Bridge pile foundation on-site-binding reinforcement cage deviation control formwork and construction method thereof

A technology for reinforcing cages and binding steel bars, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., which can solve the problems of insufficient thickness of steel bar protection layer in pile foundations, affect the internal quality of pile foundations, and high cost, etc., and achieve low production and use costs , simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

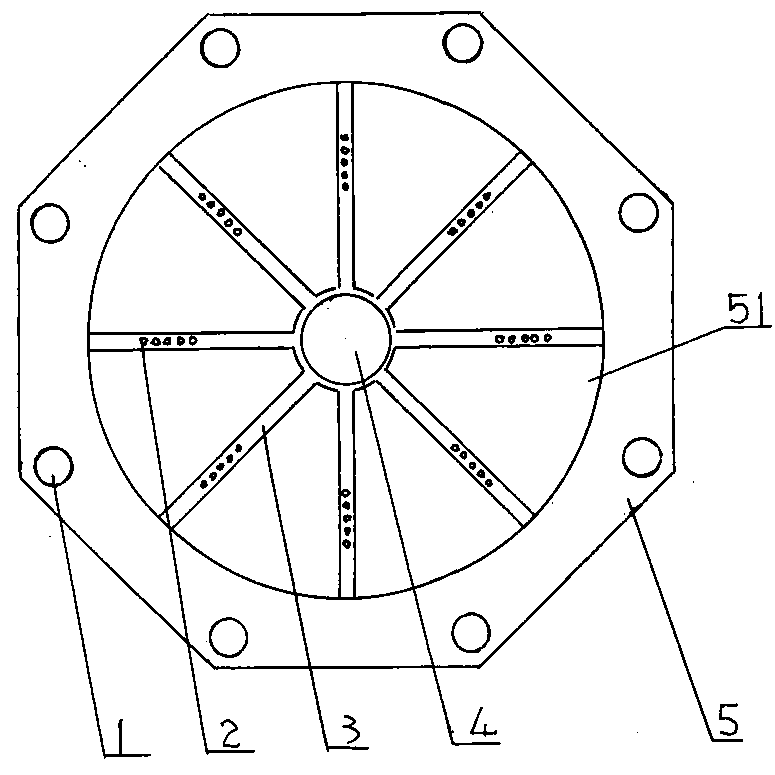

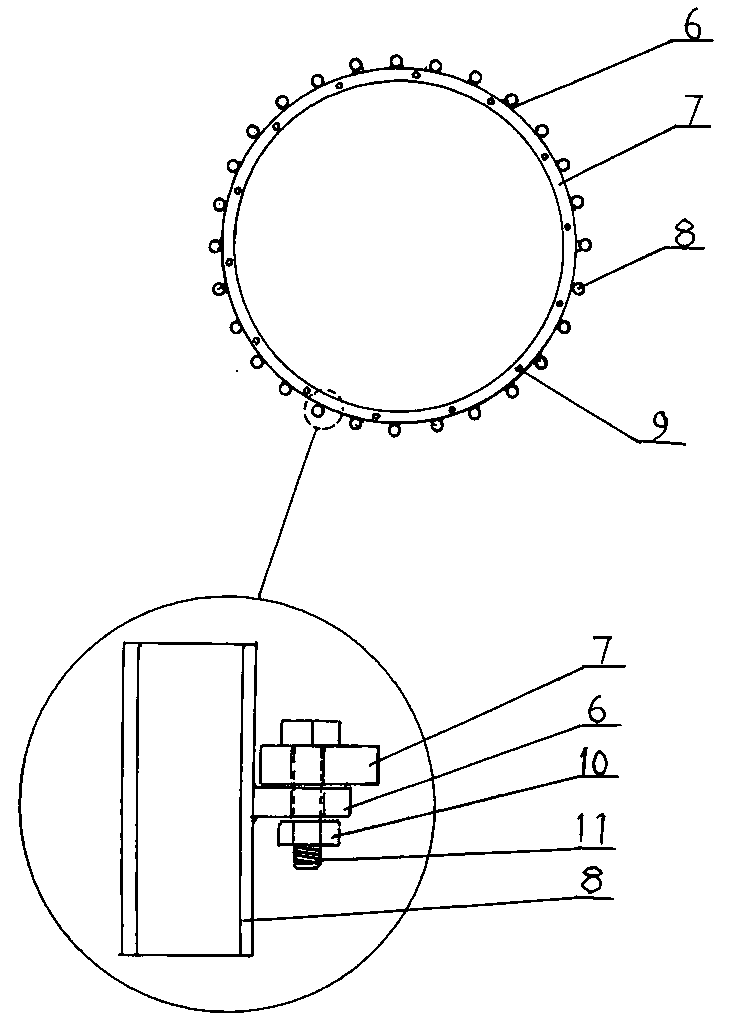

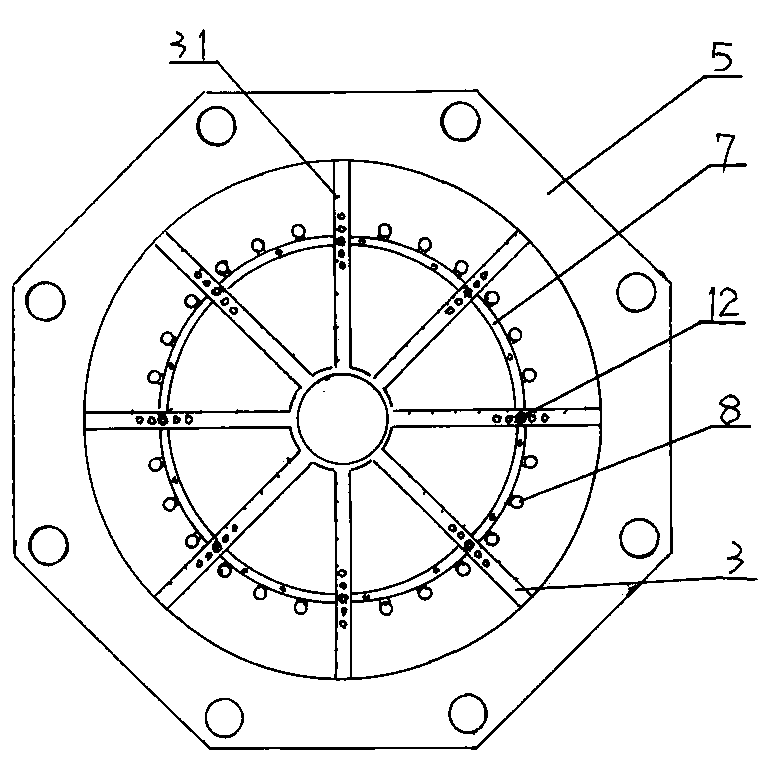

[0053] Embodiment 1: as Figure 1 to Figure 8 As shown, a bridge pile foundation is now bound steel cage deviation control formwork is composed of steel casing 8, wherein:

[0054] Fixed disk panel 5: used to support the fixed disk support frame. The fixed plate panel can be assembled and welded by 6-10mm thick steel plates. The periphery of the fixed plate panel is octagonal, and the diagonal length of the fixed plate panel is 2.75m. A pile foundation through hole 51 is provided in the middle of the fixed disk panel, the diameter of the inner circle is 2.0m, and the diameter of the pile foundation through hole is larger than the diameter of the bridge pile foundation. The opposite corner of the fixed plate panel is provided with a fixed through hole 1, and the fixed through hole is used to fix the fixed plate panel on the upper end of the steel cage construction surface of the bridge pile foundation, that is, the fixed plate panel can be fixed on the fixed through hole with ...

Embodiment 2

[0081] Embodiment 2: Different from Embodiment 1: if the steel cage bottom diameter size required by the design in the column to be constructed or in the pier is different from the top diameter size (such as a narrow column, pier, etc. on the bottom width), The construction of fixed steel cage positioning plate and steel cage positioning arc plate: then:

[0082] (1) The fixed reinforcement cage positioning plate is selected and placed at the bottom of the pouring formwork in the column or pier. The steel cage positioning arc plate is used to position and fix the steel casing assembly after assembly. Several steel cage positioning arc plates are connected end-to-end with each other, or the two ends of each other are staggered and connected to one side of the fixed plate support frame to form a diameter variable. In the circular annular body, the length of a reinforcement cage positioning arc plate is greater than the distance between two adjacent fixed disk support frames.

...

Embodiment 3

[0090] Embodiment 3: The difference from Embodiments 1 and 2 is that the positioning arc plates of the reinforcement cage and the positioning discs of the moving reinforcement cage can replace each other. At that time, it is only necessary to select and install the mobile reinforcement cage positioning plate corresponding to the same diameter as the reduction reinforcement cage in the diameter reduction reinforcement cage section; and correct the reinforcement sleeve on it to match the longitudinal reinforcement position of the reduction diameter reinforcement cage. So I won't repeat it any more.

[0091] In a word, the present invention can effectively control the correction and apply to the deflection of existing steel cages with different diameters of pile foundations, and has the advantages of simple structure, fast construction speed, good quality, low production and use cost, time-saving and labor-saving, and wide applicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com