Shaft type milling fixture

A milling and fixture technology, applied in the field of shaft keyway milling fixtures, can solve problems such as failure to meet technical requirements and affect the quality of processed shaft parts, and achieve the effects of improving production efficiency, high symmetry, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

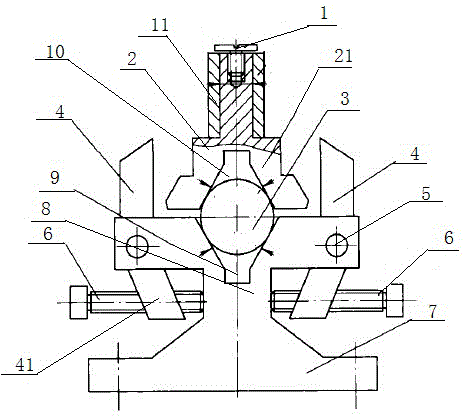

[0015] Such as figure 1 As shown, the present invention provides a shaft milling fixture, which mainly includes three parts: a base 7, a part holder body 8 and a tool setting holder body 2, wherein the part holder body 8 and the base 7 are integrally designed, and the tool setting holder The specific 2 is opposite to the above-mentioned part holder body 8, the first V-shaped groove 9 is provided in the above-mentioned part holder body 8, and the second V-shaped groove opposite to the above-mentioned first V-shaped groove 9 is provided in the above-mentioned tool holder body 2 10. The space formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com