Solid block spray pipe device applied to wind tunnel and provided with foldable profile

A wind tunnel and nozzle technology, which is used in measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of long nozzles, difficulty in guaranteeing new nozzles, and inability to install them, and achieves solid structure and long service life. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

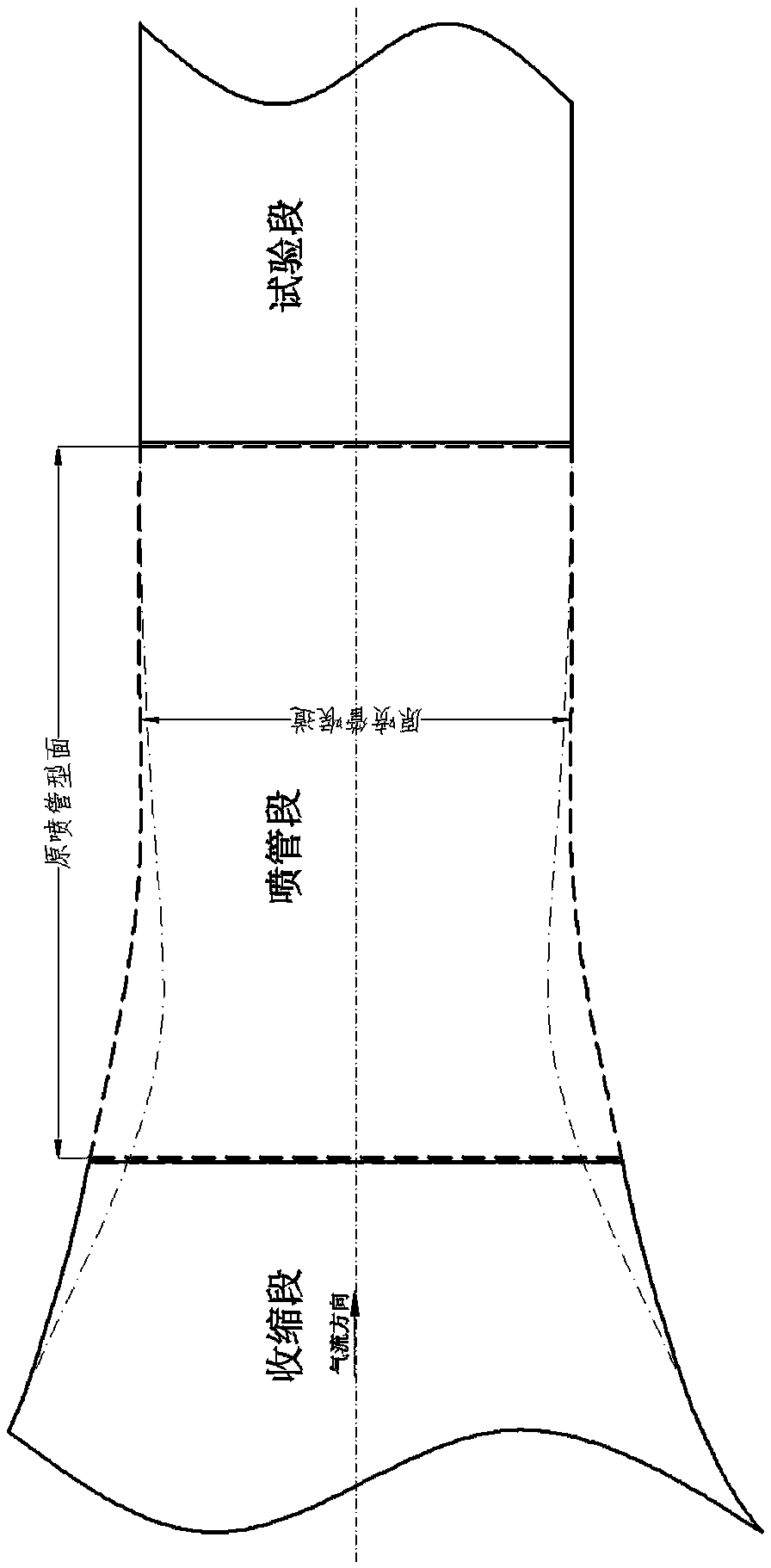

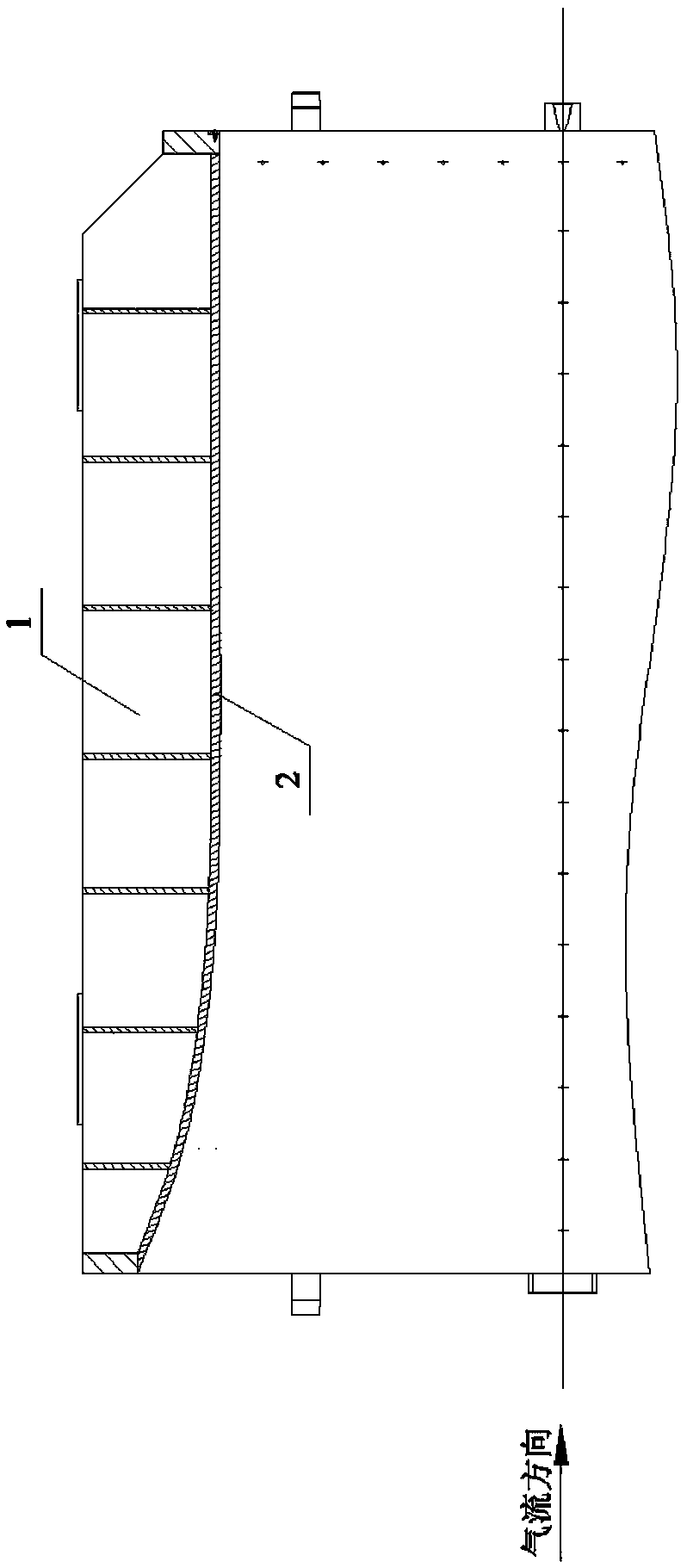

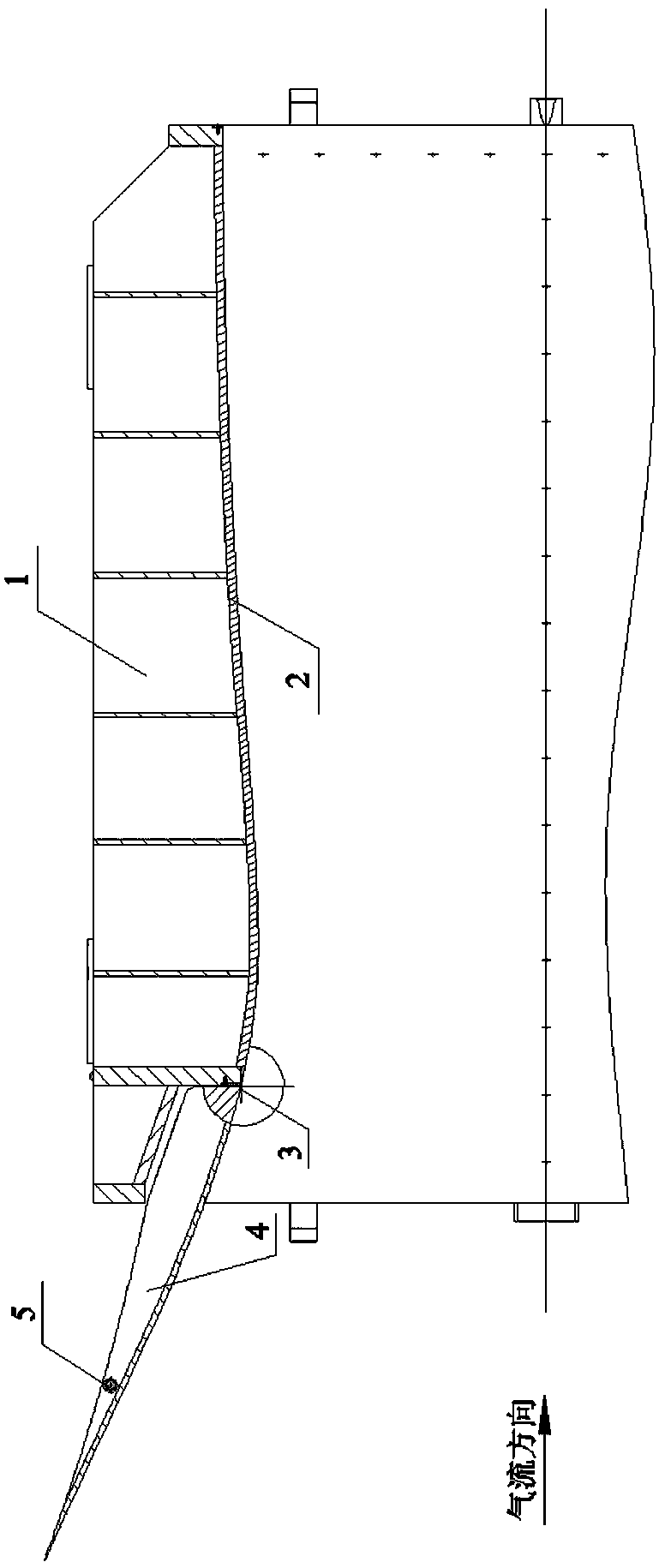

[0045] The schematic diagram of the aerodynamic profile of the nozzle section and other components of the high-speed wind tunnel is as follows: figure 1 shown. In this figure, the spatial position of each section of the wind tunnel has been fixed, and the position of the nozzle section corresponds to the installation position of the solid block nozzle device. The local schematic diagram of the original solid block nozzle device is as follows: figure 2 shown. The device is the original solid block nozzle device structure designed during the construction period of the high-speed wind tunnel. Design a qualified working flow field within the Mach number range. In terms of installation method, the original solid block nozzle device can directly enter the position of the nozzle section, and quickly connect with other section structures of the wind tunnel, and can also be directly disengaged from other section structures to move out of the nozzle section position.

[0046] The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com