Protective device making swing chute mouth being accurately located

A swing nozzle and precise positioning technology, which is applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve problems such as explosions, enterprise losses, and output false signals, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

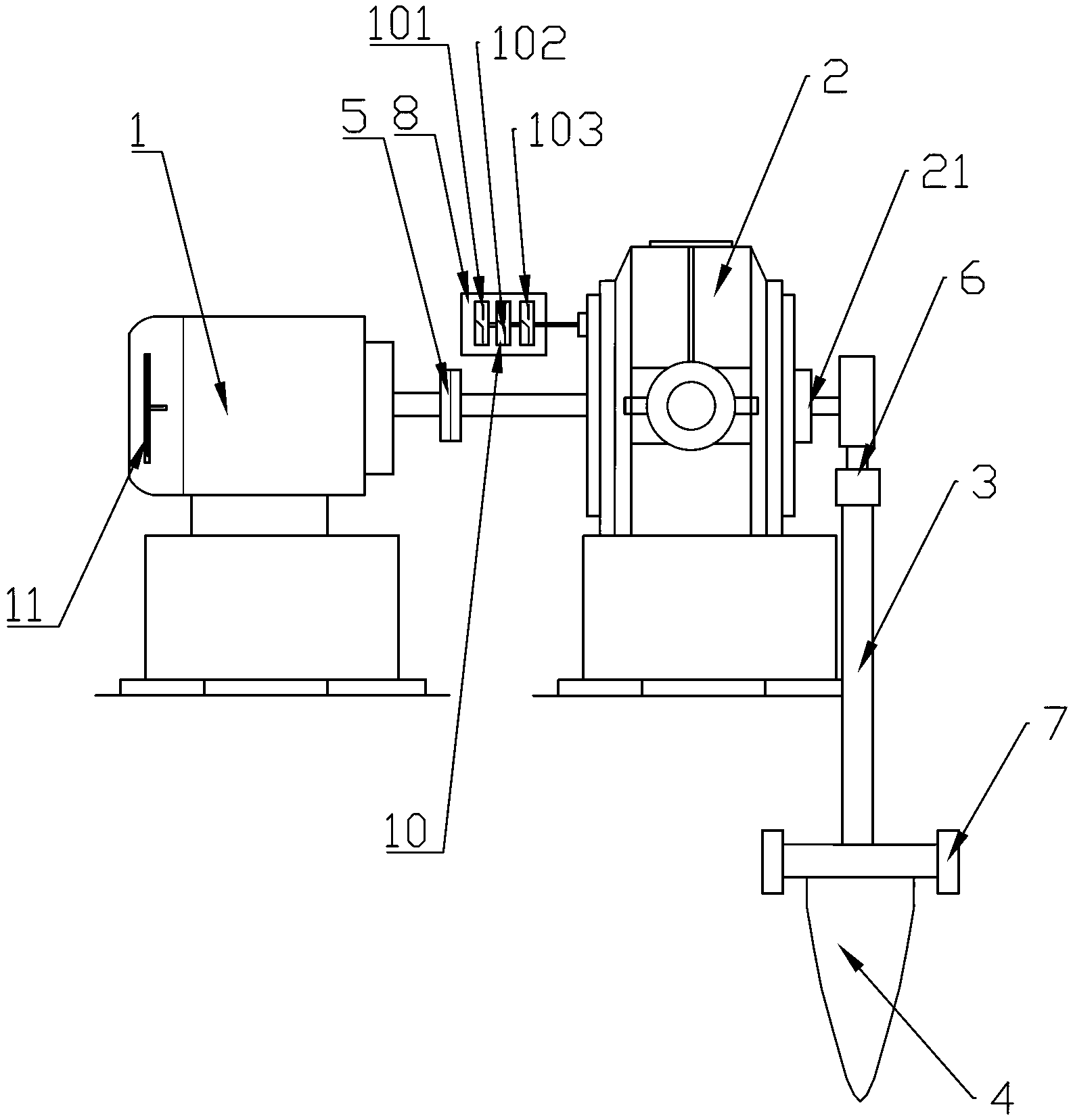

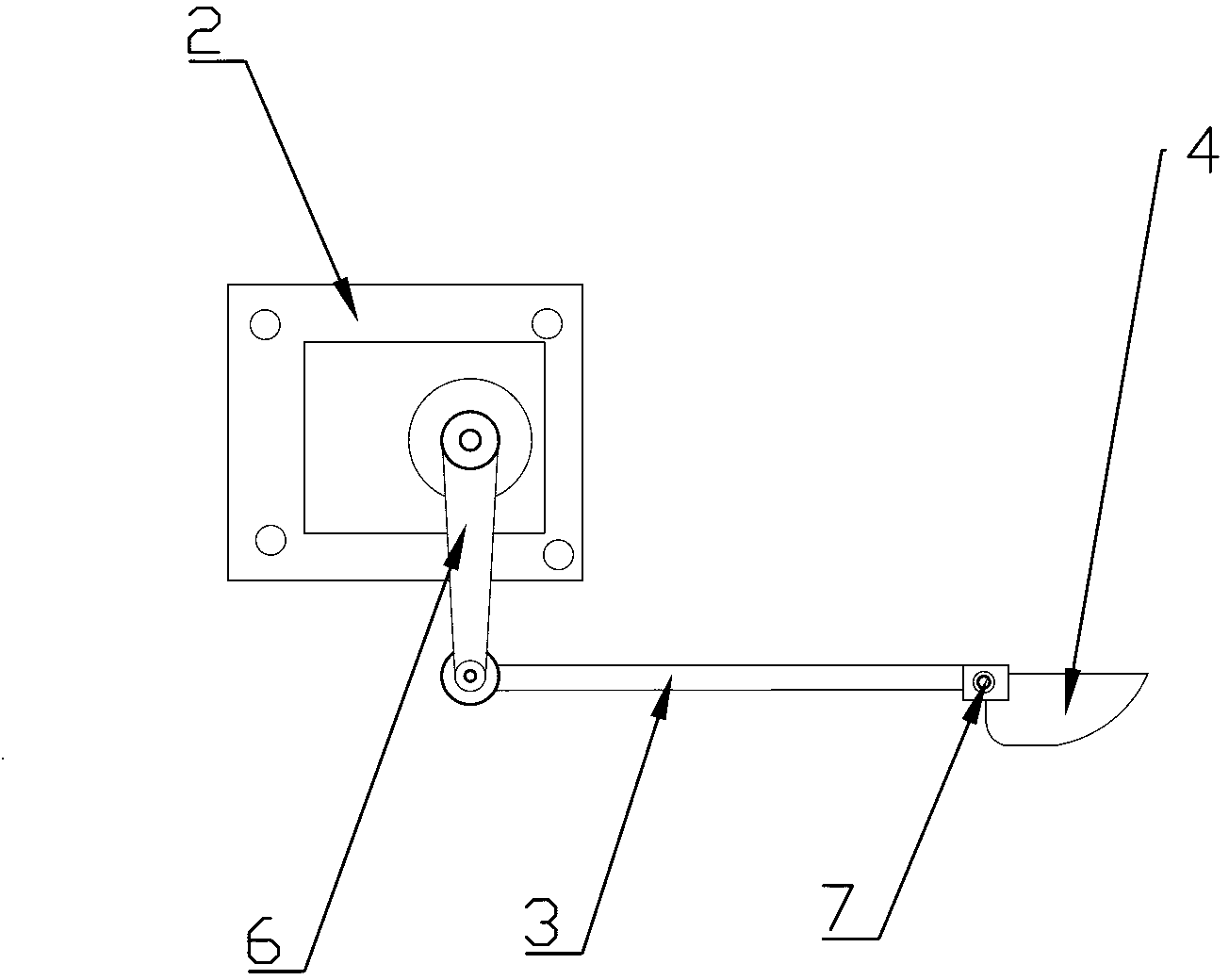

[0012] Such as figure 1 As shown, the present invention is a precise positioning protection device for a swing nozzle, which includes a motor 1, a reducer 2, a push rod 3 and a swing nozzle 4, the motor 1 is connected to the reducer 2 through a counter wheel 5, and the reducer One end of the low-speed shaft 21 of the machine 2 is connected to one end of the push rod 3 through the push rod drive mechanism 6, and the other end of the push rod 3 is connected to the swing nozzle 4 through the slip drive bearing 7; the other end of the low speed shaft 21 is fixed. A travel switch protection box 8 is provided, and the travel switch protection box 8 is coaxially connected with the low-speed shaft 21 through a hard connection fixture 9. The travel switch protection box 8 is provided with a travel switch 10 inside, and the travel switch 10 is connected to On the motor 1 installed on the side of the reducer 2.

[0013] As an optimization, the inside of the motor 1 is provided with a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com