Fixture replacing device for industrial workpiece conveying device

A technology for conveying device and fixture replacement, which is used in metal processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described;

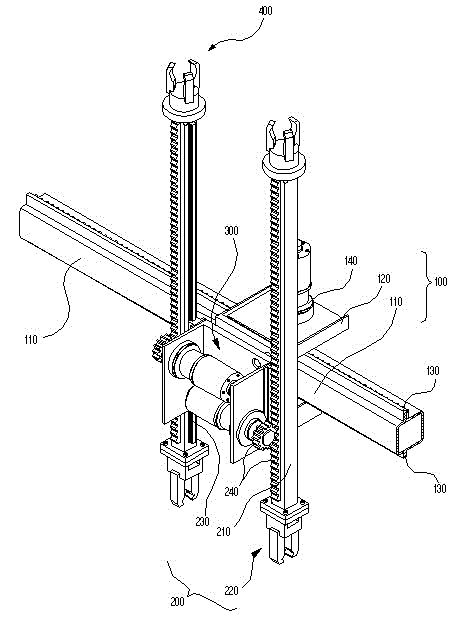

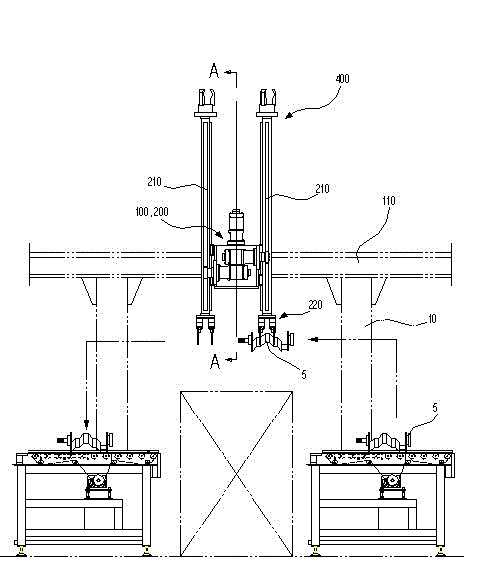

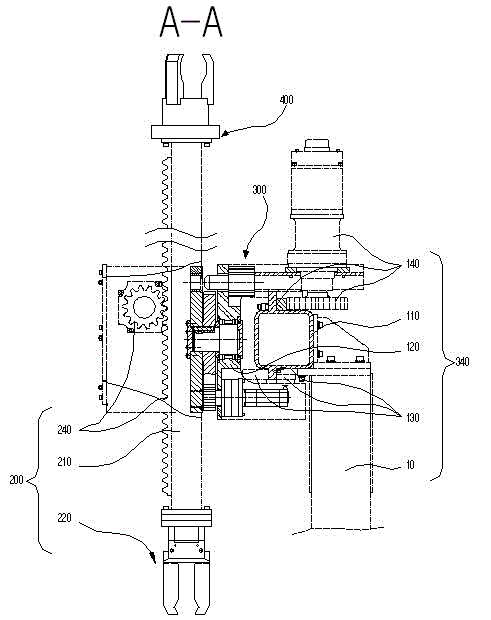

[0013] The fixture replacement device on the industrial workpiece conveying device includes a traveling beam 110 supported by a plurality of columns (10) and a loader 120 that can move horizontally left and right; between the traveling beam 110 and the loader 120, the unit is guided by a horizontal slide 130 and the horizontal guide drive unit 140 constitute the horizontal transfer device 100; on one side or both sides of the loader 120 in the horizontal transfer device 100, one or two mechanical arms 210 for lifting and lowering actions are vertically arranged. One end of 210 is provided with a No. 1 clamp 220; between the mechanical arm 210 and the loader 120, an up and down guide track unit 230 and an up and down guide drive unit 240 are installed to form an up and down transfer device 200, which constitutes a commonly used workpiece transfer device as described above. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com