Aligning system and lightscribing device using the system

An alignment system and alignment mark technology, which is applied in the field of alignment technology and lithography equipment, can solve problems such as occupancy, multi-line slot area, and large mark size, and achieve cost reduction, signal-to-noise ratio improvement, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

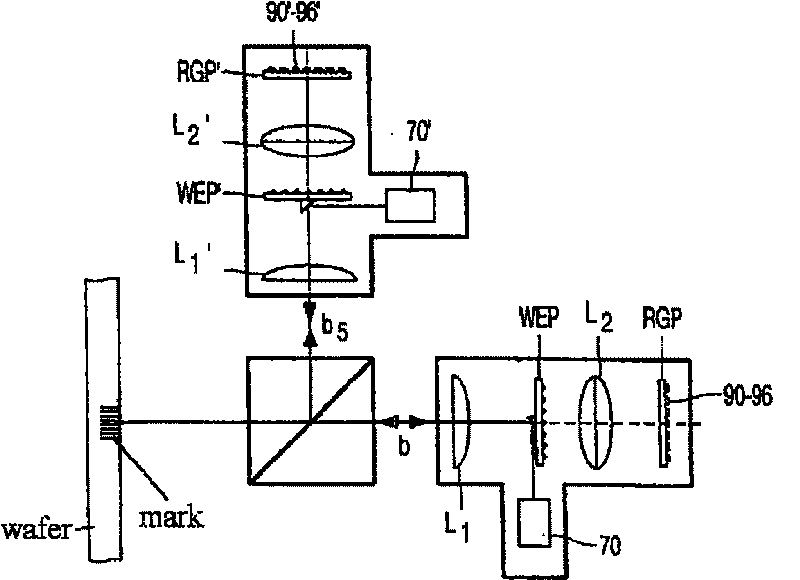

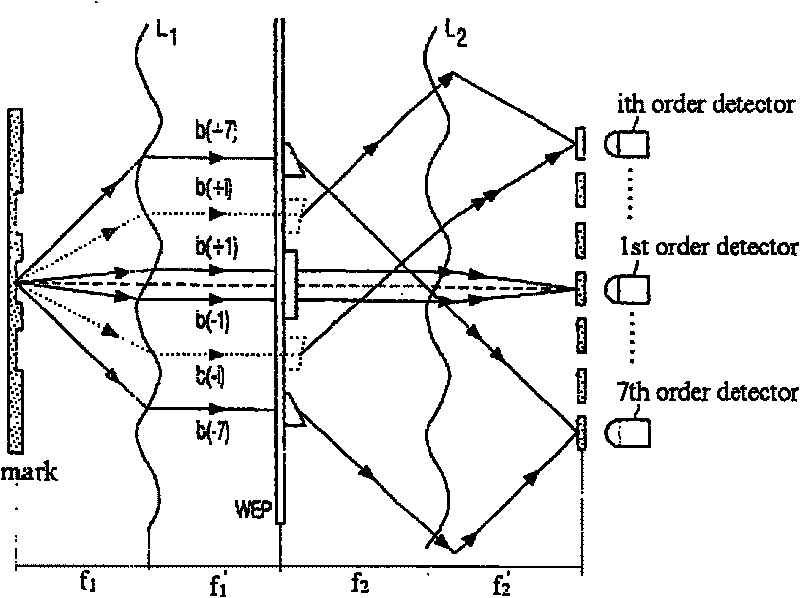

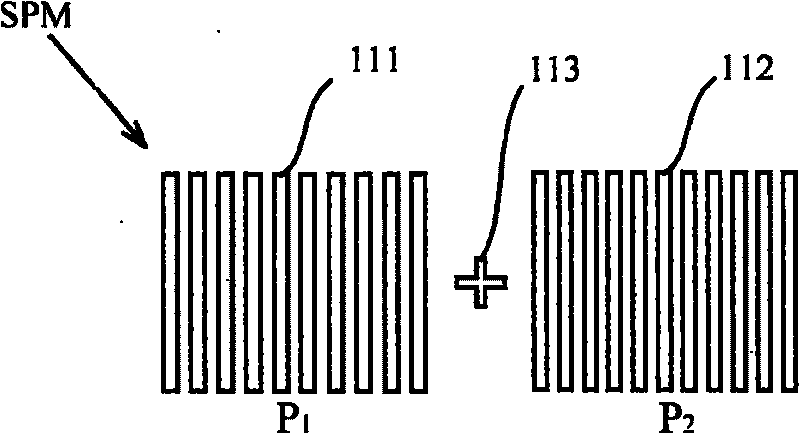

[0034] Figure 1(a) to Figure 1(g) A schematic diagram of a prior art dual-laser multi-level diffraction grating off-axis alignment (ATHENA) alignment system is shown. Among them, Fig. 1(a) shows the structure diagram of the prior art dual-laser multi-level diffraction grating off-axis alignment (ATHENA) alignment system, and Fig. 1(b) shows the prior art dual-laser multi-level diffraction Schematic diagram of the grating off-axis alignment (ATHENA) alignment system. The alignment system adopts red light 70 and green light 70' double laser light sources in the light source; the optical system structure is 4f system, and the wedge array or wedge plate group WEP and WEP' located on the spectrum plane is used to achieve alignment Separation of different orders of diffracted light marked, respectively coherent imaging on the image plane; throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com