Special Tooling for Clamping Cylinder Replacement of Quick Forging Manipulator and Its Replacement Method

A technology of clamping cylinder and manipulator, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of safety threats to construction workers, easy occurrence of dislocation, hidden dangers, etc., so as to shorten maintenance time, improve work efficiency, and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

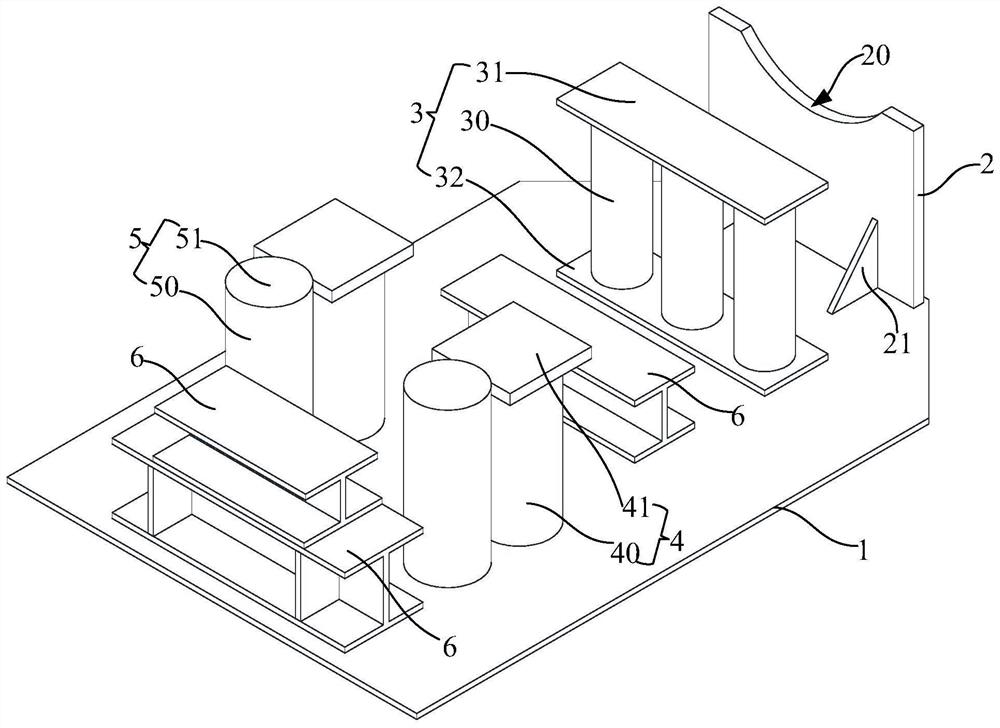

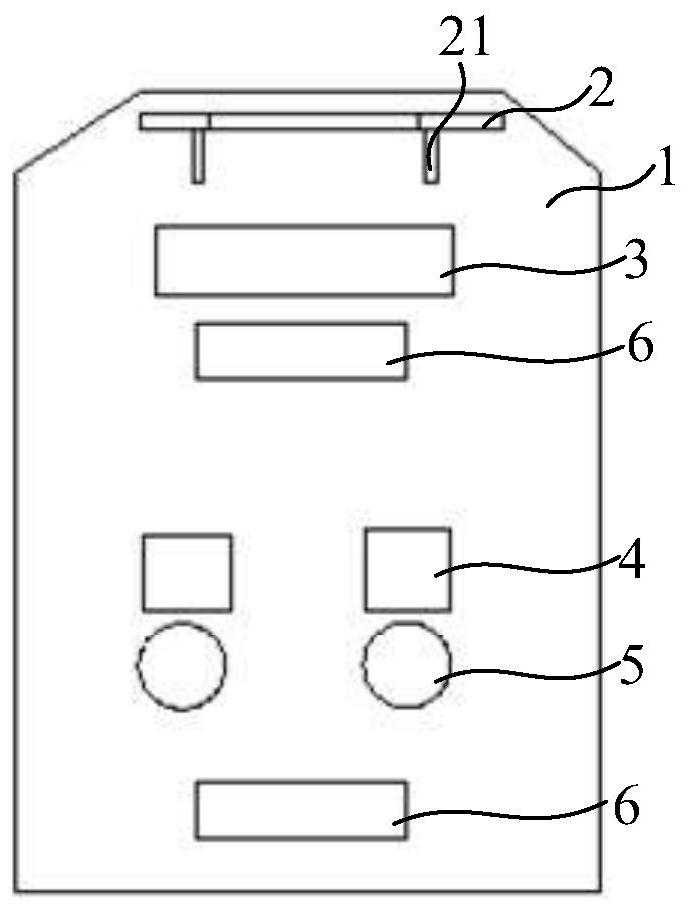

[0063] Such as Figure 1 to Figure 4 As shown, this embodiment provides a special tool for replacing the clamping cylinder of a fast forging manipulator, and the special tool includes:

[0064] Bottom plate 1, fixed on the bottom plate 1 and sequentially arranged along the length direction of the bottom plate 1, the clamping cylinder support seat 2, the clamp rear end surface support seat 3, the clamp pin support seat 4, the clamping rod pin support seat 5;

[0065] The upper end surface 20 of the clamping cylinder support seat 2 is a downward arc-shaped end surface, and the arc-shaped size of the upper end surface 20 is adapted to the outer surface size of the clamping cylinder 7. The clamping cylinder support seat 2 is used for At the 7 parts of the support clamping cylinder;

[0066] The support base 3 at the end surface of the rear part of the clamp includes three first support columns 30 arranged at intervals along the width direction of the base plate 1, and is fixed o...

Embodiment 2

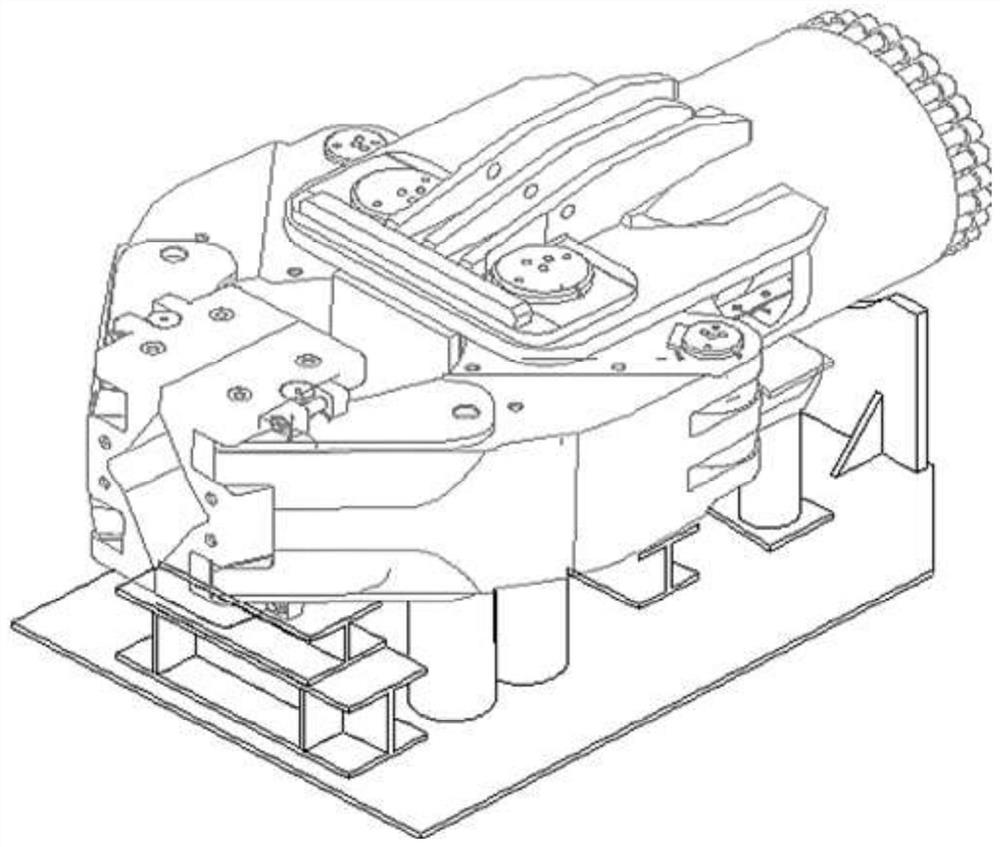

[0077] Such as Figure 5 and Figure 6 As shown, this embodiment provides a method for replacing the clamping cylinder of a fast forging manipulator, and the method for replacing the clamping cylinder at least includes the steps of:

[0078] 1) Lift the clamping cylinder replacement special tooling A of the fast forging manipulator described in Embodiment 1 to the center position in front of the clamp arm 11 of the fast forging manipulator 12 by using a crane before stopping the machine;

[0079] 2) Start the fast forging manipulator 12, place the clamp arm 11 on the clamping cylinder replacement special tooling A of the fast forging manipulator, and make sure that the clamp arm 11 is in the clamping cylinder replacement special tooling of the fast forging manipulator A's in-place state;

[0080] 3) Remove the connection between the clamping cylinder 13 and the rotary reduction box, and then move the fast forging manipulator 12 to separate the clamping cylinder 13 from the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com