Cleaning device and cleaning method for parts subjected to wave soldering

A cleaning device and wave soldering technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as difficult powder blocks, cleaning work failure, labor, etc., to reduce waste and avoid configuration The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

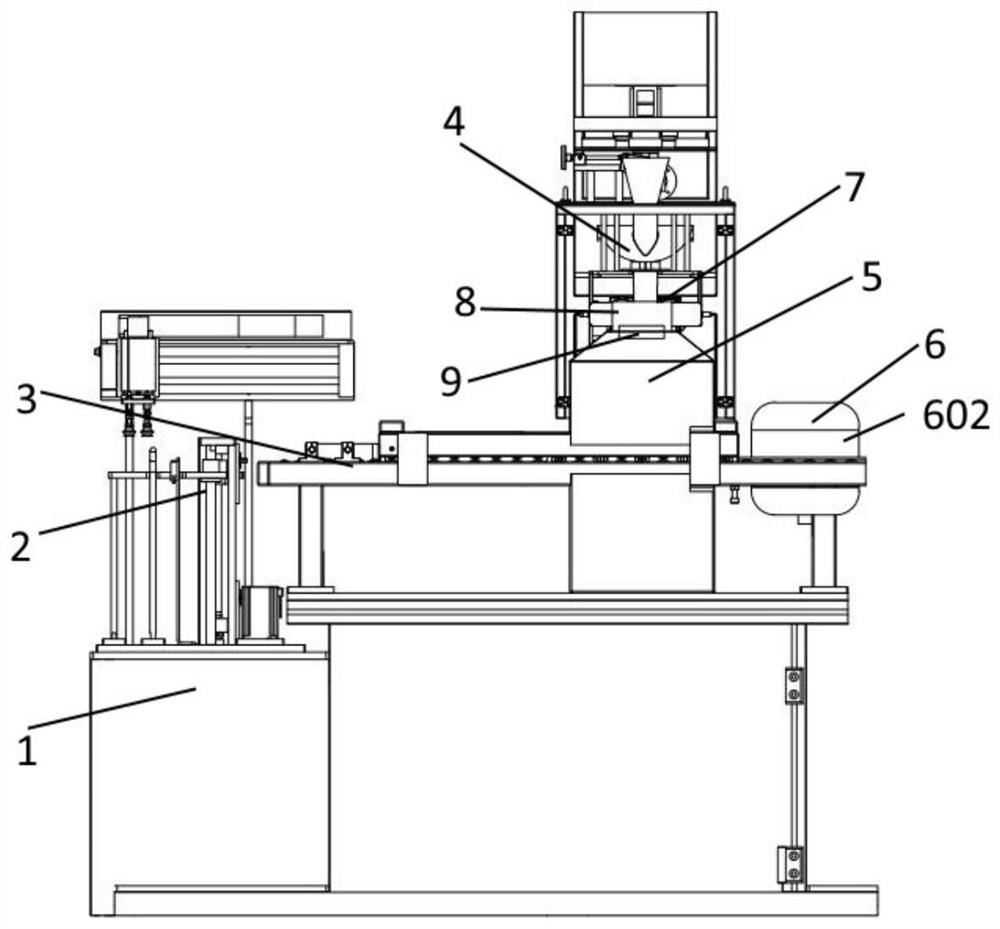

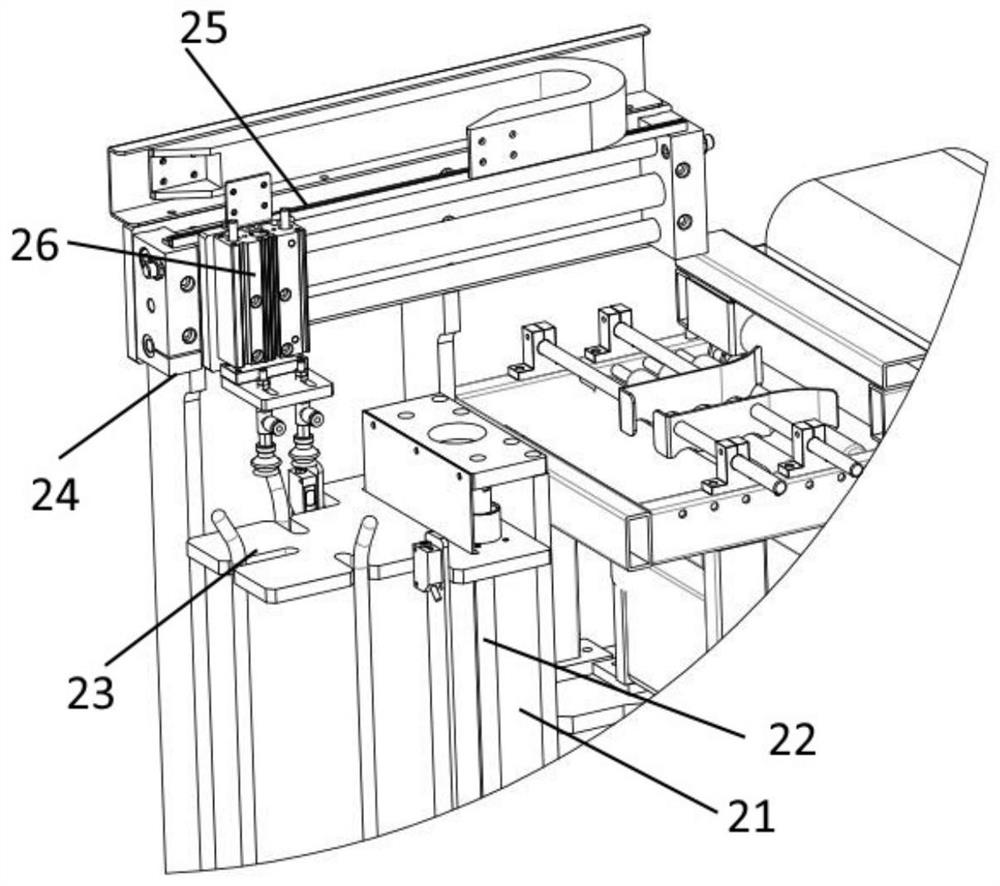

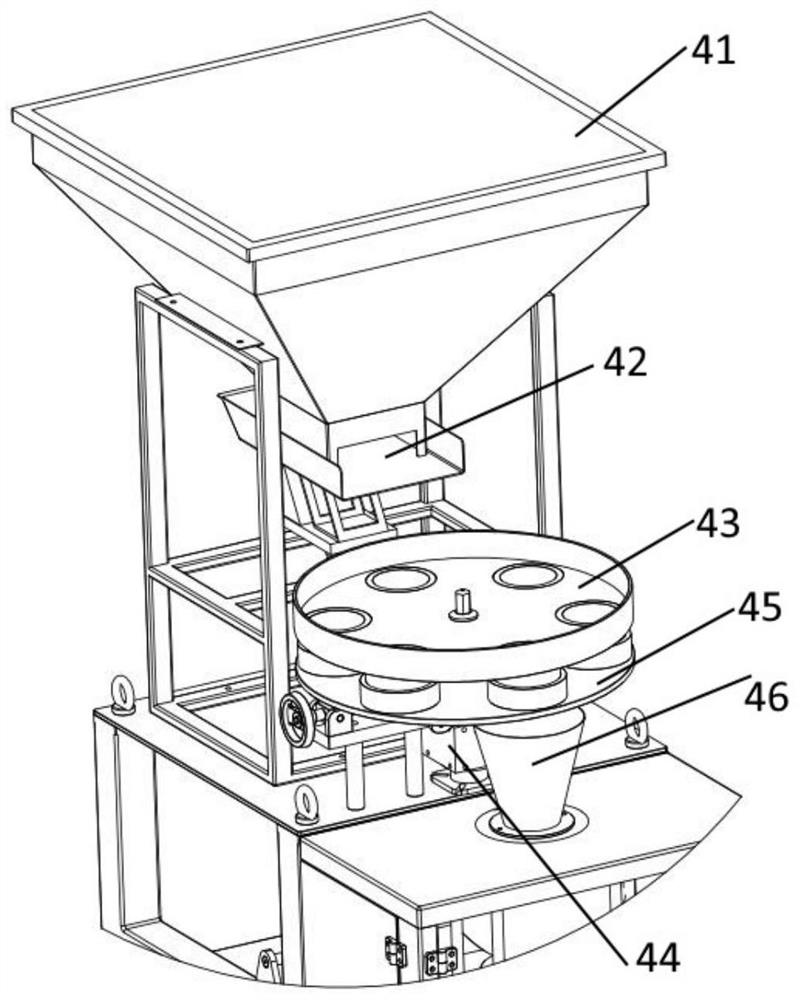

[0030]After the applicant's research and analysis, the reason for this problem (there will be some insoluble powder lumps in the cleaning solution, which will easily lead to the failure of the spray cleaning device, and thus the failure of the cleaning work) is that the existing counter aids There are still some problems in the flux cleaning device. Most of the existing cleaning devices require the operator to prepare the pre-configured liquid for cleaning, and then connect the liquid to the spray cleaning device, and then use the spray cleaning device to clean the flux. The liquid is sprayed on the surface of the parts to be welded to complete the cleaning of the parts to be welded, but the existing flux used for cleaning needs to be manually configured, which causes a lot of waste of manpower and financial resources. In order to achieve manual configuration, some companies will further set up quantitative configuration devices, and then can realize automatic configuration wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com