Dedicated tool car for 35kV transformer replacement

A special tool and transformer technology, applied in switchgear, electrical components and other directions, can solve the problems of inconvenient disassembly and installation of transformers, long power outage time for replacement of transformers, and long time for replacement of transformers, and reduce working time. and labor intensity, reduce the scope of power outages, and facilitate the reliability of power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

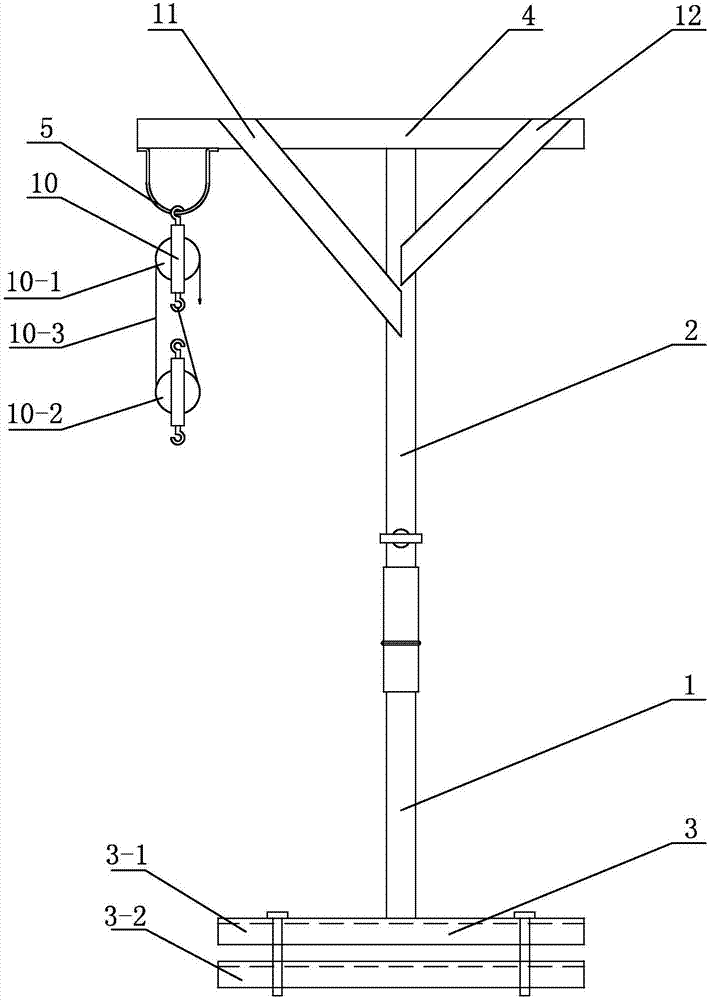

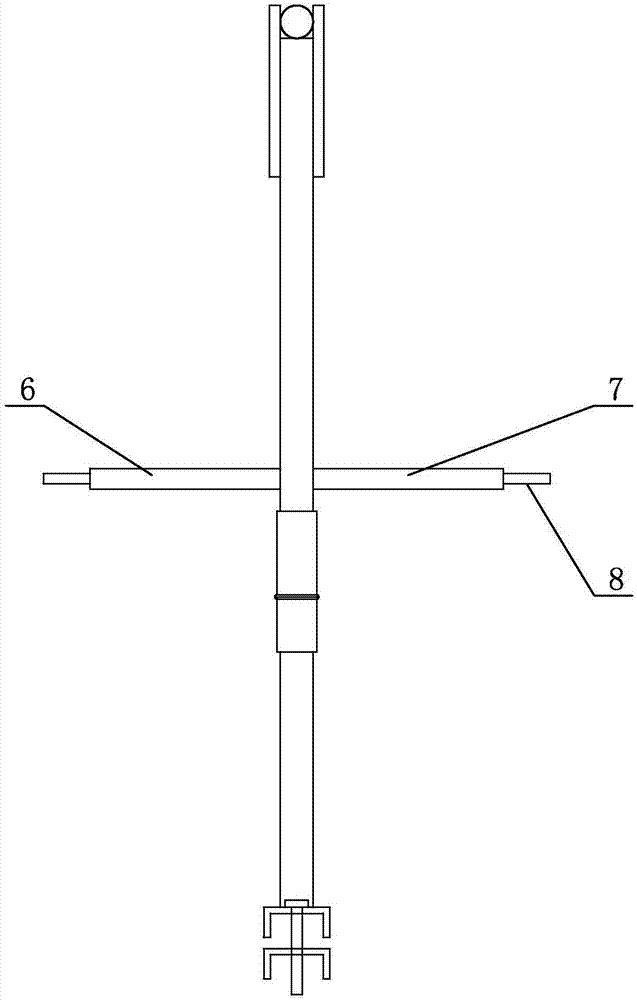

[0020] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a kind of 35kV mutual inductor of this embodiment replaces special-purpose tool cart, it comprises upper bracket 1, lower bracket 2, base 3, support pipe 4, hook 5, left operating handle 6, right operating handle 7 and The pulley block 10, the upper bracket 1 and the lower bracket 2 are hollow cylindrical brackets, the base 3 is arranged horizontally, one end of the upper bracket 1 is vertically fixed to the middle of the upper end of the base 3, and one end of the lower bracket 2 rotates with the other end of the upper bracket 1 Fixed connection, the other end of the lower bracket 2 is fixed to the support tube 4, the hook 5 is installed on one end of the support tube 4, one end of the pulley block 10 is fixed to the hook 5, the other end of the pulley block 10 is connected to the transformer, and the left operating handle 6 and one end of the right operating handle 7 are respec...

specific Embodiment approach 2

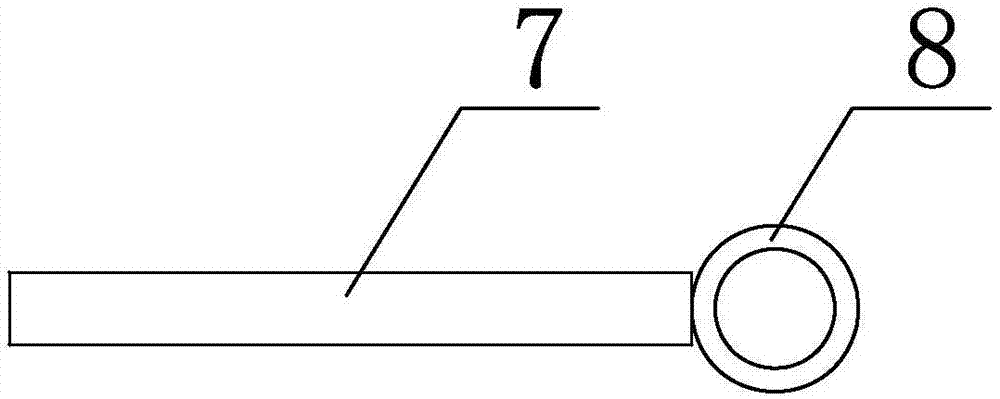

[0022] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, this embodiment also includes two connecting rings 8, and the two connecting rings 8 are fixedly connected to the other ends of the left operating handle 6 and the right operating handle 7 respectively. In this way, since the left operating handle 6 and the right operating handle 7 are relatively high from the ground, it is difficult for the staff to operate them while standing on the ground. The other ends of the left operating handle 6 and the right operating handle 7 are fixedly connected with two connecting rings 8 The staff can rotate the left operating handle 6 and the right operating handle 7 by 360° through the rope. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment also includes a first reinforcement board 11 and a second reinforcement board 12, one end of the first reinforcement board 11 is fixedly connected with the upper bracket 1, and the other end of the first reinforcement board 11 is connected with one end of the support tube 4 For fixed connection, one end of the second reinforcement plate 12 is fixedly connected with the upper bracket 1 , and the other end of the second reinforcement plate 12 is fixedly connected with the other end of the support tube 4 . In this way, the first reinforcement plate 11 and the second reinforcement plate 12 can increase the connection strength between the upper bracket 1 and the support tube 4, effectively improving the stability and safety of the upper bracket 1 and the support tube 4 during operation. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com