Split electromagnetic coupling

A coupling and split-type technology, which is applied in the direction of magnetic drive clutches, clutches, and non-mechanical drive clutches, etc., to achieve the effects of reducing the requirements for coaxial shafts, reducing the number, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

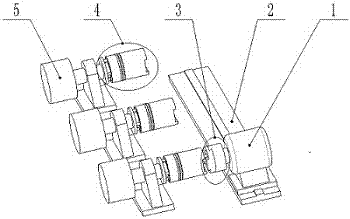

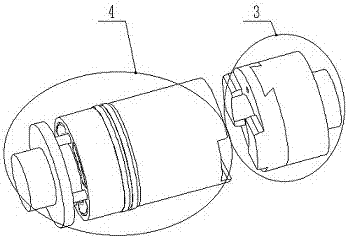

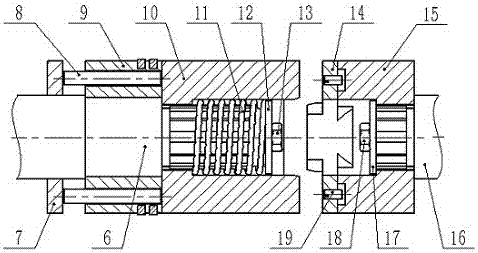

[0013] Examples, see attached Figure 1-6 , a split-type electromagnetic coupling, including a coupling input unit 3 and a coupling output unit 4, taking a power source 1 driving three horizontally arranged loads 5 in different periods as an example, a coupling input unit 3 Installed together with the movable power source 1, the three coupling output units 4 are respectively installed with the loads 5 at three different positions, and the coupling input unit 3 moves along with the power source 1 along the guide rail 2, and can be respectively Engage with any one of the coupling output units 4 arranged in the same direction at three different positions on the same line to drive three loads 5 in different periods; the fixed half-coupling 15 of the coupling input unit 3 Slidingly connected with the slider 14, the coupling output unit 4 is provided with an engaging device and a reset device, and the engaging device can push the movable half-coupling 10 outward along the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com