A key + password mixed structure anti-theft lock cylinder

A technology of mixed structure and anti-theft lock cylinder, which is applied in combination locks, locks with turning keys, keys, etc., can solve the problems of mechanical anti-theft locks, such as untrue names, reduced lock security, and high labor intensity, so as to improve productivity, Improve productivity and save copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

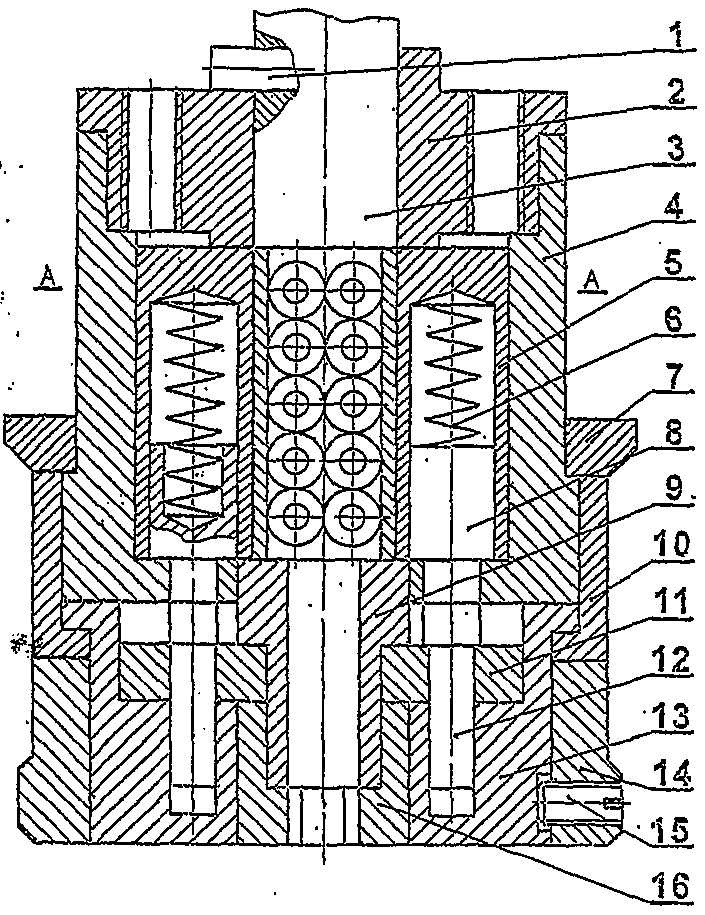

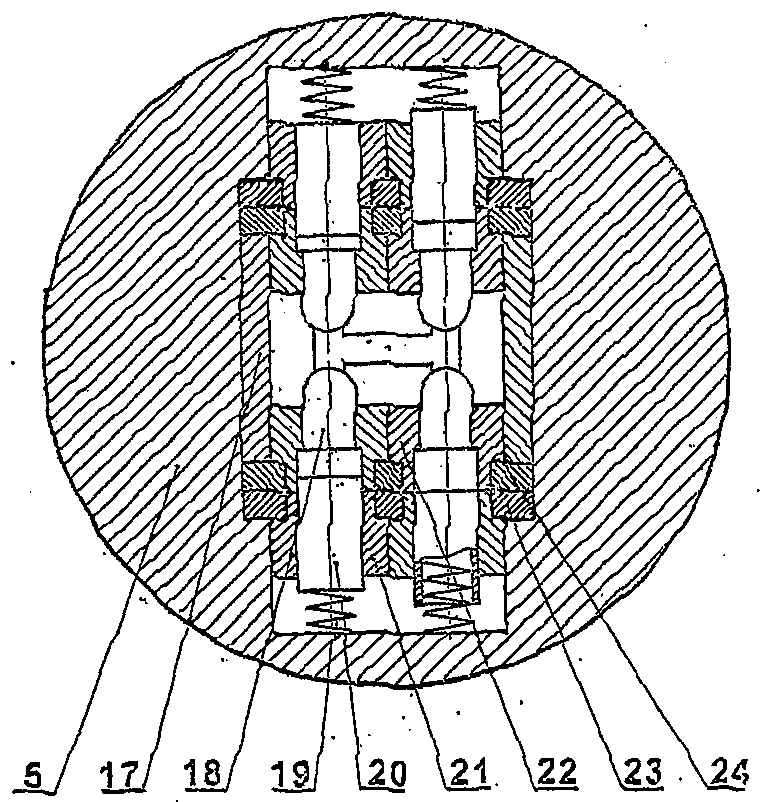

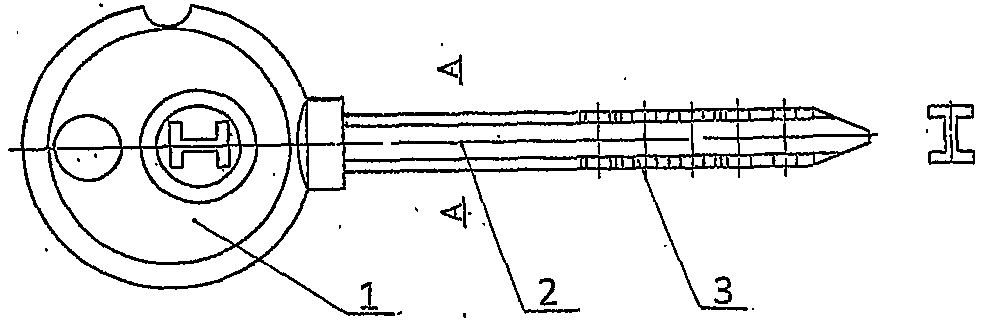

[0014] figure 1 It is the lock cylinder assembly drawing of the present invention, figure 2 yes figure 1 The cross-sectional view of A-A, an anti-theft lock cylinder with a key ten password mixed structure of the present invention, is composed of a 20-gear pin mechanism, a password mechanism and an I-shaped key. The 20-gear pin mechanism includes a positioning shaft 1, a lock cylinder cover 2, and a splint Upper fixed shaft 3, lock core seat 4, splint disk 5, compression spring 6, washer 7, lower splint fixed shaft 9, keyhole sleeve 16, splint backing plate 17, lower marble 18, pin compression spring 19, upper marble 20, Upper pinch tube 21, lower pinch tube 22, upper splint 23, lower splint 24, the pin design 20 gears of this pin mechanism are 4 rows of 5 gears, and design 4 gears of closing pins among the 20 pins, the so-called sealing pins are the Under normal condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com