a wind wheel

The technology of a wind wheel and a wind wheel shaft is applied to the wind wheel. It can solve the problems of inability to measure and measure the accuracy of measurement, difficult to afford costs for small and medium-sized enterprises, and expensive bearings, so as to save costs, reduce rotational resistance, and reduce the impact of friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

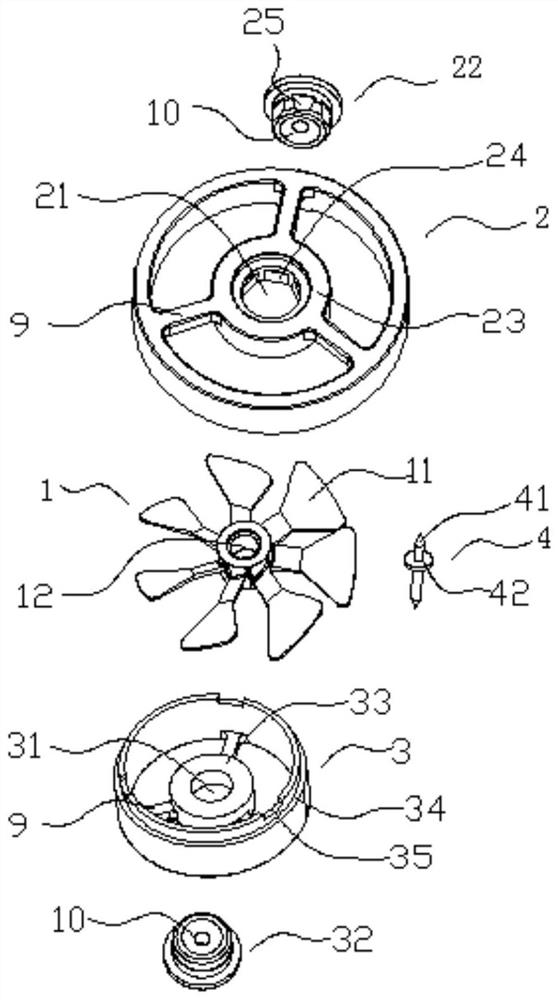

[0027] A wind wheel of the present invention is illustrated in conjunction with the accompanying drawings

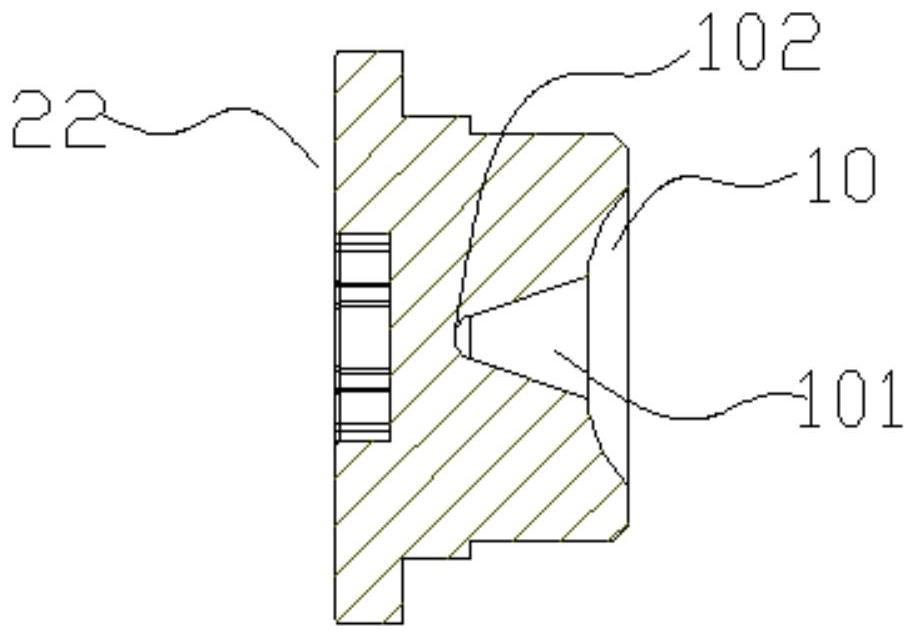

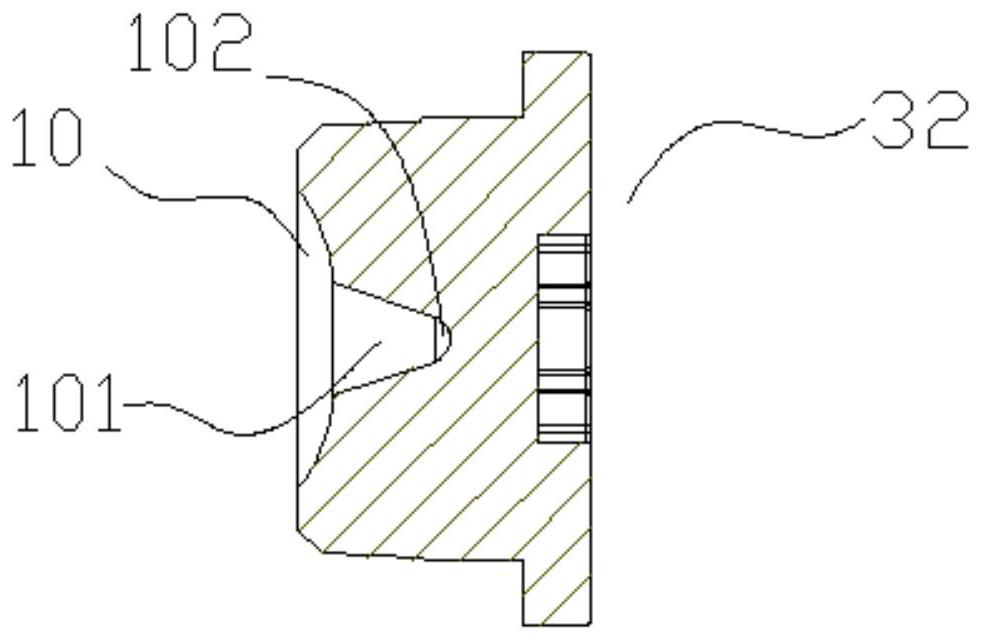

[0028] Such as Figure 1 to Figure 3 As shown, a wind wheel includes a wind wheel frame and a wind wheel blade 1, the wind wheel frame detachably clamps and fixes the wind wheel blade 1, and the wind wheel frame includes a wind wheel frame upper cover 2 and a wind wheel frame The lower cover 3, and the axes of the wind wheel frame upper cover 2 and the wind wheel frame lower cover 3 are respectively provided with a first hollow hole 21 and a second hollow hole 31 respectively corresponding to the first hollow hole 21 and the second hollow hole 31. The second hollow holes 31 are equipped with fittings, one side of the fittings is concave to form an arc portion 10, and the two fittings are installed on the upper cover 2 of the wind wheel frame and the lower cover 3 of the wind wheel frame Relatively fixed, the arc portion 10 is used to form a fixed area (not shown) locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com