Multifunctional clutch

A clutch and multi-functional technology, applied in the field of clutches, can solve the problems of different axial degrees of two shafts, single clutch function, etc., and achieve the effects of simple adjustment, small size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

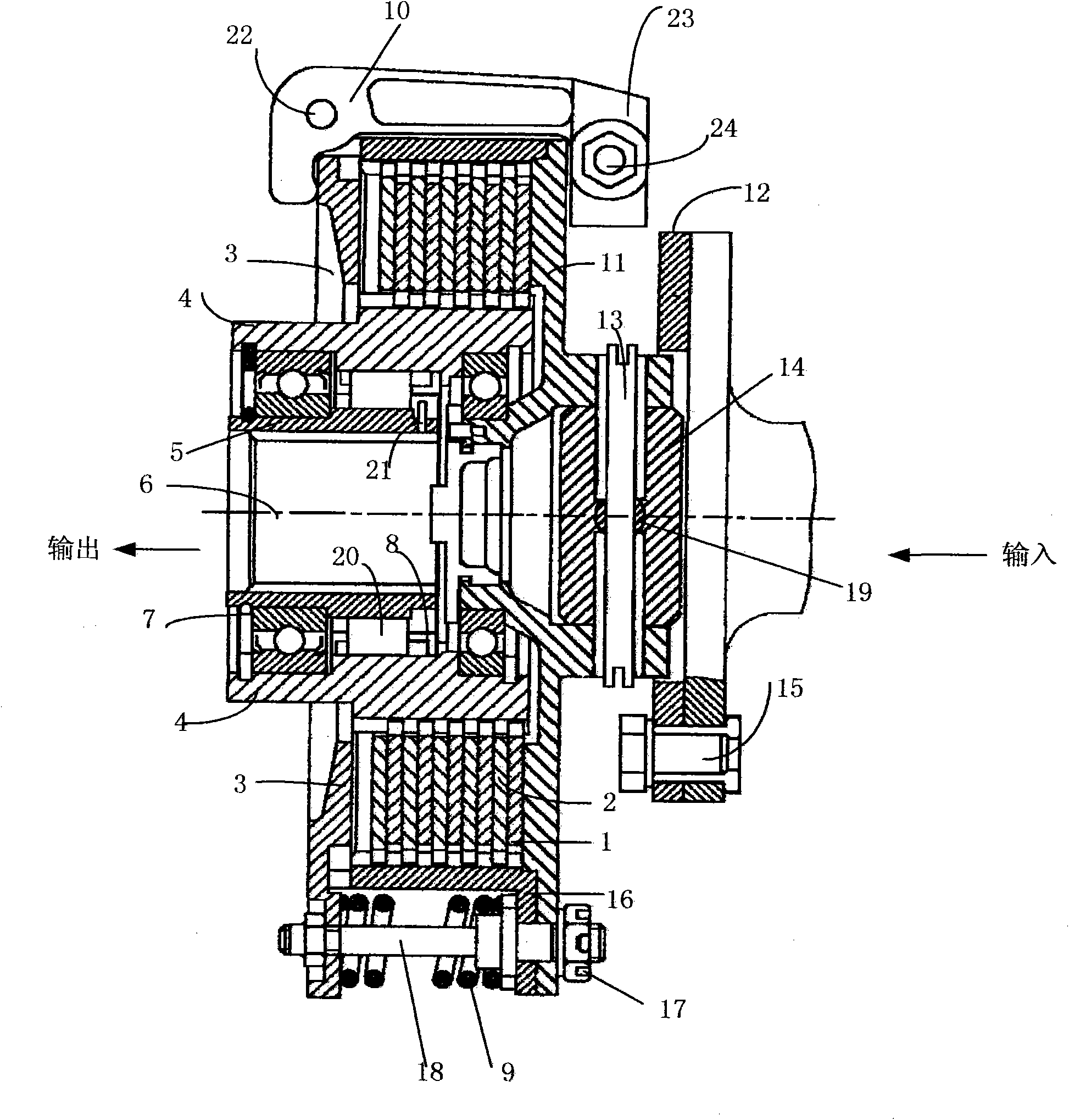

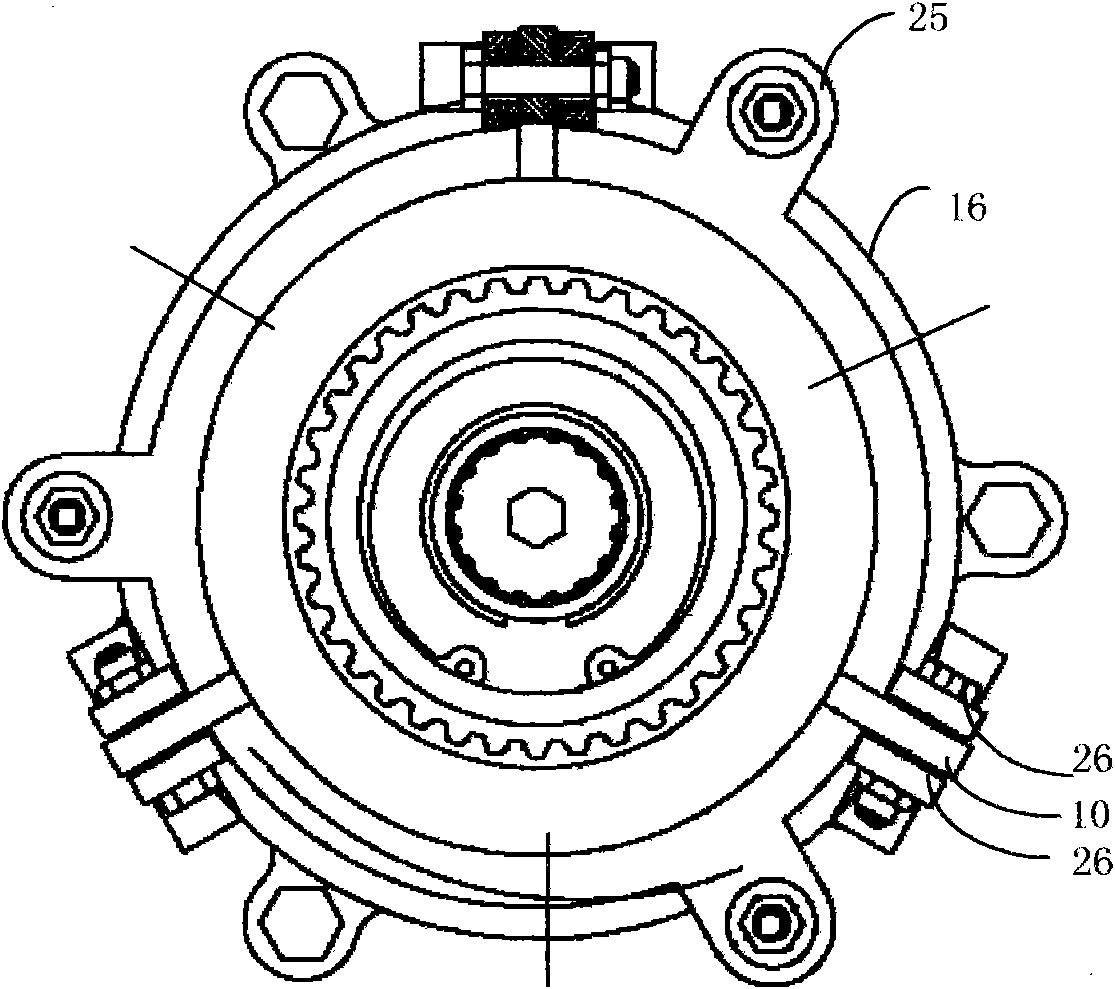

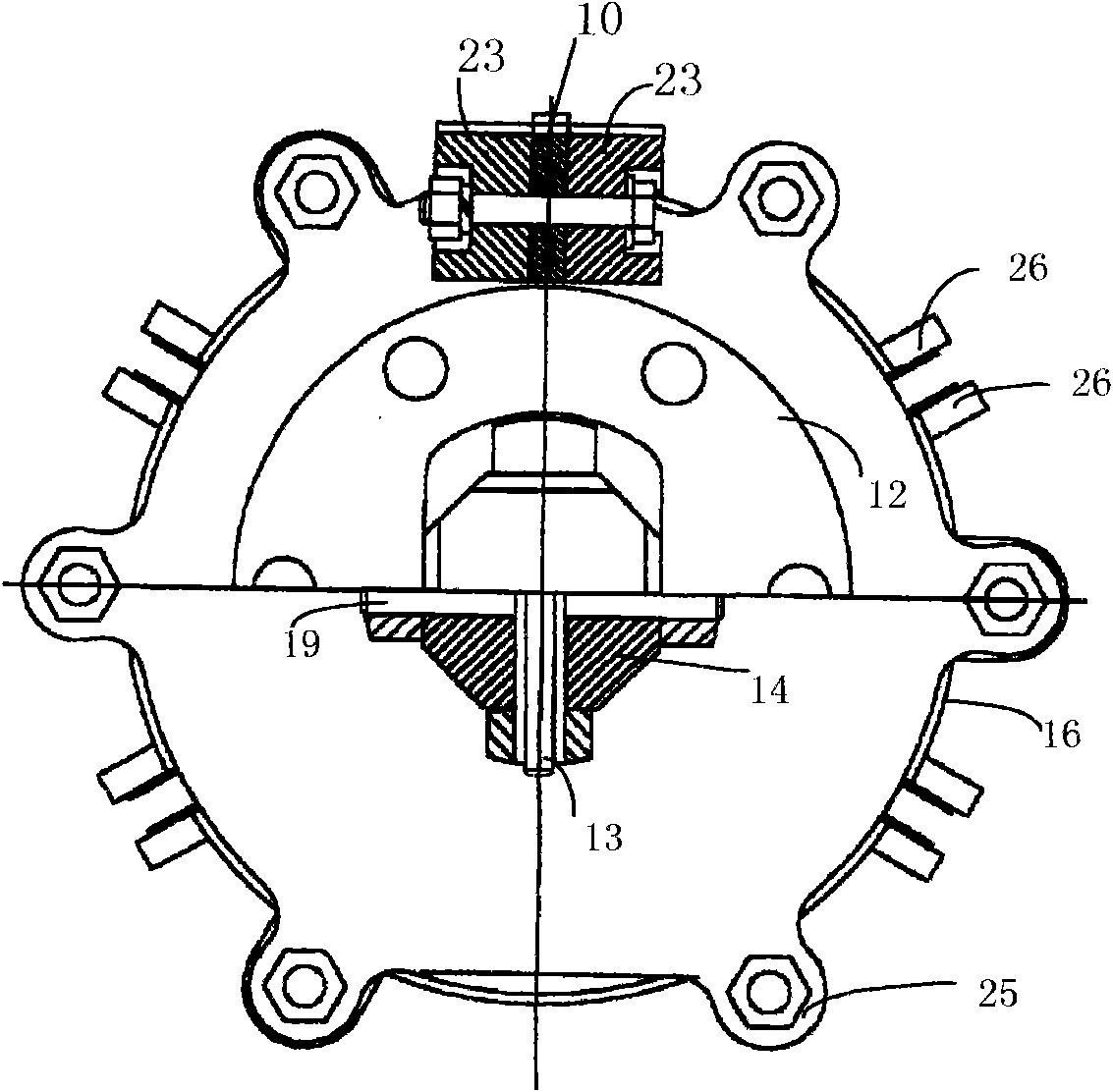

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Such as figure 1 As shown, a multifunctional clutch of the present invention includes an inner ring 4, an outer ring 16, a driving friction plate 1, a driven friction plate 2, a centrifugal block 23, a star wheel 5, a flange 12, and a hinge coupling. The hinge coupling is composed of pin rod 13, coupling shaft fork 11, cross piece 14 and plug pin 19; the clutch is connected to the output shaft through the hinge coupling, and there are five active frictions between the inner ring 4 and the outer ring 16 Plate 1 and five driven friction plates 2, the inner ring 4 and the star wheel 5 are connected by two single row radial ball bearings 7, and a return spring 21 is installed between the star wheel 5 and the retaining ring 8 of the cage. The ten cylindrical rollers 20 with cages are loosened or wedged tightly; the outer ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com