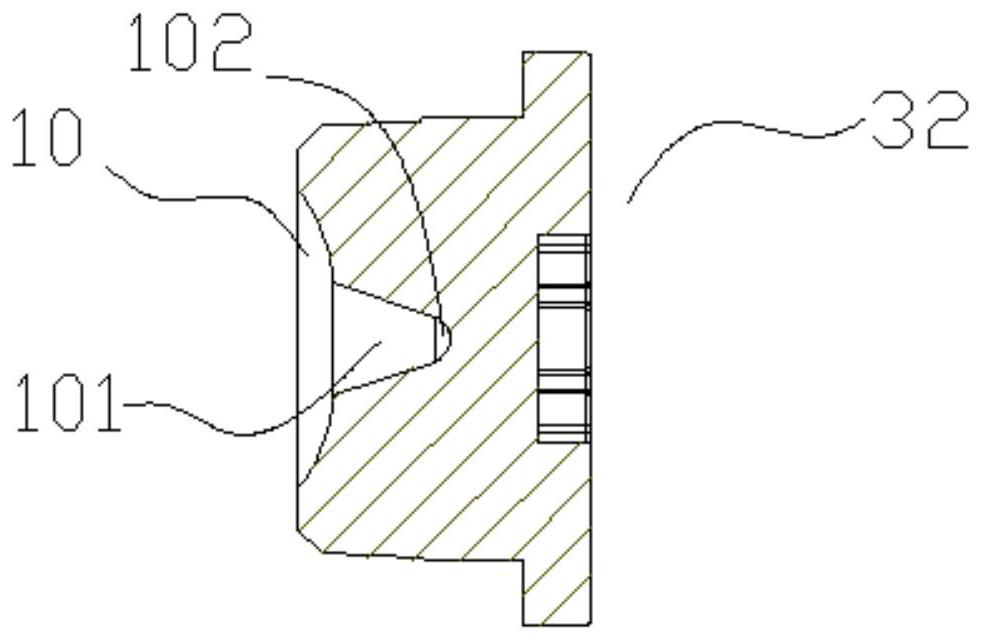

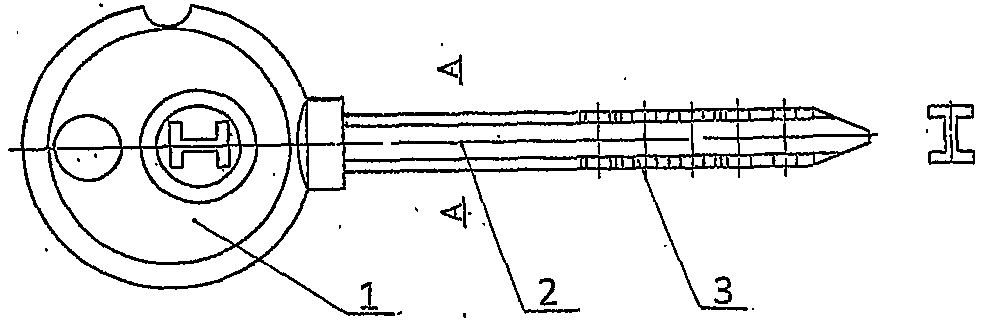

Bearing press-fit auxiliary device

The invention discloses a bearing press-fit auxiliary device, comprising: a bottom plate; an upper fixing plate connected to the bottom plate through a vertical plate; a placing seat arranged on the bottom plate, wherein the placing seat has a receiving cavity, and the receiving cavity faces the upper fixing plate; a guiding pin located in the placing seat and protruding towards the direction of the upper fixing plate; a pressing head movably disposed on the upper fixing plate in the axial direction, wherein one end, facing the placing seat, of the pressing head is the pressure end, the pressure end has a blind hole, and the blind hole is matched with the guiding pin. The bearing press-fit auxiliary device of the invention solves the problem of misalignment in the bearing press-fit processand solves the safety hazard of the press-fit of a hand-held auxiliary device. A flywheel positioning sleeve is installed in the receiving cavity of the placing seat, and a guiding hub bearing is arranged at the pressure end and is pressed into the flywheel positioning sleeve by the pressing head. Positions of the pressing head and the placing seat are fixed, and the problem of misalignment is not easy to occur. The guiding pin is also used as an auxiliary. Once there is a problem of misalignment, the guiding pin prevents the pressing head from falling.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A height-adjustable tank container unloading arm

ActiveCN111908414BHeight adjustableCompensation for Engineering DeviationsLiquid transferring devicesLinear motionEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A key + password mixed structure anti-theft lock cylinder

ActiveCN105781248BReduce consumptionSolve the problem of misalignmentKeysPuzzle locksProduction ratePunch press

The invention discloses an anti-theft lock core of a key and code mixed structure. The lock core is composed of a 20-gear marble mechanism, a code mechanism and an H-shaped key. A marble of the anti-theft lock core is designed into 20 gears divided into four rows, each row contains 5 gears, the gear number is the highest record of that of global tumbler locks, and the four-gear sealed marble and the code mechanism are additionally arranged, so that the possibility that the lock core is technically unlocked is completely eliminated. Upper and lower clamping plates of the anti-theft lock core are thin plates which are made of copper materials and can be automatically produced on a high-speed punch with materials (DOBBY punch: the speed is 300 to 1000 times / minute), and stamping is performed by using a die, so that the productivity is increased, and the problem of different axis degrees of marble holes in the upper and lower clamping plates is solved. Shaft parts of the anti-theft lock core are processed on an automatic lathe, so that the full-automatic processing of the parts is realized, the productivity of the lock core is increased by 10 times, the consumption of the copper materials is reduced by 60%, the cost is greatly reduced, and the anti-theft lock core has a high performance-to-price ratio which is the greatest advantage based on the market.

Owner:刘生豹

Method for manufacturing liquid crystal display panel

InactiveCN104111561BEvenly arrangedSolve the problem of misalignmentNon-linear opticsVoltage referenceEngineering

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com