Patents

Literature

39results about How to "Realize replacement work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

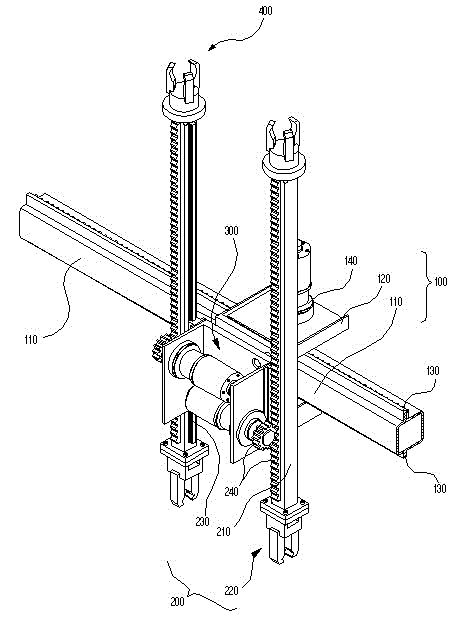

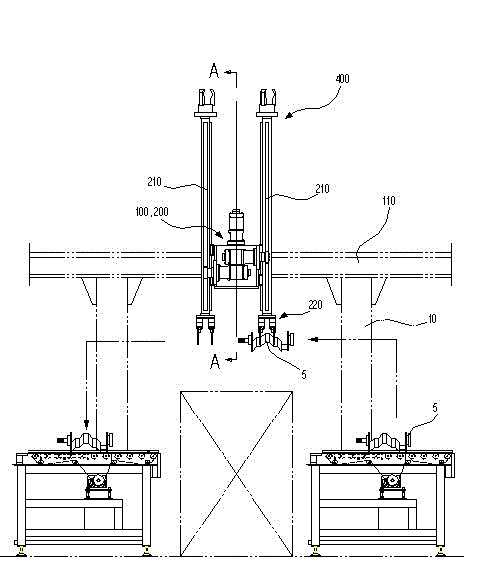

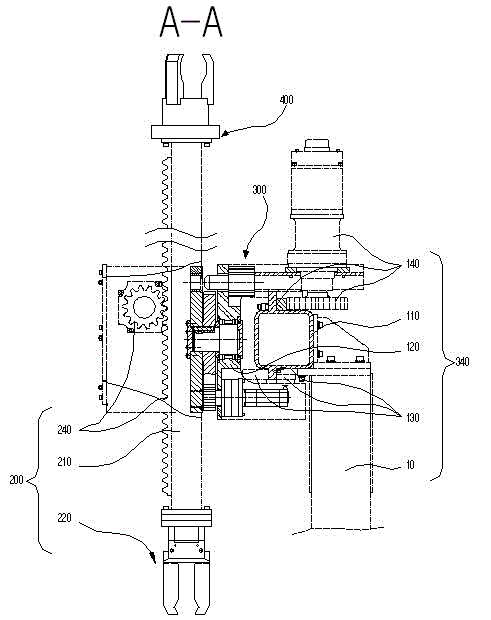

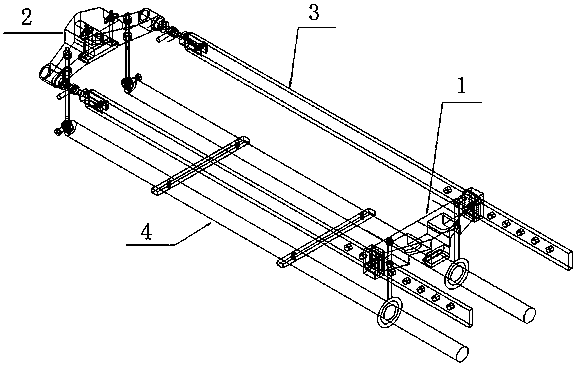

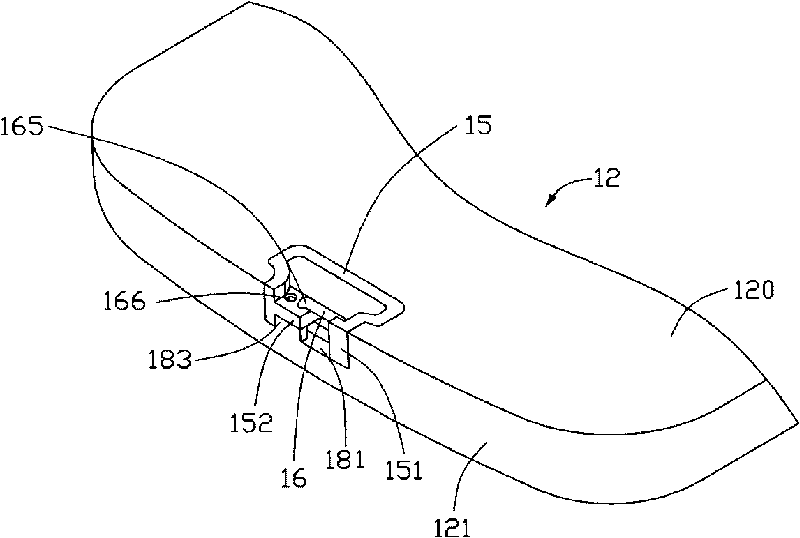

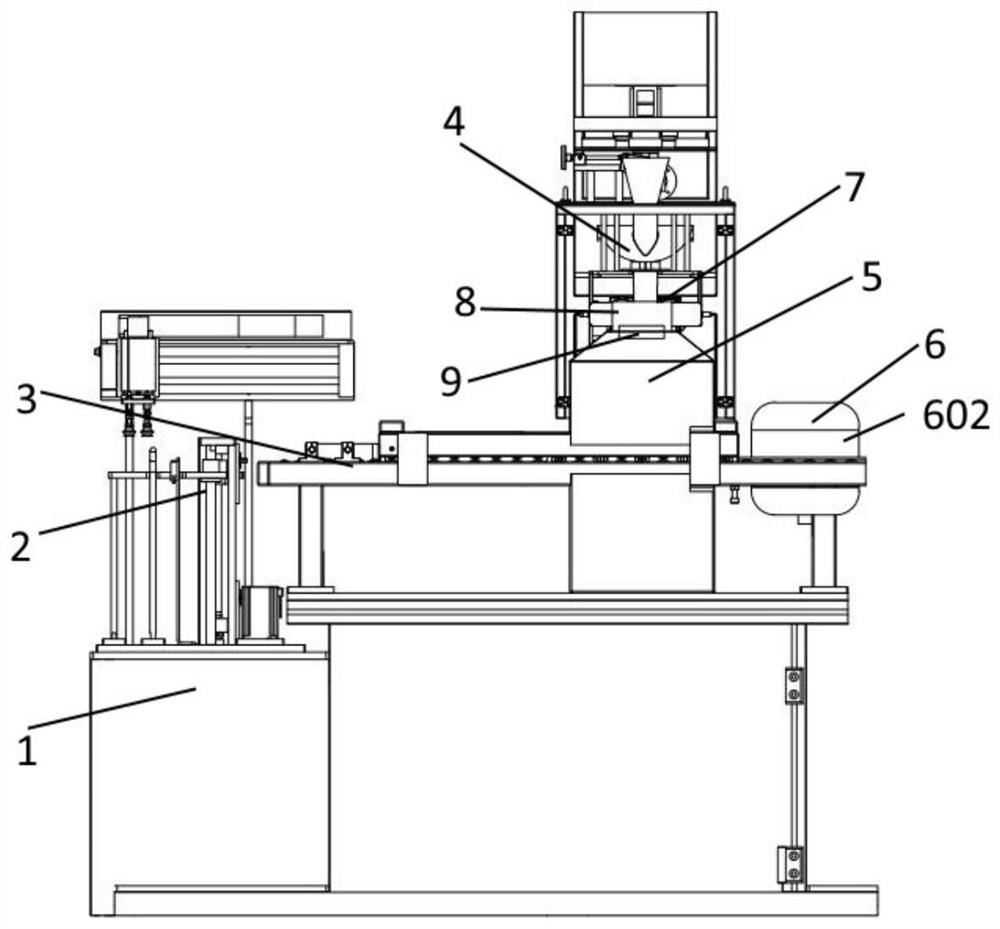

Fixture replacing device for industrial workpiece conveying device

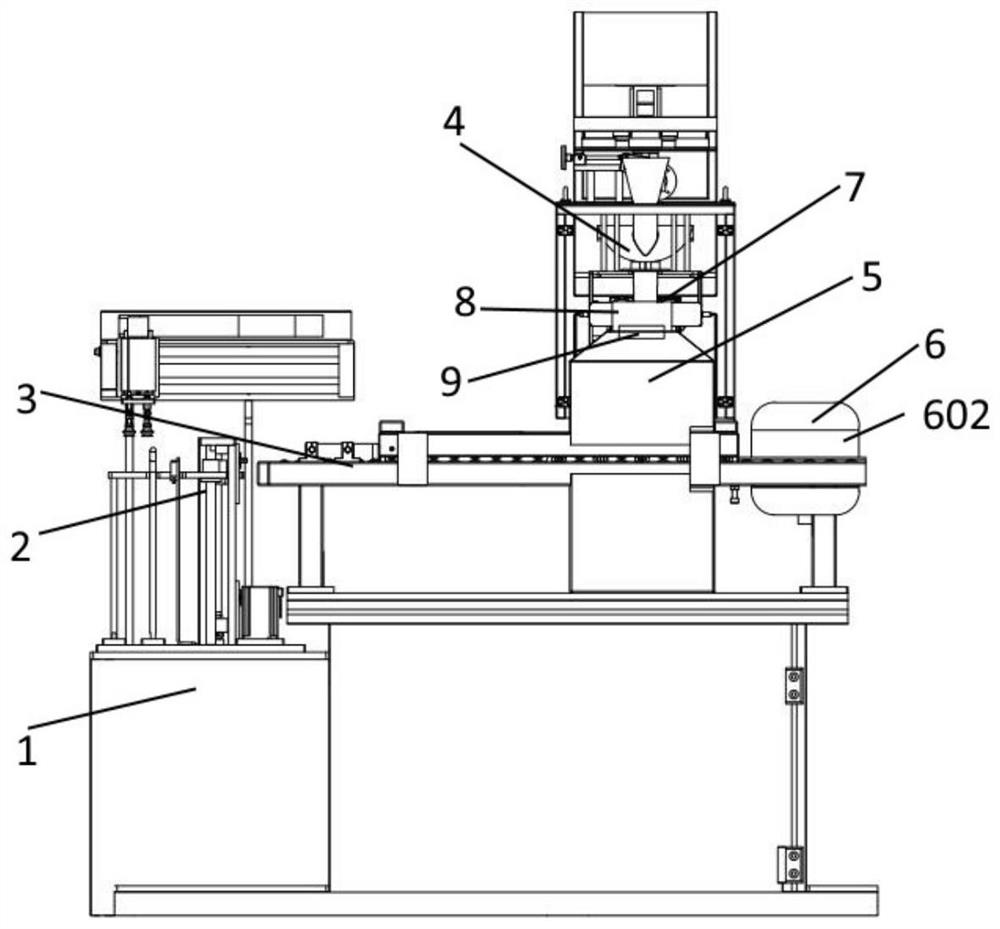

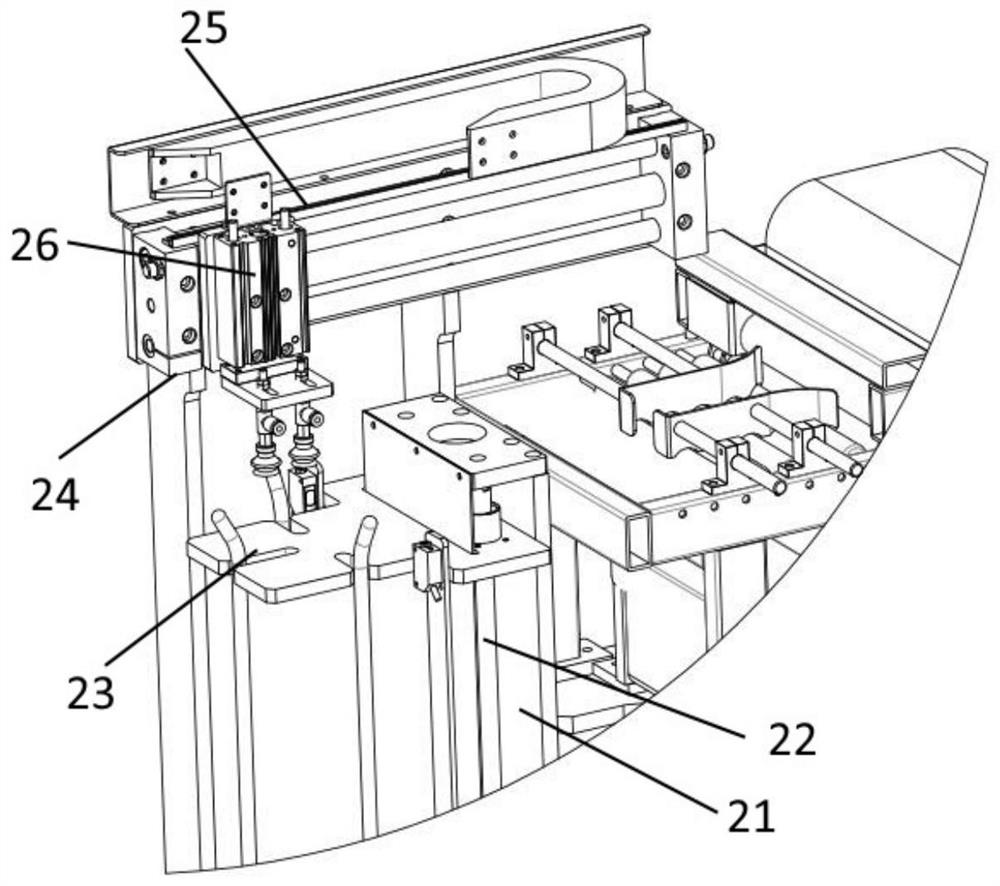

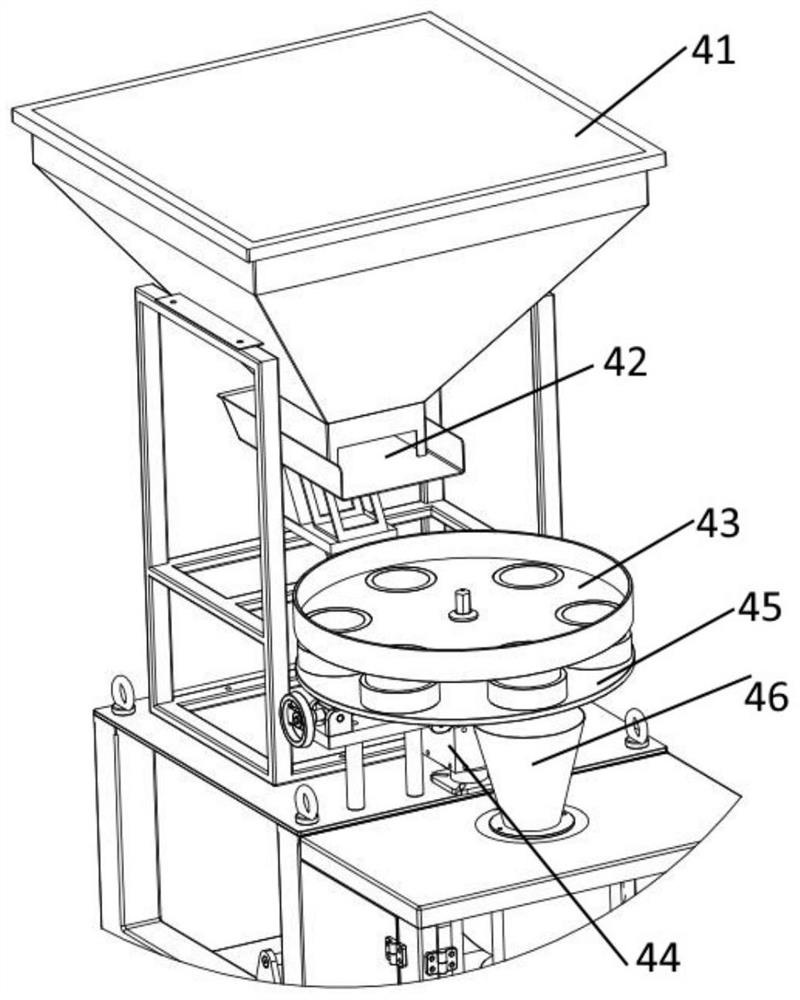

InactiveCN102975078ARealize replacement workShorten the timeMetal working apparatusMachineIndustrial engineering

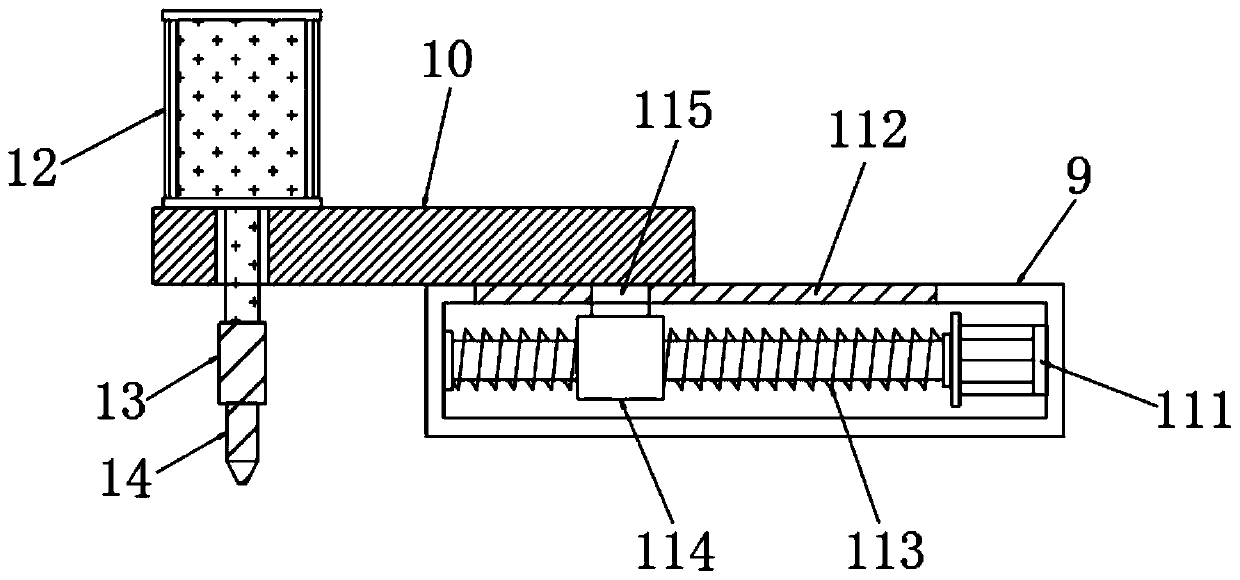

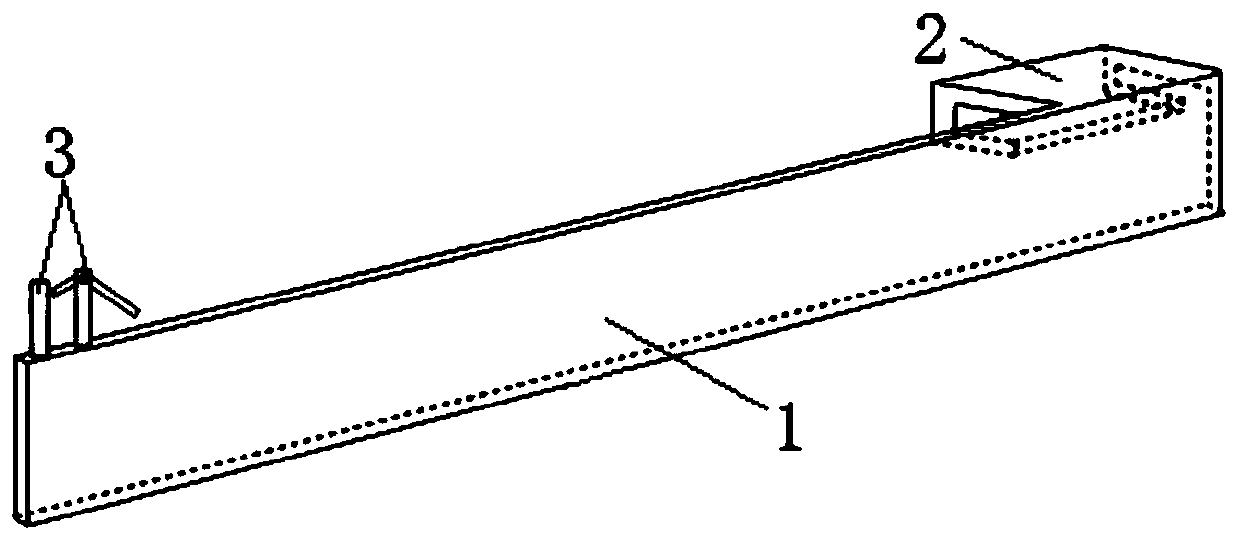

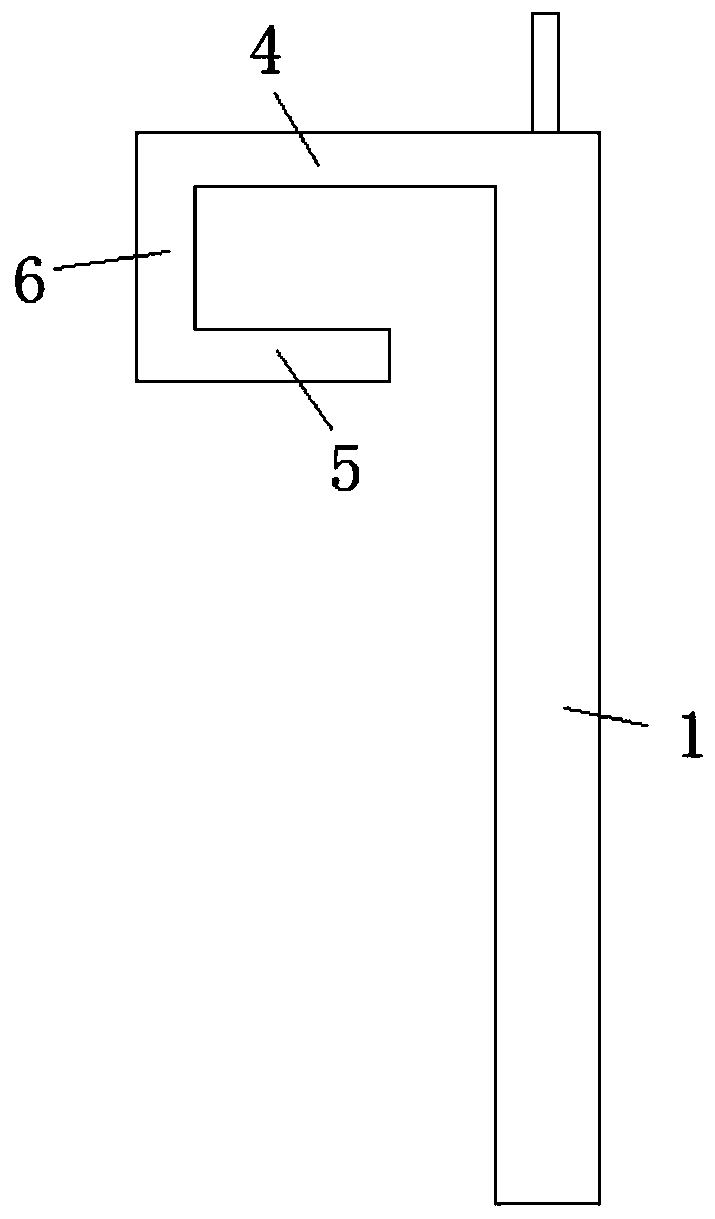

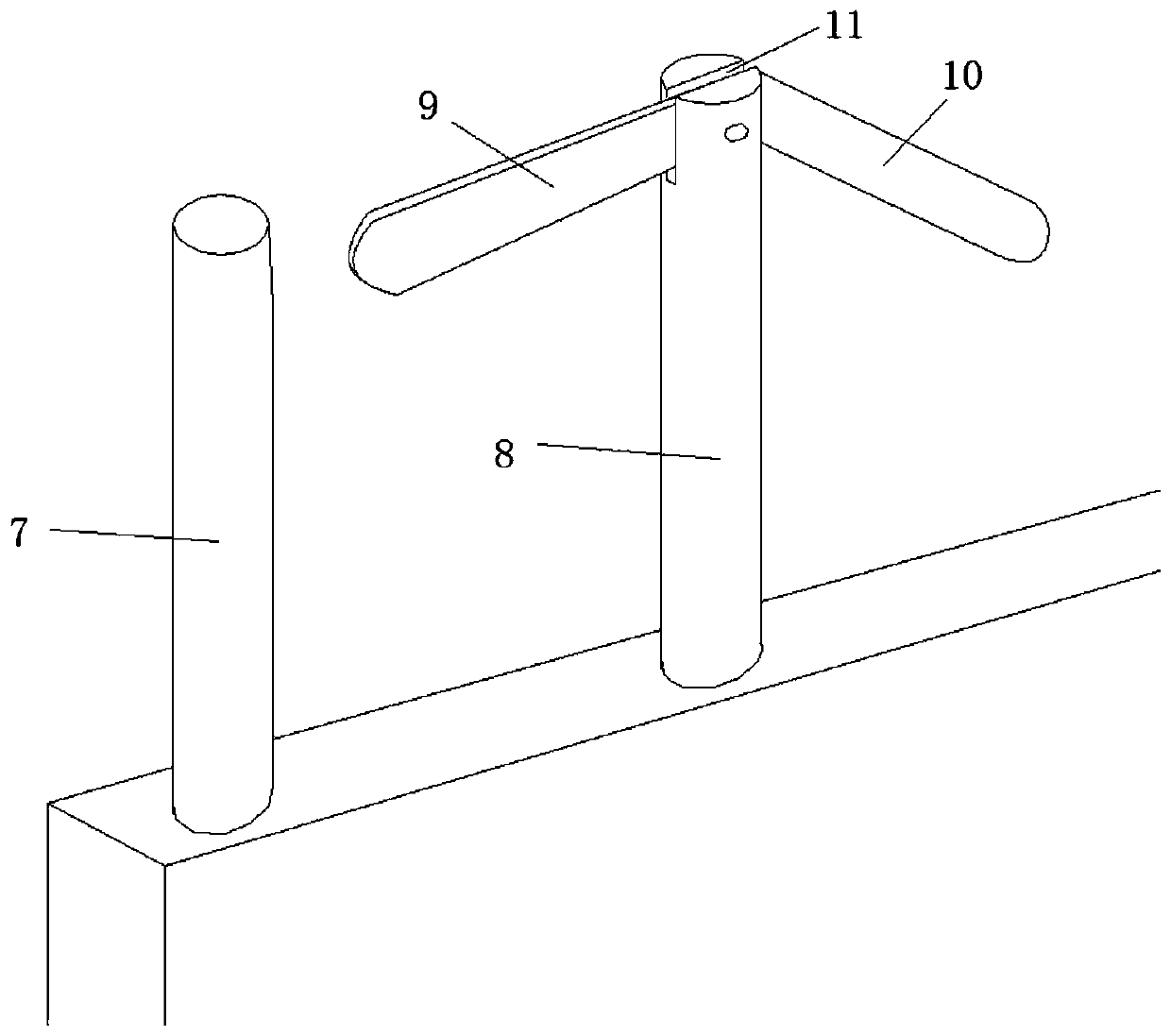

The invention relates to a fixture replacing device for an industrial workpiece conveying device, which comprises a horizontal conveying device and a loading machine. The fixture replacing device is characterized in that the loading machine on the horizontal conveying device and an upper and lower conveying devices in the industrial workpiece conveying device and the upper and the lower conveying devices including a mechanical arm are integrally turned for 180 DEG, and a mechanical arm up-and-down turning device is additionally arranged; and a No. 1 fixture and a No. 2 fixture are respectively arranged on the upper end and the lower end of the mechanical arm. According to the fixture replacing device, during automated continuous process operation, the No. 1 fixture and the No. 2 fixture which correspond to two workpieces are arranged on the upper end and the lower end of the more than one mechanical arm which is vertically installed on the workpiece conveying device, and the up-and-down turning device is additionally arranged; and when one fixture needs to be replaced, the fixture is turned for 180 DEG in accordance with the movement of the up-and-down turning device, then the fixture is replaced, thereby saving time and labor required for replacing the fixture and expenses caused by replacing the fixture, and the purpose of increasing the production efficiency is reached.

Owner:MRT JIANGSU AUTOMATION

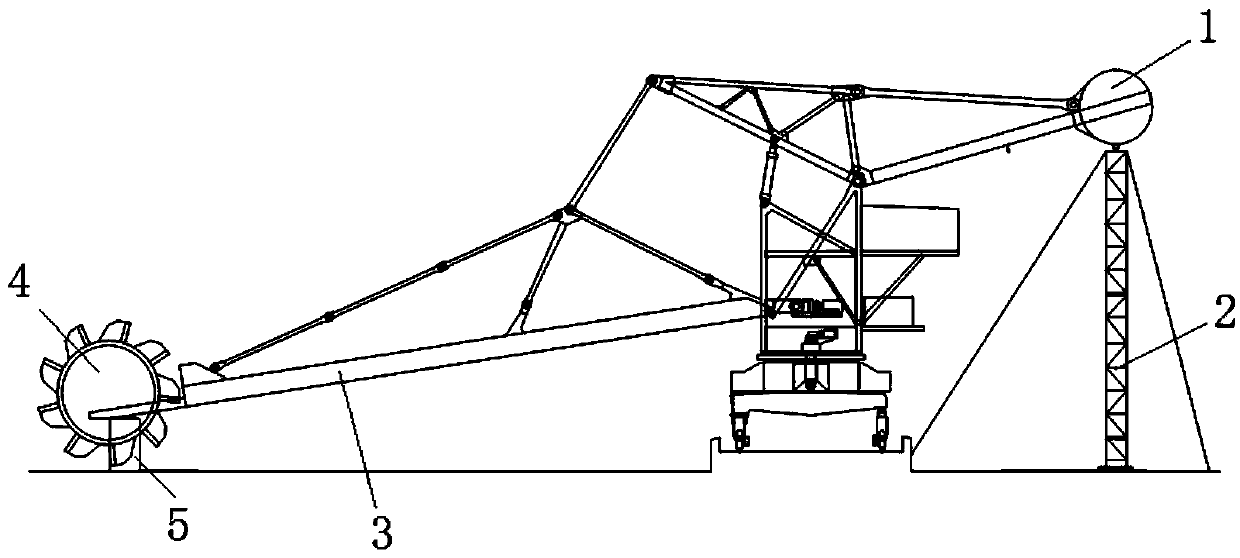

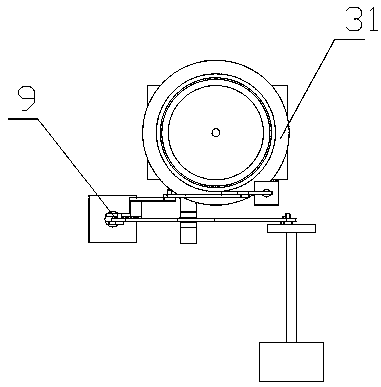

Replacement method of revolving bearing of material taking machine

ActiveCN104259738ARealize replacement workSolve the problem of misalignmentMetal working apparatusPower cableReplacement method

The invention discloses a replacement method of a revolving bearing of a material taking machine. The replacement method comprises the following steps: (1) a counterweight bracket is mounted; (2) an arm frame of the material taking machine and a counterweight are adjusted; and an arm frame bracket is arranged; (3) a gear ring protective cover, a central power cable and a central carriage are removed; a bearing bracket is welded; and a platform is built; (4) a jacking bracket is reinforced; and a jacking jack is placed; (5) a guide sleeve and an anti-tilting bracket are welded; (6) a bearing inner ring bolt is disassembled; and the upper body of the material taking machine is jacked; and (7) a plate is paved; a roller is placed; and a bearing is extracted out. The replacement method of the revolving bearing of the material taking machine, provided by the invention, is safe and effective, and effectively reduces the cost and difficulty of replacing the revolving bearing.

Owner:NORTHEASTERN UNIV

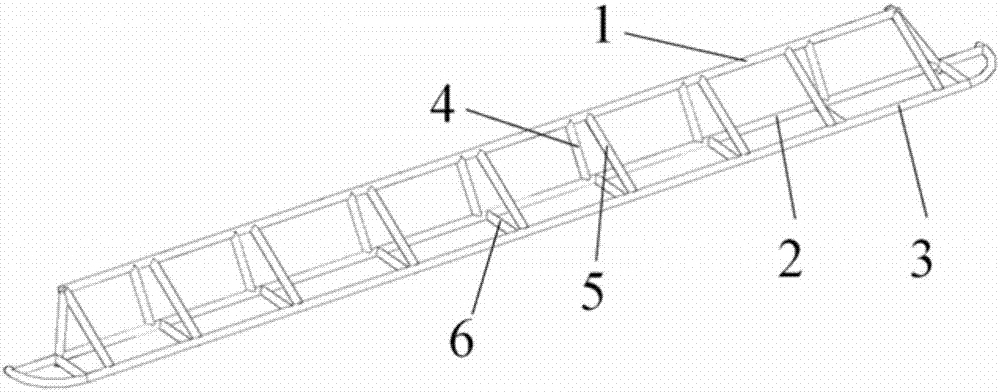

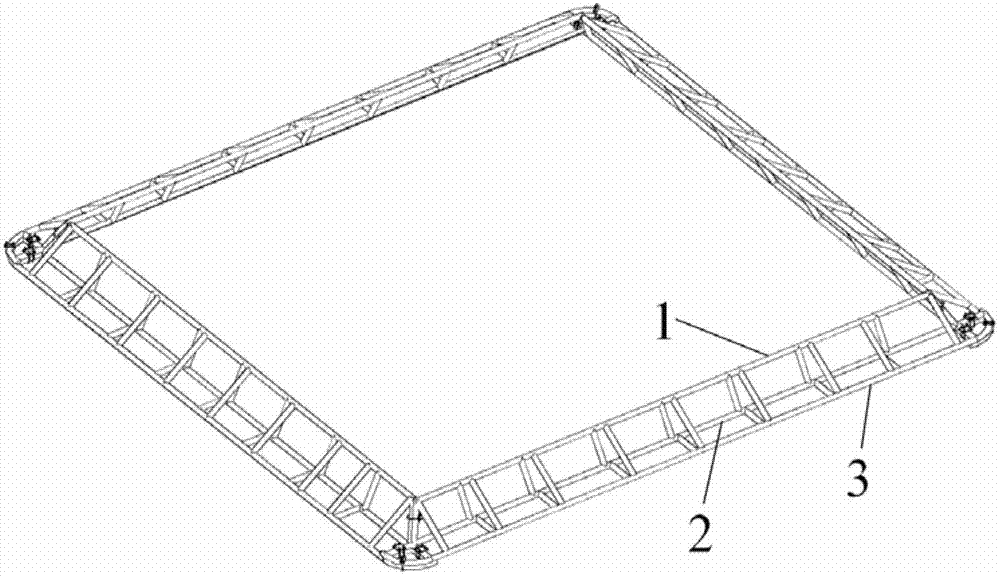

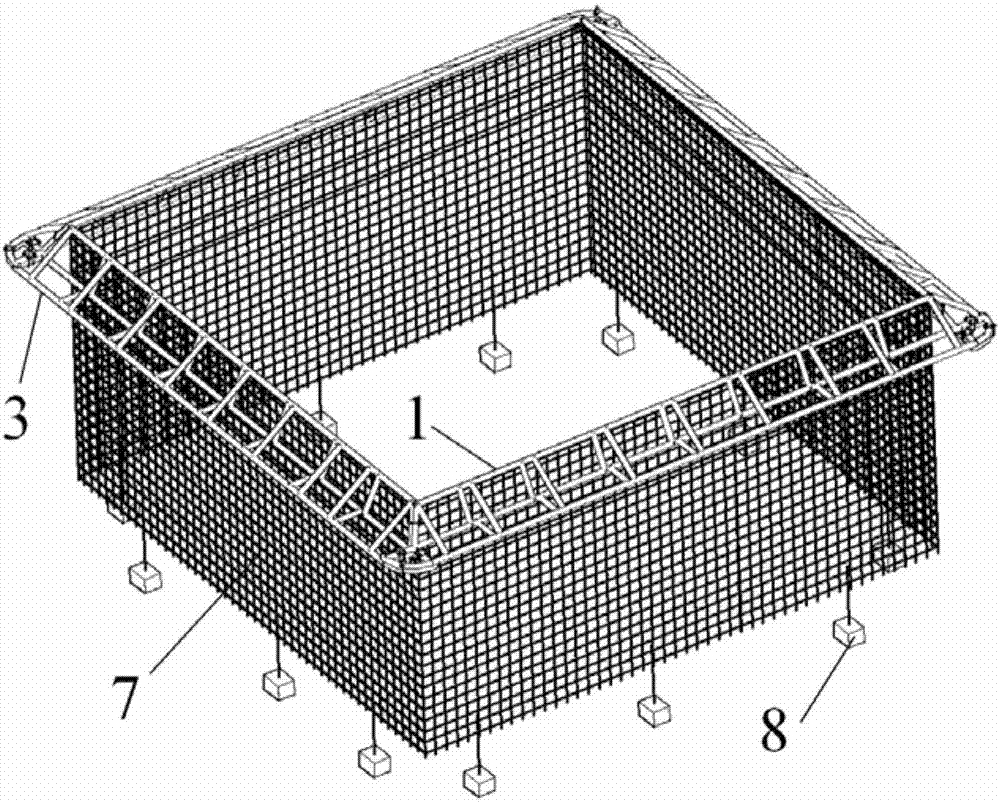

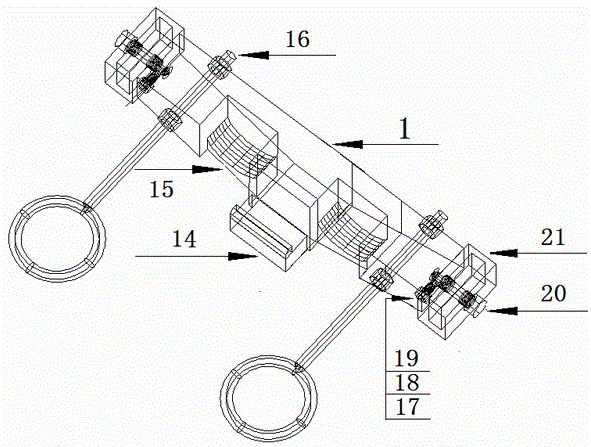

Netting fixing frame of square truss type net cage frame

InactiveCN107372259AEasy to connectEasy constructionClimate change adaptationPisciculture and aquariaVertical tubeFixed frame

The invention discloses a netting fixing frame of a square truss type net cage frame. The netting fixing frame comprises a square truss type frame. Netting is arranged in the square truss type frame, a plurality of netting fixing frame unit components are arranged below the square truss type net cage frame, each netting fixing frame unit component comprises a vertical tube, fixing cables are penetratingly inserted in inner holes of the vertical tubes, two ends of each fixing cable are connected with each other to form a closed ring, and a tetrahedral truss is welded on the outer walls of the middle upper portions of the vertical tubes; the upper end surface of the tetrahedral truss is fixed to inner beam tubes and outer beam tubes of the square truss type net cage frame; the fixing cables are connected with spiral sleeves at the front ends of connecting ropes on the netting. The netting fixing frame has the advantages that the netting fixing frame is easy to assemble and can be easily and conveniently connected with the netting and separated from the netting, the netting can be fixed and restrained by the aid of the netting fixing frame, the large volume of the netting can be kept, and accordingly aquaculture spaces can be effectively maintained.

Owner:HEFEI UNIV

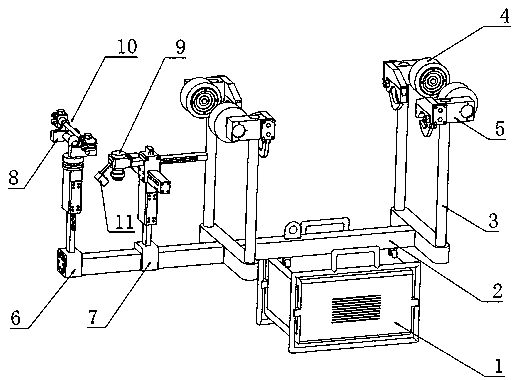

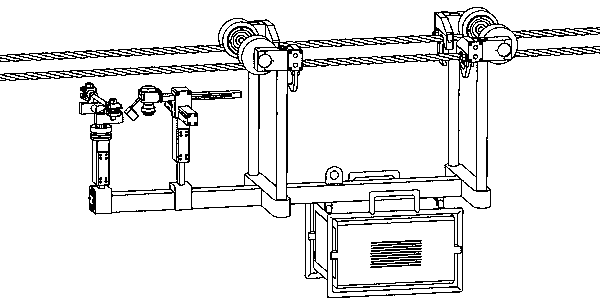

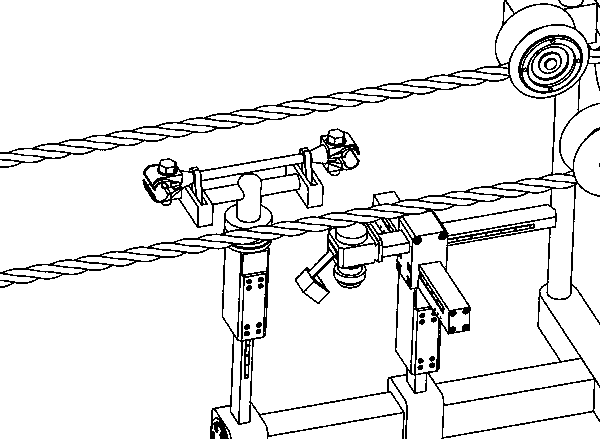

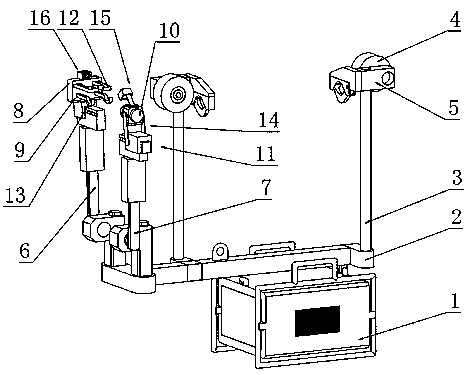

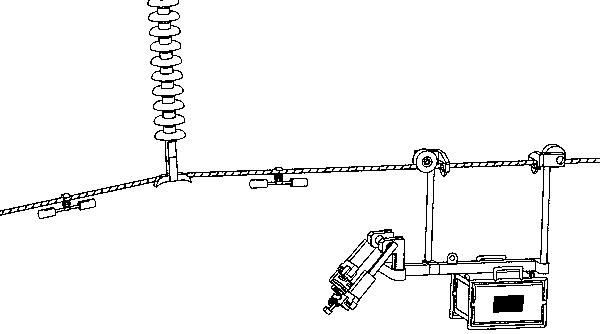

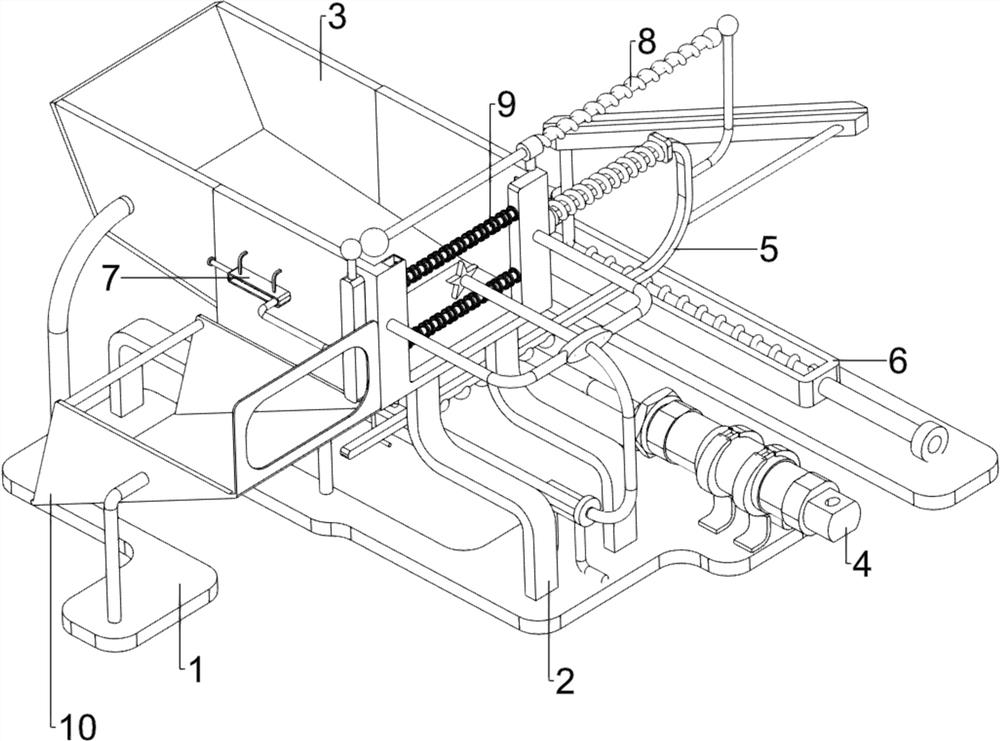

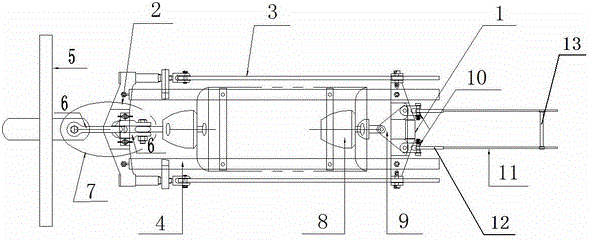

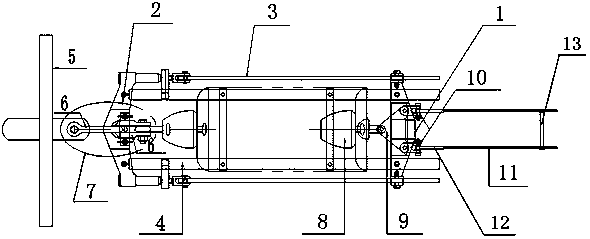

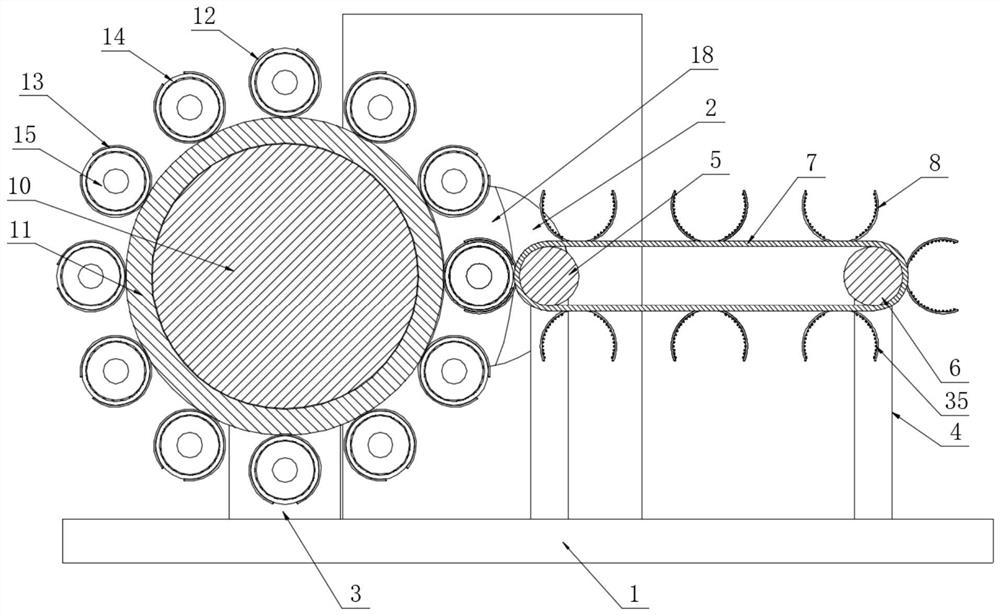

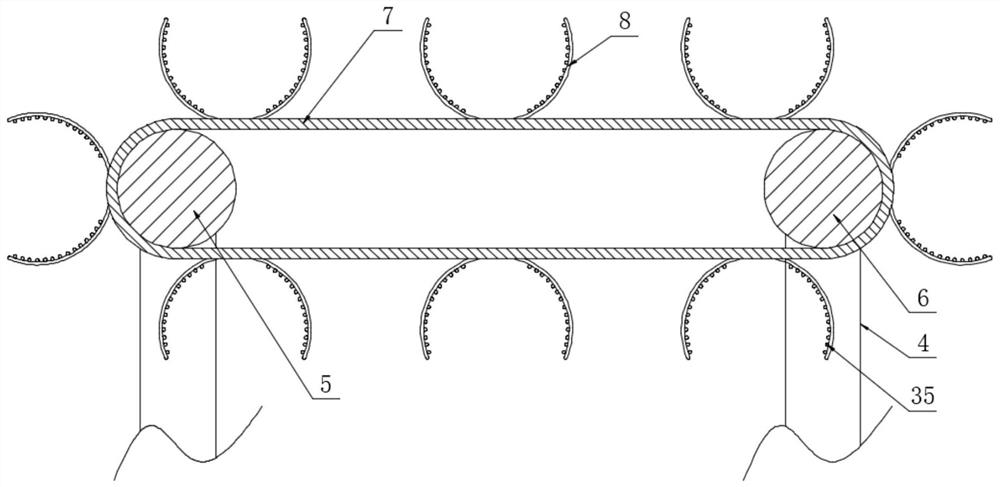

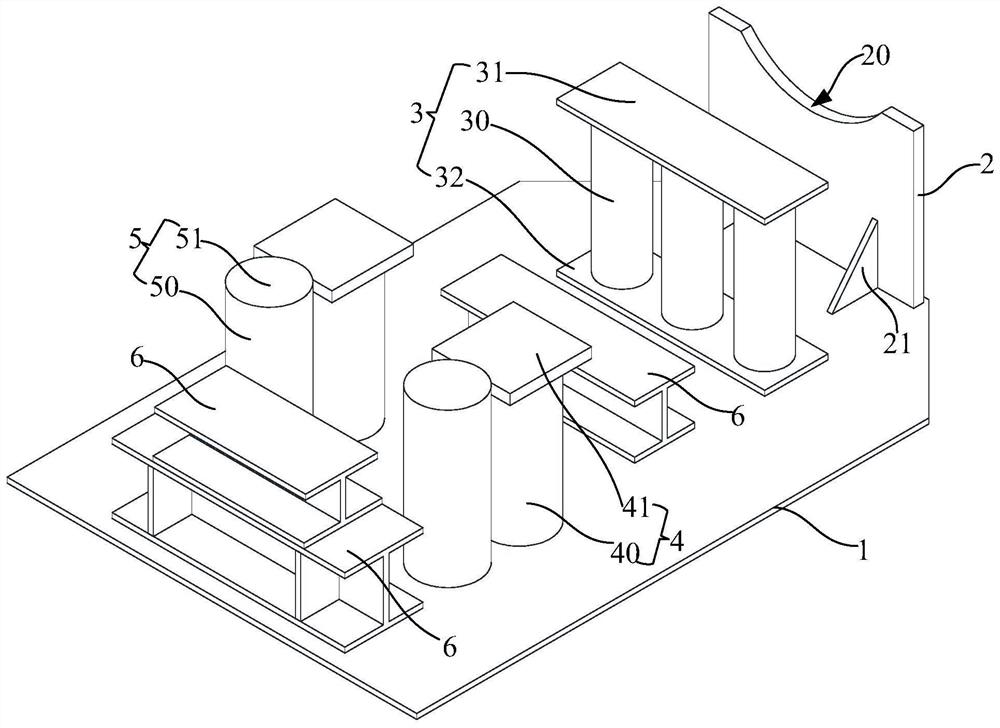

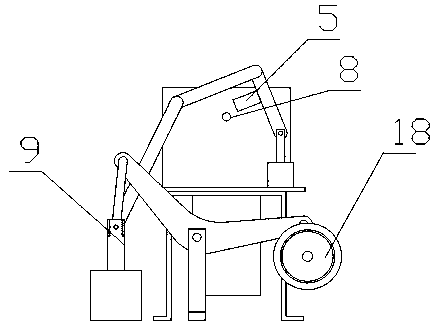

Double-split transmission conductor four-wheel drive spacer overhaul robot and operation method thereof

PendingCN110165599ARealize replacement workFastening (loosening) operation is stable and efficientMaintaining distance between parallel conductorsApparatus for overhead lines/cablesEngineeringHigh pressure

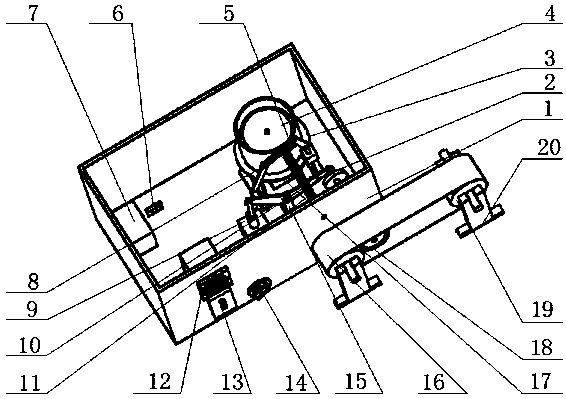

The invention relates to a double-split transmission conductor four-wheel drive spacer overhaul robot and an operation method thereof. The double-split transmission conductor four-wheel drive spacer overhaul robot comprises a case, a body, a moving arm and operation arms. The operation arms can stretch out, draw back, rotate, transversely move and longitudinally move. A clamping mechanism is arranged at the tail end of a first operation arm. The clamping mechanism is used for clamping a spacer connecting rod. A bolt fastening mechanism is arranged at the tail end of a second operating arm. Thebolt fastening mechanism is used for fastening and loosening a spacer bolt. Through the coordinated movement of all joints, the robot can realize the live-line spacer replacement operation on a high-voltage power transmission line.

Owner:WUHAN TEXTILE UNIV

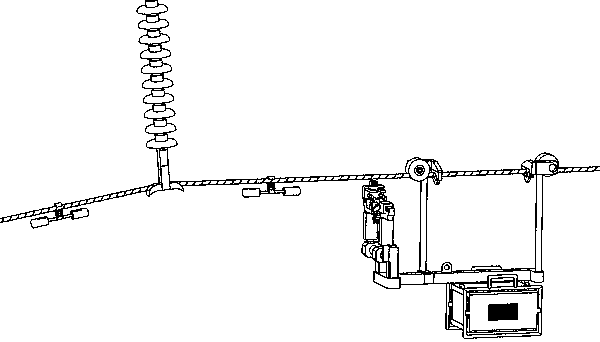

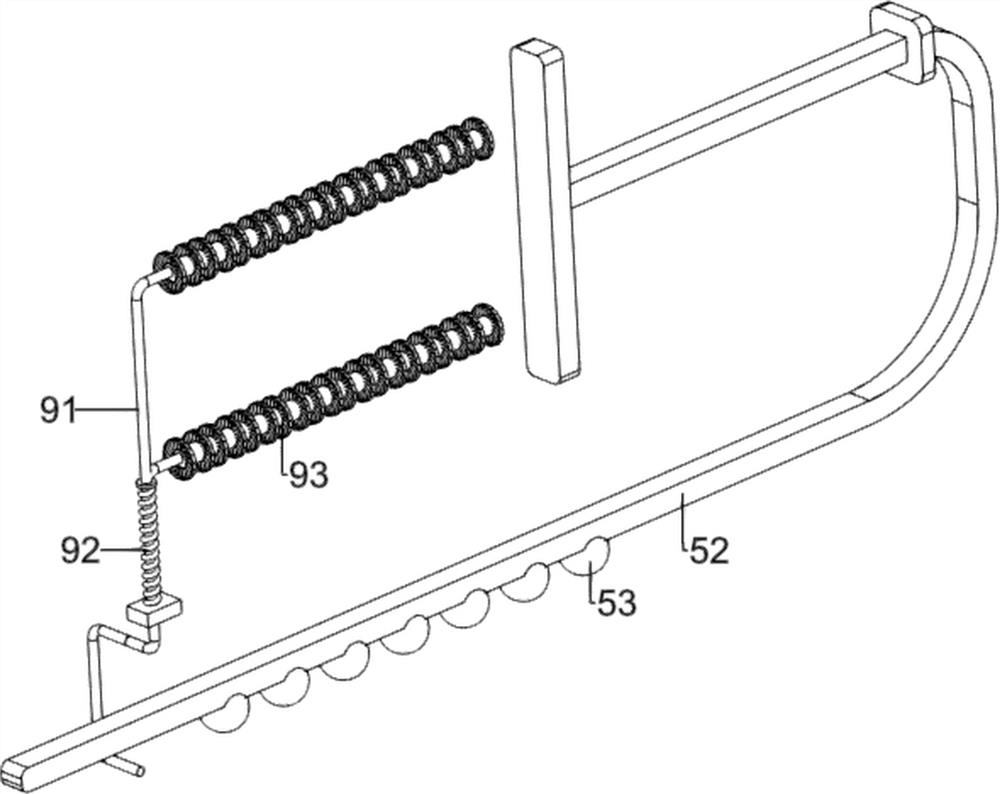

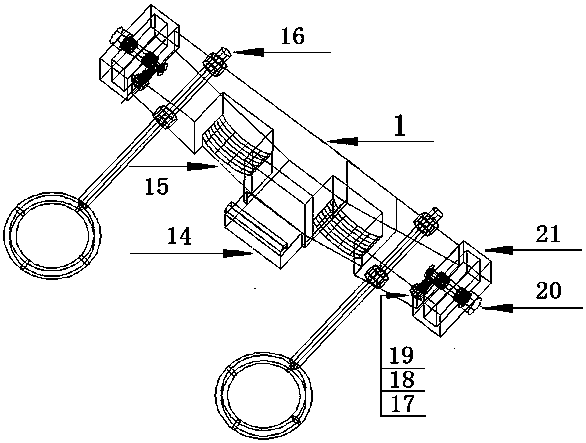

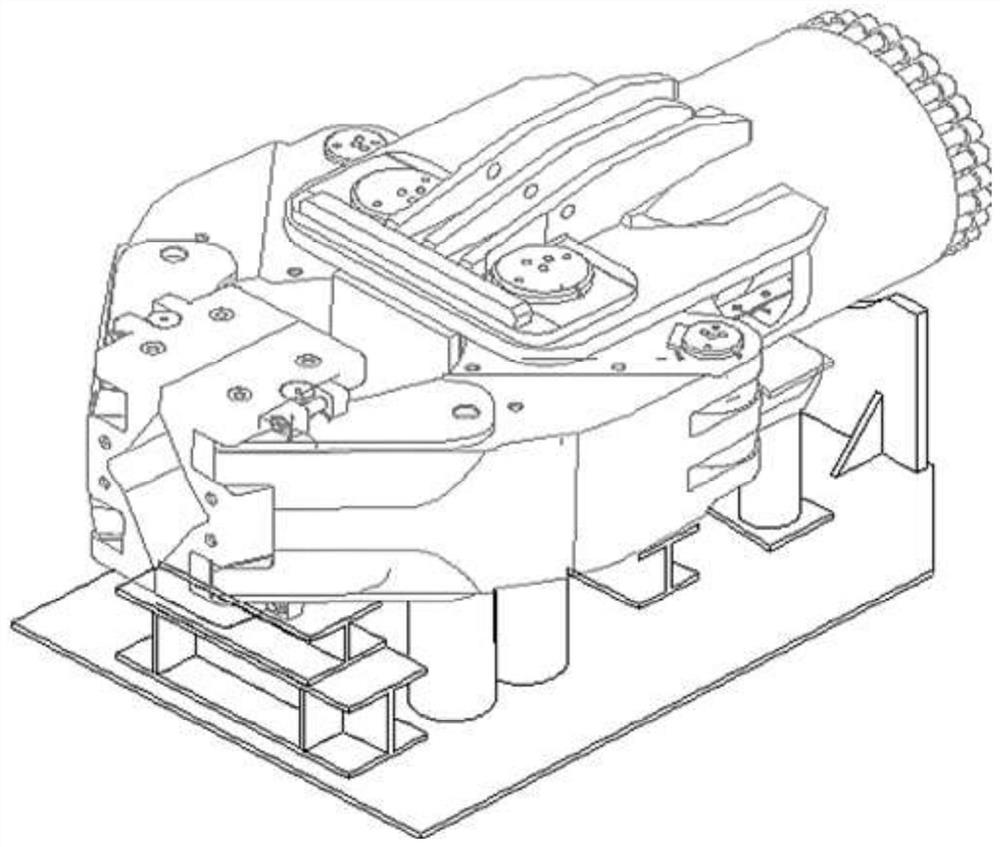

Operation device and method for replacing transmission line vibration protection hammer

InactiveCN109980574ARealize replacement workReduce tip dischargeApparatus for overhead lines/cablesHigh pressureMechanical engineering

The invention relates to an operation device and method for replacing a transmission line vibration protection hammer. The operation device comprises a case, a machine body, a moving arm and operationarms, wherein the operation arms can longitudinally move, stretch and rotate, the tail end of the operation arm I is equipped with a clamping mechanism and a supporting mechanism which are used for fixing a vibration protection hammer wire clamp, and the tail end of the operation arm II is equipped with a bolt fastening mechanism and a pitch joint which are used for fastening and loosening vibration protection hammer bolts. Through the coordination of joints, the device can realize live replacement of the vibration protection hammer on a high-voltage transmission line.

Owner:WUHAN TEXTILE UNIV

Integrated lamp unit and liquid-circulating dual pipe lamp having same

InactiveCN109691224ARealize replacement workSimple and convenient radiationBathing devicesHeating element shapesEngineeringFixed position

The present invention relates to an integrated liquid-circulating dual pipe lamp, and comprises: a lamp unit which has a plurality of coils and filaments thereinside, and which has a position-fixing ring for fixing positions of the filaments; a lamp housing which has the lamp unit thereinside, and which has a circulation hole formed thereon so that liquid circulates outside the lamp unit at a predetermined temperature; watertight members which seal both end parts of the lamp housing, and into / through which both end parts of the lamp unit are inserted and penetrate; a liquid-circulation memberwhich is coupled to the watertight member, which supplies a predetermined amount of liquid towards the circulation hole so as to circulate the same, and which discharges the circulating liquid according to the temperature of the liquid; and a reflection member in which the lamp housing is mounted, and which enhances the amount of near-infrared irradiation emitted from the lamp unit.

Owner:李宇宙

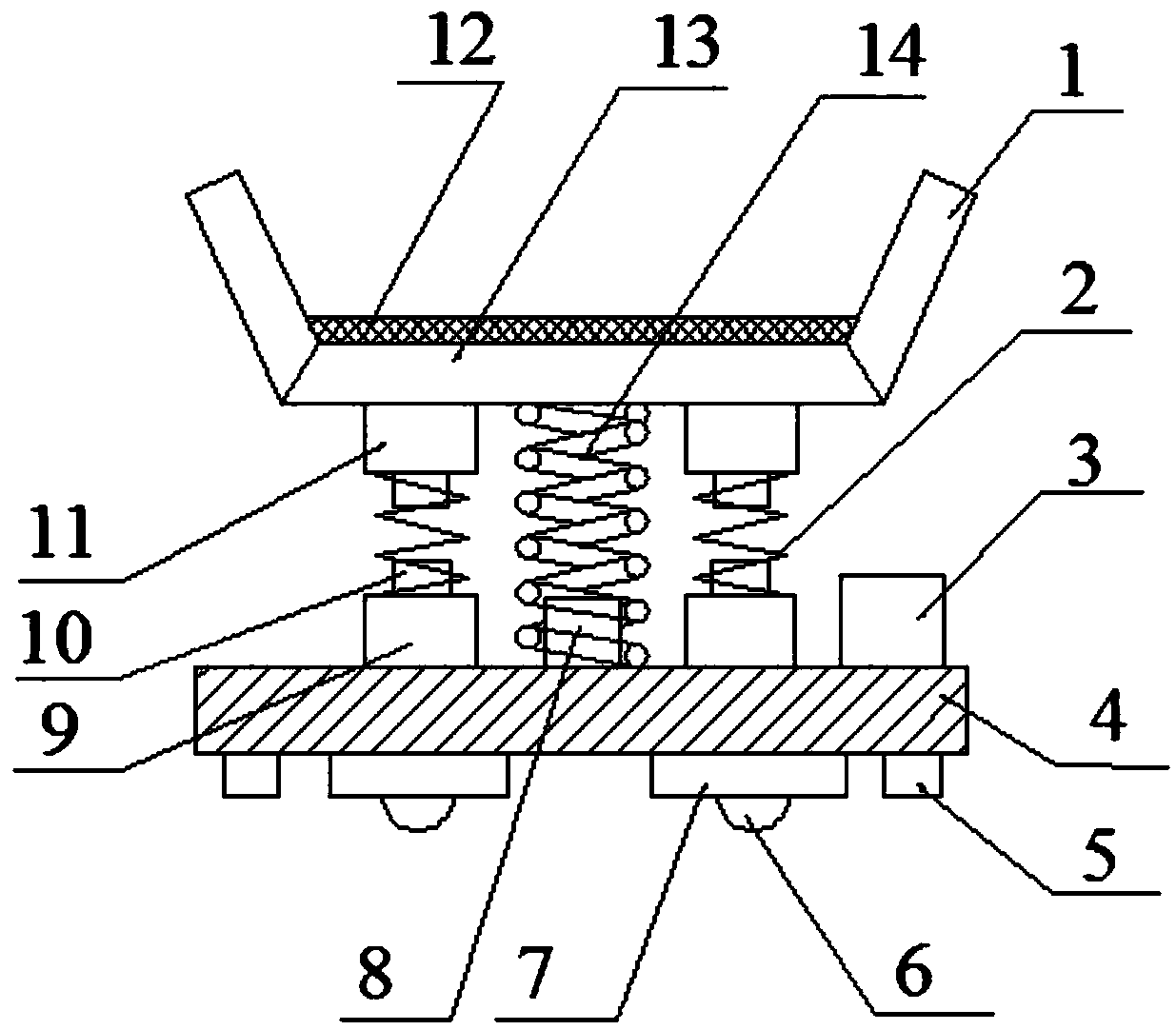

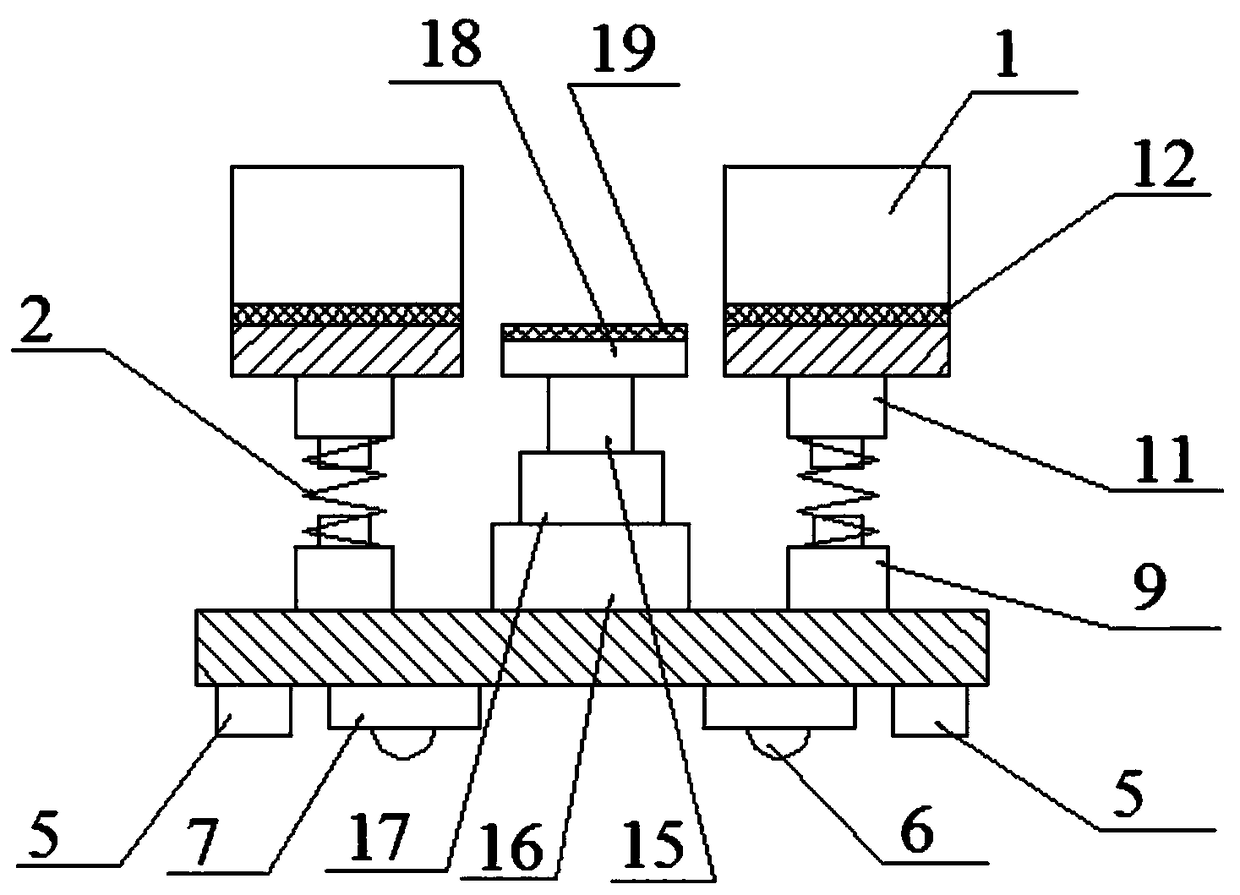

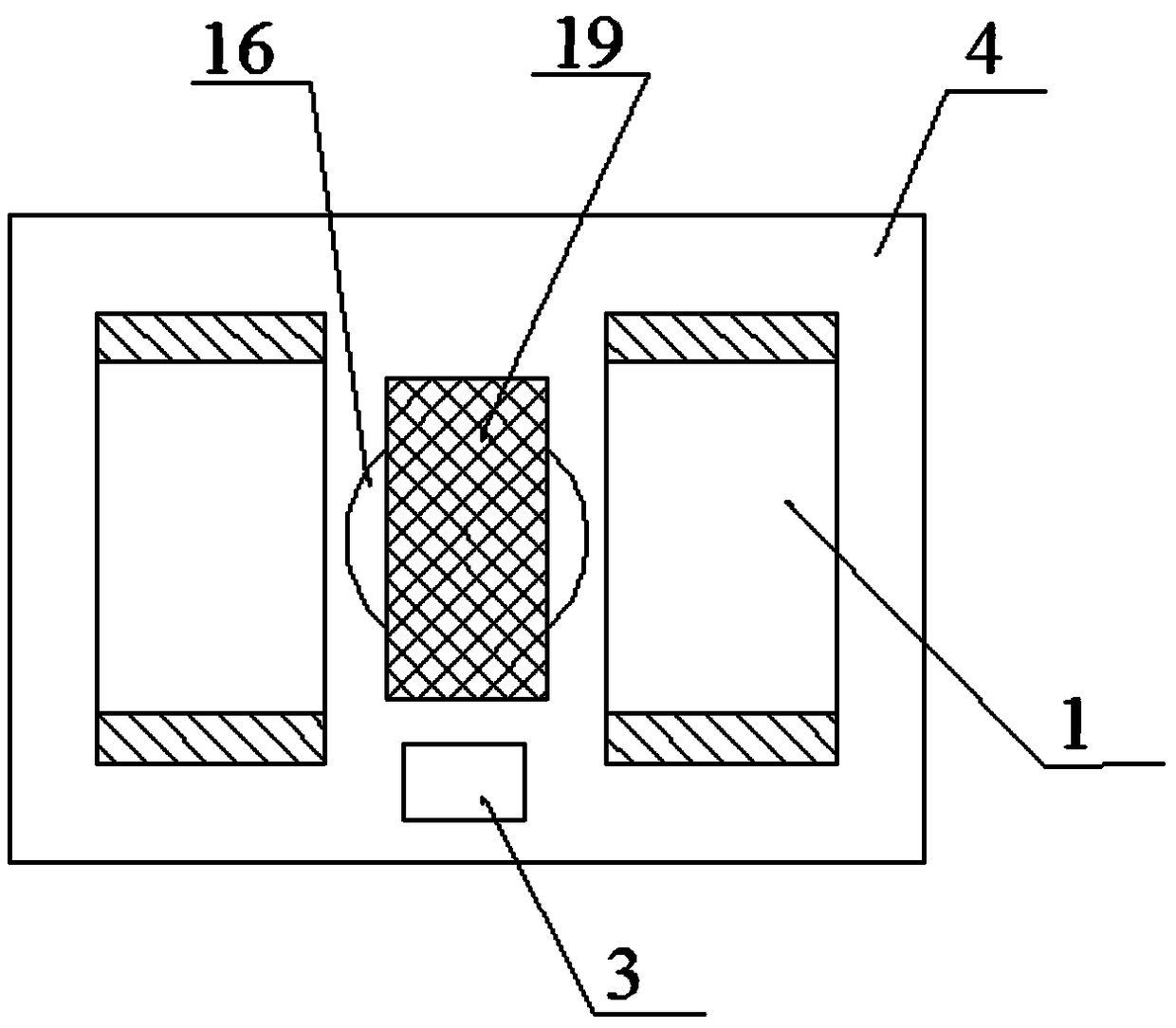

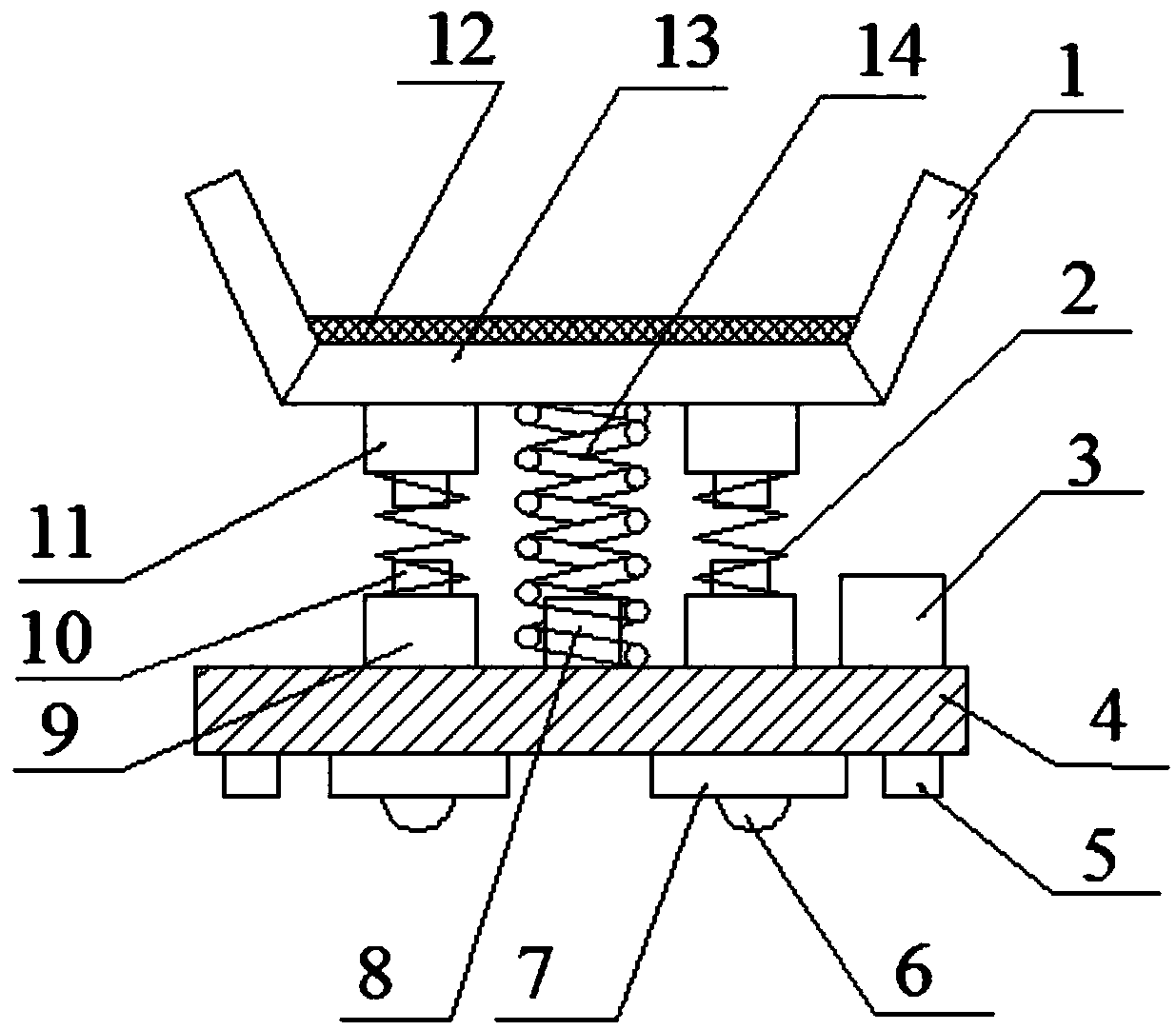

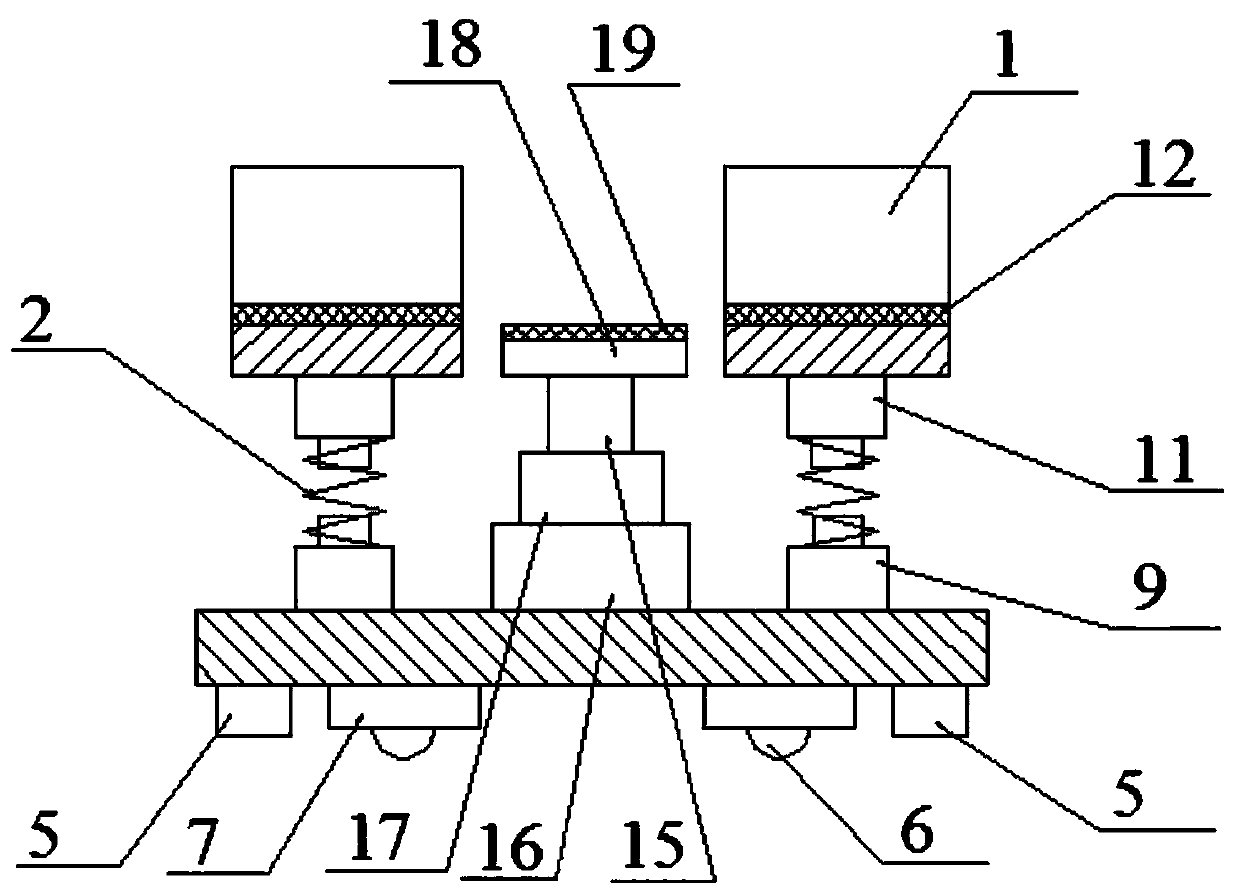

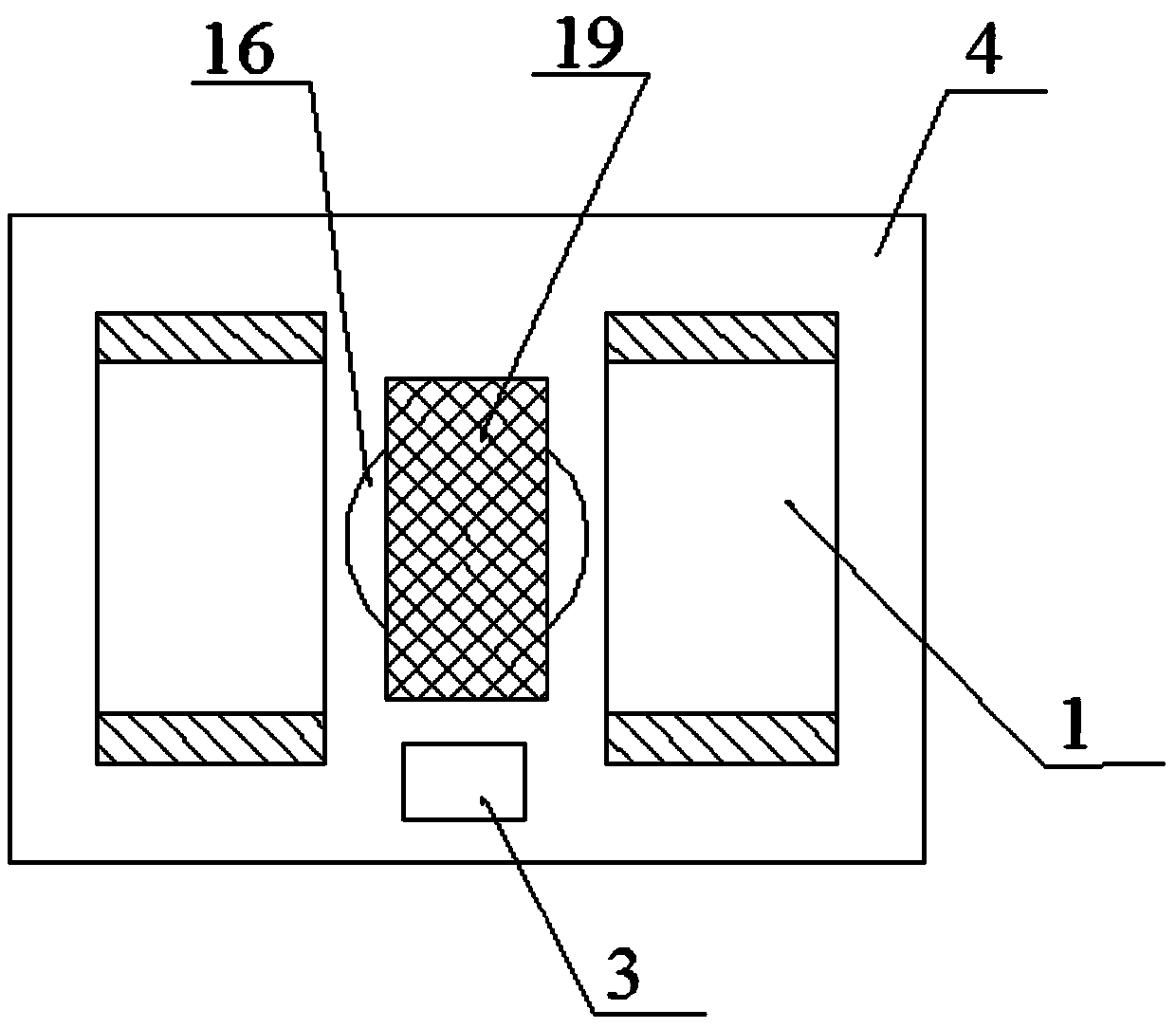

Intelligent aircraft wheel hub replacement device adjusted according to size of sliding wheel

ActiveCN108715232AAdjustable sizeRealize replacement workAircraft assemblyAircraft maintainanceHydraulic cylinderAviation

The invention relates to an intelligent aircraft wheel hub replacement device adjusted according to the size of a sliding wheel, and belongs to the technical field of aviation equipment. Through an auxiliary support plate, a hydraulic device, a main support plate, a main elastic device, hydraulic cylinders, auxiliary modules, a main module and other devices, the work of replacing an aircraft wheelhub can be achieved; meanwhile, according to the size of the aircraft sliding wheel to be replaced, the size of the main support plate can be adjusted through the intervention on the quantity of auxiliary modules; in addition, based on the arrangement of the main elastic device, four auxiliary elastic devices and a rubber elastic layer, the aircraft wheel hub can be elastically buffered when being replaced, the reliability and environmental adaptability of the device are improved to a great degree, and the intelligent aircraft wheel hub replacement device has important practical significancein the field of maintenance of aircraft wheel hubs.

Owner:桐乡乐维新材料有限公司

An intelligent aircraft hub replacement device adjusted according to the size of the taxi wheel

ActiveCN108715232BAdjustable sizeRealize replacement workAircraft assemblyAircraft maintainanceAviationHydraulic cylinder

The invention relates to an intelligent aircraft wheel hub replacement device adjusted according to the size of a sliding wheel, and belongs to the technical field of aviation equipment. Through an auxiliary support plate, a hydraulic device, a main support plate, a main elastic device, hydraulic cylinders, auxiliary modules, a main module and other devices, the work of replacing an aircraft wheelhub can be achieved; meanwhile, according to the size of the aircraft sliding wheel to be replaced, the size of the main support plate can be adjusted through the intervention on the quantity of auxiliary modules; in addition, based on the arrangement of the main elastic device, four auxiliary elastic devices and a rubber elastic layer, the aircraft wheel hub can be elastically buffered when being replaced, the reliability and environmental adaptability of the device are improved to a great degree, and the intelligent aircraft wheel hub replacement device has important practical significancein the field of maintenance of aircraft wheel hubs.

Owner:桐乡乐维新材料有限公司

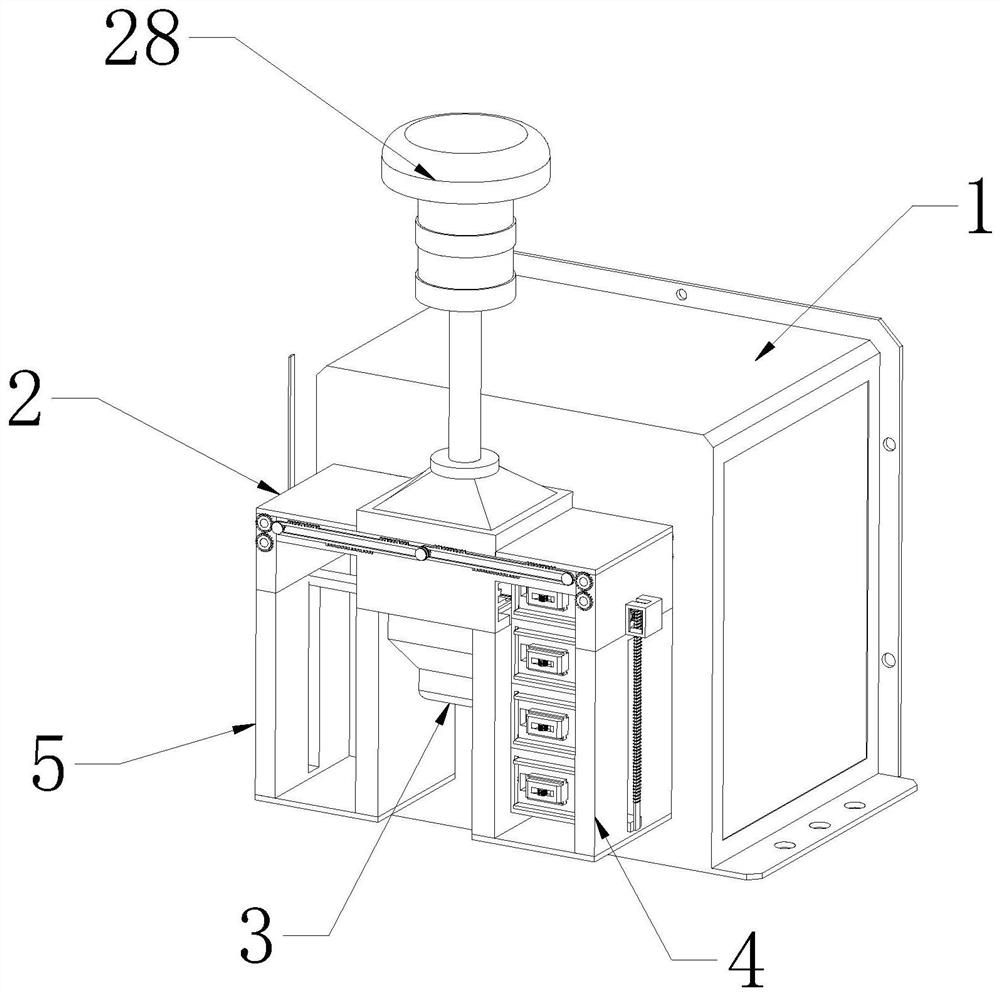

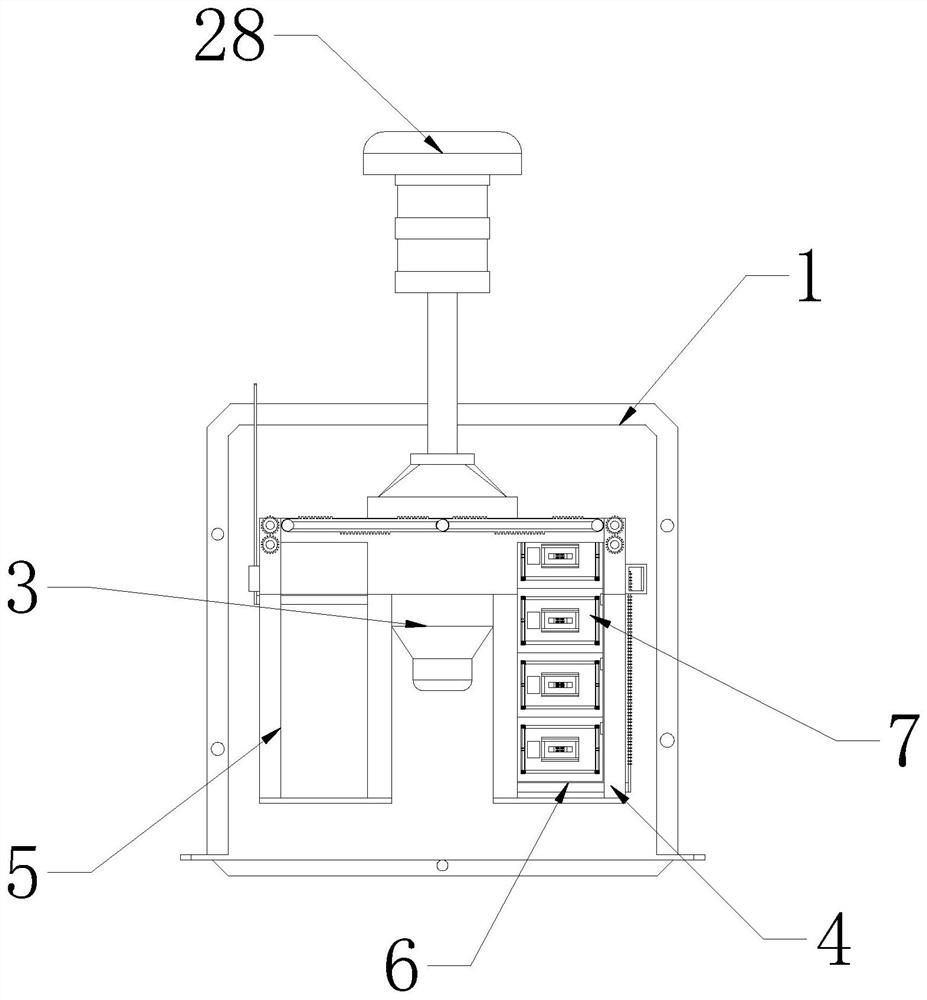

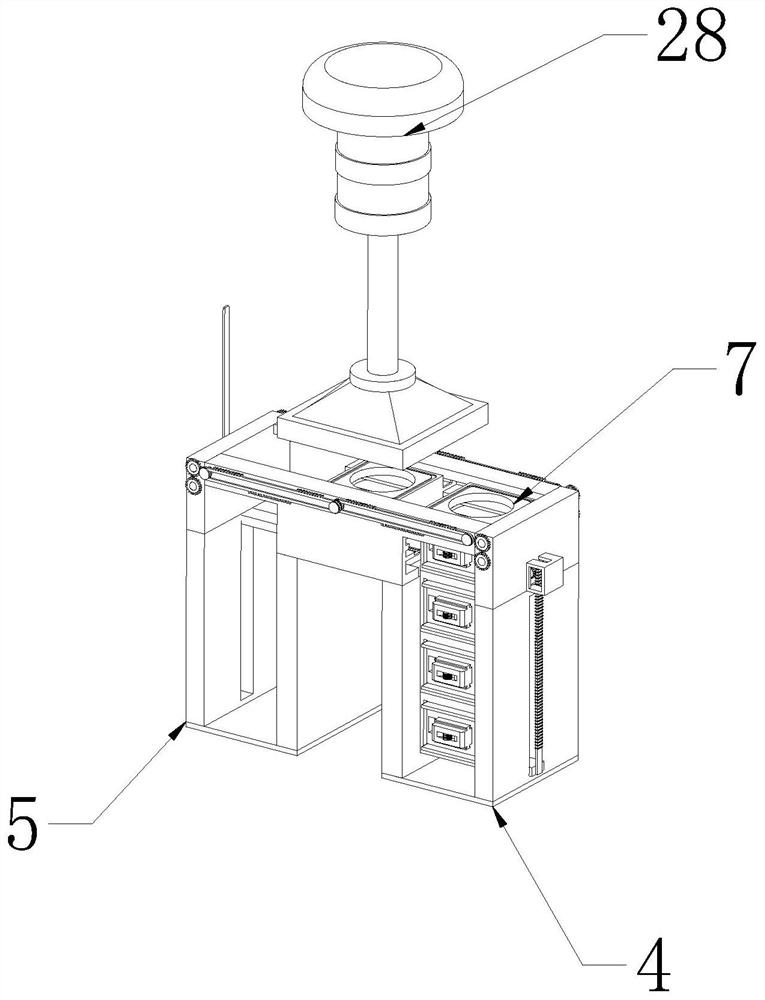

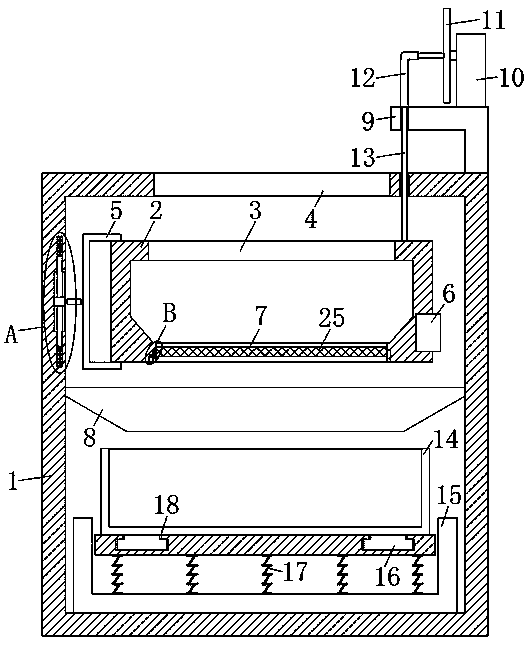

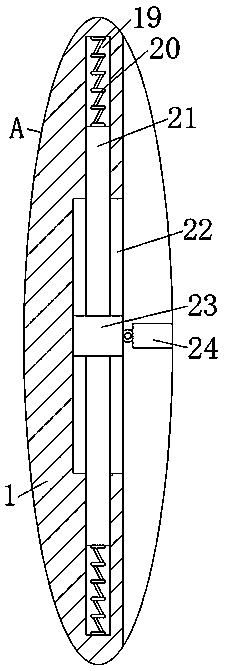

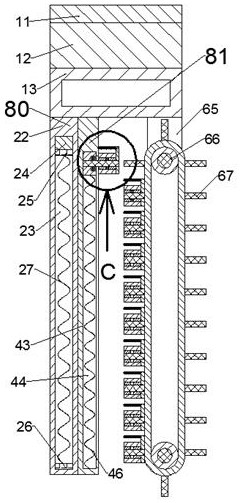

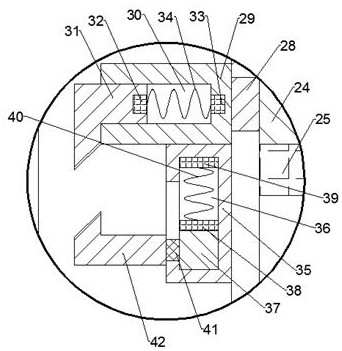

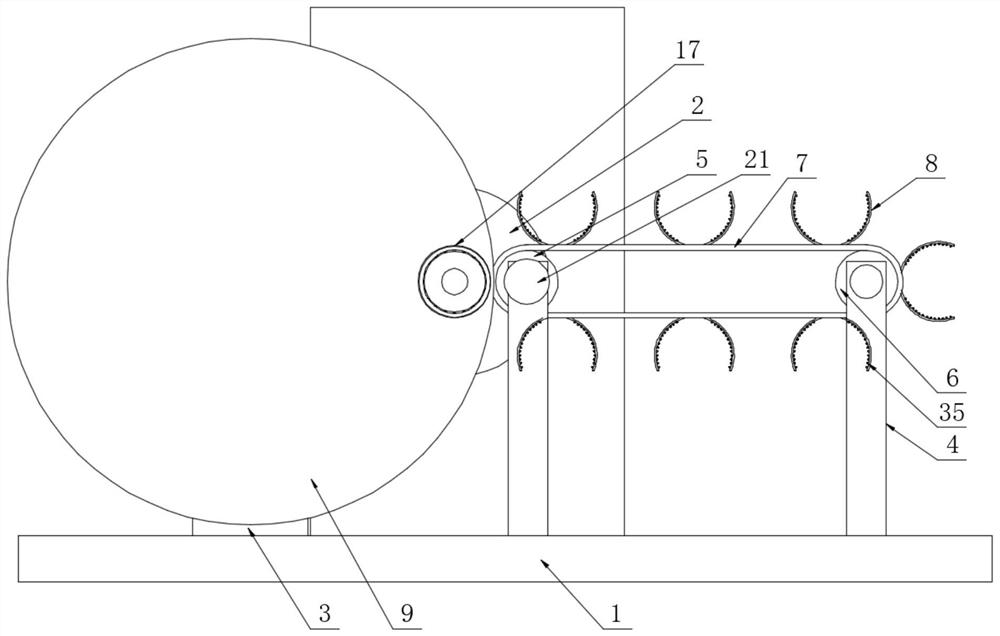

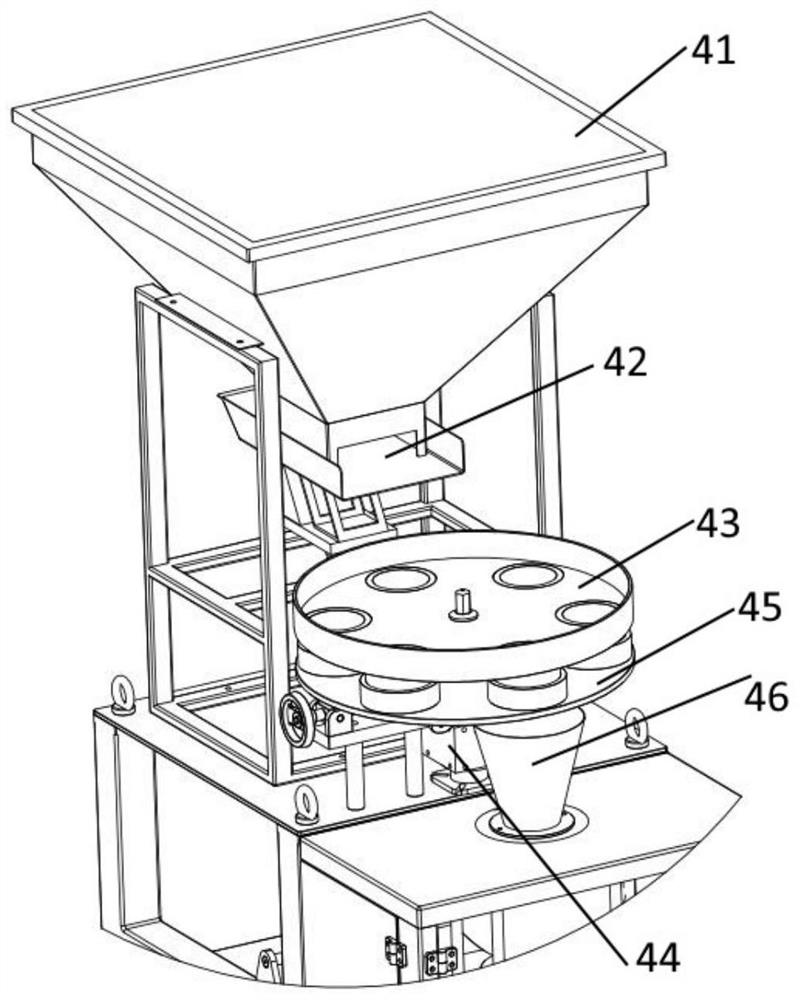

Atmospheric particulate sampling device

InactiveCN113758765ARealize replacement workAvoid damageWithdrawing sample devicesParticulatesControl engineering

The invention discloses an atmospheric particulate sampling device which comprises a shell and a sampling head installed on the shell, wherein a sampling pump is installed in the shell, the sampling pump works to drive air flow to flow through the sampling head, a feeding storage device and a discharging storage device can be assembled at the two ends of a conveying table, a certain quantity of membrane mechanisms are stored in the feeding storage device in advance, the membrane mechanisms can be automatically fed to a conveying table through cooperation with the work of a first transmission mechanism, the membrane mechanisms can be driven to automatically move to connecting pipes for sampling work or automatically move out of the connecting pipes to achieve replacement work of the membrane mechanisms through the action of the conveying table, each membrane mechanism is provided with a shielding piece, and in cooperation with the work of a second transmission mechanism, the shielding piece can be automatically opened to change to a working state when moving to the connecting pipe, and can be automatically closed when moving out of the connecting pipe, so that the sampled filter membrane is in a closed independent space, the later treatment is facilitated, and the use is more convenient and reliable.

Owner:SUQIAN COLLEGE

Chemical raw material screening machine with shaking screening effect

InactiveCN110813728ARealize shaking up and downImprove screening efficiencySievingScreeningStructural engineeringMechanical engineering

The invention discloses a chemical raw material screening machine with a shaking screening effect. The chemical raw material screening machine comprises a housing. A first feeding port runs through the upper end of the housing and communicates with the interior of the housing, a communicating hole runs through the front side wall of the housing and communicates with the interior of the housing, and a swing door is arranged at the communicating hole. The inner side wall of the housing is provided with a connecting mechanism, the interior of the housing is provided with a screening mechanism, and the free end of the connecting mechanism is rotationally connected with the side wall of the screening mechanism. The upper end of the housing is provided with a power mechanism, and the free end ofthe power mechanism penetrates through the side wall of the housing and is fixedly connected with the screening mechanism. The interior of the housing is provided with a guiding hopper, and the innerbottom of the housing is provided with a receiving mechanism. The chemical raw material screening machine is reasonable in structural design, can realize automatic screening to improve the screeningefficiency and also can realize stable receiving to make it convenient for a user to take materials.

Owner:李亚良

Raw material melting device for producing rubber products

InactiveCN108372599AImprove melting efficiencySolve the problem of low melting efficiencyMelting tankDc dc converter

The invention discloses a raw material melting device for producing rubber products. The raw material melting device comprises a base, wherein a mounting platform is fixedly connected to one side of the upper end of the base, a servo motor is mounted in the center of the upper end of the base between the inner walls of the mounting platform through a fixed seat, a round mounting tank is rotationally connected to an output end of the servo motor through a shaft rod, an electromagnetic heater is fixedly connected to a middle section in the round mounting tank, and the center of the upper end ofthe electromagnetic heater is connected with a C-shaped heat conducting plate through an electromagnetic heating coil; and a raw material melting tank is placed in the center of the top end of the mounting platform through a round fixed frame, a mounting rack is fixedly connected to a middle section of the top of the raw material melting tank through a transparent plate, and an infrared probe is fixedly connected to the middle of the top end in the mounting rack. By arranging a structure with a first replacement region, a second replacement region, the electromagnetic heater, the electromagnetic heating coil, a DC-DC converter and an infrared probe, the raw material melting device has the advantages that the melting efficiency is high, the replacement is convenient and fast, and the real-time monitoring is realized.

Owner:响水煦隆贸易有限公司

Advertising paper replacement equipment for three-side turnover advertising board

InactiveCN111816097ARealize replacement workImprove replacement efficiencyIdentification meansStructural engineeringMechanical engineering

The invention discloses advertising paper replacement equipment for a three-side turnover advertising board. The equipment comprises a support plate, wherein two connecting blocks are symmetrically and fixedly arranged on the left side and the right side of the lower end face of the supporting plate, a clamping box is fixedly arranged on the lower end surface of the connecting block, a replacementmechanism is arranged on the front side of the lower end surface of the right clamping box, the replacement mechanism comprises a first sliding rail, the first sliding rail is fixedly connected withthe lower end face of the right side clamping space, and a first sliding groove with a leftward opening is formed in the first sliding rail. According to the invention, replacement work of advertisingpaper on a three-side turnover advertising board can be automatically achieved, original advertising paper is torn down through a scraper and a sliding rail, and transmission, unfolding and pasting of new advertising paper are achieved through a conveying belt, an air cylinder, the sliding rail and an electromagnet on the rear side.

Owner:WEIFANG YUBEI STATIONERY CO LTD

Novel efficient green printing equipment

ActiveCN112406337ARealize the printing jobRealize replacement workStampingMechanical engineeringIndustrial engineering

Owner:深圳市天亮环保科技有限公司

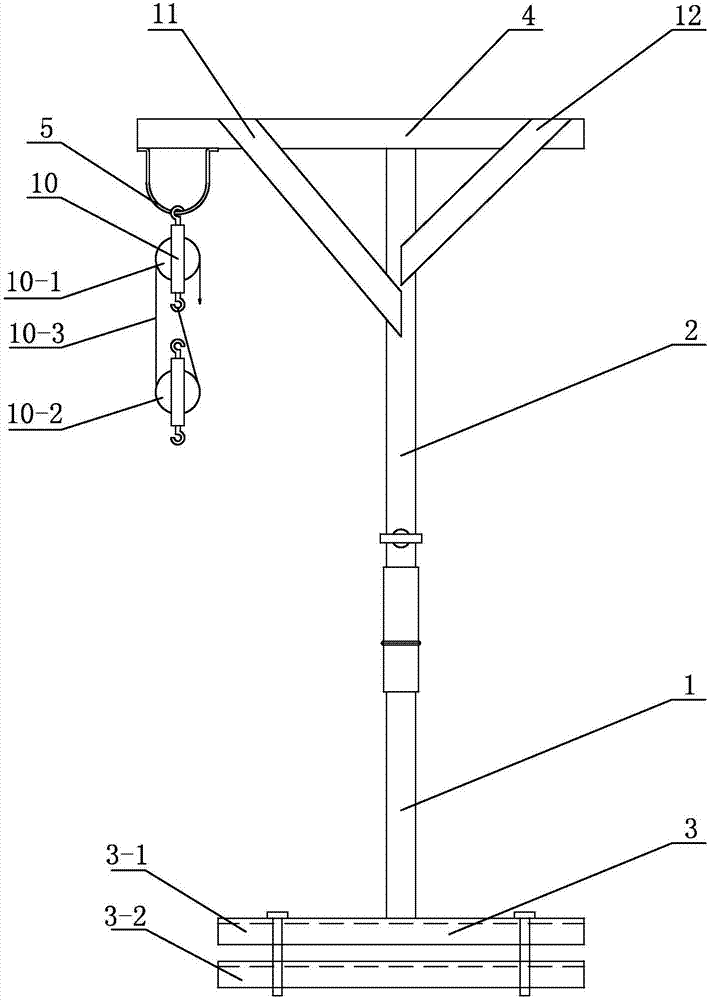

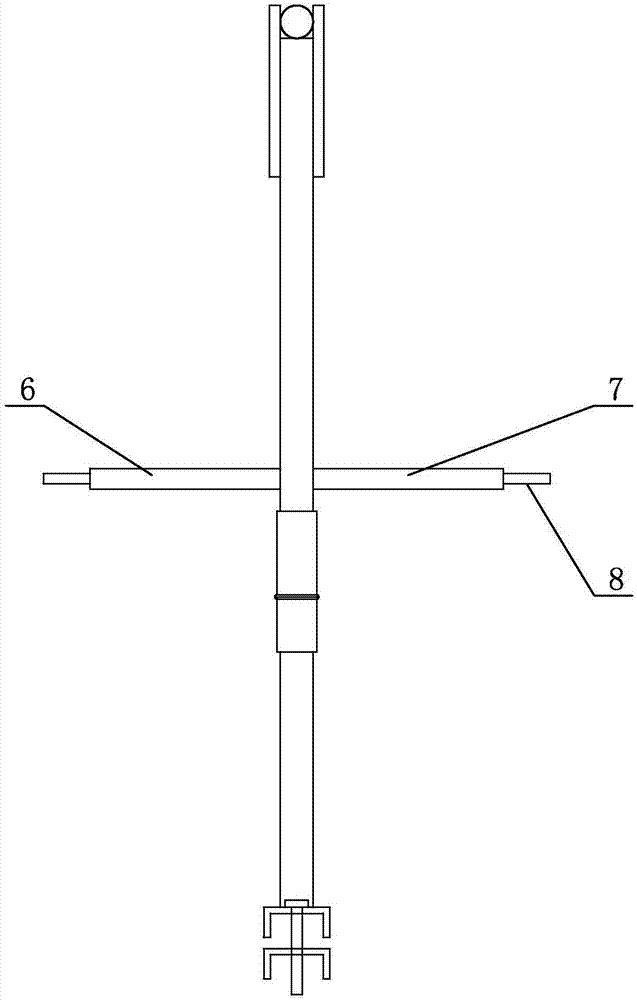

Dedicated tool car for 35kV transformer replacement

InactiveCN107196221AImprove work efficiencyReduce outage timeSwitchgearElectric power systemTransformer

The utility model relates to a special tool cart for replacing a 35kV transformer, which relates to the field of power tools. In order to solve the problem that the construction distance between substation equipment in some existing early construction substations is small, the replacement of transformers has a long power outage time and a large power outage range, which brings inconvenience to the reliability of power supply; and the staff replace The transformer takes a long time, and it is inconvenient to disassemble and install the transformer, which causes a large workload for the staff. The base of the present invention is arranged horizontally, one end of the upper bracket is fixed vertically on the middle of the upper end of the base, one end of the lower bracket is fixedly connected to the other end of the upper bracket by rotation, the other end of the lower bracket is fixedly connected to the support tube, and the hook is installed on the support tube One end of the pulley block is fixedly connected to the hook, the other end of the pulley block is connected to the transformer, one end of the left operating handle and the right operating handle are respectively fixed on both sides of the middle of the upper bracket, and the base is fixed on the channel steel frame of the transformer . The invention is used to replace the 35kV transformer.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD ELECTRIC POWER RES INST +1

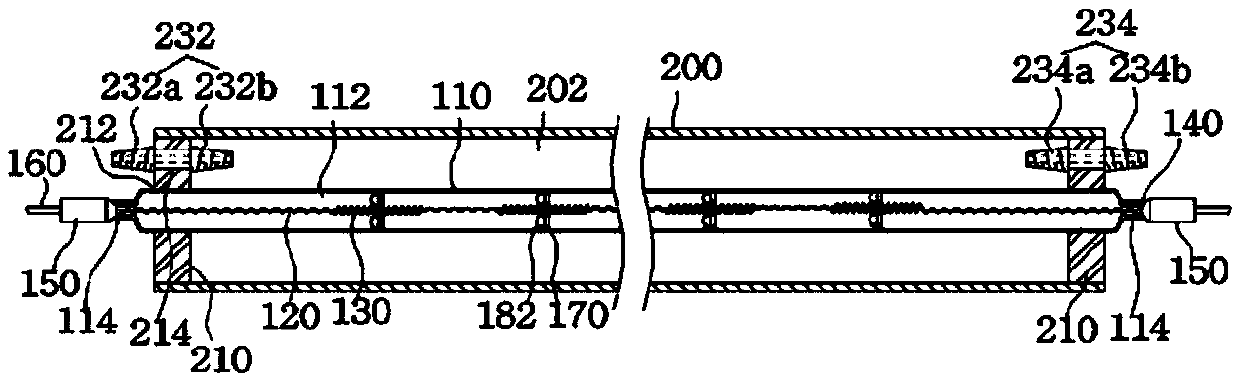

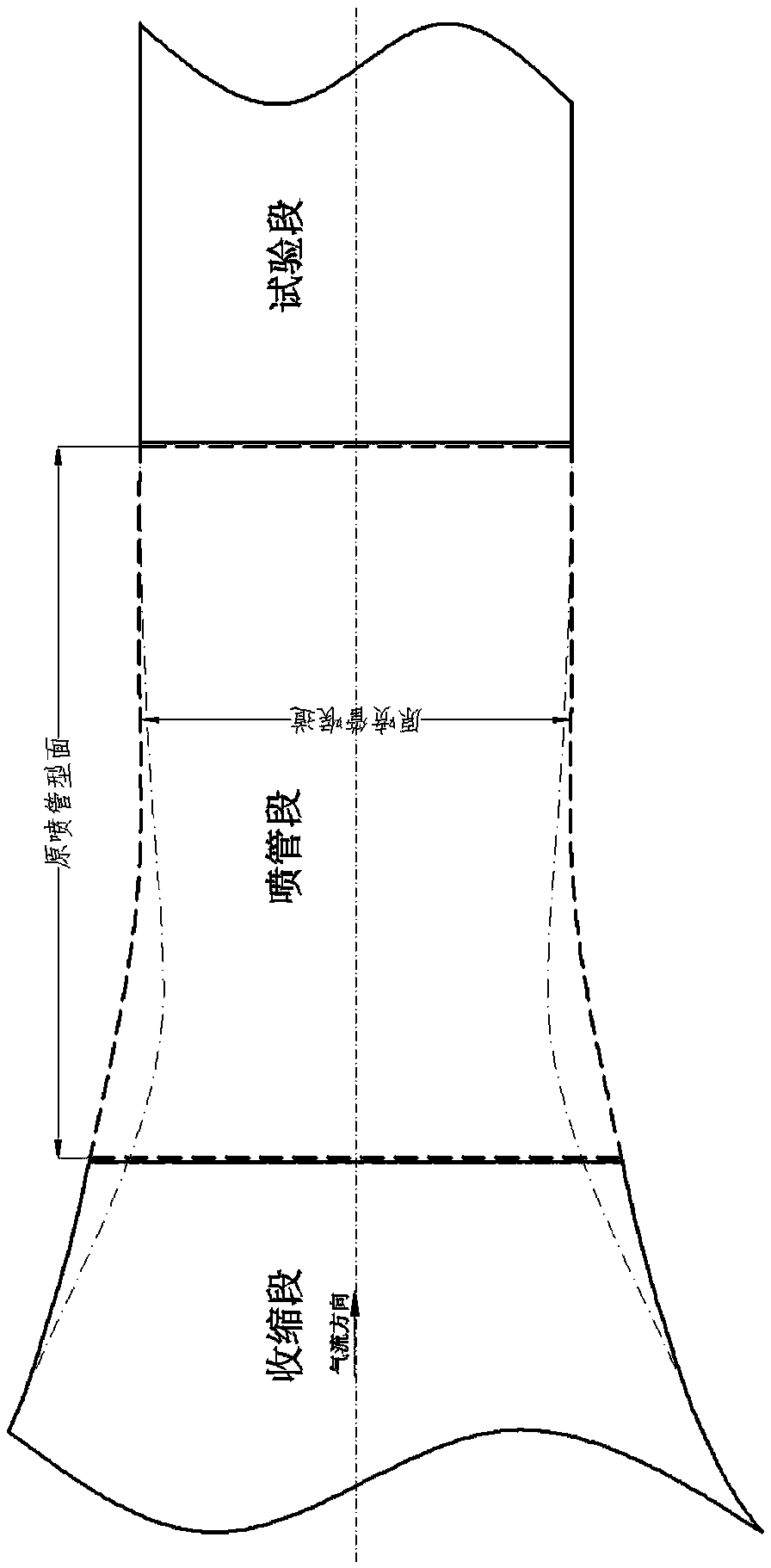

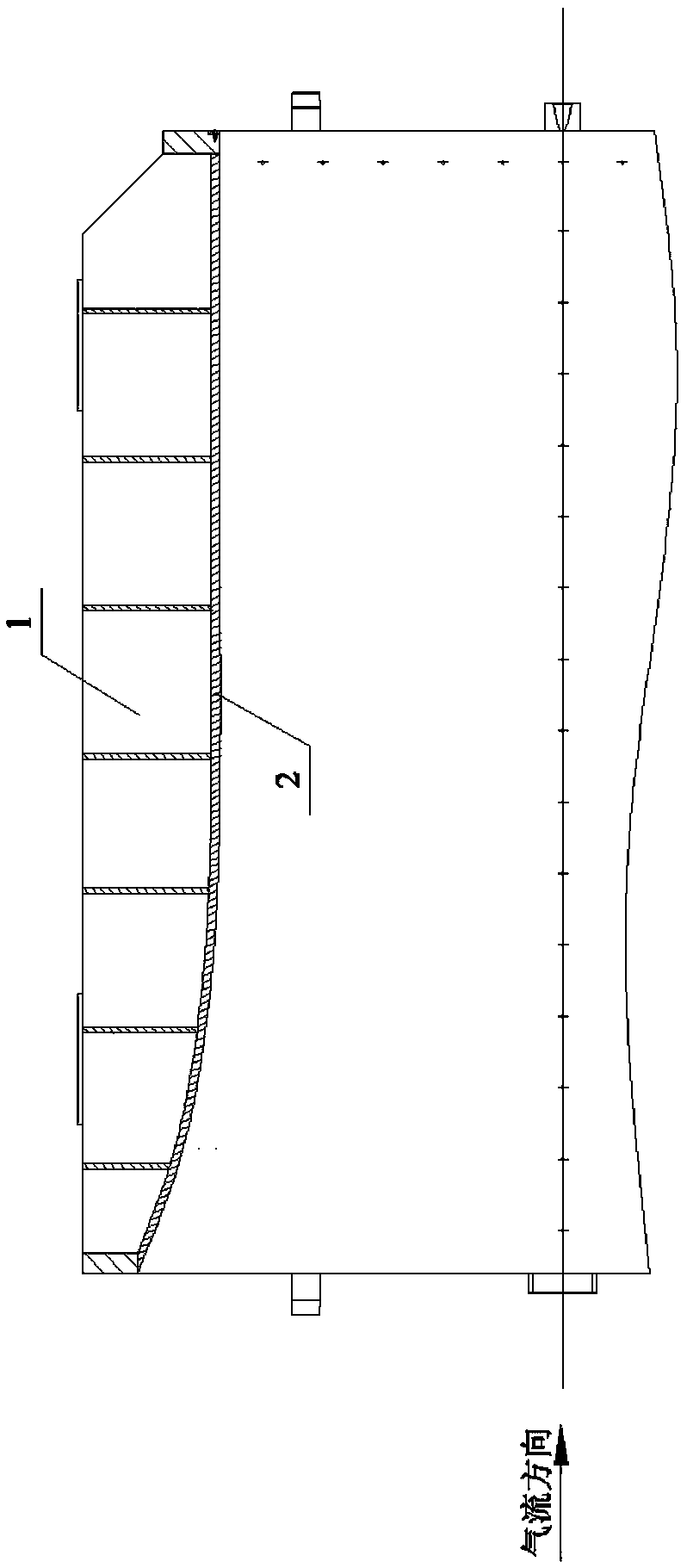

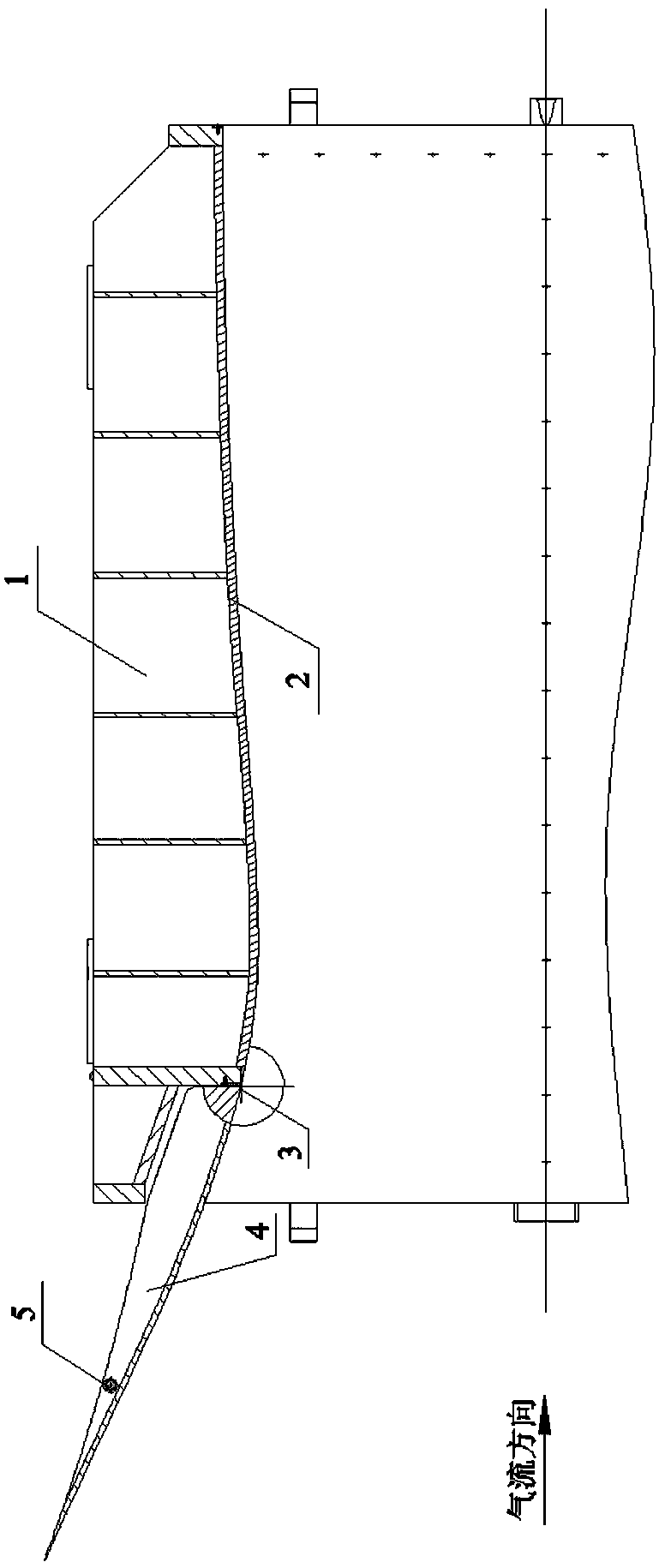

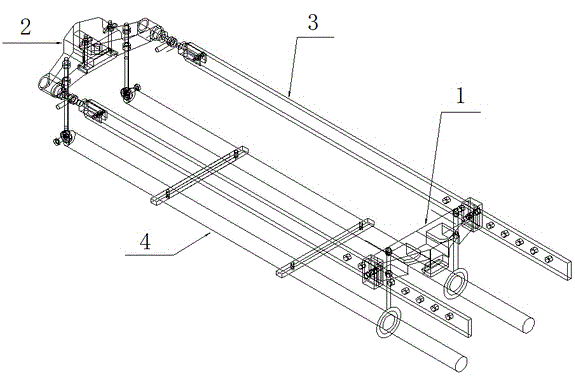

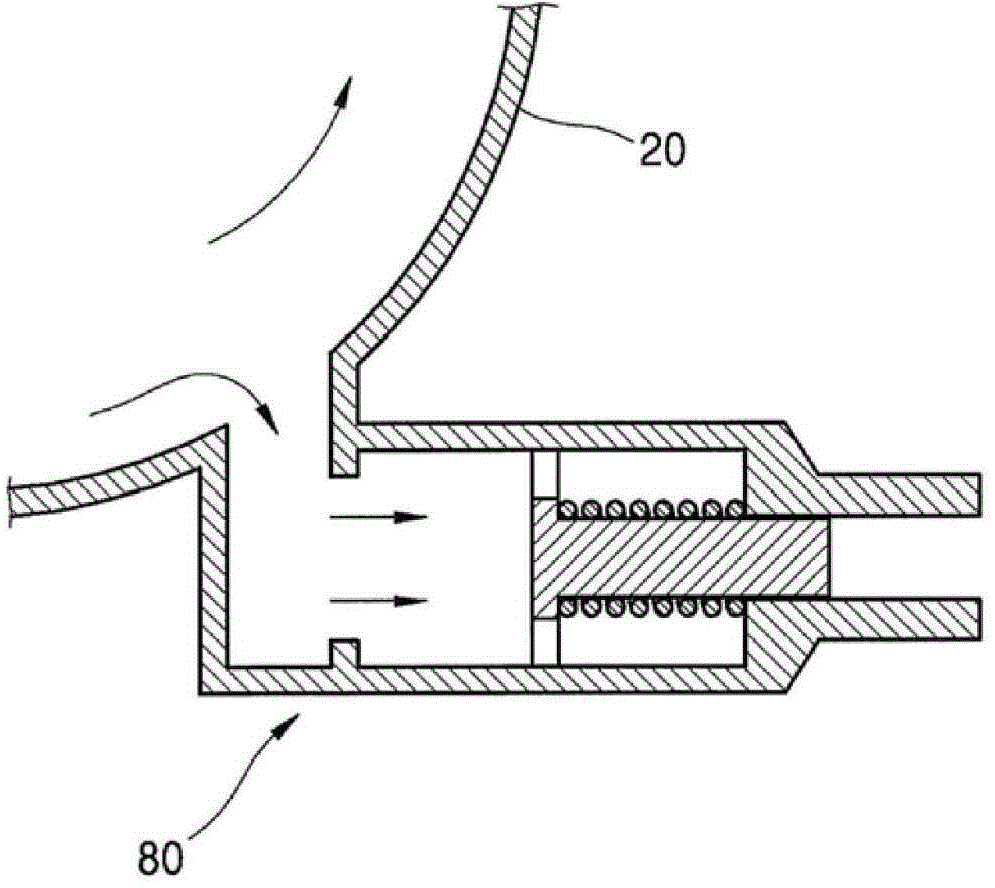

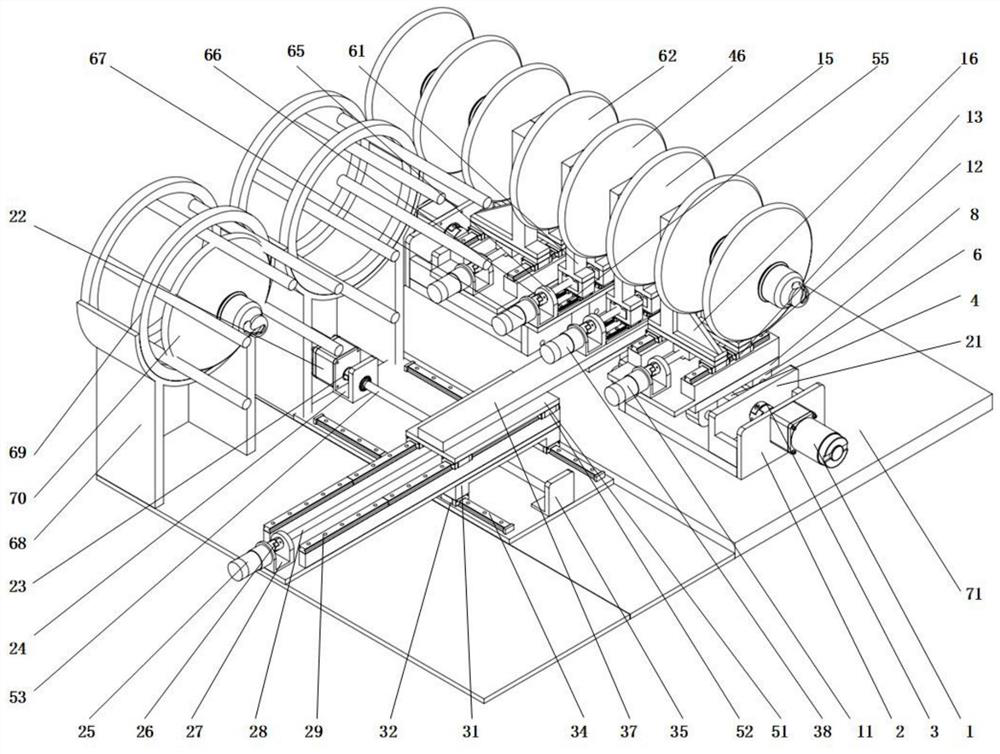

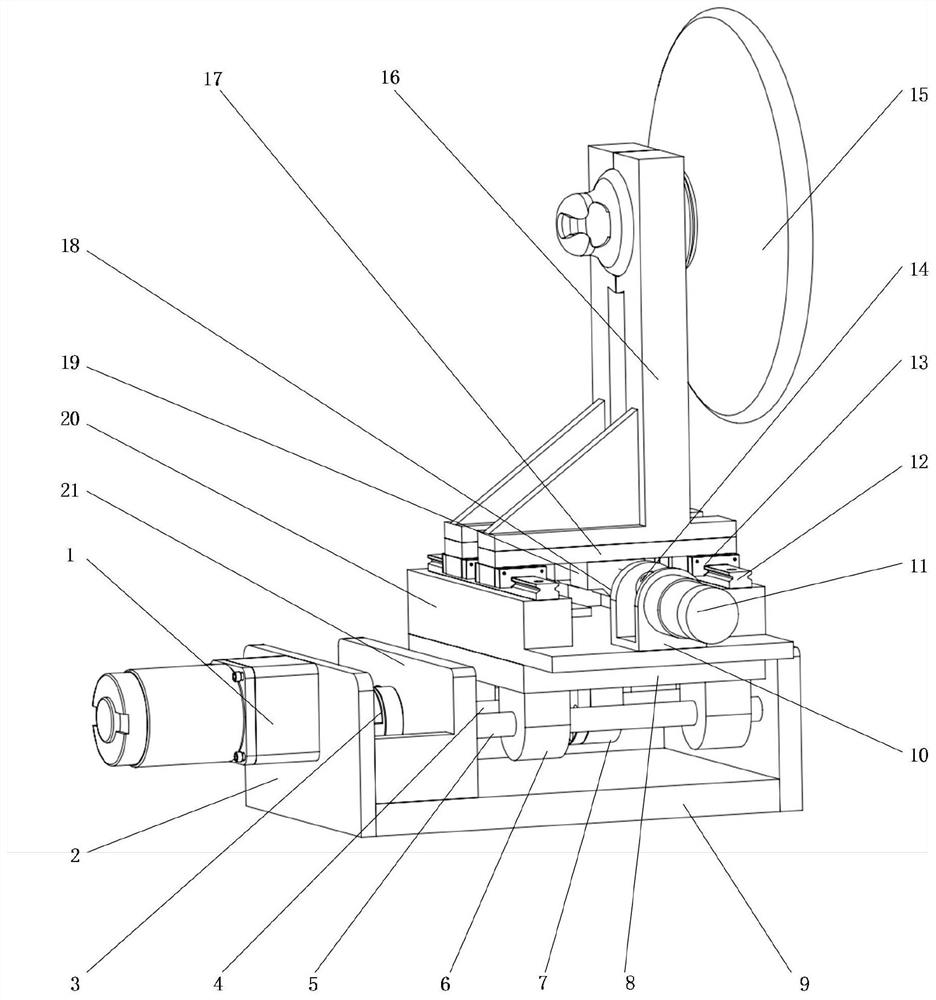

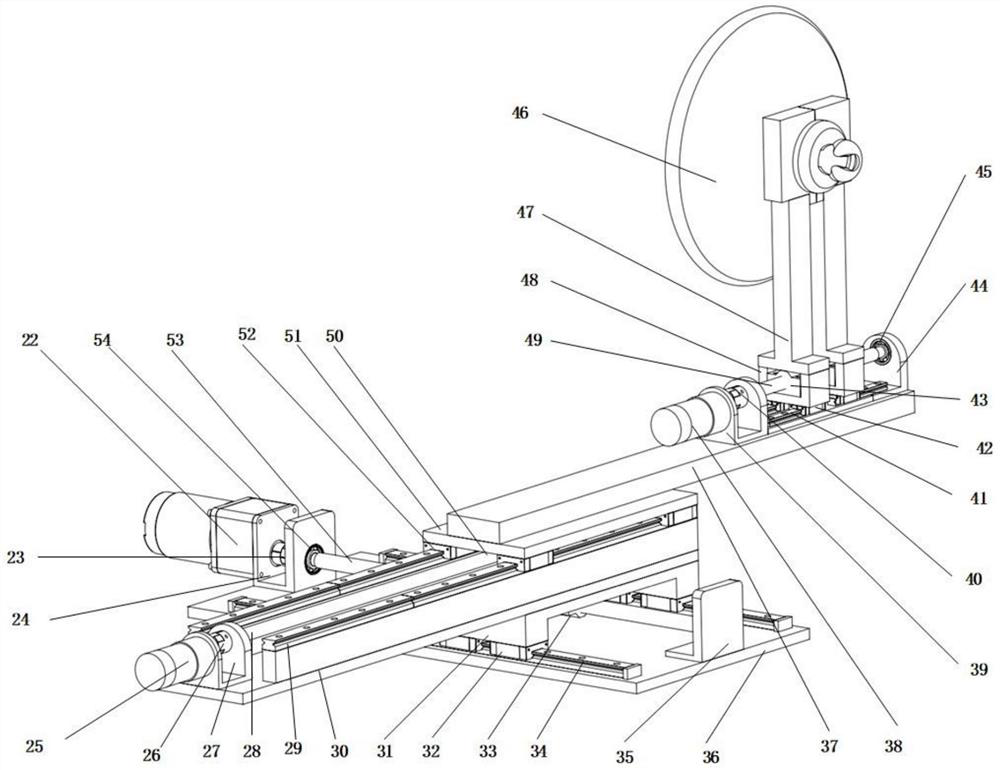

Solid block spray pipe device applied to wind tunnel and provided with foldable profile

The invention discloses a solid block spray pipe device applied to a wind tunnel and provided with a foldable profile, and aims to solve the problem that a solid block spray pipe device with a lengthened spray pipe is required to be developed in a process of reconstructing a high-speed wind tunnel to expand the highest work Mach number range of the high-speed wind tunnel but a new spray pipe device always cannot be mounted due to the too long spray pipe under the influence of fixed space position left by the wind tunnel to the spray pipe device. The solid block spray pipe device applied to thewind tunnel and provided with the foldable profile is provided and comprises a box body, a spray pipe assembly, a frame and a power drive assembly, wherein the box body is arranged on the frame, andthe frame is arranged on the power drive assembly. On the basis of structural improvement, the new spray pipe can be mounted on a wind tunnel structure in limited space, a lengthened spray pipe profile meeting the pneumatic design requirement is formed, furthermore, the new spray pipe profile is in stable streamline contact with other section structures of the wind tunnel, and effective expansionof the highest work Mach number range of the wind tunnel is realized jointly.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

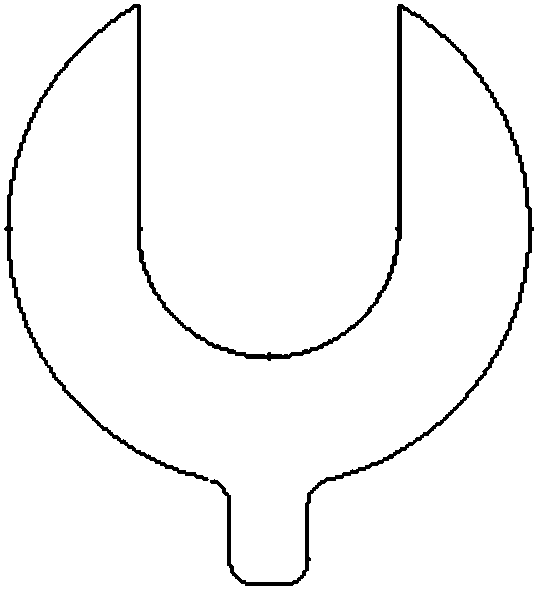

Tool for equipotential replacement of single-joint double-flexible bus tension insulator

ActiveCN106033872ARealize replacement workReduce switching proceduresApparatus for overhead lines/cablesMechanical engineeringElectric power

The invention, which relates to the technical field of electric power overhaul, provides a tool for equipotential replacement of a single-joint double-flexible bus tension insulator. A front clamping plate and a rear clamping plate are connected in an insulating pulling plate; a bracket is connected with the front clamping plate and the rear clamping plate respectively; a fixed connecting plate bayonet is arranged on the front clamping plate and U-shaped grooves for placing a right-angle hanging plate and a bolt are formed in the front clamping plate; and a vertical U-shaped clamp groove and a horizontal U-shaped clamp groove are formed in the rear clamping unit. A suspension loop string is fixed by a safety board assembly and a bufferfly nut. A lead screw assembly, a left rotating lead screw and a right rotating lead screw are connected with the insulating pulling plate. An insulating pulling plate locking pin fixes the insulating pulling plate; and the bracket is fastened by a bracket locking pin. Besides, a ball head pin is arranged at the front clamping plate; a marble, a spring, and a plug screw are used for localizing the ball head pin. The suspension loop string is formed by two suspension loops in series connection. According to the invention, the connecting plate, the right-angle hanging plate, and the double-flexible bus are connected and the suspension loops are connected with a portal at the other side based on a series connection structure, so that the provided tool is different from the existing ones in terms of appearance, functions, and application occasions; and the tool can be applied to replacement work of a single-joint double-flexible bus tension insulator on the equipotential condition. Moreover, the tool with a simple structure has high operability.

Owner:STATE GRID CORP OF CHINA +1

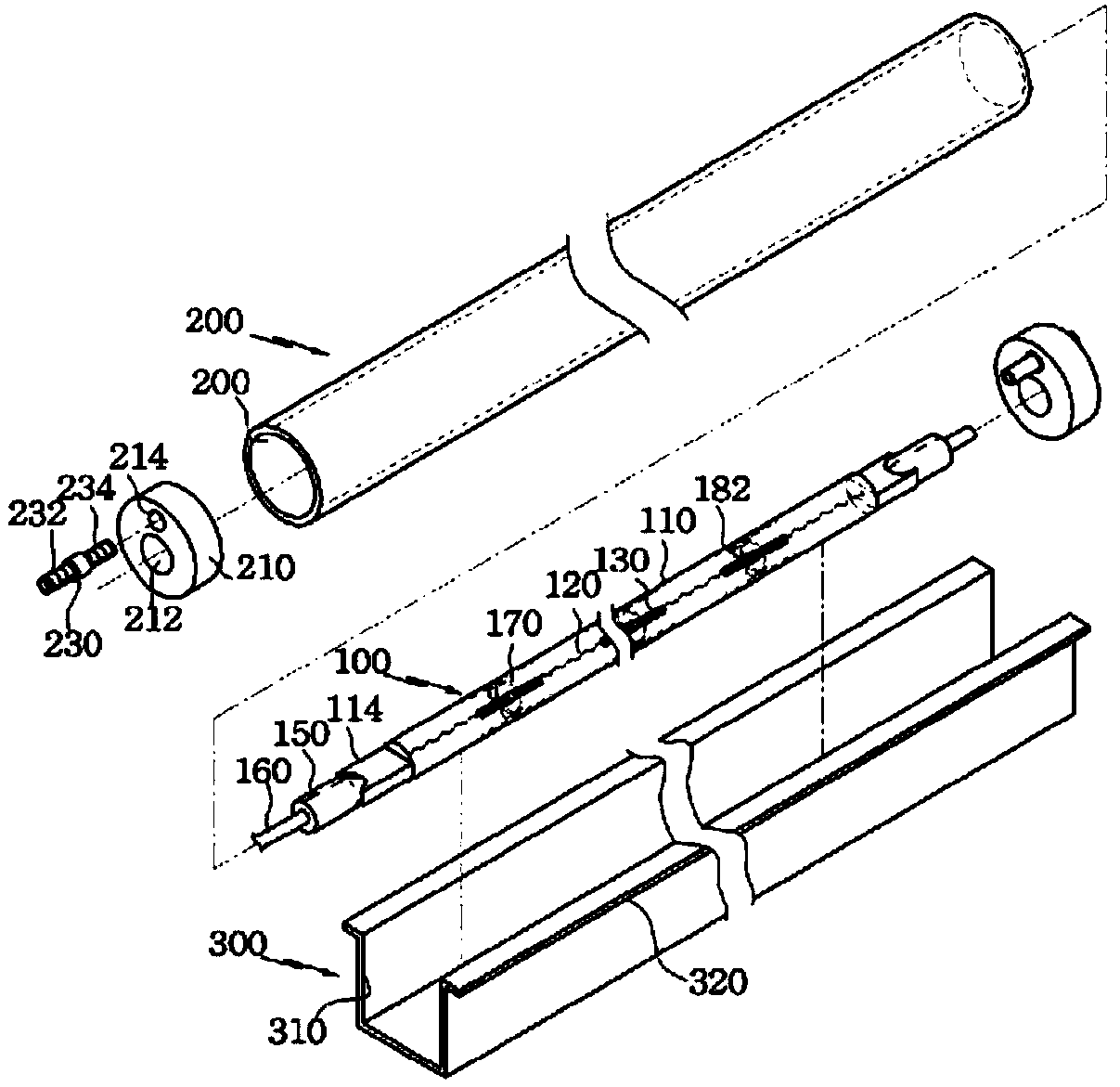

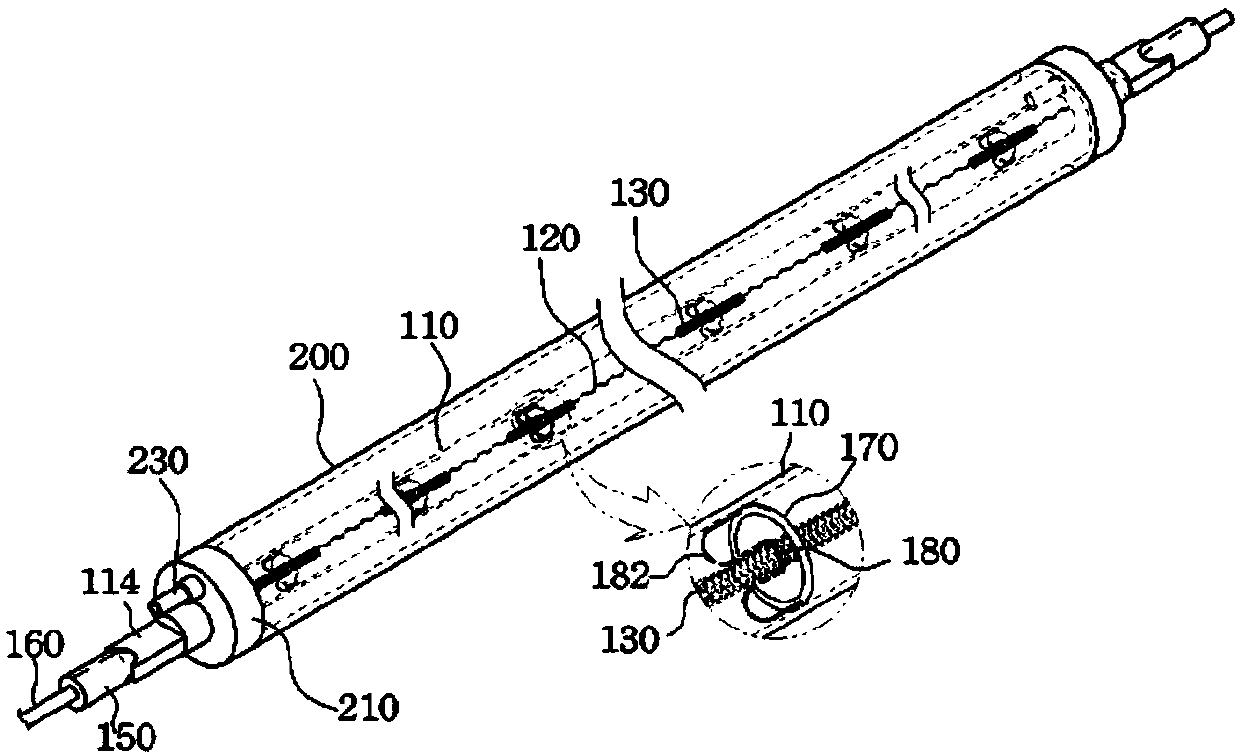

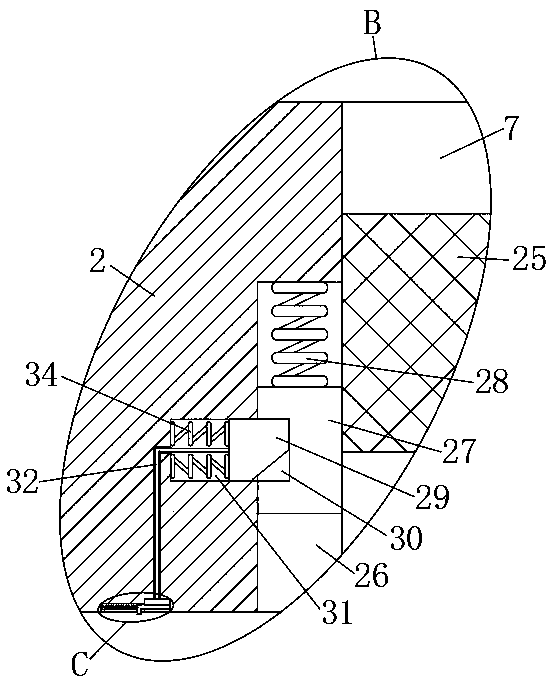

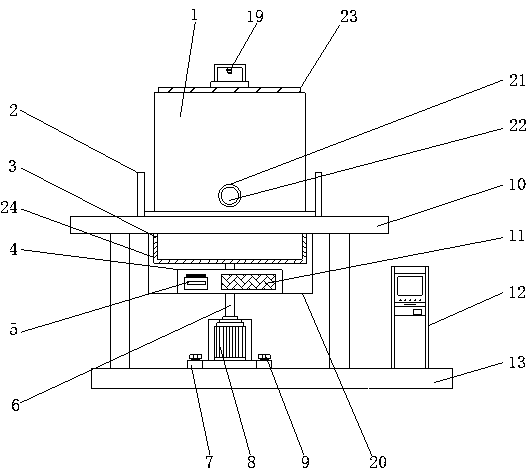

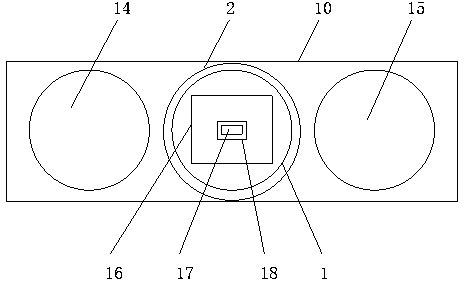

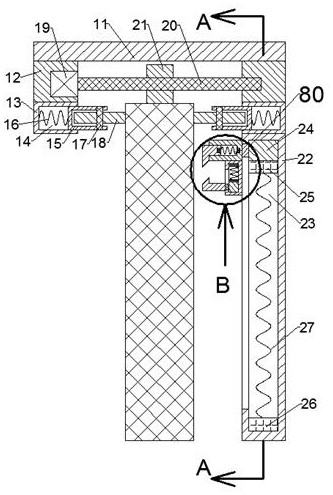

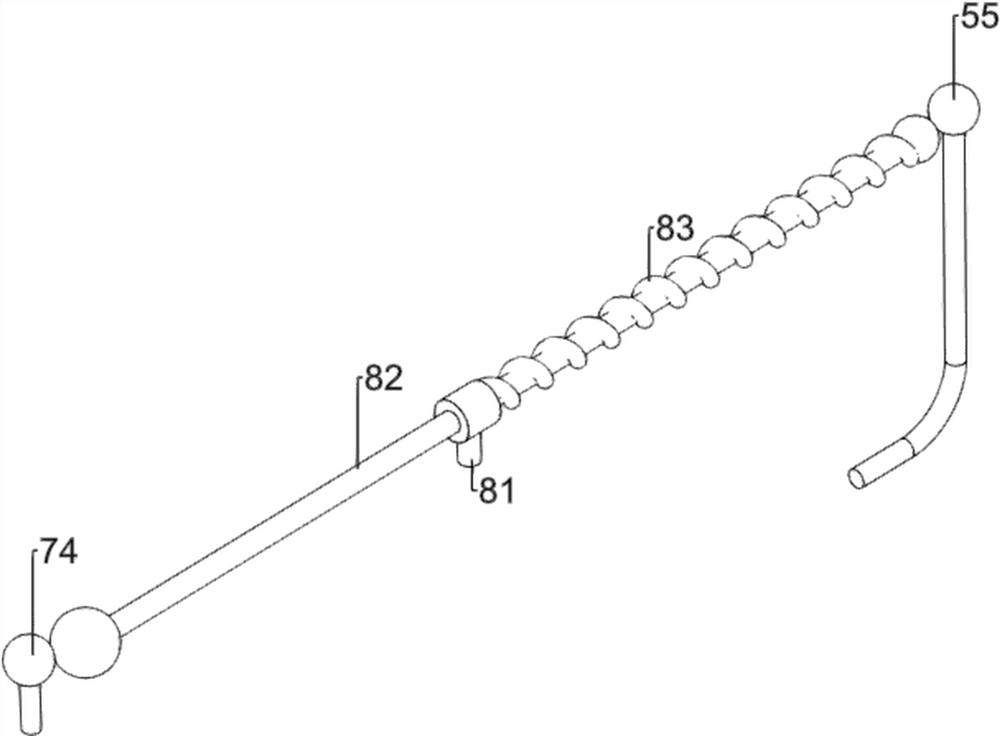

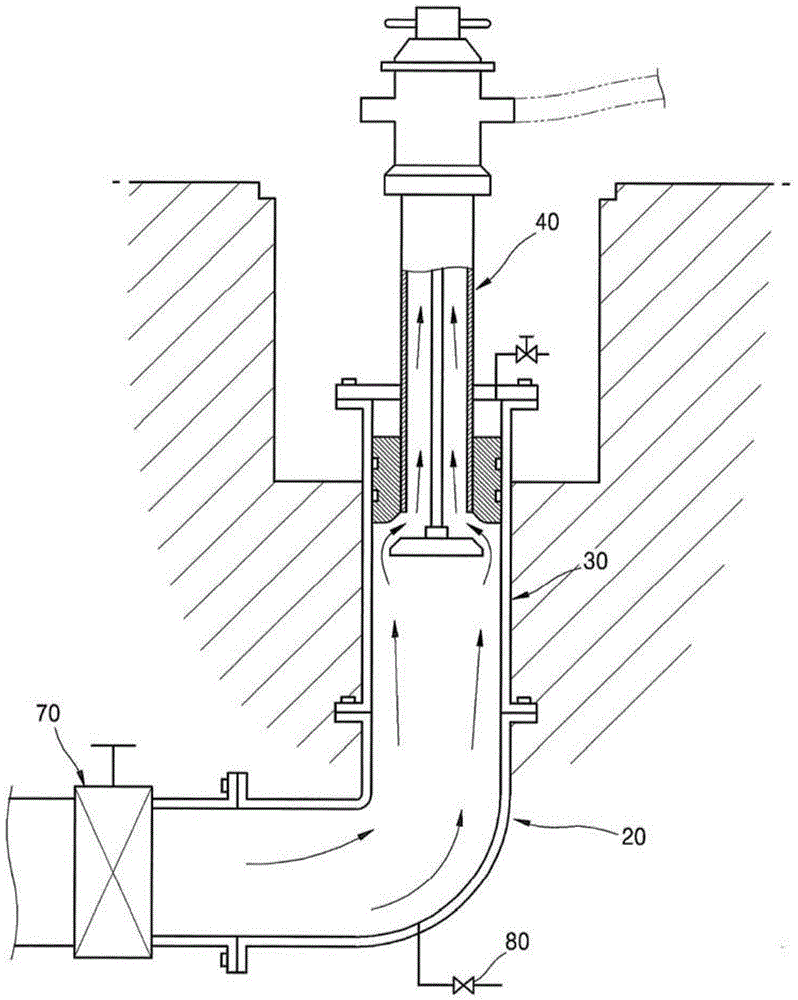

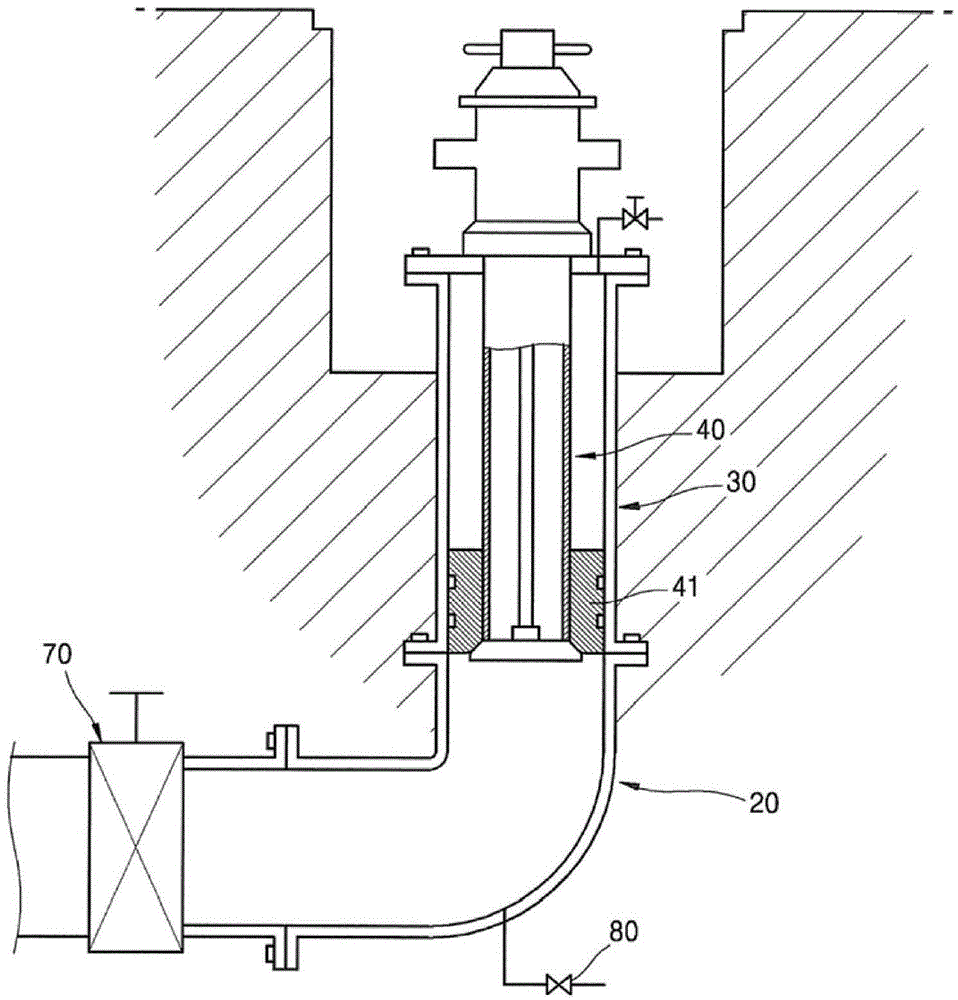

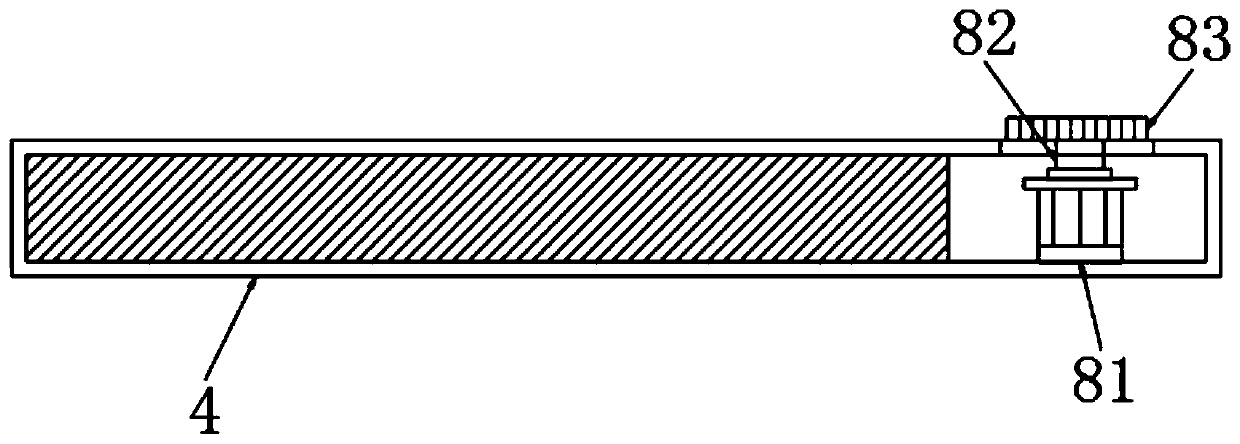

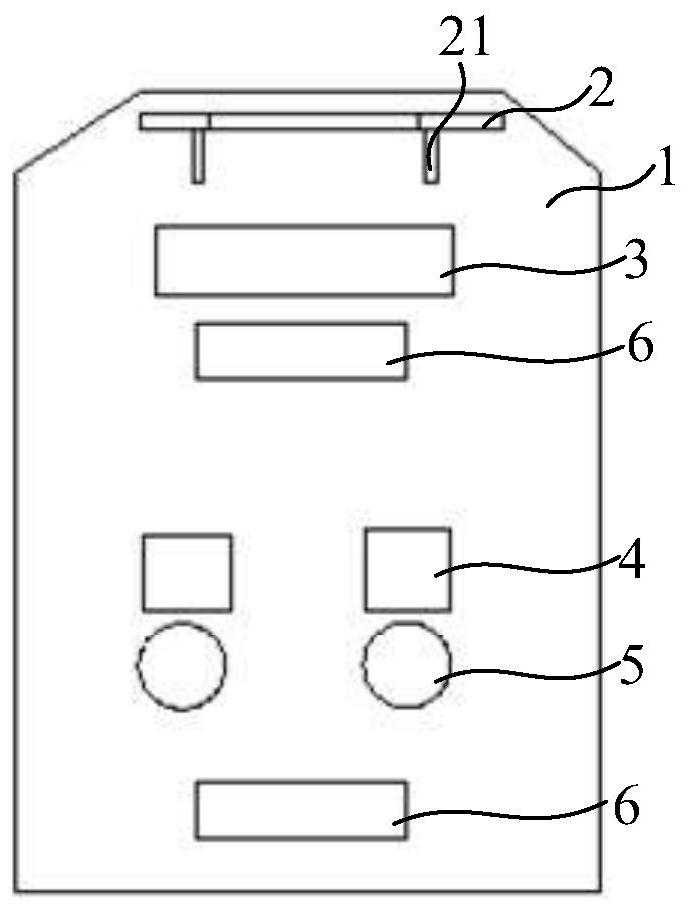

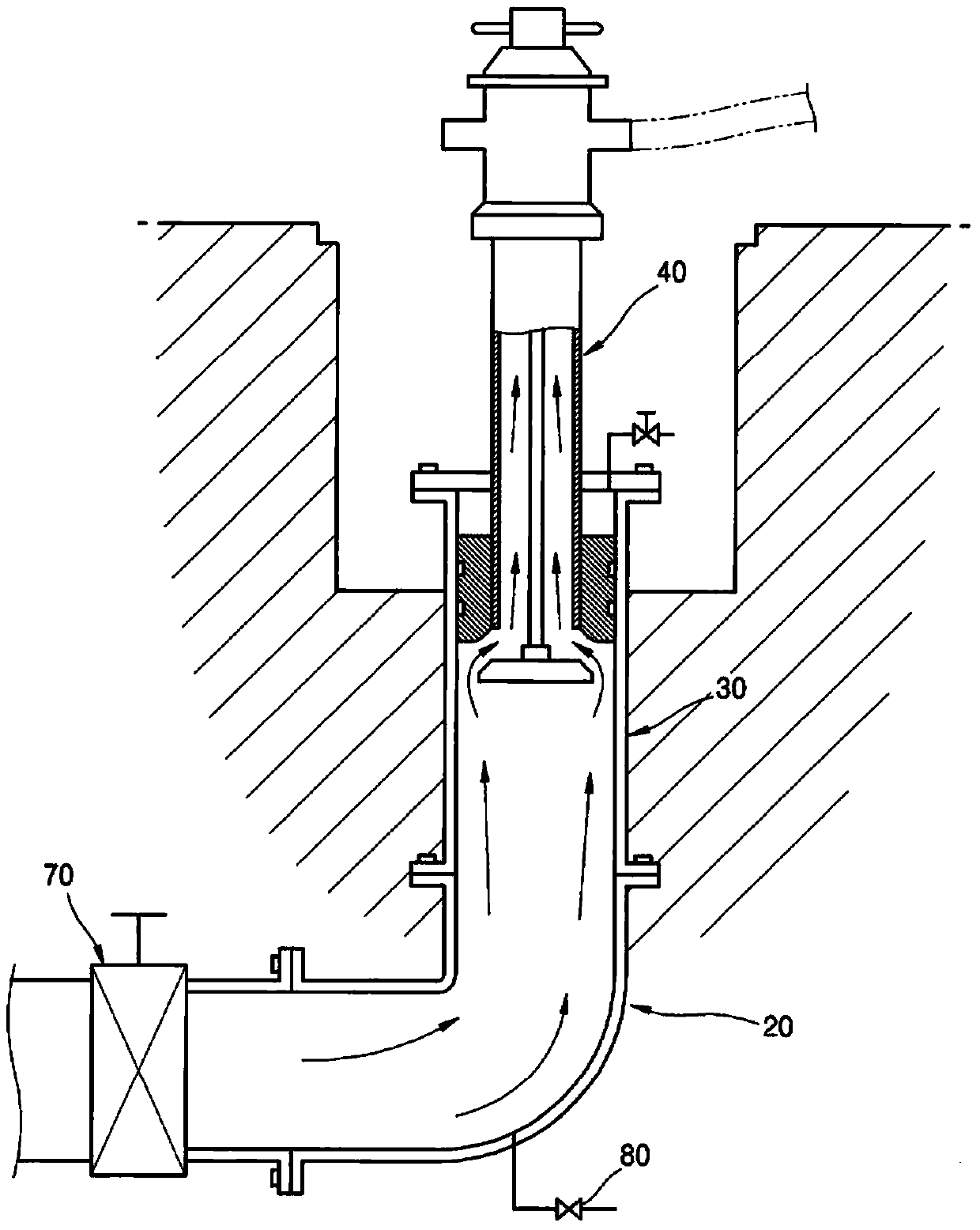

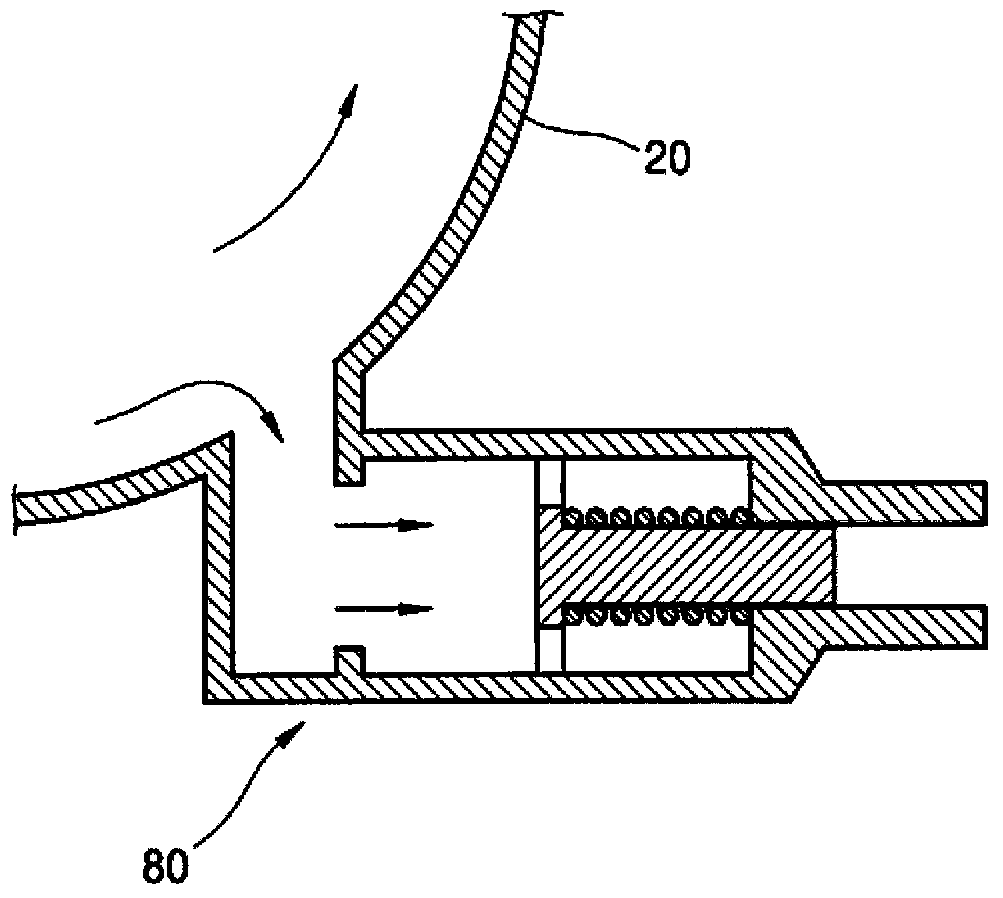

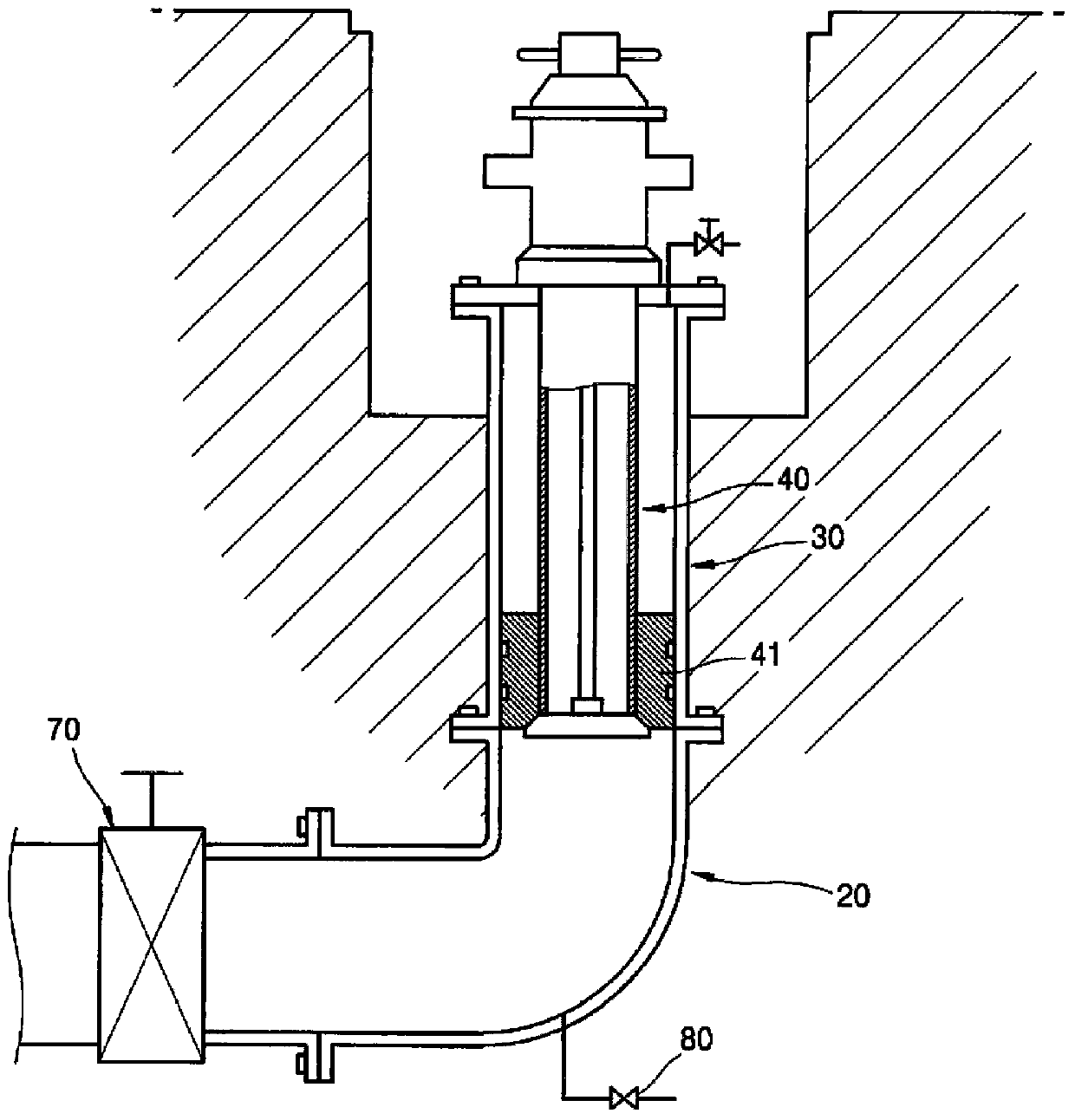

A hydrant assembly using a check valve

ActiveCN105986600ARealize replacement workEasy replacement workFire rescueDrawing-off water installationsEngineeringInhaled air

The present invention relates to a hydrant assembly having a check valve, which has an improved structure to simplify the replacement of a check valve embedded underground. A female screw hole (21) is formed in the curved part of an elbow pipe (20) of the hydrant assembly having the check valve. A check valve (80) is detachably coupled to the female screw hole (21). The hydrant assembly comprises a protection pipe (200) and an air valve (90). The top end of the protection pipe (200) is coupled to the top end of the elbow pipe (20), and the bottom end is located under the check valve (80) to protect the check valve (80) from buried soil. The air valve (90) is opened and closed to exhaust or inhale air between a fixing pipe (30) and a lifting pipe (40).

Owner:元承渊

Suspension Insulator Replacement Job Kit

ActiveCN111146727BRealize replacement workMeet the needs of degrees of freedomApparatus for overhead lines/cablesAutomationElectrical and Electronics engineering

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Tool for equipotential replacement of tension insulators for single-connected double soft busbars

ActiveCN106033872BRealize replacement workReduce switching proceduresApparatus for overhead lines/cablesBusbarOperability

The invention, which relates to the technical field of electric power overhaul, provides a tool for equipotential replacement of a single-joint double-flexible bus tension insulator. A front clamping plate and a rear clamping plate are connected in an insulating pulling plate; a bracket is connected with the front clamping plate and the rear clamping plate respectively; a fixed connecting plate bayonet is arranged on the front clamping plate and U-shaped grooves for placing a right-angle hanging plate and a bolt are formed in the front clamping plate; and a vertical U-shaped clamp groove and a horizontal U-shaped clamp groove are formed in the rear clamping unit. A suspension loop string is fixed by a safety board assembly and a bufferfly nut. A lead screw assembly, a left rotating lead screw and a right rotating lead screw are connected with the insulating pulling plate. An insulating pulling plate locking pin fixes the insulating pulling plate; and the bracket is fastened by a bracket locking pin. Besides, a ball head pin is arranged at the front clamping plate; a marble, a spring, and a plug screw are used for localizing the ball head pin. The suspension loop string is formed by two suspension loops in series connection. According to the invention, the connecting plate, the right-angle hanging plate, and the double-flexible bus are connected and the suspension loops are connected with a portal at the other side based on a series connection structure, so that the provided tool is different from the existing ones in terms of appearance, functions, and application occasions; and the tool can be applied to replacement work of a single-joint double-flexible bus tension insulator on the equipotential condition. Moreover, the tool with a simple structure has high operability.

Owner:STATE GRID CORP OF CHINA +1

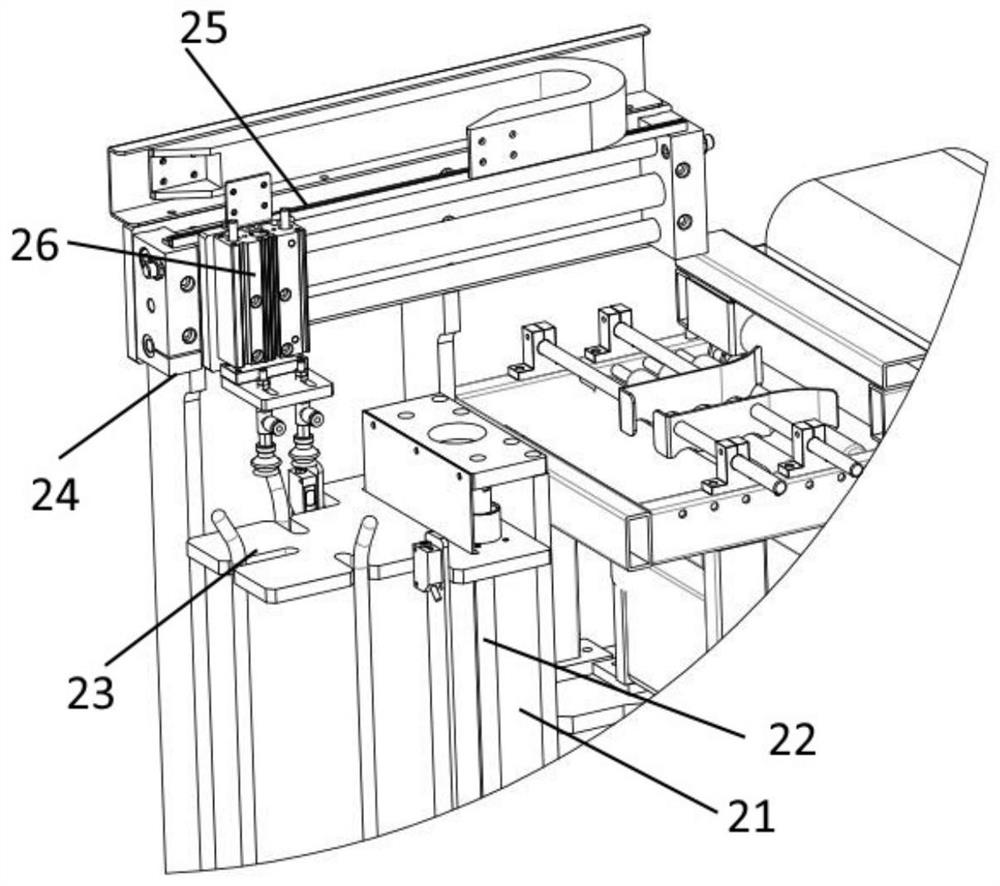

A mobile spindle machine tool with quick tool change function

ActiveCN112846883BRealize rotary motionRealize replacement workPositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a spindle mobile machine tool with quick tool change function, relates to the technical field of machine tool equipment, including machine tool, spindle, tool magazine, auxiliary frame, crawler belt, arc bar, support disc, arc clamping frame and tool . In the present invention, it is only necessary to turn on the motor to realize the replacement operation of the cutting tool. The operation is convenient and fast. Two adjacent arc bars are symmetrically arranged to ensure that the arc bars are paired in pairs. The outer side of the arc-shaped clamping frame further improves the stability of the arc-shaped clamping frame, thereby improving the stability of the tool and tool change operation, driving the tool to move downward, and the tool is always located in the arc-shaped clamping frame and arc-shaped during the installation and replacement process. The double clamping treatment of the bar can further improve the stability of the tool, and the track and the first support sleeve move in opposite directions, so that the track and the first support sleeve exert an inward extrusion force on the tool, which can further improve Tool stability.

Owner:JIANGSU BOSUNMAN IND EQUIP

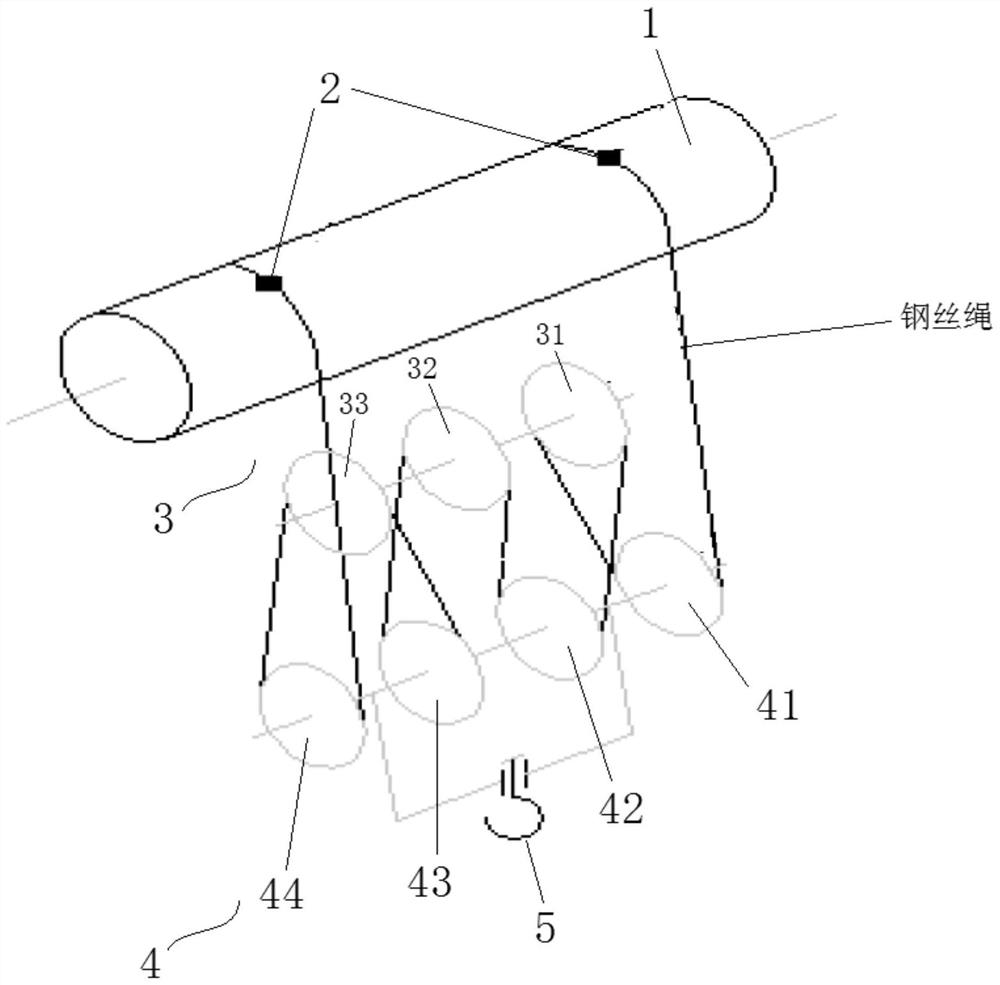

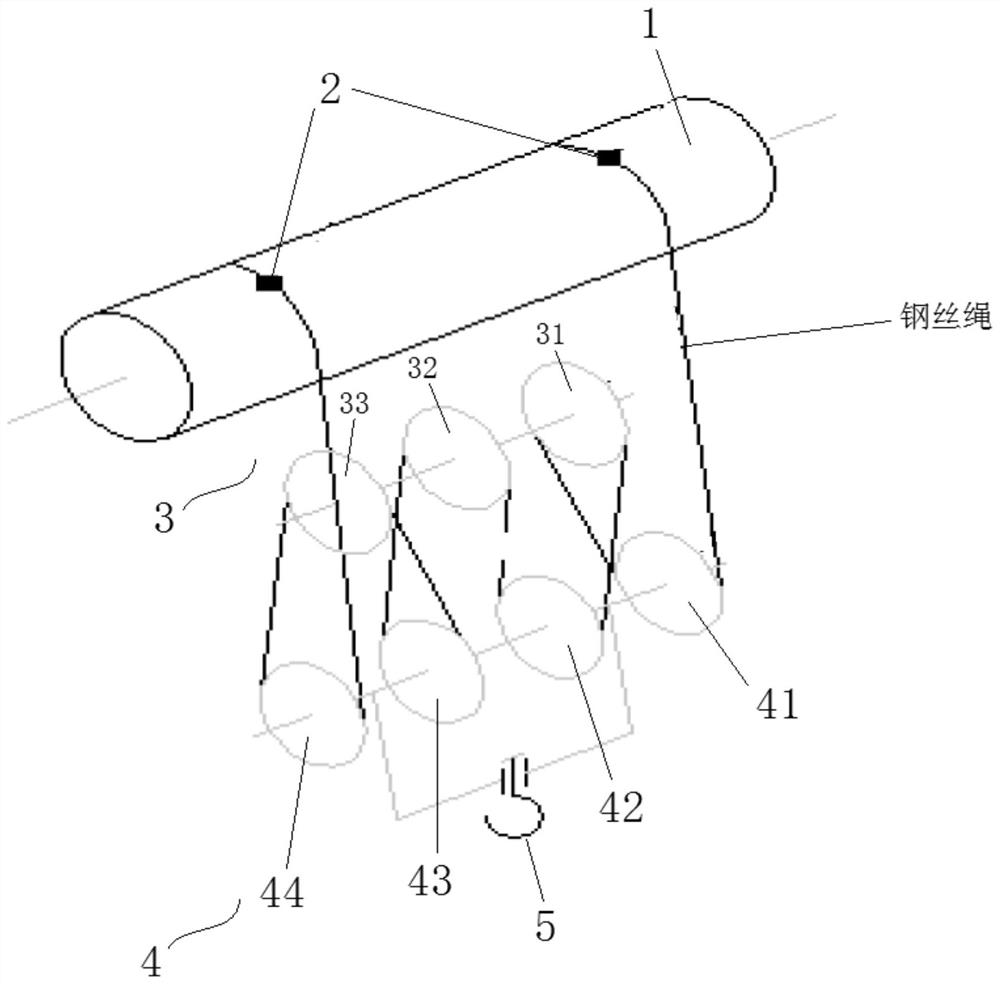

Crane wire rope replacement method

ActiveCN110395660BShort replacement timeReduce labor intensityLoad-engaging elementsWire ropeEngineering

The invention discloses a replacement method of a steel wire rope of a crane. The replacement method comprises the steps that an old steel wire rope is cut off, and the distance between the cutoff position and the center of the old steel wire rope is X; two rope ends of a new steel wire rope are connected with two rope ends obtained after cutoff correspondingly, and the length of the new steel wire rope is equal to the sum of the length of the old steel wire rope and 2X; press plates on a winding drum are dismounted, the winding drum is rotated, and the old steel wire rope is driven to move; when X=0, two joints rotate to the winding drum at the same time, and the winding drum stops rotating at this moment; when X is not equal to 0, when the front joint arrives at the winding drum, the winding drum continues to rotate, and the winding drum stops rotating till the back joint arrives at the winding drum; the two synchronously-arriving joints are cut off; or, the back joint is cut off, and the new steel wire rope is cut off at the same position of the other end of the winding drum; the press plates are adopted for fixing the cutoff rope ends to the winding drum; and the winding drum continues to rotate till the preset number of circles of winding is achieved. According to the replacement method of the steel wire rope of the crane, the time used for replacement is short, labor intensity is reduced, and work efficiency is improved.

Owner:SHANDONG IRON & STEEL CO LTD

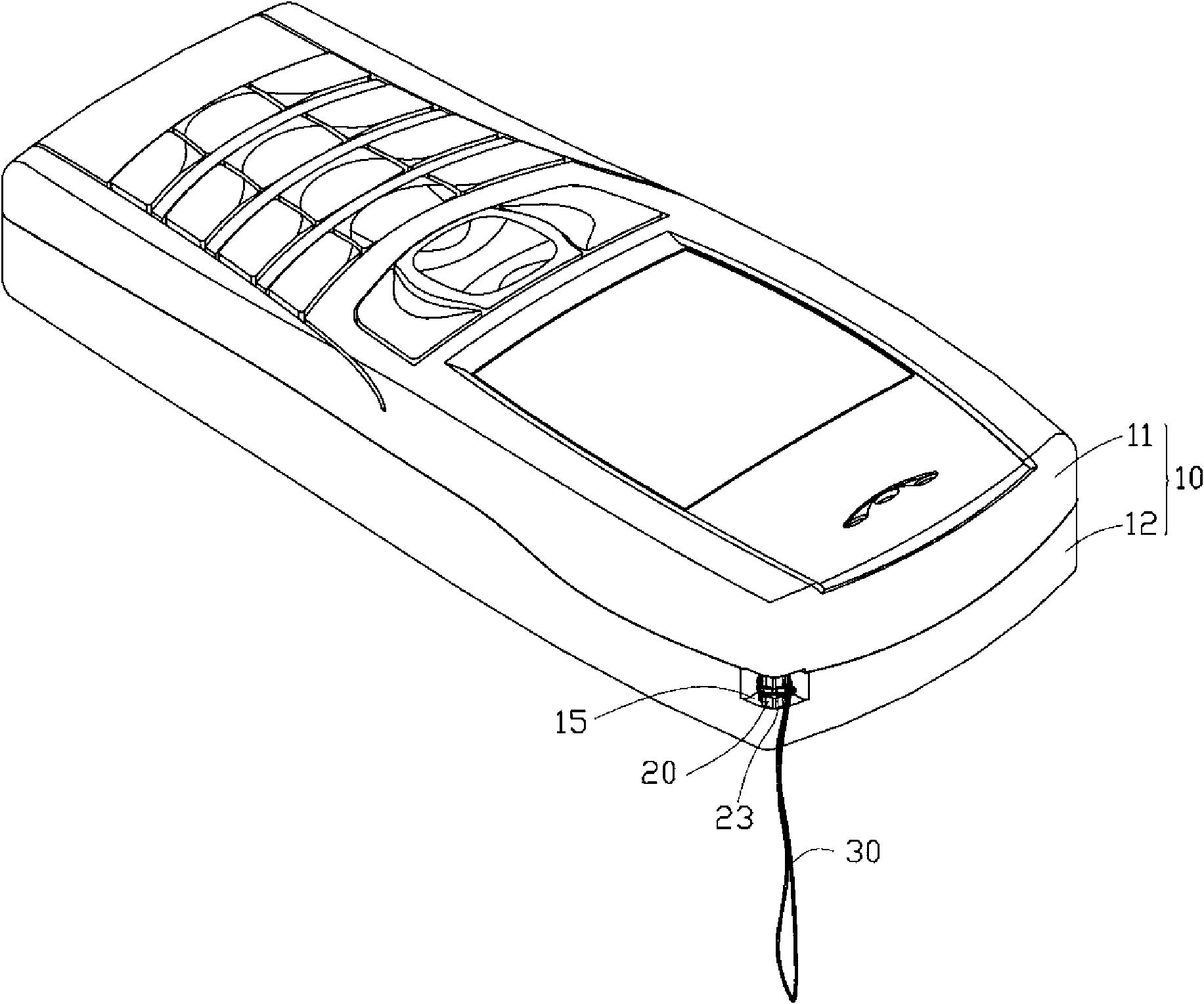

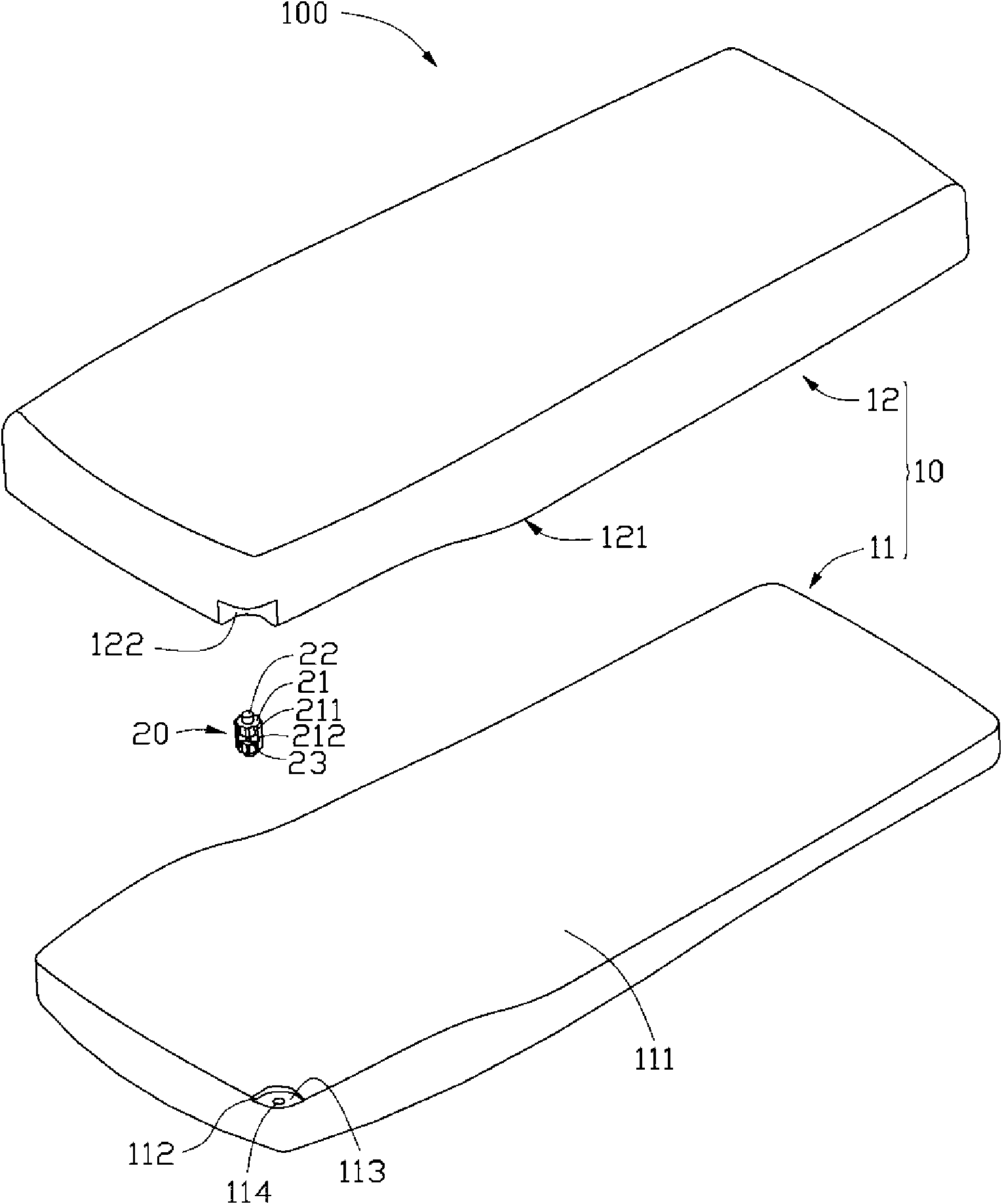

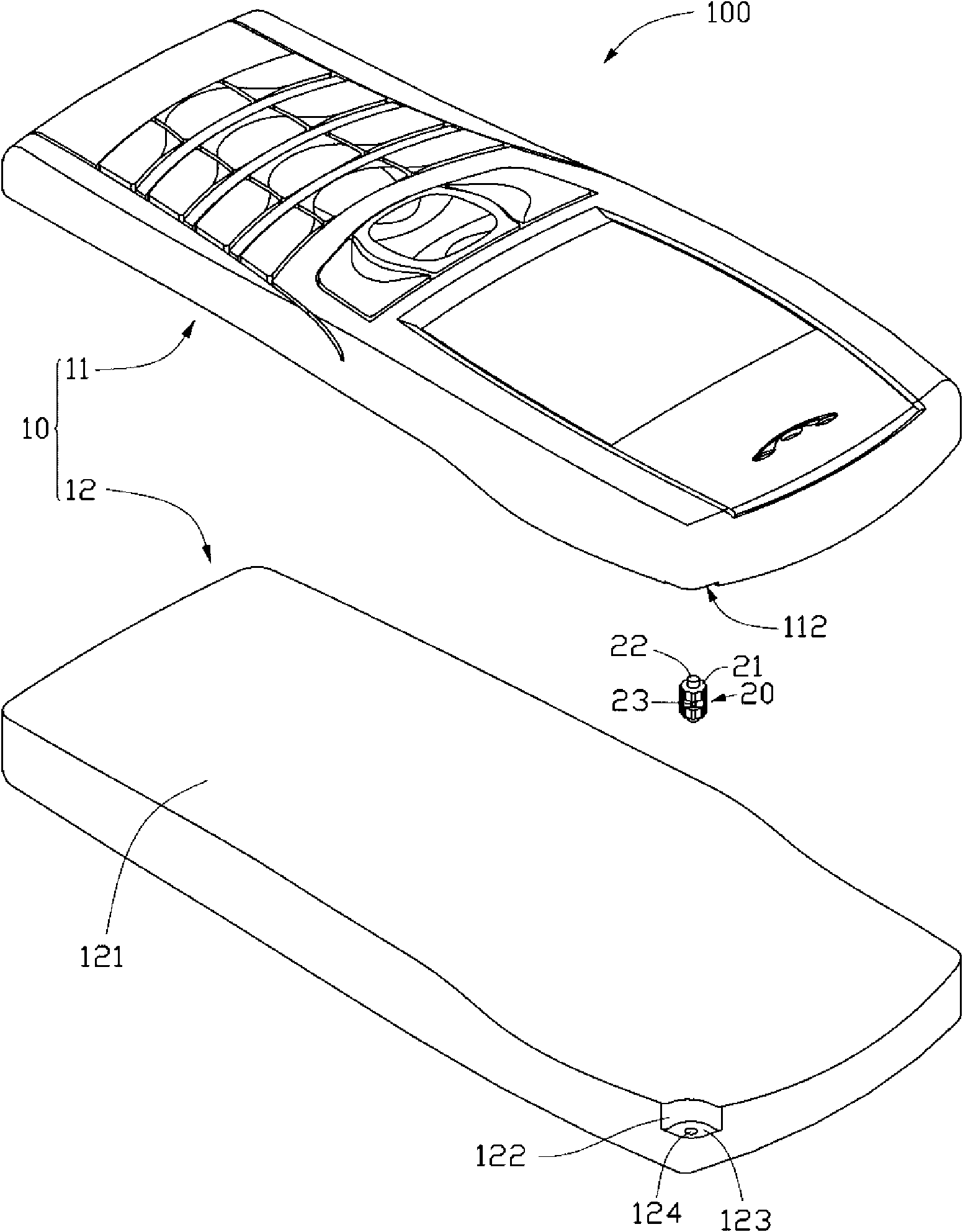

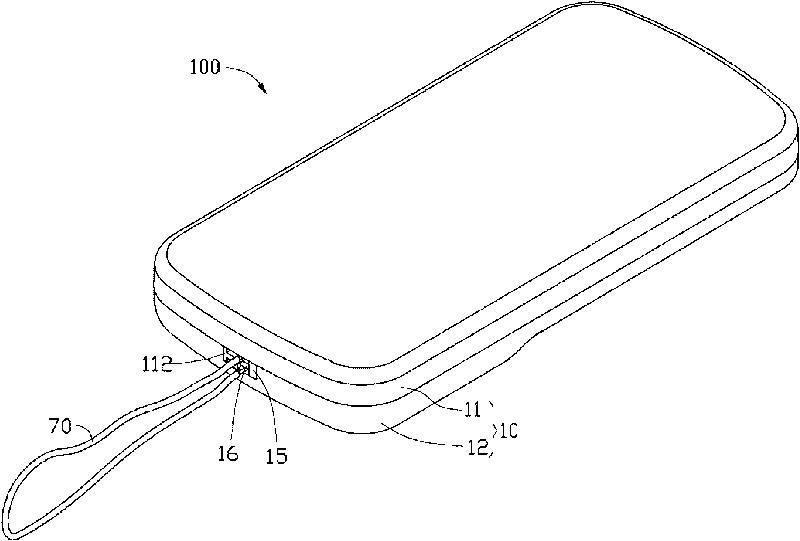

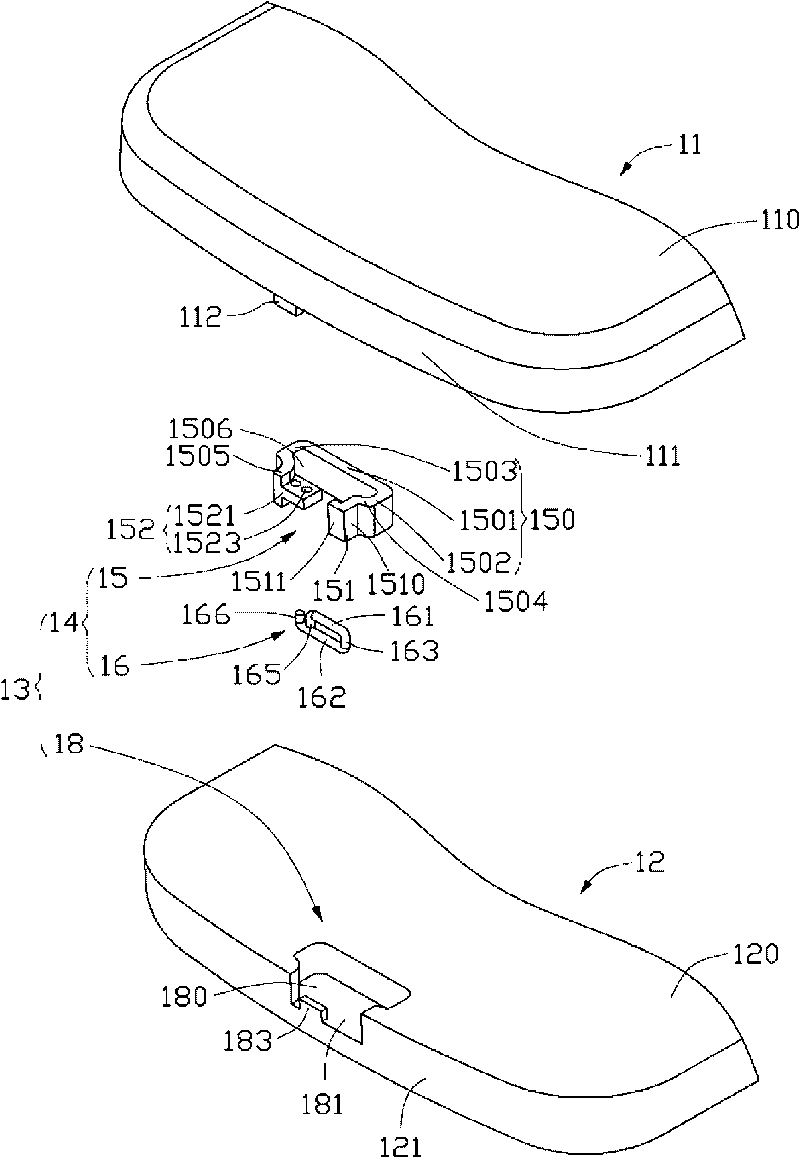

Hanging ornament installation structure and portable electronic device with same

InactiveCN101834919ARealize the installation workRealize replacement workTravelling carriersHoldersWaste managementOrnaments

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

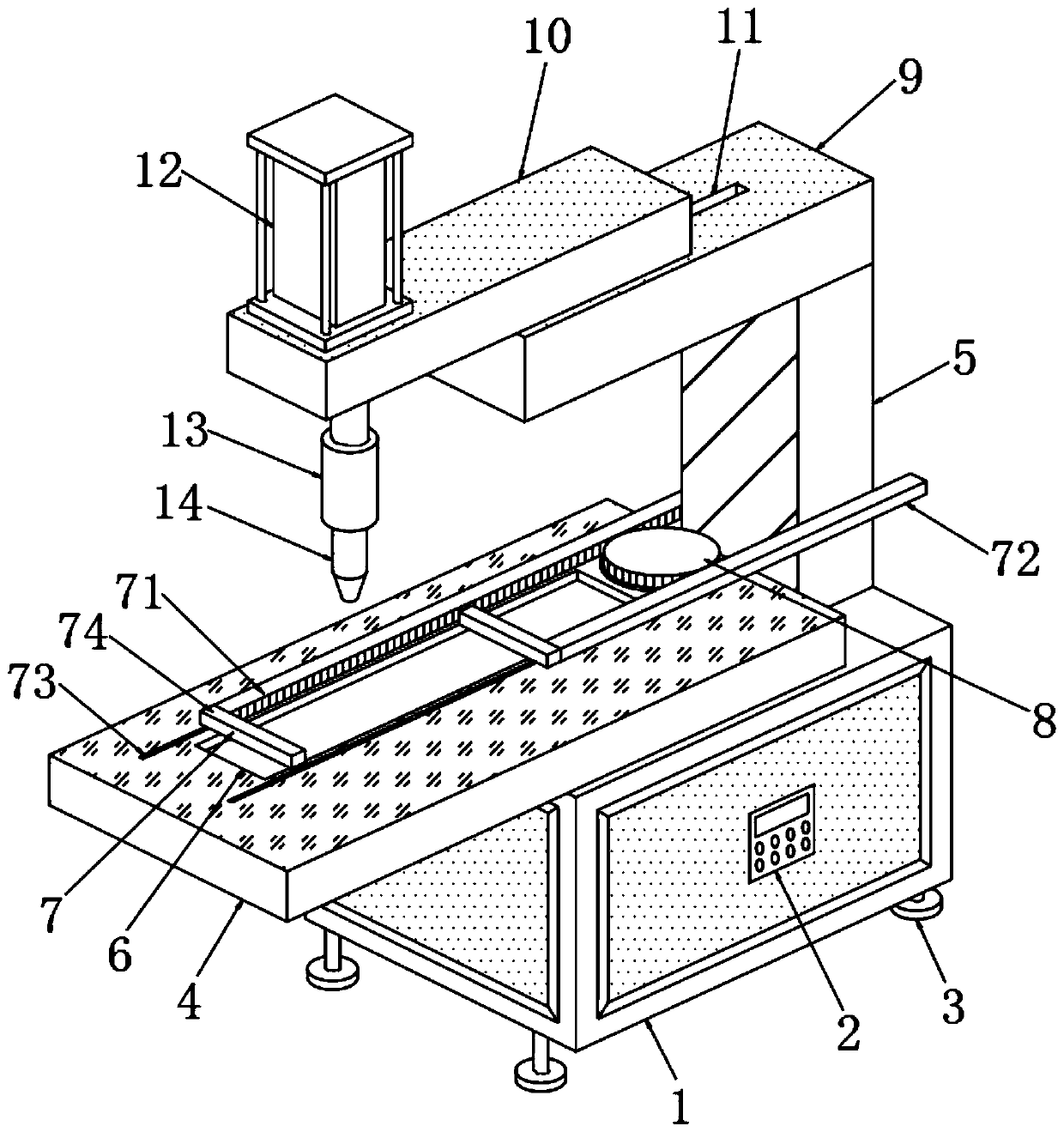

Punching equipment for D500E alloy steel machining

PendingCN111451364AOvercome the phenomenon that affects the punching accuracyEasy to punchShaping toolsMetal-working feeding devicesPunchingSlide plate

The invention discloses punching equipment for D500E alloy steel machining and relates to the technical field of alloy steel machining. The equipment comprises a frame, a control panel, a ground foot,an operation panel and a stand column, wherein the control panel is embedded and mounted on the front side of the frame, the ground foot is fixedly mounted on the lower surface of the frame, the operation panel is fixedly mounted on the top end of the frame, and the stand column is fixedly mounted on the position, located on one side of the operation panel, of the top end of the frame. The equipment is scientific and reasonable in structure and convenient to operate, fixing work for machining alloy steel can be achieved through a clamping mechanism and a driving mechanism which are arranged,convenience is provided for punching operation, practicability is increased, the equipment can be suitable for fixing workpieces with different sizes, the use range of the equipment is enlarged, leftand right sliding of a sliding plate can be achieved through an arranged sliding mechanism, and therefore left and right sliding of a drill bit can be achieved. The automation degree and the safety are improved, and the working efficiency is effectively improved.

Owner:JINGYE STEEL CO LTD

Hanging ornament installation structure and portable electronic device with same

InactiveCN101742851ARealize the installation workRealize replacement workTravelling sacksTravelling carriersEngineeringMechanical engineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Special Tooling for Clamping Cylinder Replacement of Quick Forging Manipulator and Its Replacement Method

ActiveCN110788771BEffectively fixedRealize replacement workWork holdersRotational axisForging manipulator

Owner:上海五钢设备工程有限公司 +1

Auxiliary device and method for linear rods in shared corridor with electromigration

ActiveCN108683122BRealize replacement workSave timesApparatus for overhead lines/cablesControl theoryElectric cables

The invention relates to the field of an overhead mounting device of a line or a cable, and particularly to an auxiliary device of a live migration common corridor linear rod. The auxiliary device comprises a crossbeam. One end of the crossbeam is provided with a linear cross arm snapping part. The linear cross arm snapping part is C-shaped and comprises a horizontal plate I, a horizontal plate IIand a vertical plate. The other end of the crossbeam is provided with a lead fixing device which is fixed. The lead fixing device comprises a fixing column I, a fixing column II and an automatic locking board. The auxiliary device according to the invention matches an original linear rod pole and can move the lead in the horizontal direction, thereby supplying a sufficient space for mounting of anew pole and detachment of an old pole, and realizing electric pole changing operation on the condition of incapability of hoisting the lead. The auxiliary device according to the invention does notrequire a crane or a hoisting vehicle for hoisting the lead, thereby preventing dangers in a lead hoisting process, and realizing higher safety and higher efficiency of the operation method.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

A ball counting device

ActiveCN107301451BAccurate and efficient calculationGood for scrollingCounting mechanisms/objectsRatchetEngineering

The invention relates to a small ball counting device, which includes a support seat, a turntable, a cover tube, a push-pull electromagnet, a first link mechanism, a second link mechanism, a blocking piece, a conveyor belt mechanism and a ratchet wheel. The turntable is rotatable It is arranged on the support seat, and the cover tube is set on the peripheral side of the turntable, so that the cover tube forms a space for receiving small balls on the turntable; the side wall of the cover tube is provided with a discharge hole, so The conveying surface of the conveyor belt mechanism is equidistantly provided with packing boxes, and the discharge hole is connected to the packing box through a guide groove; the side of the guide groove is provided with an electronic counting mechanism opposite to the inside of the guide groove . The invention can efficiently and accurately calculate the number of small balls, and is applicable to small balls with various diameters.

Owner:南通大学技术转移中心有限公司

Cleaning device and cleaning method for parts subjected to wave soldering

ActiveCN112547630AAvoid configuration workReduce wasteCleaning using liquidsProcess engineeringWorkbench

The invention discloses a cleaning device and a cleaning method for parts subjected to wave soldering. The cleaning device for the parts subjected to wave soldering comprises a carrying assembly and aconveying device that are fixedly connected with a workbench, a quantifying assembly located on one side of the conveying device, a limiting assembly connected with the quantifying assembly, and a cleaning chamber and a drying chamber that are arranged on the conveying device. According to the cleaning device and the cleaning method, through arrangement of the quantifying assembly, needed cleaning liquid can be automatically prepared, so that manual preparation work is avoided, and labor waste is thus reduced; and meanwhile a connecting device is arranged, so that when the cleaning device isused for a too long time, and consequently the water yield of the cleaning device is not large enough to complete cleaning of parts, and the cleaning device can be replaced through the connecting device at the moment, and smooth operation of cleaning work is thus guaranteed.

Owner:南京江川电子有限公司

Fire hydrant assembly with check valve

ActiveCN105986600BRealize replacement workEasy replacement workFire rescueDrawing-off water installationsEngineeringInhaled air

The present invention relates to a hydrant assembly having a check valve, which has an improved structure to simplify the replacement of a check valve embedded underground. A female screw hole (21) is formed in the curved part of an elbow pipe (20) of the hydrant assembly having the check valve. A check valve (80) is detachably coupled to the female screw hole (21). The hydrant assembly comprises a protection pipe (200) and an air valve (90). The top end of the protection pipe (200) is coupled to the top end of the elbow pipe (20), and the bottom end is located under the check valve (80) to protect the check valve (80) from buried soil. The air valve (90) is opened and closed to exhaust or inhale air between a fixing pipe (30) and a lifting pipe (40).

Owner:元承渊

A cleaning device and cleaning method for parts after wave soldering

ActiveCN112547630BGuaranteed uptimeAvoid cloggingCleaning using liquidsProcess engineeringCleaning methods

The invention discloses a cleaning device for parts after wave soldering and a cleaning method thereof. The device for cleaning parts after wave soldering includes a handling assembly and a transportation device fixedly connected to the workbench. A quantitative component on one side, a limit component connected with the quantitative component, and a cleaning room and a drying room arranged on the transport device. Through the set quantitative components, the required cleaning solution can be automatically configured, thereby avoiding manual configuration work, thereby reducing the waste of manpower. When the water output of the device is not enough to complete the cleaning of the parts, the connection device can be connected at this time to complete the replacement of the cleaning device, thereby ensuring the smooth operation of the cleaning work.

Owner:南京江川电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com