Replacement method of revolving bearing of material taking machine

A replacement method and a technology for slewing bearings, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult bearing access, replacement bearings that cannot be rotated and reset, high requirements for jacking and positioning, and achieve the effect of solving misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

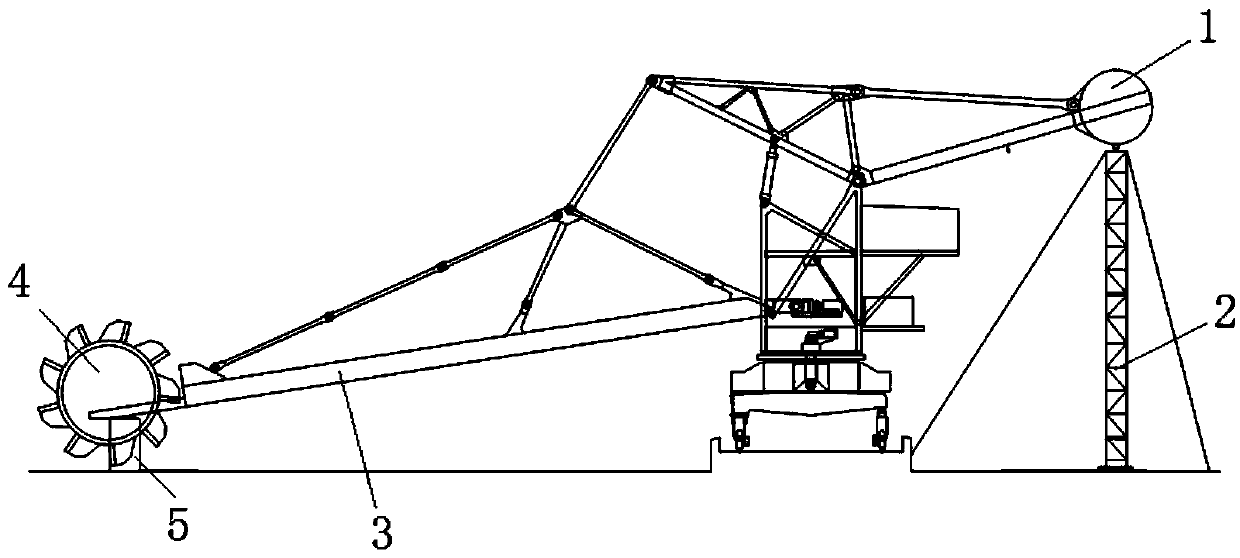

[0028] Embodiment 1 of the present invention: as figure 1 As shown, a method for replacing the slewing bearing of a reclaimer specifically includes the following steps,

[0029] Preparations: Necessary conditions for on-site disassembly of slewing bearings. The wind speed at the work site must be less than 10m / s (level 5 wind). When the wind speed is greater than 10m / s, the disassembly work must be stopped, and the slewing connection bolts must be reset and reconnected. . Prepare counterweight support, jib support, hydraulic jack and other machinery, tools and facilities.

[0030] Step 1, install the counterweight bracket: set the counterweight bracket 2 directly under the counterweight 1 of the reclaimer, place two sets of 200-ton counterweight jacking jacks on the top of the counterweight bracket 2, and set the counterweight jacking jack on the top of the counterweight jack. Heavy jacking mould;

[0031] Step 2, adjust the arm frame and counterweight of the reclaimer and ...

Embodiment 2

[0038] Embodiment 2 of the present invention: as figure 1 As shown, a method for replacing the slewing bearing of a reclaimer specifically includes the following steps,

[0039] Step 1, install the counterweight bracket: set the counterweight bracket 2 directly under the counterweight 1 of the reclaimer, place two sets of 200-ton counterweight jacking jacks on the top of the counterweight bracket 2, and set the counterweight jacking jack on the top of the counterweight jack. Heavy jacking mould;

[0040] Step 2, adjust the arm frame and counterweight of the reclaimer and set the arm frame support: the reclaimer pitches and lifts the arm frame of the reclaimer 3 At the same time, adjust the counterweight jack to compact and lift the mold, and then anchor the large traveling wheel, Weld the stopper on the track and add iron shoes; set the boom bracket 5 directly below the bucket wheel 4 of the boom bracket of the reclaimer, place a pier on the jib bracket 5 to adjust the height, ...

Embodiment 3

[0046] Embodiment 3 of the present invention: as figure 1 As shown, a method for replacing the slewing bearing of a reclaimer specifically includes the following steps,

[0047] Step 1, install the counterweight bracket: set the counterweight bracket 2 directly under the counterweight 1 of the reclaimer, place two sets of 200-ton counterweight jacking jacks on the top of the counterweight bracket 2, and set the counterweight jacking jack on the top of the counterweight jack. Heavy jacking mould;

[0048] Step 2, adjust the arm frame and counterweight of the reclaimer and set the arm frame support: the reclaimer pitches and lifts the arm frame of the reclaimer 3 At the same time, adjust the counterweight jack to compact and lift the mold, and then anchor the large traveling wheel, Weld the stopper on the track and add iron shoes; set the boom bracket 5 directly below the bucket wheel 4 of the boom bracket of the reclaimer, place a pier on the jib bracket 5 to adjust the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com