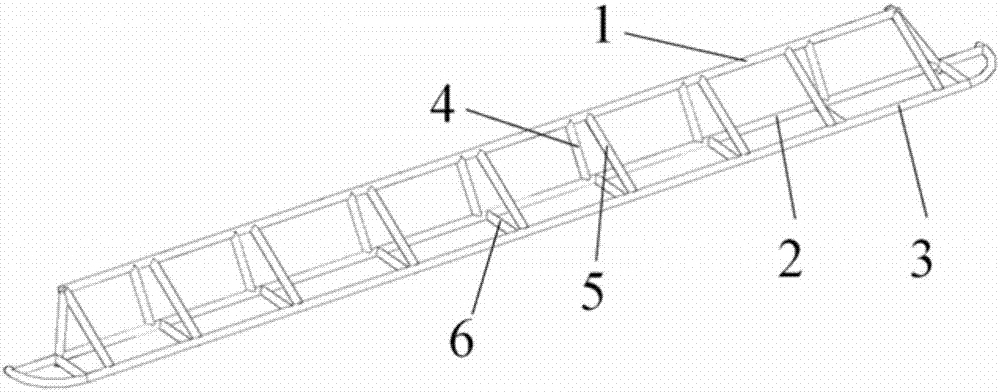

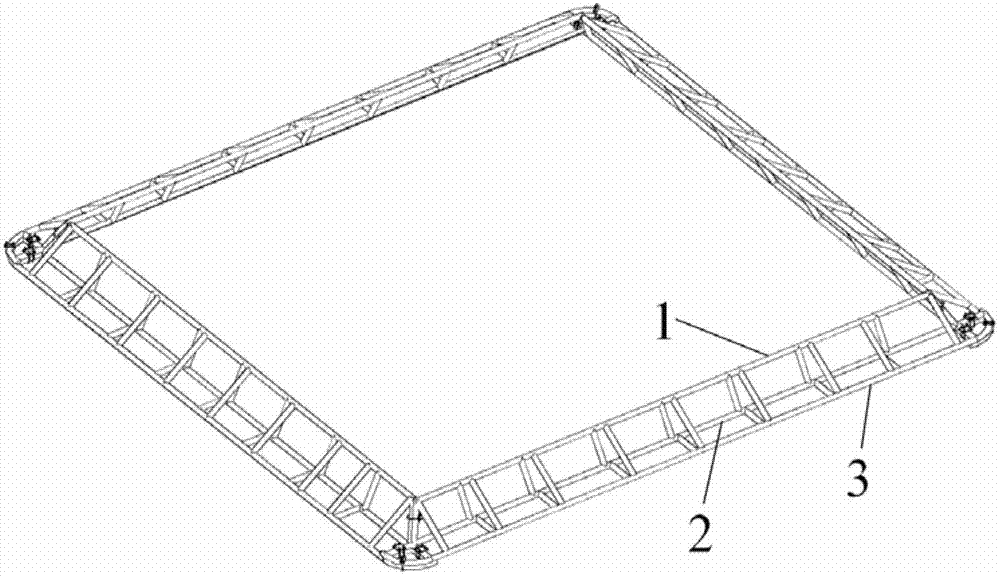

Netting fixing frame of square truss type net cage frame

A truss-type, fixed-frame technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of increased farming costs, low work efficiency, increased labor time, etc., to achieve small friction, easy operation, and reduced volume The effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

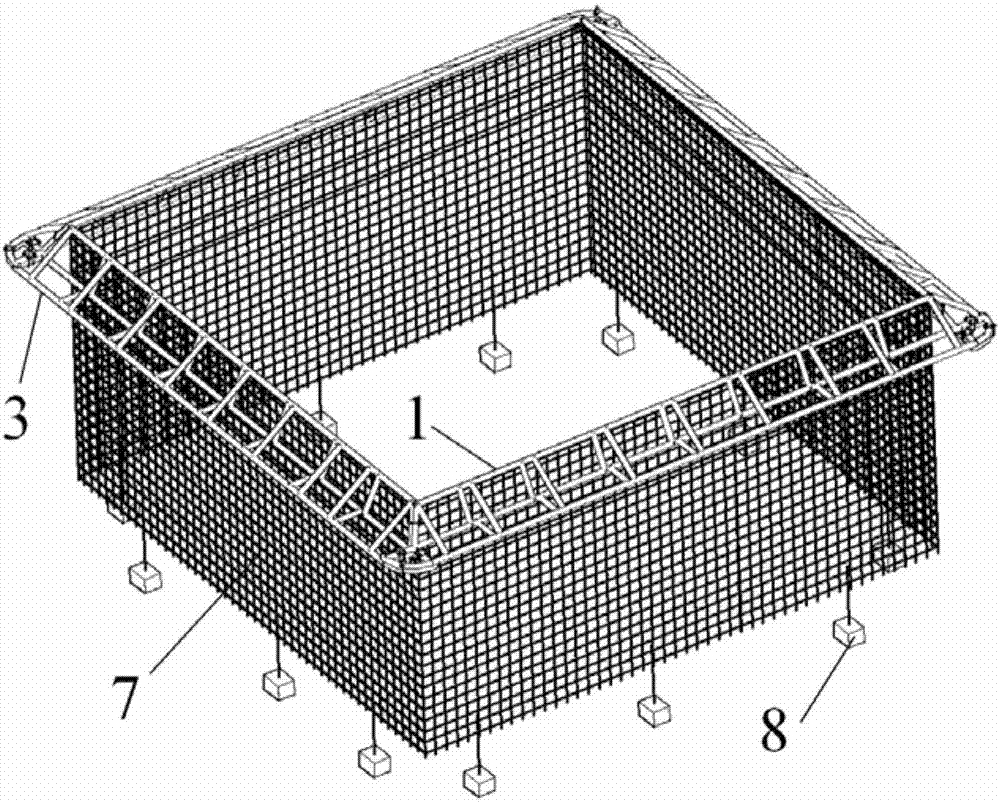

[0076] Embodiment 1: as Figure 13 , Figure 14 Shown, the length of standpipe 10 on the net clothes fixing frame is equal to the draft of net clothes 7, and three net clothes fixing racks are evenly installed respectively on both sides of a direction, and four net clothes are evenly installed respectively on both sides of another direction. fixed frame. The side with four net fixing racks should be arranged in a direction roughly perpendicular to the seawater flow, and the side with three net fixing racks should be arranged in a direction roughly parallel to the sea water flow, so that the nets Fixation is more effective.

Embodiment 2

[0077] Embodiment 2: as Figure 15 , Figure 16Shown, the length of standpipe 10 on the net clothes fixed mount equals 3 / 4 of net clothes 7 drafts, and all the other situations are identical with embodiment 1. The upper 3 / 4 section of the net can maintain a large volume ratio by relying on the fixing and restraining effect of the net fixing frame; the lower 1 / 4 section of the net relies on the sinker 8 to straighten and fix it, just like the traditional net cage, This part of the net can shrink and gather under the action of a large seawater velocity.

[0078] According to the above ideas, more embodiments can be derived, which are not exhaustive here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com