Operation device and method for replacing transmission line vibration protection hammer

A technology for operating devices and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as inconvenience, and achieve the effect of reducing tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

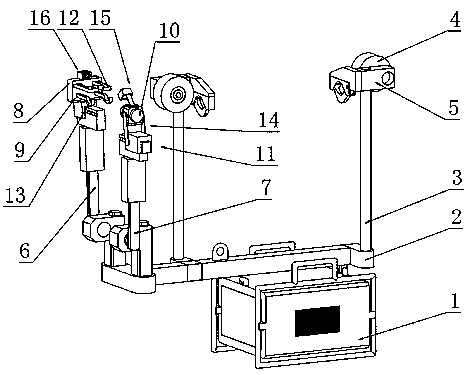

[0031] The structure of an anti-vibration hammer replacement operation device of the present invention is as follows: figure 1 As shown, it includes basic components such as a chassis 1, a body 2, moving parts, operating arm parts, and working end parts. The moving parts specifically include a moving arm 3, a moving wheel 4, and a moving wheel driver 5; the operating arm parts specifically include an operating arm one 6 and an operating arm two 7, wherein the moving joint and the telescopic joint are matched by a chain track, and the rotating joint is Crank and rocker mechanism; the working end part specifically includes a clamping mechanism 8, a supporting mechanism 9, a bolt fastening mechanism 10, and a pitch joint 11; the clamping mechanism has a set of jaws 12, which are decelerated The box controls the opening and closing of the jaws; the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com